Compression-type tube connections, such as those manufactured by Swagelok Company, are specified for use in fluid circuits because of their ability to seal leak-tight despite frequent disassembly/reassembly—that is, unless the threads are damaged in the process by debris, misalignment, or inadvertent impact. Cross-threading of the nut on the tube end, which can occur while connecting it to the male end of the fitting, is the most common type of damage.

Compression-type tube connections, such as those manufactured by Swagelok Company, are specified for use in fluid circuits because of their ability to seal leak-tight despite frequent disassembly/reassembly—that is, unless the threads are damaged in the process by debris, misalignment, or inadvertent impact. Cross-threading of the nut on the tube end, which can occur while connecting it to the male end of the fitting, is the most common type of damage.

When the threads are damaged to the point that the connection cannot be remade leak-tight, replacement is required. Change-out of both the male end of the fitting and the captured nut on the tube end may be necessary. The male fitting sometimes can be replaced quickly by unthreading and installing a new fitting. The tube end, with the nut retained by the compression ferrule, has to be replaced.

The standard repair when threads are damaged: Cut back the tube to an acceptable location and add an additional fitting. This also requires adding a piece of tubing with new nuts and ferrules to return the tubing run to its original length. The most common, and preferred, repair option is to replace the complete run of tubing from fitting to fitting.

Ken Knecht, the former maintenance supervisor at a generating plant equipped with gas turbines in simple- and combined-cycle configurations, has developed, and is offering for sale through KnechtionRepair, a new tool capable of repairing damaged threads. He told the editors that in his 35-plus years on the deck plates he was forced to deal with damaged threads more often then he’d like to remember. “They can cause hours of delay in job completion,” Knecht said, “costing owner/operators thousands of dollars in lost time, parts, and repairs.”

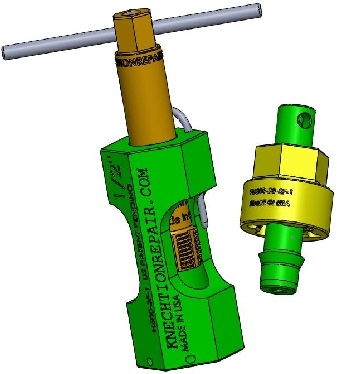

The manual thread-chasing tool Knecht developed is designed to repair both the male end of the fitting and the female captured nut on the tubing at the connection location. It is compact and can be used in space-challenged locations, right at the point of connection, as the video illustrates. The tool includes a holder to restrain the nut on the tube in concentric alignment with the thread-chasing hollow-bore tap, which is turned manually to repair/clean the damaged threads.

For the male end, a thread-chasing die with a concentric alignment hole is used in conjunction with an alignment pilot inserted in the fitting. The die, held in alignment by the pilot, is turned manually to repair/clean the damaged threads. After the repair, the pilot is removed and the fitting is ready for assembly.

The repair tool for two-ferrule, tube-type compression fittings currently is available for 3/8 and ½ in. tubing; additional sizes are under development.