Safety underpins plant’s approach to predictive motor maintenance

A challenge facing the empowered staff at this 2 × 1 501F combined cycle was how perform predictive maintenance (PdM) on low- and medium-voltage motors while reducing—with a goal of eliminating to the degree possible—personnel exposure to electrical hazards and improving the accuracy and repeatability of data collected.

Historically, a contractor has performed the testing necessary to capture the LV and MV online and offline data required at Dogwood. To do this, the vendor would open the motor feeder cubicle to connect test leads and then leave that cubicle open while the motor was started to permit data collection.

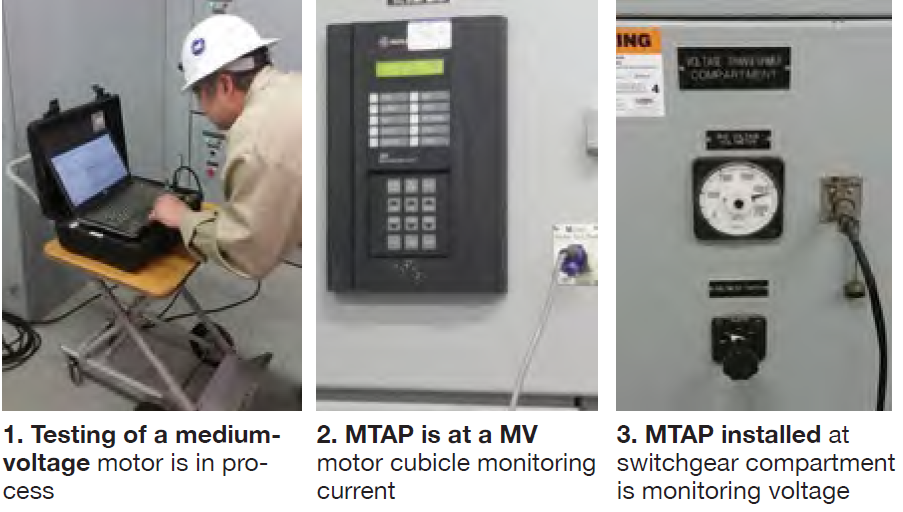

The contractor was required to follow NFPA 70E requirements, but even when wearing arc-flash protective clothing, he could not safely connect the leads necessary for online testing to the medium-voltage bus. The voltage was monitored at the cubicle being tested using a test cart and multiple cables strung throughout the area. Because of the electrical hazards, the contractor had to wear NFPA 70E gear while collecting data on a laptop (Fig 1).

Solution. To address the challenge, Dogwood implemented PdMA Corp’s MTAP technology for testing LV and MV equipment. It uses current transformers (CT) and potential (voltage) transformers (PT) to reduce hazardous currents and voltages to levels that meet OSHA and NFPA 70E requirements.

The safety system was installed on each MV motor covered by the plant’s six-month predictive maintenance plan—one MTAP to monitor current (Fig 2), another to monitor bus voltage (Fig 3). This upgrade protected contractor personnel from electrical hazards. Each MTAP was mounted to the cubicle door, allowing data collection by simply plugging the test lead into the receptacle as shown in the photos.

In the past, test accuracy relied on the CT being set to the proper setting ad oriented in the correct way, requiring a test re-run if it was not set up correctly. The MTAP removes the setup from the equation as all internal connections already have been made and tested. Accurate and repeatable test results are assured, regardless of who perform the test.

Results. Installation of the MTAPs allows the simultaneous collection of data from multiple devices at multiple locations without requiring equipment isolation. This saves money by reducing the number of contractor visits required because of plant conditions. Plus, nuisance traps have been reduced because cubicle doors remain closed during the procedure.

More benefits attributed to MTAP technology: (1) Data can be collected by one person and in only five or six hours compared to a full day previously. (2) Having specific test points with the CTs and PTs permanently mounted assures data are reliable and repeatable.

Project participants:

Mike O’Reilly, IC&E technician

Glenn Brons, project oversight

Dogwood Energy Facility

Owned by Dogwood Energy, City of Independence, Missouri Joint Municipal Electric Utility Commission, Kansas City Board of Public Utilities, and the Kansas Power Pool

Operated by NAES Corp

650-MW, gas-fired, 2 x 1 combined cycle located in Pleasant Hill, Mo

Plant manager: Steve Hilger