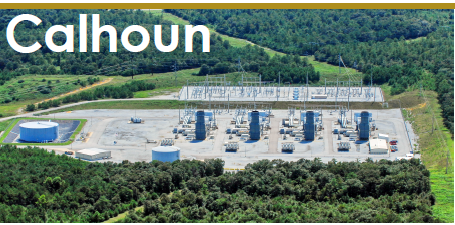

Calhoun Power, a 748-MW, dual fuel, four-unit simple-cycle plant in Eastaboga, Ala, is owned by East Alabama Generating LLC and operated by Consolidated Asset Management Services (CAMS). Plant manager is Mike Carter.

Lockwire prevents water-injection and fuel-oil purge-valve actuators from coming loose

Challenge. An RCA conducted after Calhoun Power experienced an unsuccessful fuel-oil swap found lose mounting screws on fuel-oil and water-injection purge-valve actuators had allowed stem binding to occur during operation. The stem binding was attributed to vibration.

Solution. Upgraded actuator mounting screws were installed—ones with pre-drilled holes. Staff connected the screws together with lockwire to prevent them from backing out.

Results. Calhoun has not experienced a trip or unsuccessful fuel-oil swap caused by an actuator hang-up since the installation of new screws and lockwire.

Project participants: Mike Carter, Steve Murray, Rob Fletcher, Neil LaMantia, and Terry Sandefer

Sounding-cap addition on oil-tank lid

Challenge. Calhoun’s 2.5-million-gal fuel tank did not have a safe way to manually sound tank level without opening a 24-in. lid. This created an unsafe condition because a technician could become disorientated from tank fumes. Plus, operators could possibly drop rags, sounding tape, manhole gasket, etc, into the manhole. A worst-case scenario was the potential for an operator falling into the tank.

Solution. Site personnel removed the lid and took it to a local shop to install a 4-in. pipe nipple and cap on manhole cover.

Results. Modification allows technician to sound tank and pull fuel samples in a safe manner.

Project participants: Mike Carter, Rob Fletcher, and Steve Murray