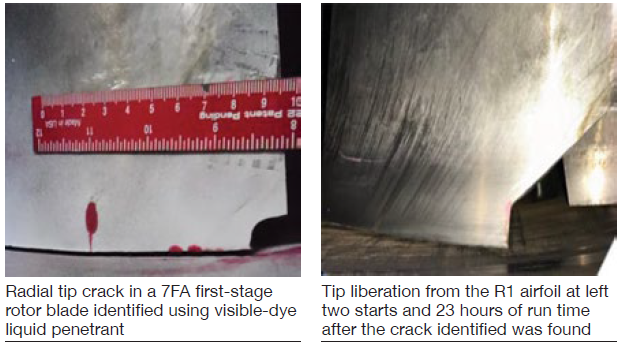

Mike Hoogsteden, Advanced Turbine Support’s director of field services, called to say his company has informed customers that it believes visible-dye liquid penetrant (PT) is the most dependable in-situ inspection process for identifying radial tip cracks in 7FA Stage 0 and Stage 1 rotor blades. The OEM recommends in Technical Information Letter 1509-R3, “F-Class Front-End Compressor Inspections,” that owner/operators check for R0 and R1 tip cracking in regular borescope inspections. The TIL explains why blade tip distress occurs and how to mitigate it.

Advanced Turbine Support has deep experience in compressor borescope inspections, citing the finding of more than 265 cracked rotor blades since 2001 using PT. Hoogsteden said the superiority of PT over eddy current (ET) for identifying the presence of radial tip cracks (photos) in 1509 inspections recently was confirmed when his company was called in to validate the findings of another vendor that had used ET. In this case, the engine owner/operator wanted a second opinion on the findings before it decided on possible corrective action. Second opinions are standard practice for some owners in critical situations.

Advanced Turbine Support’s inspectors confirmed the two cracks found with ET, but also identified three additional cracks that went undetected. “Any of these missed cracks could have led to a catastrophic compressor failure prior to the next annual inspection,” Hoogsteden said. Based on this result and previous experience, he recommends PT as a best practice for identifying radial tip cracks and for immediately conducting in-situ blend repairs of cracks found.