How wet cooling tower operates in extreme cold without freeze-up

Challenge. Operating wet cooling towers can be problematic in extremely cold weather, when the minimum amount of cold-air cooling exceeds heat-transfer requirements and starts to affect the plant cycle. Compounding this problem, ice can form on the outside of the tower and, if left unchecked, accumulate, possibly causing structural damage, safety hazards, and perhaps even a plant shutdown.

Solution. To prevent ice-related issues, State Line personnel came up with a simple but effective solution. Perhaps the best analogy is the cover semi drivers put on the front of their rigs in extreme cold. These “winter fronts” reduce the amount of cold air entering the engine compartment to maintain the optimum operating temperature.

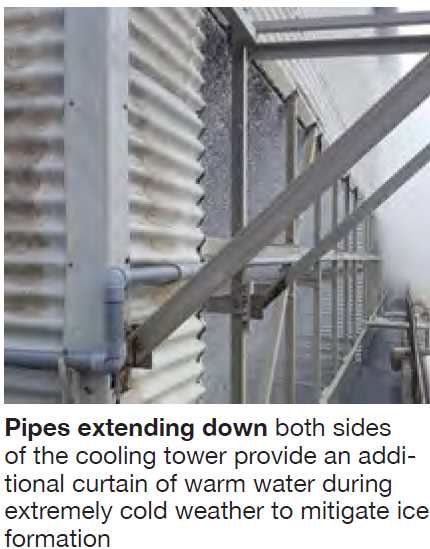

This same principle was adopted for the plant’s cooling tower. Pipes were installed longitudinally down both sides of the tower, along horizontal fiberglass members. When temperatures are very low, warm water is run through these lines at circulating-water pressure, providing an additional curtain of warm water to mitigate ice formation.

Results. While warm curtain water is required only infrequently, it has enabled the plant to continue running during severe weather when power prices were high and customers needed the electricity to stay warm. Since implementation, the plant has not experienced an outage caused by cooling-tower icing.

Project participants: The entire staff—especially Terry Krause, Phillip (Scott) Boatright, and Ken Case.

State Line Combined Cycle

Empire District, a Liberty Utilities Company

500-MW, gas-fired, 2 x 1 combined cycle located in Joplin, Mo

Plant manager: Brian Berkstresser