Linden Generating Station

Owned by JERA Co (Japan), EGCO Group (Thailand), Development Bank of Japan, and GS EPS

Operated by NAES Corp

972 MW, 5 × 3 7EA-powered 800-MW combined cycle designed to burn natural gas and butane and equipped with three D11 steam turbines, plus a 1 × 0 7FA-powered 172-MW cogen unit (Linden 6) designed to burn natural gas and distillate and later modified to co-fire up to 40% hydrogen. Power station is located adjacent to the Bayway oil refinery in Linden, NJ

Plant manager: Stephen Reinhart

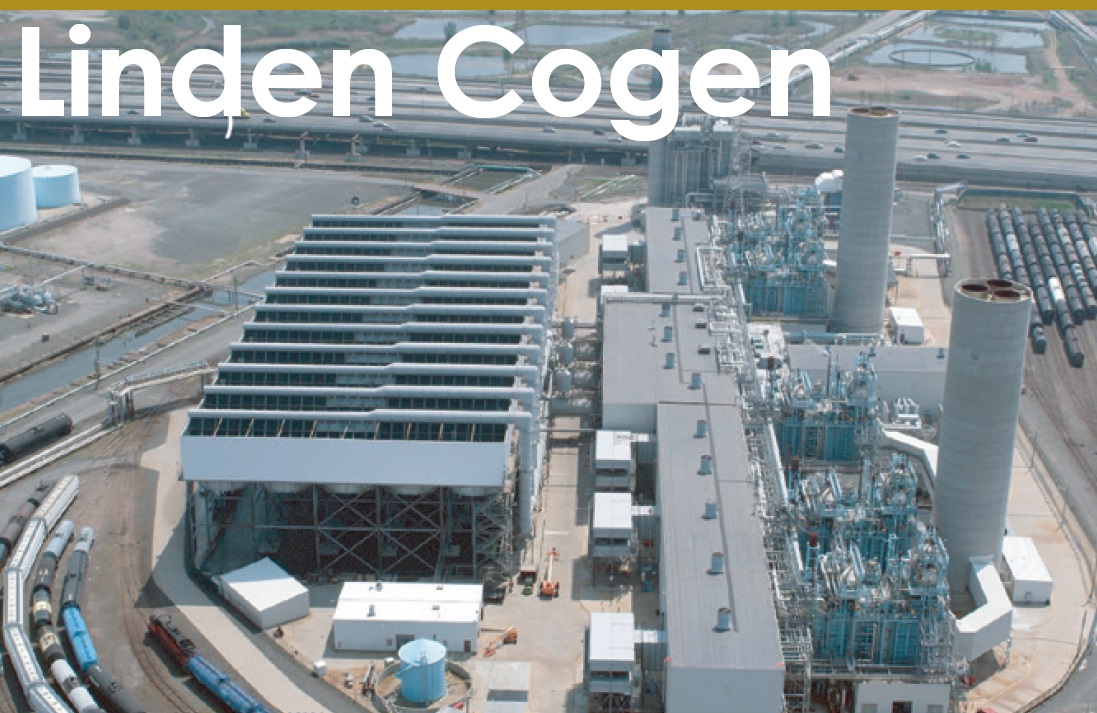

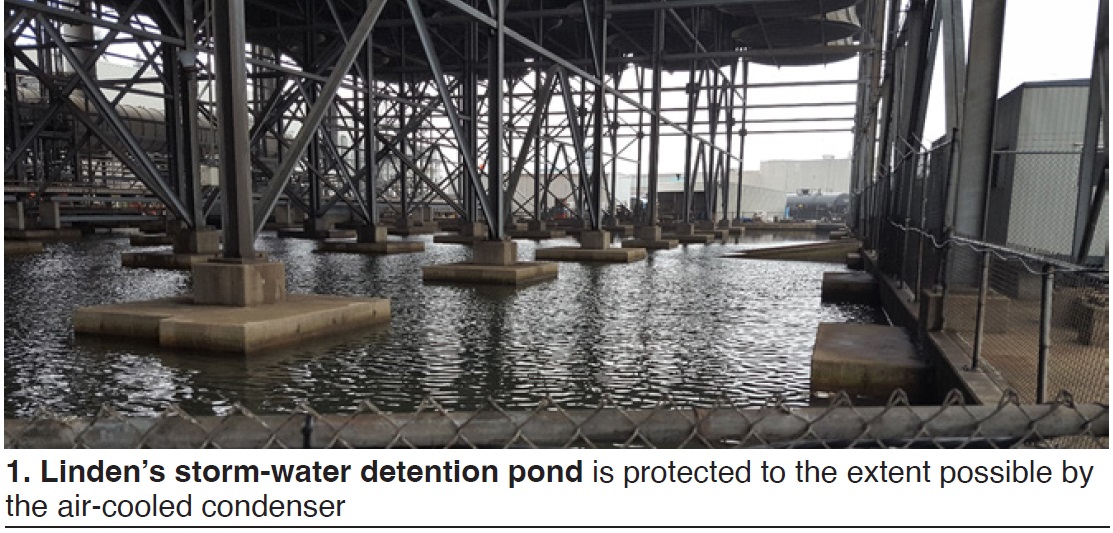

Challenge. Linden Cogen is located on a very small footprint in Linden, NJ. Storm water is collected in one central location—a detention basin under the air-cooled condenser shown in the plant photo above. Given the pond is open to the environment, debris collects in the water, which is pumped into the Arthur Kill, a narrow saltwater channel that separates New Jersey from Staten Island.

To improve the quality of its discharge water, Linden Cogen began periodic cleaning of the detention basin to remove collected debris and organic growth (Fig 1). Manual collection of the detritus with shovels, brooms, and vacuum trucks was expensive and required removal of all the water. Plus, the exposed arrangement of the detention basin limited the site’s ability to perform cleaning activities without consideration for the weather. Precipitation added water to the pond and made cleaning challenging at best.

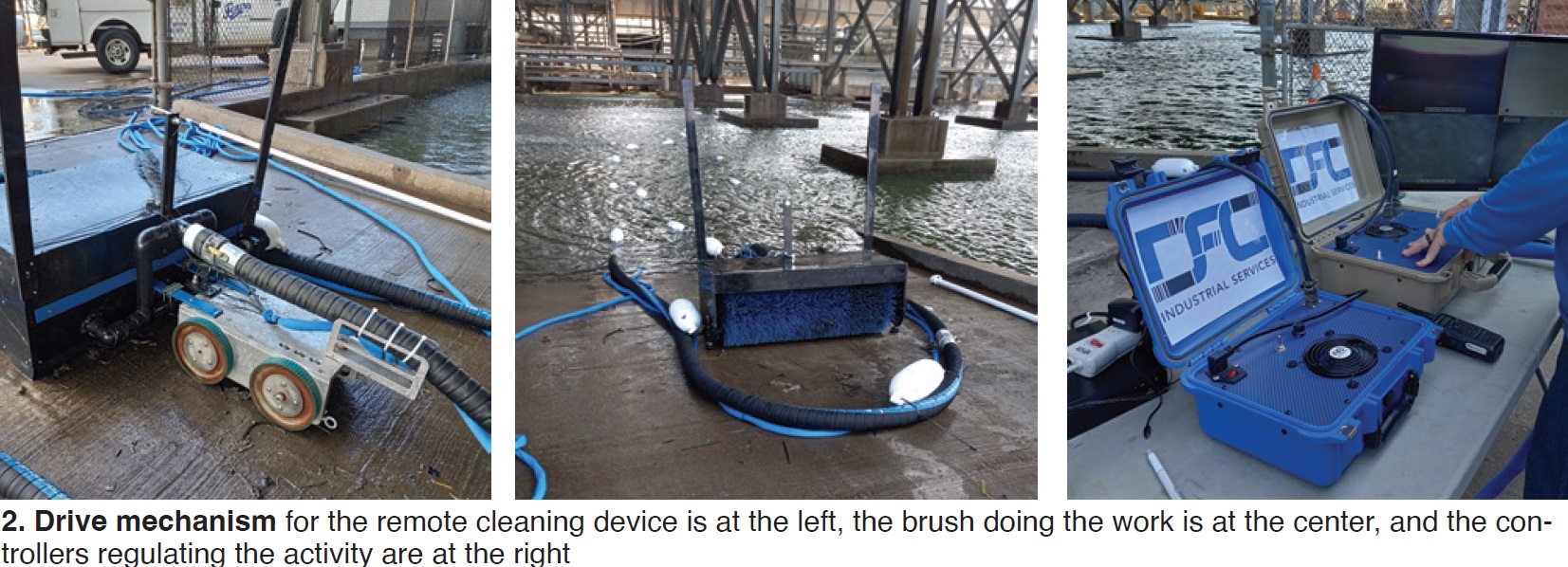

Solution. To increase cleaning frequency, an in-situ process was developed. It uses a remote-controlled vacuum system to clean the pond (Fig 2).

Results. Use of the in-situ process described for periodic cleaning of the storm-water detention pond improved the quality of water discharged to the Arthur Kill while reducing the cost of cleaning.

An added benefit of the process: Employees and contractors were not exposed to the waste material collected, helping to prevent slip, trip, and dust issues.

Project participants:

Stephen Reinhart, plant manager

Barry Durham, EHS manager