Bearings Plus Inc

As one of the most critical components of high-performing rotating equipment, fluid-film bearings are designed to provide long, reliable service. When a bearing does suffer damage, the root cause is often external to the bearing. Damage can be the result of inadequate lubricant, overloading, misalignment, or a number of other issues.

As one of the most critical components of high-performing rotating equipment, fluid-film bearings are designed to provide long, reliable service. When a bearing does suffer damage, the root cause is often external to the bearing. Damage can be the result of inadequate lubricant, overloading, misalignment, or a number of other issues.

While immediate bearing repair or a direct replacement may be the most expedient way to get machinery back up and running, performing a bearing damage analysis can, in the long run, improve overall availability and reliability. If equipment is experiencing recurring issues, a direct replacement can provide an interim solution while an analysis is performed and an upgrade made ready for the next outage.

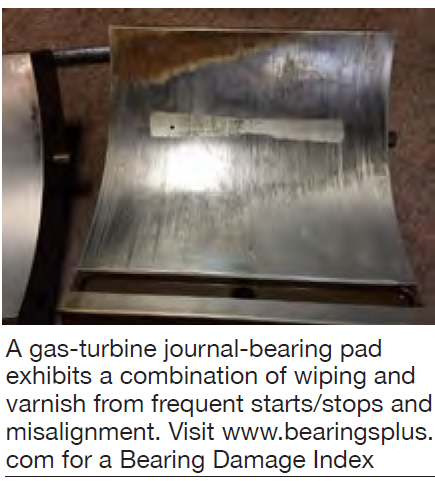

Since bearing damage is frequently an effect, rather than the cause, identifying the root of a problem can be difficult. For example, among the most common types of bearing damage is wiping, characterized by a rubbing, melting, or smearing of the bearing’s babbitt material. The cause of wiping may be any number of issues: excessive load at startup or shutdown, insufficient lubricant, operational overload, inadequate or loss of clearance, excessive vibration, or misalignment. The common factor is that contact occurs between the bearing and rotor.

To properly identify the root cause of wiping, it is necessary to look at the characteristics of the wiped bearing surface and for other damage on the bearing. Wiping that occurs during startup and shutdown may exhibit as successive thin layers of wiped bearing material.

Misalignment, on journal bearings, may cause a parabolic-shaped wiping or a wear pattern angled across the bearing surface. On thrust bearings, it may result in a group of pads on one side of the bearing being wiped.

Inadequate clearance may be indicated by an evenness of the wiping on all of the pads or lobes in a journal bearing. However, high dynamic loads may also cause wiping on all of the journal pads and resemble the effect of a loss of clearance.

Additional types of damage may provide clues to the root cause: On tilt pads, wiping caused by excessive load typically is seen together with significant pivot deformation. Wiping accompanied by oil varnish may indicate insufficient oil flow to support the bearing load or to cool the bearing. Yet, diagnosing bearing damage is frequently complicated by the fact that one type of damage may progress from—and hide—other types, or may lead to further damage.

Analysis of the bearing damage alone may not be enough to identify the root cause. As much information as possible regarding the equipment startup and operating conditions should be provided. For example, in the case of a journal bearing that exhibits even wear on all pads, knowing whether the equipment experienced high dynamic vibrations or whether there was a sharp increase in pad temperature during start-up would be of significant value.

Data provided as part of a diagnosis should include the frequency of starts/stops, startup loads, operating loads, dynamic loads, bearing clearances, oil supply, operating temperatures, and steady-state position and vibration data.

In addition to helping to identify the root cause, bearing specialists can advise on the appropriate steps to address damage, be it repairs to the existing bearing, a replacement bearing, or an upgrade that will better handle the machine’s unique conditions.