SVI INDUSTRIAL (Booth 49)

HRSG outage planning can be a difficult task, particularly when the outage scopes have varying levels of support required—including inspection, analysis, engineering, labor, equipment, and project management. SVI INDUSTRIAL is positioned to support turnkey work including anything from liner repairs and upgrades to specialty welding and turnkey valve services. ASME and valve-repair certifications allow SVI to support the broad range of outage services required for HRSG maintenance and upgrades.

Design and Engineering

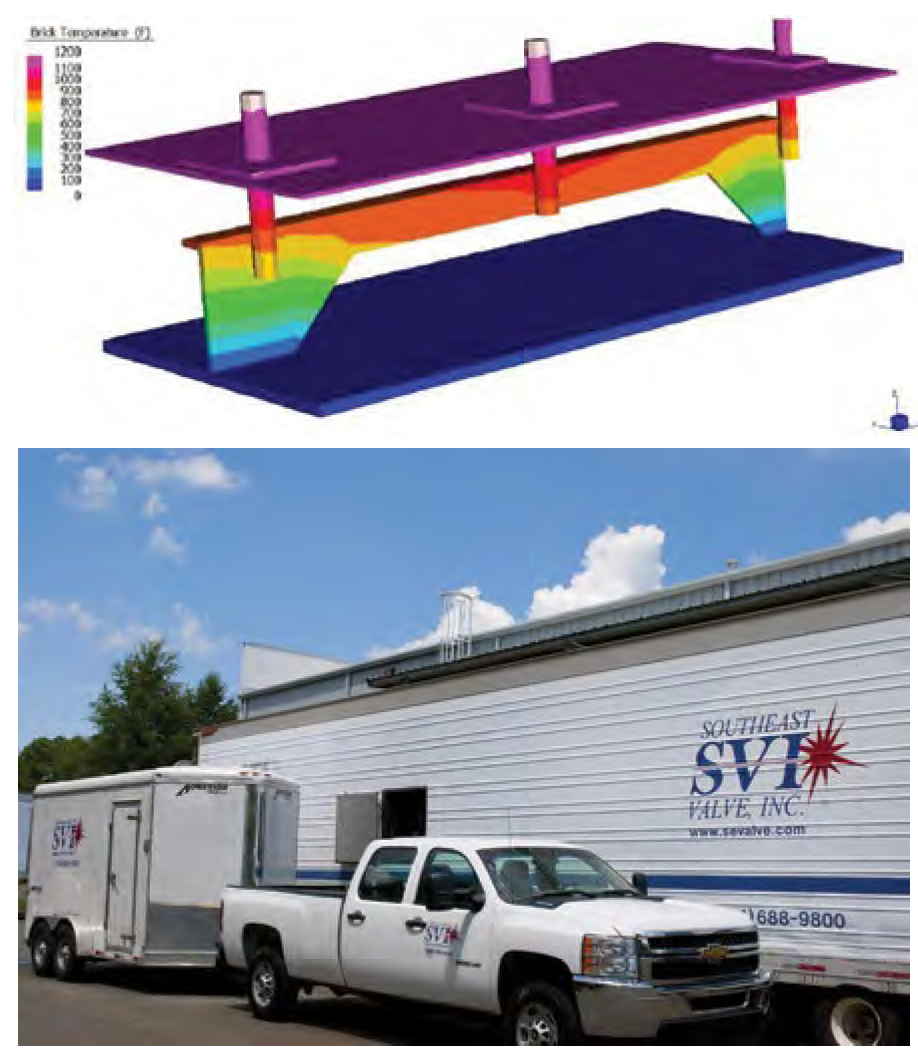

If exhaust flow would just go where it is supposed to go! Liner systems in HRSGs are not overly complicated, but when problems develop it can be a downhill battle if not fixed or upgraded correctly. With extensive experience from GT exhaust systems (simple-cycle peakers) over the years, SVI applies various liner designs and fixes to leave the gas path as exactly that, a place to reliably channel exhaust flow without leaks and failed liners that can lead to anything from a hot spot to a safety issue.

For systems that are more degraded and have developed cracks and stack wall thinning, SVI can support the structural engineering to fix areas of major concern. Systems experiencing potential structural issues because of failing casings or stacks should be inspected and repaired accordingly at the earliest opportunity.

SVI can help keep your flow in line, don’t let gas-path liner issues lead to significant failures.

Equipment Supply

With ASME code certifications, SVI is flexible for equipment supply of pressure and non-pressure parts from its own fabrication shop in Pineville (NC), or using its network of contact fabricators. This allows SVI to be a sole source to obtain high-quality equipment when it is needed.

Field Work

There are many mechanical contractors that specialize in boiler field work but not all have the depth of support that SVI has developed to ensure a one-stop shop to meet all outage requirements. By incorporating all the resources needed to support the complete project lifecycle, SVI streamlines the execution and eliminates finger pointing and costly surprises for outage work. We strive to make safety the top priority and avoid any shortcuts that may compromise safe project execution.

Project Management

A dedicated project engineer is the sole point of contact to handle all things related to your project. We understand that many times plant resources are limited so we act as an extension of your organization to ensure all project goals are met.

SVI INDUSTRIAL is headquartered in Pineville (NC), with operating locations around the US. SVI DYNAMICS is a division of SVI INDUSTRIAL providing additional synergies to support engineered noise control and gas-path solutions.

is headquartered in Pineville (NC), with operating locations around the US. SVI DYNAMICS is a division of SVI INDUSTRIAL providing additional synergies to support engineered noise control and gas-path solutions.

To learn more about how SVI can help support your next outage, email Scott Schreeg at sschreeg@svidynamics.com. Or call Scott at 219-380-9267.