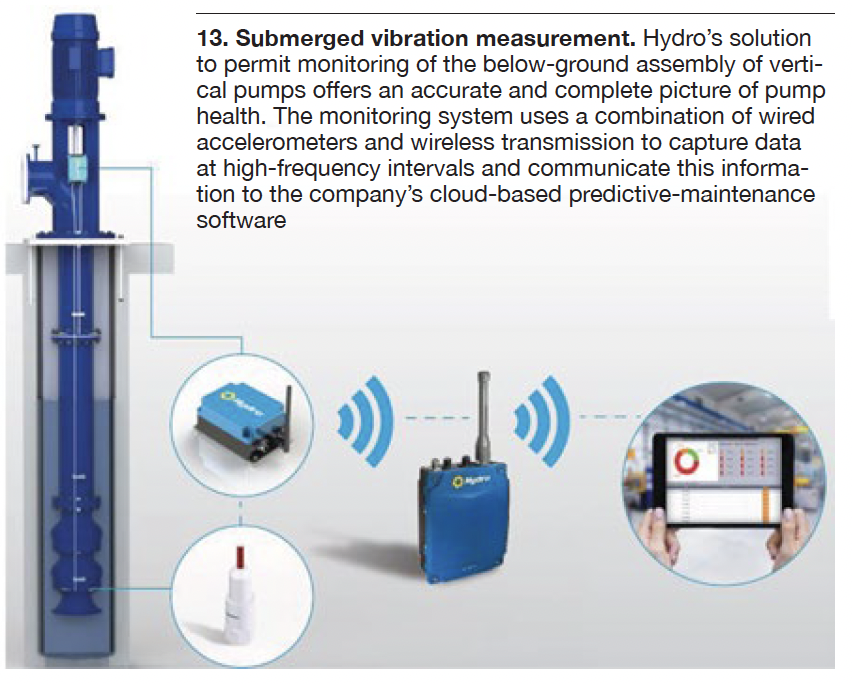

Based on sheer number of slides (87), this presentation by Hydro Solutions fulfilled batting-order slots five through nine. The first presenter, Ares Panagoulias, reviewed a relatively new, but proven, capability to monitor vibration of submerged vertical pumps using a single-axis piezoelectric accelerometer directly wired to a wireless transmitter with its own power source (Fig 13). Data go to a “cloud-based” app.

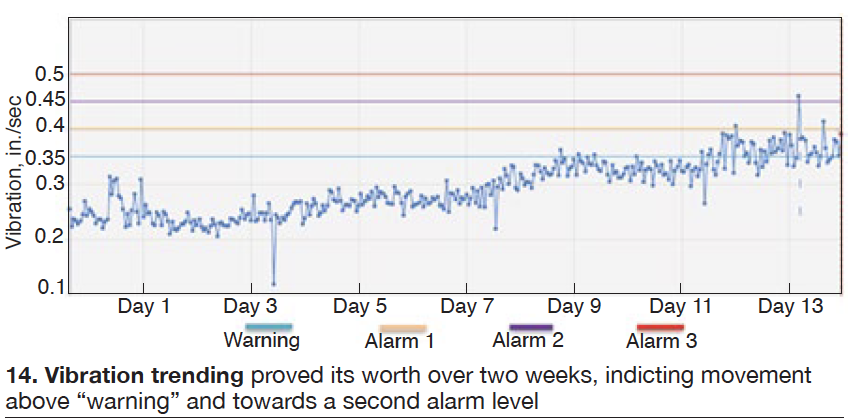

Included is a case study of a problem pump with a history of unexpected failures. Two different sensors were mounted 90 deg apart at the motor/pump interface with guard brackets to keep them in place. Specialists were able to “see” a significant vibration trend moving upward over a period of two weeks (Fig 14). Vibration is, of course, a direct indication of wear and fatigue. All three main components—sensor, data transmitter, and data collector gateway— require batteries which are said to last up to 36 months depending on data-collection frequency.

Pump performance under load cycling. Ares’ co-presenter, Michael Mancini, essentially delivered a primer on pump design and operation, specifically the relationship of best efficiency point (BEP) to changing unit load output. Needless to say, or at least good to be reminded, the farther your pump operates from its design BEP, the more performance problems it will experience. Geometry of pump internals (like the impeller) are fixed, and therefore cannot accommodate significant changes from design flow parameters.

Some problems may stem from original design, said Mancini, especially older pumps which didn’t have the advantage of computer-aided design, or were specced out by inexperienced young engineers in applications engineering.

The presentation includes spectacular video clips from lab plexiglass test stands showing how non-optimum flow conditions create waves, stall areas, back vortexes, and thick swirls. At 40% to 50% flow points, backflow grows dramatically, and significant reliability impacts occur at 20% below BEP, the presenter stressed.

This slide deck is a must for any young engineers on your staff or older engineers who have forgotten all this stuff. Not only does it provide dramatic illustration of pump issues at less than design parameters, it also includes practical solutions to common issues. The presenter has over 45 years of experience in design, operation, troubleshooting, and repair of pumps worldwide.

If you are hesitating, consider this analogy: A pump operating at its BEP is like a professional diver entering the water with almost no wake; a pump operating away from its BEP is like doing a belly-flop. Not only are significant waves created, but it hurts like hell. CCJ