In what was a truly international gathering of scientists and power-industry engineers, European Technology Development Limited (ETD) orchestrated and conducted a virtual conference on high-temperature plant materials, inspection, monitoring, and assessment (MIMA), Oct 27-28, 2020, drawing attendees from 22 countries.

In what was a truly international gathering of scientists and power-industry engineers, European Technology Development Limited (ETD) orchestrated and conducted a virtual conference on high-temperature plant materials, inspection, monitoring, and assessment (MIMA), Oct 27-28, 2020, drawing attendees from 22 countries.

Dr Ahmed Shibli, managing director of ETD Consulting, Leatherhead, England, said that “Although in the past ETD has organized many conferences and training courses throughout the world, this is a unique experience for us.

“Due to Covid-19, such exchange has become prohibitive during 2020 resulting in cancellations of many international conferences, thus limiting access to and exchange of knowledge, data, and discussions on many new and exciting developments.

“This conference is meant for materials and systems developers, plant designers, fabricators, owner/operators, and service providers, as well as researchers and inspection companies,” he continued.

MIMA 2020 was arranged in these six sessions:

1. Materials, including MarBN steels for high-temperature applications.

2. Inspection.

3. Cracking/failures of plant materials, plus operating flexibility and efficiency.

4. Weldments and monitoring.

5. Materials degradation, damage, and life assessment.

6. Risk-based inspection (RBI), reliability-centered maintenance (RCM), and stress analysis.

7. Prerecorded presentations (not discussed live) on risk-based monitoring (RBM), cracking, and modeling.

As you read through the conference highlights below, and have questions, or want to dig deeper into the details, contact Shibli and his team of experts directly @ enquiries@etd-consulting.com. The presentation summaries were compiled by Consulting Editor Steve Stultz, who participated in the meeting, and made his selections based on their applicability to combined-cycle plants.

MarBN in the UK, Japan, Germany, Austria. Shibli opened the meeting thusly: “I would like to especially thank my Japanese colleagues who persuaded ETD to organize this conference. They said no high-temperature plant or materials event has taken place this year in Japan and perhaps ETD could bring together an international community working in this area.”

Session 1 was, therefore, dedicated to ongoing development work with MarBN steels, which are gaining traction in Japan and Europe. At the beginning of 2020, the UK government and industry began a three-year study of these materials, in a project named “Implant,” with coordination by ETD. The general goal is to develop higher-efficiency, less polluting powerplants for the future.

MarBN, a 9Cr martensitic steel with the addition of boron and nitrogen, depends on an extremely sensitive heat-treatment process.

The following six presentations focused on MarBN-related material:

-

- Alloy design of MarBN for boiler and turbine applications at 650C/1200F (National Institute of Materials Science, Japan).

- Development of UK MarBN steel IBN1 for advanced powerplant applications (ETD, UK).

- Casting, welding, and forging of MarBN components (Voestalpine Bohler Welding, et al, Austria and Germany).

- Manufacture of large MarBN steel castings (Goodwin Group, UK).

- Development of the matching filler metal for creep-resistant MarBN (Lincoln Electric Europe).

- Intergranular rupture of the heat-affected zone (HAZ) of welds after short-term creep rupture (Loughborough University, UK).

Materials and inspection. Session 2 compiled recent information on material inspection methods, focusing on innovative techniques. Ignacio Marcelles, Tecnatom SA, Spain, presented an overview of inspection engineering and life assessment with both web-direct and offline access, combined with business-intelligence tools. His premise: both speed and capability of computers will increase progressively, and prices will continue to fall (Moore’s Law).

Marcelles covered inspection and analysis tools including drones, and remote-operation vehicles and crawlers for buried pipelines and small pipes, as well as tank floors, walls, and ceilings. These included devices for both manual and automated data capture. New software for integrated and 3-D results focused on structural members, valves, and transformers.

Marcelles covered inspection and analysis tools including drones, and remote-operation vehicles and crawlers for buried pipelines and small pipes, as well as tank floors, walls, and ceilings. These included devices for both manual and automated data capture. New software for integrated and 3-D results focused on structural members, valves, and transformers.

Long-term inspection solutions such as these will become more widespread both during and after the pandemic as only the system operators need to be on location. Monitoring and analysis are currently remote and could remain so.

Although security concerns remain with data transmitted away from the plant, benefits are reduced cost, quality of data and analysis, and centralized plant comparison capabilities.

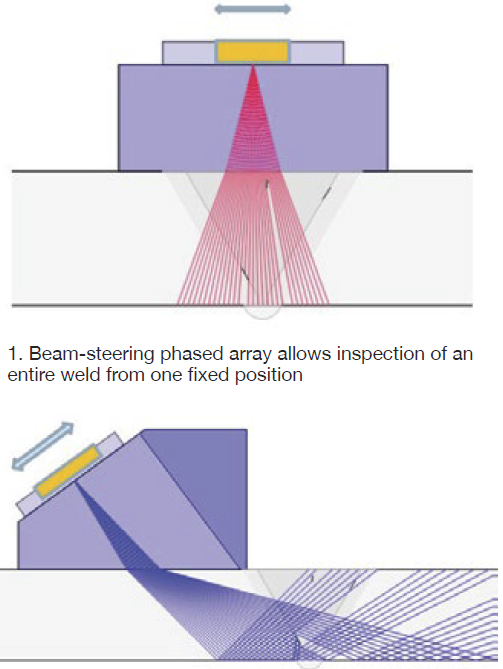

Phased array. John Trelawny, team leader at Uniper Technologies (formerly E.ON) in the UK, discussed an ultrasonic phased-array total focusing method (TFM) for inspection, suggesting that this could perhaps be a solution for the future. “Accuracy of flaw sizing is paramount,” he stressed.

Trelawny offered an example of beam-steering phased array, which uses a probe with multiple elements, each receiving all signals. This technology, tested in both mockup and real-time onsite, allows for angular inspection. The entire weld can be inspected from one fixed position (Fig 1).

He explained TFM in three modes (2T, 3T, and 4T). TFM clarity exceeded that of standard beam steering. Lack of such clarity can cause confusion, he explained.

The presentation showed detailed comparisons of angled phased array versus offset total focusing, among others. Visuals included mockups with testing methods and options, followed by site testing experience and validation.

Some conclusions:

1. TFM is an advancement in ultrasonic technology.

2. For simple butt welds, TFM is superior to current techniques.

3. For complex geometries, TFM can be an advantage, but not in every situation.

Trelawny estimates that phased array is currently used in about 20% of applicable investigations; the remainder, conventional UT. Phased array/TFM is also a very repeatable technique.

Electromagnetic (EM) sensor techniques for creep cavity damage detection and assessment were offered by the Univ of Manchester, ETD, and Nippon Steel Technology Corp, Japan.

Ferromagnetic materials are comprised of polarized magnetic domains which grow and shrink with the application of an external magnetic field. Microstructural changes are based on so-called pinning of these walls by features such as cavities, inclusions, and dislocations. Magnetic properties reveal the microstructural properties.

Univ of Manchester’s John Wilson explained the use of EM on aberrant, mis-heat-treated materials for testing—specifically Grade 91 components. The work was initially developed through the testing of cylindrical samples machined from P91 pipes. He presented the results of BH loops and Magnetic Barkhausen Noise (MBN) on some of the laboratory samples and the tests on in-service pipes, as well as the test-equipment configurations.

Background: A BH loop measures the hysteresis loop flux density (B) versus field intensity (H) of a thin magnetic film sample by applying a field to the sample and measuring the magnetic field produced by the sample’s magnetization. The Barkhausen effect is a name given to the noise in the magnetic output of a ferromagnet when the magnetizing forced applied to it is changed.

A planned follow-up of this work will be an ETD Group Sponsored Project, “Early-Stage Damage Inspection, Repair, and Life Extension of Aberrant P91 Components.” The goal is improved microstructural investigation.

Challenges to industrial deployment, Wilson explained, include:

-

- Irregular surface geometry (tee pieces, etc) in onsite components (problematic for contact techniques).

- Some difficulty in sourcing post-service samples with varying levels of creep.

- Identifying further the effects of surface conditioning (grinding, decarb layer).

Correlations have been established between material (creep, aberrance) and magnetic properties for Grade 91 steel using laboratory measurement systems, but further work is needed on field-deployable devices. Ultimately, this application should support, and later replace, the traditional replication and reduce both testing costs and schedule impact because, unlike replication, it does not require surface preparation. Furthermore, EM can detect damage a few millimeters below the surface which is a distinct advantage over replication.

TesTex. Frank Neil of TesTex, Pittsburgh, Pa, presented three novel techniques: low-frequency electromagnetic to inspect HRSG finned tubes from the outside, the innovative Claw to inspect tube-to-header welds with a balanced-field electromagnetic technique, and a remote-field electromagnetic to inspect HRSG tubes from the inside. All search for corrosion cells and cracks in materials.

In cooperation with EPRI, various new methods are being applied in challenging areas of the combined-cycle powerplant. TesTex methods are used for condenser-tube and auxiliary-boiler inspections, thickness testing on tubing and piping, deaerator heater and storage tank examinations, assessing corrosion under insulation, and a growing number of inspections for balance-of-plant heat exchangers.

Results of specific dry inspection methods, he stated, are competitive with radiography, at reduced cost, improved personnel safety, and less schedule impact.

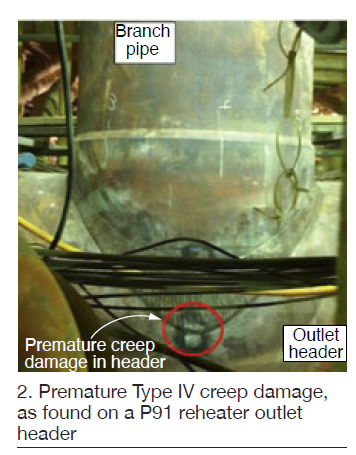

Life assessment. Dr David Robertson, lead metallurgist at ETD, addressed life-assessment tools and root-cause failure analysis for boiler/HRSG components, highlighting recent experience at various world locations.

For remaining-life assessments, ETD uses an organized, staged approach. Initial inspection-based assessments combine many techniques, often teamed with international NDE partners.

Robertson explained some of the newer techniques, including low-frequency electromagnetic methods for waterwall tubes (see TesTex above) and pulsed eddy current for feedwater piping.

His specific examples included pulsed eddy current as a screening tool to identify corrosion under insulation (CUI) and flow-accelerated corrosion (FAC) without removing insulation; borescopes for tubes and bends that are difficult to inspect from the outside; and metallurgical assessment of P91 branch connections (reheater outlet headers, for example).

His specific examples included pulsed eddy current as a screening tool to identify corrosion under insulation (CUI) and flow-accelerated corrosion (FAC) without removing insulation; borescopes for tubes and bends that are difficult to inspect from the outside; and metallurgical assessment of P91 branch connections (reheater outlet headers, for example).

In one example, premature Type IV creep damage was found on a P91 reheater outlet header. At this position, orientation of the HAZ at the flank position of the branch weld is perpendicular to the hoop stress on the header side of the joint. This led to higher risk of Type IV creep damage (Fig 2), similar to that found on longitudinal seam-welded pipe. This was fully analyzed and the client advised to grind out the cavitated area after which the component would be fit for service for another few years.

During the RCA, Robertson reviewed typical scope of work, highlighting a vertical-path HRSG and specifically thermal-mechanical fatigue cracking at tube-to-header welds.

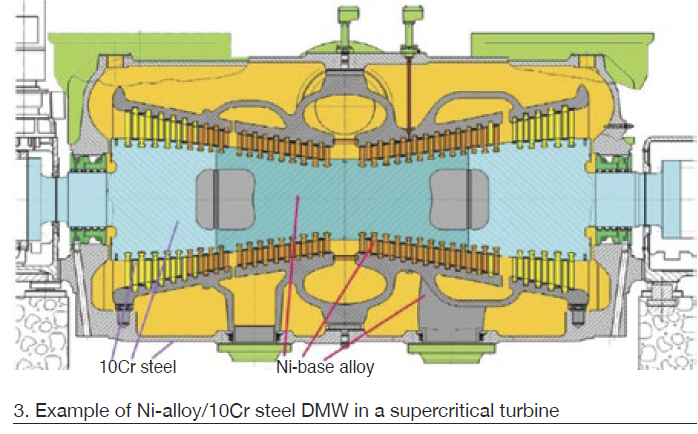

DMWs. Stuart Holdsworth, Swiss Federal Laboratories for Materials Science and Technology (EMPA), reviewed microstructural damage development adjacent to fusion lines of dissimilar metal welds (DMWs). He began with high-temperature damage of a Ni-alloy/10Cr steel DMW in an advanced ultra-supercritical (A-USC) steam turbine application (Fig 3).

He followed with DMW creep-rupture strength reduction and cycle/hold creep fatigue; some concluding observations:

1. Creep-rupture weld strength factors for A617/1Cr DMWs at 550C/1020F indicate that fusion-line cracking becomes increasingly dominant at lower stresses.

2. For A617/10Cr, fusion-line cracking dominates even at higher stresses.

3. At 575C/1065F, strain-controlled creep-fatigue damage develops initially in the over-tempered parent materials, with an increasing damage influence with less strain.

Cost and performance. ETD’s Shibli focused on cost and performance analysis when operating in both base and cycling modes. Methods included performance benchmarking, top-down and bottom-up cost analysis, and the negative impacts of cycling on both performance and cost.

Presenting a detailed and comprehensive case study, Shibli stated that “Recently a utility with 11 combined cycles located in North America was looking for an increase in profitability. The head office approached ETD to assess the maintenance strategy for each of its 11 plants.”

Some units had relatively low availability factors because of a large number of forced outages and excessive planned outages. These data were plotted against total maintenance costs on a five-year average, showing plant performance comparisons and ratings. Performance comparisons were compared among the 11 plants studied and also with ETD’s database of about 150 other plants. Benchmarking study recommendations were then provided to each plant based on performance results and failure types.

These included the following:

-

- Creation of an integrated service- and maintenance-history database.

- Implementation of a condition-based maintenance strategy.

- Development of a risk-based boiler tube failure (BTF) prevention program.

- Implementation of a regional reliability-centered maintenance approach.

Top-down factors included the influence of market-driven cyclic operations. As Shibli explained, “Estimates of increased costs and the basic causes are vital so that utilities can better understand the true economic implications of cyclic operations.”

An often-overlooked factor was also considered: high fuel consumption during startup and shutdown because of inefficient heat transfer and non-optimum heat rate.

Shibli identified these common data-collection challenges for accurate unit-specific cycling cost analysis:

-

- Overall plant design.

- Operational history.

- Individual major component design—including material, thickness, and related factors.

- Water-chemistry quality and procedures.

- Size and age of plant. Note: Shibli suggested that size is often more important than age.

- Previous maintenance philosophy (during baseload operation, prior to going into cyclic service).

- Plant accounting-practice comparisons.

Shibli then offered a detailed methodology matrix for cycling impact assessments: “Estimates of per-start costs use elements of a bottom-up approach, namely engineering and risk assessment to identify plant-specific critical components. Statistical analysis is used to estimate the impact of an increased number of starts on performance, reliability, and non-recurring maintenance and capital replacement costs—thus providing the current and projected per-start cost range of cycling for a defined period and operating environment.”

Results help to understand “how costs can be reduced by making plant design and operating changes to reduce component damage,” he said.

Corrosion. Cesar Buque, TUV SUD Group, Spain/Germany, focused on the cost of corrosion, explaining current inspection practices and their limitations. His lead-in graphics showed the often-catastrophic impacts of non-detection between inspection periods. He then offered an asset health monitoring solution using sensors for wall-thickness monitoring, and the ability to detect corrosion in insulated pipes, elbows, and difficult-to-access locations.

Current practices and technologies can lead to spot measurements with a large error bandwidth, and inability to determine long-term corrosion trends. Increasing the traditional inspection frequency can lead to higher costs with haphazard trending information.

He offered one solution: continuous (ultrasonic) sensors for wall-thickness monitoring. The stated goal is to inform operators before major negative consequences arise. “Send early warnings to plant operators according to determined thresholds, and find root causes through pattern recognition,” he suggested. Analysis would help determine best operating practices for asset longevity, and achieve higher plant availability over time.

This could also reduce needless early retirement of components.

Sensors also monitor each other for any malfunctions. Expected degradation mechanisms and types of equipment studied determine the number of sensors used.

Creep strain measurement. Christian Ullrich, VGB PowerTech, Germany, followed with creep strain measurement using high-temperature strain gages. The premise: Because components are designed for a specific lifetime under given parameters, their condition must be monitored to identify threats to component integrity. This is particularly important for P91 and P92.

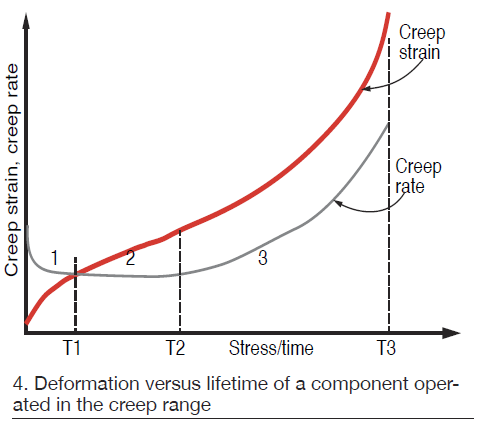

Case studies explained the stages of creep graphically in Fig 4:

-

- Creep rate is high in first stage.

- Creep rate is linear in secondary stage.

- In third creep stage, there is an exponential behavior of creep strain. Cause is the formation of micropore chains.

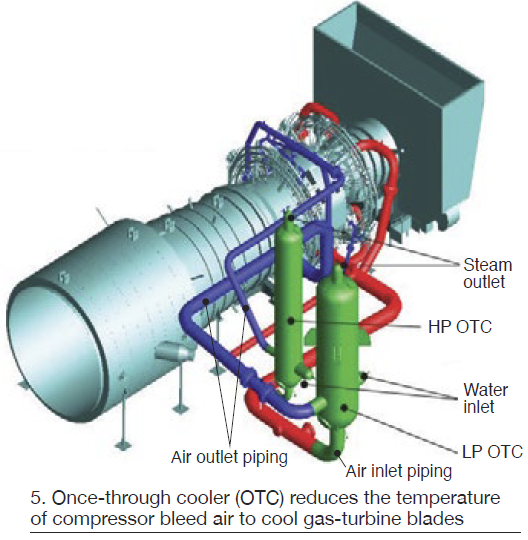

Once-through GT coolers. Alexandros Antonatos, Public Power Corp, Greece, discussed once-through coolers for Alstom GT24 and GT26 engines. The water-cooled heat exchangers reduce the temperature of compressor bleed air for cooling critical parts of the gas turbine; steam is produced in the process (Fig 5). The steam outlet is Type 316 stainless steel transitioning to P91, therefore requiring dissimilar metal welds or a combination of mixed weld seams.

Operational stresses, including demanding steam parameters, contribute to high stress in the weld joints. “Weld-crack incidents at various sites worldwide have been reported in this transition zone,” he stated.

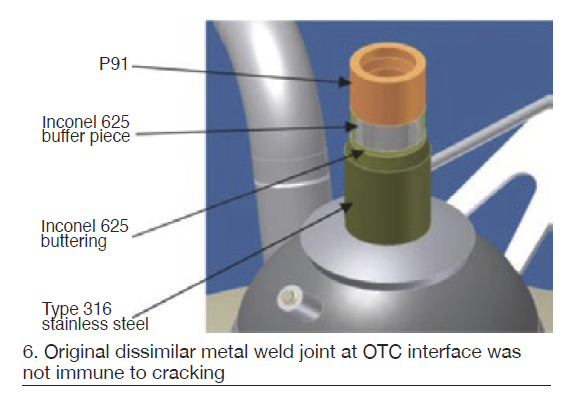

Antonatos presented various dissimilar-metal weld joints being used in an effort to avoid creation of these cracks. In its original configuration, the transition included an In625 buffer (Fig 6). But after a few years of operation, cracks were reported.

A suggestion was to choose a location with lower system stresses (a vertical pipe section) and provide a gradual transition with 6-in. bridging pieces (Fig 7). However, cracks appeared in this “new” design at one of the weld joints.

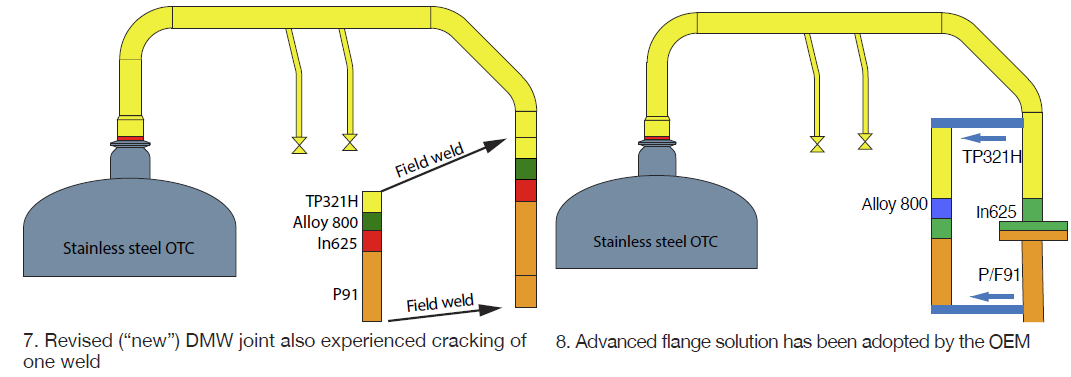

The latest design features Alloy 800 between the In625 and TP321H segments, joined by three dissimilar-metal welds, to form a so-called “advanced flange solution” now offered by the OEM (Fig 8). The speaker said the flange has not yet been installed in the field.

Maintenance forecasting. Martyna Tomala, Silesian University of Technology, Poland, offered a review of coal-fired 200-MW units in Poland, and the effects of operational changes as they adjust to renewables. She focused on steam turbines. Prevailing concerns are turbine-blade erosion, corrosion attributed to shutdown practices, increased crack propagation (first rotor failure scenario), and low-cycle fatigue (second rotor failure scenario).

“Crack propagation is one of the most dangerous processes in the turbine rotor,” she explained. “The most vulnerable area is the turbine central bore. FEM (finite element method) analysis allows determination of stresses occurring in the rotor during startup and steady-state operation (under creep conditions).”

She explained the components of stress during heat-up and creep relaxation. Calculations were presented for three operating scenarios with these assumptions:

-

- Rotor service life, 20 years.

- Operation time, 6000 hr/yr.

- Number of annual starts, 200.

- Steady-state operation time between starts, 30 hours.

Crack propagation rates were shown based on the Monte Carlo Method (repeated random sampling to obtain numerical results). Fracture toughness was determined using nondestructive small punch tests. This led to preventive activities planning based on avoided-risk criteria.

A highlight was a detailed explanation of net present value (NPV) sensitivity analysis, leading to optimization of preventive activities and intervals, as well as cost impact.

Also in Session 5 were the following:

-

- Stress corrosion cracking in T24, VGB PowerTech, Germany.

- Hardness methodology for creep deformation and residual life, Toshiba, and Tokyo Institute of Technology, Japan.

- Creep degradation in reformer tube after 17,000 hours at 980C, TNB Research et al., Malaysia.

- Creep life estimation by crystal misorientation frequency distribution, Nippon Steel, Japan.

- Development of oxide scales on inner and outer surfaces of reformer tubes, TND and Petronas Berhad, Malaysia.

In Session 6, various presenters concentrated on risk-based investigation methods and stress analysis. This included finite-element (FE) analysis of stress fields in steam pipeline components, from the school of mechanical and design engineering, University of Portsmouth, UK.

This particular presentation included residual stress analysis of pipe bending through an FE model for bending simulation, verified by published data. Featured was field-structure interaction (FSI) using ABAQUS.

Models presented simulated the pipe bending and fluid structure interaction at the pipe elbow. Further work is required to correctly capture precise stress fields in pipe under high temperatures.

In another presentation, ETD’s Feroza Akther discussed risk-based maintenance and performance optimization of powerplants. Examples were taken from a recent study for a client in Canada. Planned maintenance was suggested in three categories: preventive, predictive, and proactive.

A section on recent developments in smart analyses of equipment performance included SmartCET, a corrosion monitoring technique developed by InterCorr International (Houston), now part of Honeywell Inc. Smart thermal scanning and digital radiographic techniques were also presented.

This detailed presentation ended with the following list of common aspects for a best-practice risk management procedure:

-

- Assess credible hazards for threats to equipment based on plant experience and equipment knowledge.

- Identify failure modes and potential causes.

- Determine probabilities and resulting impacts.

- Set risk treatments or mitigation measures.

- Assign a measure of risk to each item.

- Define acceptable or tolerable risks.

- Combine risk with inspection history to determine future inspection intervals and methods.

Also presenting were Best Material Co and IMC Co of Japan discussing new software for the execution of boiler risk-based investigation; modeling of grain-boundary cavitation and rupture by the school of computing and engineering, Univ of Huddersfield, UK; and the benefits of RCM implementation in power generation by ETD.

Wrap-up. Prerecorded sessions also were integrated into the meeting. They covered Type IV failure in 9Cr weldments; defect assessment with ETD’s Crackfit technology; creep rupture modeling of P92 by grain-boundary cavitation; calibration of creep cavitation modeling for 316H steel; creep cavitation by cavity histogram; and creep damage constitutive equations.

The online sessions were chaired by EMPA’s Holdsworth and ETD’s Shibli, Akther, Robertson, and Dr David Allen.

The conference concluded with a one-hour discussion session where all participants could switch on their videos and participate. This was a very positive feature with attendees able to see other participants and ask more questions.

Based on the success of the two-day virtual conference, ETD is organizing the following three online events in early 2021:

1. A two-day Boiler Life Assessment Training Course in February.

2. A three-day event focused on high-temperature defect assessment in April. This will be the eighth in the series of triennial HIDA conferences covering high-temperature plant component failure, cracking, damage, and condition/life assessment.

3. A four-day course on gas turbines.