Investigative process addresses, helps correct generator thermal sensitivity

Quail Run Energy Center

Owned by Quail Run Energy Partners LP

Operated by NAES Corp

550-MW, gas-fired, two 2 × 1 combined-cycle power blocks located in Odessa, Tex

Plant manager: Steve Reinhart

Over the years, one of the plant’s four gas turbine/generators developed excessive vibration on the exciter end of the machine, sometimes exceeding alarm limits. Personnel were unable to pinpoint the source of the problem and an investigative process was initiated. Contractors were hired to conduct vibration testing and determine the cause of the vibration. Analysis revealed no correlation between vibration and speed and/or load, indicating the machine was sensitive to another variable—most likely rotor temperature.

By following the plant’s root cause analysis (RCA) processes, staff was able to eliminate the excessive vibration on the gas turbine/generator without use of balance weights, which might have caused other problems.

To resolve the vibration issue, plant management planned to inspect and repair the generator during the fall 2018 outage. This included removal of the rotor from the generator for inspection and repair, removal of the bearings for inspection and repair, and inspection and repair of the stator.

The rotor (a/k/a field) was sent to a repair facility, where the steps below were taken to determine if it was thermally sensitive, then to attempt to find the cause of the thermal sensitivity, and finally to find a solution to the sensitivity issue:

Step 1. At the shop, a visual inspection and electrical testing of the rotor were conducted, along with NDE of the retaining rings. Once the retaining rings were off the rotor, the shop found some turn-insulation migration. There were about 10 turns were the slot turn insulation had worked its way out. A patch of insulation was added with an air-dry epoxy. This was not believed to have been a major factor in the vibration issue.

Step 2. With no initial finding for the cause of the vibration, Quail Run management decided to perform a balance and thermal sensitivity test on the rotor in a high-speed balance pit. This included the following:

-

- Perform dial-indicator runouts and slow-roll TIRs (total indicator runout) of journals, TE coupling, retaining rings, and collectors.

- Perform a rough balance.

- Perform flux probe run.

- Perform overspeed run.

- Perform flux probe after overspeed.

- Balance for thermal run.

- Perform thermal run.

- Perform flux probe after thermal run.

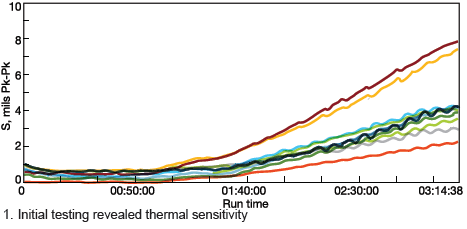

The test results (table) indicated that there was thermal sensitivity with just under 8 mils deflection (Fig 1).

Step 3. With confirmation that the rotor was indeed thermally sensitive, plant leadership decided to rewind the field. This required removing the coils, wedges, blocks, sand blasting the forging, and reassembly.

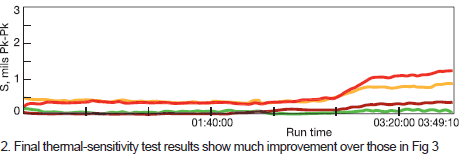

Step 4. After completion of the rewind another balance and thermal sensitivity test were performed (Fig 2), finding thermal sensitivity was no longer an issue. Maximum thermal deflection was just over 1.3 mils. Electrical testing of the rotor was performed with no issues noted.

After completion of the inspections, testing, and rewind, the rotor was returned to the plant and installed in the generator. Vibration was monitored on restart to ensure performance had returned to design specifications. This was confirmed.

The generator tilting-pad bearings were inspected and repaired by a local bearing shop to ensure they were not a cause of the vibration. Nothing was found to suggest they were.

Bottom line: The generator now operates within its proper design parameters.