European Technology Development Ltd conducts multi-client projects to address concerns and challenges within the international electric-power industry. Known as ETD Consulting, the 20-year-old UK company’s projects are aimed mainly at developing new tools, technologies, and methodologies for powerplant inspection, integrity, and life assessment/extension; and improvements to materials, welding, and design.

Collaboration with the international power industry is key to developing new tools and cutting costs while achieving useful scientific results. This approach pools both financial and technical resources, technical know-how, and lessons-learned databases. Among the company’s current group-sponsored projects (GSPs) of interest to CCJ ONsite readers are these:

-

- Aberrant P91 long-term creep rupture data collection, inspection, and repair.

- Crack assessments in boilers/HRSGs and turbines.

Closer to home for many readers, note that these are among the topics included in the robust presentation/discussion agenda for the HRSG Forum with Bob Anderson, March 5 – 7 at the Hyatt Regency Houston (see sidebar below).

ETD concentrates heavily on the integrity and life assessment of plant systems and components based on disciplines of mechanical engineering, materials science and metallurgy, and inspection and maintenance in high-temperature applications—somewhat similar to what US-based EPRI and Structural Integrity Associates Inc do as well. It specializes in probabilistic crack and life assessments, which require large databases.

According to Dr Ahmed Shibli, CEO, “ETD has expertise in plant services and technical consulting backed by R&D conducted with manufacturers, plant operators, service providers, and researchers from around the world. We are in an ideal position to conduct such projects for industry sponsors, and bring together plant experience from best-run plants in Europe, Japan, US, Canada, Australia, and elsewhere.” A few examples of GSPs follow.

Creep rupture strength of P91 materials and welds, a six-year project, is generating long-term creep rupture data to help plant operators establish safe operating lives of aberrant or abnormal P91 base- and weld-metal microstructures often found in powerplants and HRSGs. The aberrant materials and weldments arise when heat treatment during either steel production or component fabrication is not conducted to the precise requirements for P91—a high-chrome martensitic steel. With incorrect microstructure, creep rupture strength is reduced, leading to early failure.

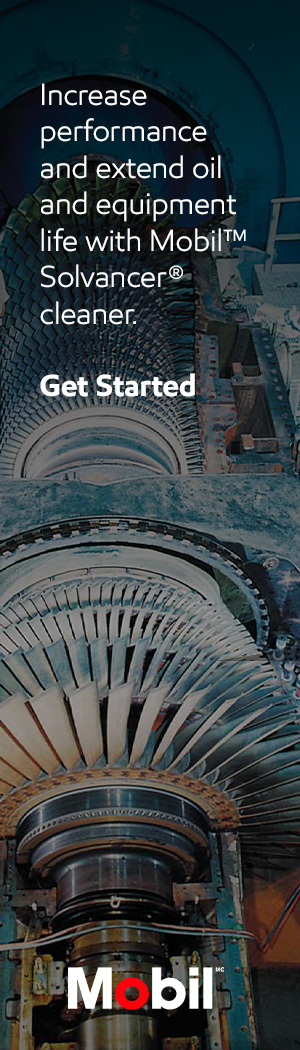

Given the absence today of long-term rupture strength data for aberrant microstructures, some plant owners and operators are not sure how to deal with such components and often treat them as either P22 or P9 steels, sometimes unnecessarily condemning critical and costly components too early, at great expense to owner/operators (Fig 1).

Within this project, tests are being conducted on 15 aberrant microstructures at durations of up to 30,000 hours. Current sponsors include organizations from Europe and Japan.

As background, ETD plant experience includes NDT of boiler P91 welds at the 460-MW Quezon Power Plant in the Philippines; P91 work for EdF in France, Inpex in Australia, Malakoff and TNB in Malaysia; plus work at Uch Power Plant in Pakistan and other facilities in the Middle East, Europe, and Far East. Also significant is an ETD Grade 91 Users Group initiative for the supercritical Keephills Unit 3 in Canada.

Although not part of the original Abnormal P91 GSP scope, the work on this project also is helping to establish new inspection regimes for both P91 and P92 components.

Inspection techniques and life assessment for P91 and P92 welded in-service components is a closely aligned GSP with a three-year duration. According to Shibli, “Welded-pipe creep tests are being performed and stopped at 30%, 50%, and 70% of estimated life to enable an assessment of new inspection techniques and study of damage development with lifetime consumption.”

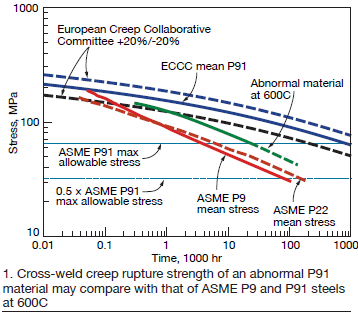

Inspection techniques include (1) replication, (2) hardness, (3) innovative UT, (4) boat sampling using a newly developed portable spark erosion machine, (5) portable scanning force microscopy (SFM) to detect early-life damage and the creation of 3-D creep-cavity images (Figs 2 and 3) using cavity volume for life assessment, (6) electromagnetic property measurements, and (7) AC- and DC-potential-drop techniques.

Inspection techniques include (1) replication, (2) hardness, (3) innovative UT, (4) boat sampling using a newly developed portable spark erosion machine, (5) portable scanning force microscopy (SFM) to detect early-life damage and the creation of 3-D creep-cavity images (Figs 2 and 3) using cavity volume for life assessment, (6) electromagnetic property measurements, and (7) AC- and DC-potential-drop techniques.

The aim of this GSP is to develop and experiment with innovative techniques that can detect and quantify creep cavitation damage in P91 and P92 steels at an early-life stage. At present this is difficult because traditional NDE techniques are inadequate for the task.

Three large P91 pressure vessels and one P92 vessel, with both butt and seam welds, are being tested under pressure and high temperature—and with end loads to obtain in-service-like Type IV failures in butt-welded pipes at a planned duration of about 10,000 to 15,000 hours.

States Shibli, “Tests have now been completed along with supporting cross-weld rupture data and finite-element analysis. Relationships between damage in the Type IV or fine-grained region of the heat-affected zone (HAZ) and the remaining life of the welded components are developed to help plant operators detect and quantify early-stage damage. This will give them time to develop repair or replacement strategies before potential and possibly abrupt failure takes place.”

Participants are from the UK, US, Japan, Germany, Italy, and Belgium.

A similar project has been planned using P91 pipes containing aberrant microstructures to further demonstrate the above NDE techniques together with a few new and promising methods. This GSP will help in developing inspection strategies for components with aberrant microstructures. In addition, it will demonstrate a Japanese-developed technique for strengthening creep-damaged pipe for which ETD has the rights for further development. Existing sponsors are from the UK, US, Europe. and Japan; new sponsors are being pursued.

CrackFit. This new group-sponsored project uses ETD’s CrackFit procedures and software to assess cracks in both low- and high-temperature high-pressure equipment. The technology presently covers 17 geometries of pressure vessels and piping components typically found in power and process plants. Steam and gas turbine geometries also are being investigated. CrackFit software significantly reduces the time required to complete assessments, in some cases reducing weeks to days.

Initial work by ETD was supported by the European Commission and leading European universities and industry; data were supplied by operating plants.

Says Shibli, “CrackFit comes with an optional crack initiation and growth database for base metal, HAZ, and welds for many materials of interest to the power and process industries. It deals with defects such as lack of fusion/penetration in welds (defects at weld toes), internal- and external-surface emerging or embedded defects in straight pipes and pipe bends, defects at stress concentrations such as sharp corners (T-pieces, nozzles), and defects in plates, among others.”

Shibli further explains that the software is “user friendly for industry engineers who would like to carry out defect assessments without having to go through the different established codes or country/in-house defect assessment practices.” Procedures including BS7910 (a BSI-British Standards Code of Practice for the assessment of flaws), Nuclear Electric (UK) R5, the French nuclear code RCC-MR A16, and the European HIDA (high-temperature defect assessment procedure) are available as software options.

“The software allows for failure analysis (fast fracture, plastic collapse, and ligament rupture) and the evaluation of damage mechanisms such as creep, fatigue, and creep-fatigue interaction,” he explains.

A fitness-for-service program incorporated into the software performs calculations to determine a defect’s criticality in line with the assessment codes. The software carries out both deterministic and probabilistic crack assessments. Modules within the study are:

-

- Materials.

- Cyclic loading of powerplants.

- Sensitivity and probabilistic analysis.

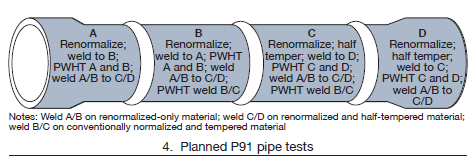

Weldlife. This five-year GSP launches in early 2018 and will investigate changing the heat-treatment cycle of P91 welding with some changes to the welding processes. The initial basis is specific research in both Japan and the UK that shows weldment rupture life improvement by a factor of two to three. Japanese and UK companies have committed support; additional sponsors are invited. Fig 4 shows some of the planned pipe tests.

Drones. ETD is also beginning a group-sponsored project to study drones, robots, and other automated devices available in the market, and to develop recommendations for appropriate and cost-effective devices that may even be used as consumables. This includes 3-D printed drones with light plastic frames and safety cages. Ultimate uses include inspection and possibly repair capabilities.

Shibli ended the interview, conducted by Consulting Editor Steve Stultz, by referring readers interested in learning more about these and other projects to the organization’s website.

HRSG Forum with Bob Anderson

March 5 – 7, Hyatt Regency Houston

Several presenters and discussion leaders at the second annual HRSG Forum with Bob Anderson will be speaking on the topics described in the accompanying article on research in Europe and Asia regarding failure mechanisms, inspection, and welding of advanced materials for high-temperature/high-pressure steam systems.

A few examples:

-

- Jeff Henry, respected internationally for his work associated with creep-strength-enhanced steels, will present on the evolving issues with these materials. The ASME Fellow is intimately familiar with the subject, serving as chair of that august professional organization’s Working Group on CSE Ferritic Steels. Henry, who was director of Alstom Power’s Materials Technology Center in Chattanooga, now is president of ATC Inc, a materials engineering services company.

- Barry Dooley, perhaps the world’s best-known powerplant water chemist, will speak on flow-accelerated corrosion, the leading cause of HRSG tube/pipe failures. His presentation will cover the causes of FAC, methods to detect and monitor its presence in HRSGs, and chemistry actions to prevent its occurrence. Dooley, who works for Structural Integrity Associates Inc, volunteers most of his personal time to industry organizations focused on helping plant owner/operators improve safety, availability, and profitability. To illustrate: He is executive secretary of IAPWS, which provides Technical Guidance Documents free-of-charge to improve operating practices relating to water chemistry, metallurgy, etc. Dooley also is an active participant on the steering committees for several user-focused organizations—including Air-Cooled Condensers UG, Canadian HRSG Forum, Australasian HRSG UG, HRSG Forum with Bob Anderson, European HRSG Forum, and International Conference on Film-Forming Amines and Products.

- HRST Inc’s Director of Engineering Bryan Craig will discuss factors affecting superheater and reheater metal temperatures, perhaps the variable with greatest impact on the lives of these components. Long-term overheating of superheaters and reheaters is conducive to repairs and component replacements costing millions of dollars. Many HRSGs installed during the “bubble” are at significant risk today. Craig will help attendees better understand and manage remaining life.