If you’ve attended Western Turbine meetings since the 25th anniversary celebration you might think there haven’t been many changes since 2015. In outward appearance that’s true, as noted earlier in this report: The conference remains two and a half days and the lineup of sessions and events is the same. However, what’s behind the curtain is different in several respects; in sum, the changes have increased the organization’s value to owner/operators.

If you’ve attended Western Turbine meetings since the 25th anniversary celebration you might think there haven’t been many changes since 2015. In outward appearance that’s true, as noted earlier in this report: The conference remains two and a half days and the lineup of sessions and events is the same. However, what’s behind the curtain is different in several respects; in sum, the changes have increased the organization’s value to owner/operators.

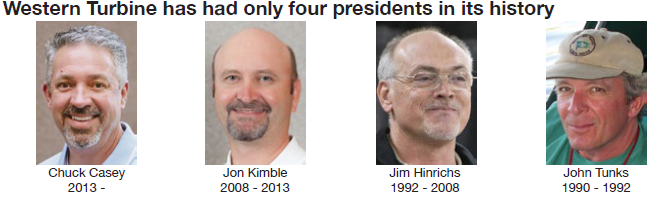

Leadership changes are a given as officers, directors, breakout chairs, and staff complete their terms of voluntary service, retire, leave the industry, change positions in their companies, etc. The injection of new blood generally is a positive: New people bring new ideas, have experiences to share on the latest engines in the fleets served, etc.

In the last five years, Bryan Atkisson, Jermaine Woodall, Devin Chapin, Howard Hoffmann, Rick McPherson, Andrew Robertson, John Hutson, and Charles Lawless completed their terms on the board of directors, with Wayne Feragen, Al VanHart, Andrew Gundershaug, Rob Nave, Todd Kutz, Dennis Johnson, and Paul Park elected to fill those positions.

The officer corps has changed as well with Ed Jackson and John Hutson elected VPs, Jermaine Woodall replaced retiree Alvin Boyd as secretary, and Wayne Feragen took over for Wayne Kawamoto as treasurer.

Kawamoto resigned the volunteer officer position he had held since the organization’s incorporation and transitioned to a new WTUI staff position, conference executive director, Jan 1, 2018. You may recall that Kawamoto retired from his day job as plant manager of Corona Cogen when that facility’s power-purchase agreement expired and the plant was closed at the end of 2017.

Among the breakout chairs, John Baker resigned his chairmanship of the LM2500 group after serving in that capacity for nine years. He was replaced by the incumbent Garry Grimwade. Andrew Gundershaug, who served the LM6000 group with distinction for five years (and the LM5000 group prior to that), was replaced by Dave Fink. Steve Worthington took over the LMS100 chairman’s duties from Jason King.

WTUI’s first office was opened two years ago at 25201 Paseo de Alicia (Ste 215) in Laguna Hills, Calif (92653). All of the organization’s records since incorporation are now resident at that location.

Best practices. At the 26th annual meeting, VP Ed Jackson announced that WTUI and CCJ would be pooling resources beginning in 2017 to expand the sharing of best practices and lessons learned among owner/operators of GE aero engines. The plant manager of Missouri River Energy Services’ Exira Generating Station in Brayton, Iowa, said the organization’s mission is to help members better operate and maintain their plants, and that a proactive best practices program supports this objective.

Award recipients in the first three years of the program included Equus Power, the J-Power Long Island fleet, Orange Cogen, Orange Grove Energy, Pinelawn Power, Reo Town Cogen, Shoreham Energy, Terry Bundy Generating Station, West Valley Power, Worthington Generation, Edgewood Energy, Exira, Energia del Valle de Mexico (a/k/a EVM), Channel Island Cogen, Greater Toronto Airport Cogen, Lawrence Generating, and PSEG Kearney. Most of these facilities are powered by LM6000s.

WTUI’s efforts in sharing best practices and lessons learned have encouraged others in the aero community to contribute their experiences. Brian Hulse, who has been involved with aero engines for more than four decades and was elected to the organization’s board of directors for a three-year term in 1993, has been a major contributor in this regard.

Hulse, today a consultant who has attended most Western Turbine meetings since incorporation, shared the following observation with the editors during a recent conference: Many of the problems identified by plant O&M personnel during the open discussion periods were solved years back. He thought we must still be asking some of the same questions and sharing the same experiences as our predecessors because no one took the time to write them down for posterity.

So Hulse volunteered to write a few articles for CCJ to help those in the industry with less experience avoid some of the mistakes they might otherwise make. His insights were published in 2018. You can access his articles thusly:

- “Lube-oil cleanliness critical to long bearing life.”

- “Proper O-ring storage promotes leak-tight sealing.”

- “Building the better mouse trap” speaks to the importance of serving aero engines clean air at the proper temperature and with minimum directional disturbances at the compressor inlet to achieve optimal performance.

- “The importance of cleanliness” focuses on the need to review Material Safety Data Sheets before working with any chemicals, oils, foreign substances, etc, and the importance of good personal hygiene.

The leadership team recognized the importance of capturing the technical information disseminated at the annual meetings long ago—of course. Example: The breakout-session chairs work closely with representatives of the ASPs and OEM throughout the year to develop session notebooks identifying shop findings and presenting recommendations for damage mitigation and repair solutions. These invaluable resources, typically numbering more than 100 pages for LM2500 and LM6000 engines, are distributed to session participants.

In addition, CEO Sal DellaVilla and his team of engineers at Charlotte-based Strategic Power Systems Inc (SPS®) have actively participated in Western Turbine meetings since incorporation by taking notes during the discussion sessions for posting on the user group’s website. These notes go beyond the workbooks described in the previous paragraph in that they summarize key aspects of the floor discussion.

And don’t forget the ongoing coverage of WTUI presentations and discussions in the CCJ.

The bottom line: There’s plenty of meaningful guidance for O&M teams at plants equipped with GE aeros in the WTUI and CCJ archives. You might want to riffle through these resources before tackling your next challenge. Follow-on steps might be calling one or more colleagues that you met at annual meetings (phone numbers were provided with your registration materials) for advice, or, in the case of LM6000s, posting a question online.

Online forum. Perhaps the most significant of the WTUI services added in the last five years is the LM6000 Forum launched by Webmaster Wayne Feragen and supported by the entire leadership team. When you don’t know whom to call about a current problem and have searched through related materials posted on the organization’s website to no avail, posting your question online likely will provide the guidance to get you moving in the direction of a solution.

The diversity of topics discussed online in the last year or so (bullets below) illustrates the value of an online communications “channel” for identifying colleagues with the particular expertise you can benefit from:

- Dry-ice cleaning of an HP compressor.

- Coupling replacement.

- Clutch oil-system starting reliability.

- Compressor washing.

- Exhaust stack noise mitigation.

- Crane and rigging for HSE work on LM6000PF.

- Hydraulic starter pump and motor issues.

- Rad-Rad combustor experience.

- Sub-synchronous resonance.

- Leading-edge cracking on second-stage nozzle for LM6000PD.

You can gauge the value of the information communicated over the LM6000 Forum by following the discussion below on the likely reason for a high T48 spread on an LM6000PC SAC engine.

Help requested from User 1: We experienced a high temperature spread when our engine returned from the shop following a major overhaul, which included replacement of the combustor and first-stage nozzles. The test-cell temperature spread was fine, but without steam injection and while running on borrowed fuel nozzles.

After the engine was reinstalled and run with our fuel nozzles, the spread went to 363 deg F. Changing fuel nozzles reduced the spread to 290 to 300 deg F. Thermocouples and harnesses were changed with minimal impact. A borescope inspection revealed nothing significant. We plan to pull the engine and return to the shop to inspect combustor seals and look for swirler damage. Any other items we should check closely?

Consultant (former user): Several dimensions in the combustor are in play during a repair that can affect both spreads and the emissions profile. If the combustor is pulled, check everything not just one or two callouts. The other assembly that could be suspect is the HP-turbine nozzle assembly. Check the nozzle throats for both correctness and balance; look at the fishmouth seals as well.

User 2: I had the same issue a few years ago. New hot section with combustors. Spread was 270 deg F and we could not keep the simple-cycle engine in emissions compliance on CO (no SCR, so tight permit). Ran well in our ASP’s test cell with their nozzles—like yours. Shop also did not test on liquid fuel or with water injection, which is how our plant operates.

The G42 combustor was found out of spec; liners and cowls were clocked by a few thousandths when it was built. Might not be your issue, but it looks like you covered all the bases with the nozzles and T48 system. Unfortunately, the only way to find out would be to swap out the combustor and put the same nozzles back in.

User 3: Same issues as well on our unit; had to go back to the shop for a combustor swap.

Shop expert: What has been experienced by User 1 is rare but certainly plausible; I am aware of at least two other occurrences where the scenario described has occurred. My recommendation is to start by ensuring fuel and steam lines are clear from obstruction—a relatively low-cost procedure.

Next, I would at least do the paper exercise on that first-stage nozzle throat area. It should cost the shop nothing but a few minutes to verify the as-built records against requirements specified in the owner’s manual.

If you elect to go after the combustor, I would have the shop go one step further at the same time and physically measure the A4 throat area to be sure what is stamped on the part is actually what it is. I have seen incorrectly stamped parts. Recall that A4 is the measurement of the exit throat area—essentially the gap between the trailing edges. The top shops should have that tool, which would provide a good estimate of accuracy and identify gross errors.

Finally, I would ensure all nozzles are within the expected individual range and not just the total average within limits.

Consultant (former user): Over the years I’ve found at least four overhauled combustors with dimensional issues. The jigging process used at repair facilities to hold the pieces together for welding is pretty complex. One little mistake is all it takes.

How the shop expert described measuring A4 is correct. But it’s not uncommon to see a difference between the “calculated” A4 (adding up all the stamps) and the “actual” A4, as measured by the tool, because the stamp measurement is made with the vane assembly in a slave rig. Once it’s measured with other vanes, the numbers will vary. Sometimes the aggregate variances will make a discernable difference.

Finally, keep in mind that the A4 measurement tool is supplied with a calibration block and should be calibrated frequently (every two or three uses). Reason: the inner workings of the tool are very delicate and can be disturbed easily.

Fleet population. The LM2500, LM6000, and LMS100 fleets have grown since the 25th anniversary meeting; the LM5000 fleet has fewer engines in service. Calculation of fleet size is not an exacting science, to be sure. OEMs tend to base their engine stats on shipments and consider the machines “operational.” However, they may be in storage or installed but not operating. The bigger the number the better an OEM typically would feel.

By contrast, SPS, the industry’s leading analytics consultancy specializing in the collection, analysis, and dissemination of O&M data for owners and operators of generating plants, focuses on engines actually in service. Note that SPS has been the industry’s go-to source for O&M data on gas turbines for more than three decades. It has served WTUI members since incorporation, enabling the benchmarking of specific units against like engines as well as the fleet.

The size of the LM2500 fleet reported by GE at WTUI25 (data compiled in late 2014) was 2031 engines. Last year, SPS reported the fleet size at 2413 machines—certainly robust growth. However, keep in mind that this model serves in many markets—including power generation, gas compression, and ship propulsion—so don’t get giddy about the increase.

The number of engines in the LM6000 fleet, used primarily for electric generation, increased from 1185 (GE data) at the beginning of the five-year period to the 1229 units reported as “in service” by SPS last year. In the same period, the number of LMS100 machines increased from 51 (GE data) to 69 (SPS data).

Meanwhile, the LM5000 fleet continues to fade, primarily because engine performance lags behind that achieved by more modern machines of about the same size. The fate of Kawamoto’s LM5000 at Corona Cogen likely will be suffered by others no longer serving steam hosts.

Industry records put the number of LM5000s manufactured at 102. Five years ago, GE said there were 55 operating engines. By the end of 2019 that number had dropped to 30 among 19 owners worldwide, according to ANZGT, which was assigned global responsibility for the machine by the OEM.

A few weeks prior to WTUI25, GE selected Sulzer to become the exclusive licensed repair provider for the LM5000 power turbine. Repairs are done at Sulzer’s Houston Service Center.

Operating metrics. One could not expect a rosy sales picture for gas turbines in the last five years given the influx and growth of renewables and the technical and policy changes influencing investments in conventional generating assets. But as DellaVilla points out in his commentary, gas turbines are a major part of the nation’s “Clean Energy Future.”

SPS data from its Operational Reliability Analysis Program (ORAP™) for aero peakers supplied by GE, Siemens, and Mitsubishi Hitachi Power Systems show annual service hours were off about 25% over the last five years; annual starts were down by about 20%. Reliability and availability of peaking units remained essentially constant during the period.

For baseload units, the key performance indicators—service hours, service factor, capacity factor, availability, and reliability—have been relatively constant since WTUI25, with annual starts down but service hours per start up.

Exhibit hall characterized by subtle changes. While the number of companies represented at each vendor fair since the 25th anniversary meeting has been relatively constant, hovering between about 150 to 160, a couple of dozen exhibitors in any given year had not participated in the previous show. Plus, many “regular” exhibitors revealed new products and services and/or were represented by different personnel. All good reasons to spend quality time on the carpet.

Some of the things the editors recall from their time at recent vendor fairs include the following:

- GE’s launch of the LM6000PF, designed for increased performance and flexibility. MTU Aero Engines took a 13% work share as a risk- and revenue-sharing partner in the development and production of the engine.

- The emergence of Baker Hughes as an important provider of services to the LM community. Baker Hughes Co, which merged with GE Oil and Gas in 2017 to become Baker Hughes, a GE company, divested from GE in late 2019 and re-established itself as Baker Hughes Co. GE owns 38% of the new company.

- Southern California Edison, GE, and Wellhead Power Solutions partner to demonstrate the world’s first hybrid battery/gas turbine at SCE’s Center Peaker Facility. Retrofit of a lithium-ion battery to the existing LM6000 transforms the non-spin peaker into spinning reserve.

- ProEnergy’s success as an independent aero depot—performing scheduled maintenance, emergency outages, and everything in between for owner/operators of LM6000 and LM2500 gas turbines. Its Level IV service facility is centrally located in Sedalia, Mo.

- The launch of Victory Turbine LLC by industry veteran Rodney W Kohler (GE, Whitton Technology, Gas Turbine Efficiency, Caldwell Energy, and Danfoss Pumps) an Keith Flitner (Eaton and Parker Hannifin) currently offering ZOK compressor cleaning products online, plus stationary and mobile water wash skids, and a wide array of auxiliary parts—including pumps, valves, actuators, flanges, adapters, and connectors.

Total booth space has increased over the years as some companies looked to enhance their visibility. Among the exhibitors occupying the equivalent of three or more standard booths last year were the following CCJ business partners: AGTSI, EthosEnergy Group, TransCanada Turbines, IHI, MTU Power, SPS, Maximum Turbine Support, and Turbine Technics.

Sponsors. A constant, and a good one, has been the continuity of support by platinum sponsors GE, IHI, ANZGT, Maximum Turbine Support, TransCanada Turbines, Umicore (formerly Haldor Topsoe), and MTU Power. All have taken the highest level of sponsorship in each of the last five years.

Attendance also has remained relatively constant—a significant accomplishment given the business challenges facing fuel-burning generators, reductions in plant staffing, etc. Average over the last five years has been 1051, with a range of 996 to 1148.

The first 25 years of WTUI: A history

A history of the Western Turbine Users Inc, the world’s largest independent organization for gas-turbine owner/operators was published by CCJ and distributed at the organization’s 25th anniversary meeting at the Long Beach Convention Center, March 15-18, 2015. You can access this special publication via the links below.

Major contributors to the commemorative publication included Wayne Kawamoto, then WTUI treasurer and plant manager of Corona Cogen; Mike Raaker, WTUI’s historian and ambassador, and president of Raaker Services LLC; Sal DellaVilla, CEO of Strategic Power Systems Inc; Mark Axford, president of Axford Turbine Consultants LLC; Jason Makansi, president of Pearl Street; and Steve Johnson, president of SJ Turbine Inc.

1. Before incorporation, Mike Raaker

2. After incorporation, Sal DellaVilla

3. Legislative drivers of GT technology, Jason Makansi

4. The LM engines, Team GE

5. A turbine salesman remembers, Mark Axford

6. WTUI’s place in gas-turbine, power-industry history, Wayne Kawamoto and Mike Raaker

7. Aero engine portfolio highlights, Team GE

8. Profiles of the authorized service providers: ANZGT, TCT, IHI, MTU, provided by the ASPs

9. User remembrances, Team CCJ

10. Vendor remembrances, Team CCJ