Griffith Energy

Owned by Griffith Energy LLC

Operated by Consolidated Asset Management Services (CAMS)

570 MW, gas-fired 2 × 1 7FA.03-powered combined cycle equipped with NEM HRSGs and a Toshiba steam turbine, located in Golden Valley, Ariz

Plant manager: Scott Henry

Challenge. Griffith Energy typically spent well over $100,000 annually to rebuild its boiler feedwater control valves to accommodate the wear and tear of operation and the need to ensure high availability and reliability.

The plant had been approached several times over the years to replace the original control valves with IMI CCI Drag® valves. Not so simple. In addition to the valve and actuator, such an upgrade would require board approval of a CapEx project, welding, cleaning of the piping, NDE of the welds, new spare-parts inventory, and drawing and manual updates (MOC).

Griffith management hadn’t pursued the installation of new valves primarily because of project scope and cost. At least 16 of the plant’s control valves could have been involved. Note that the plant has had excellent experience with IMI CCI Drag valves—including HP and hot-reheat steam bypass, spray attemperator, and desuperheater valves.

Griffith management hadn’t pursued the installation of new valves primarily because of project scope and cost. At least 16 of the plant’s control valves could have been involved. Note that the plant has had excellent experience with IMI CCI Drag valves—including HP and hot-reheat steam bypass, spray attemperator, and desuperheater valves.

Griffith was aware that IMI CCI had done custom retrofit projects 20 years ago, but not recently—mostly because of a corporate decision to focus on valve sales. Staff requested that the company re-evaluate the possibility of retrofit trim for the Griffith valves. However, flow requirements would have made the disk stack too tall to fit in the existing valve body.

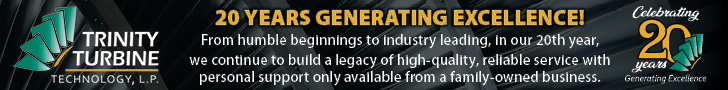

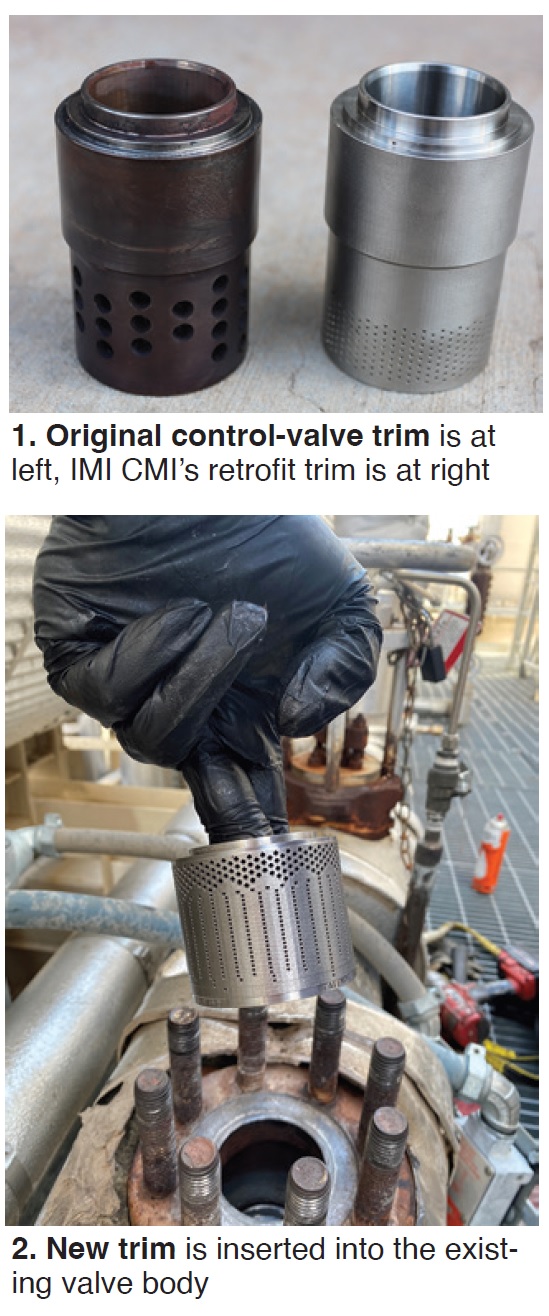

Solution. Over the last few years, advances in additive manufacturing (3D printing) processes became cost-effective and IMI CCI engineers were able to design Drag valve trim to fit the valve body. This was a game-changer. Rather than the need for a large CapEx project, the site would be able to simply install new trim, change the part number in the CMMS system, and be done. IMI CCI provided new valve tags with names, trim characteristics, part numbers, etc.

Griffith entered a pilot program with the valve manufacturer to install the first Retrofit3D trim sets into four of the most critical and difficult applications (Figs 1 and 2). Staff supplied IMI CCI with the OEM’s valve data sheets and historical operating data for engineering to accurately calculate flow/pressure needs across a wide range of plant operations.

Results. The first trim sets were installed in fall 2019 and performed well, as expected. These valves were inspected the following spring after about five months of operation. The trim parts looked like they had just been installed. The valves were reassembled with new soft goods and returned to operation.

The decision was made to upgrade all the remaining valves on HRSG 1 and reinspect after two years. Reinspect/rebuild intervals might be extended based on the as-found condition of the parts. HRSG 2 is consuming the remaining OEM and refurbished-parts inventory. As those parts are scrapped, IMI CCI trim sets will replace them.

The Retrofit3D trim is comparable in cost to the refurbished OEM trim and is expected to last at least three years longer—likely more. This could equate to a $500,000 to $900,000 saving on parts, not including the annual labor cost to rebuild. In sum, this project has resulted in a high-reliability, long-life, low-cost operation that simply requires a change to the inventory record and library.