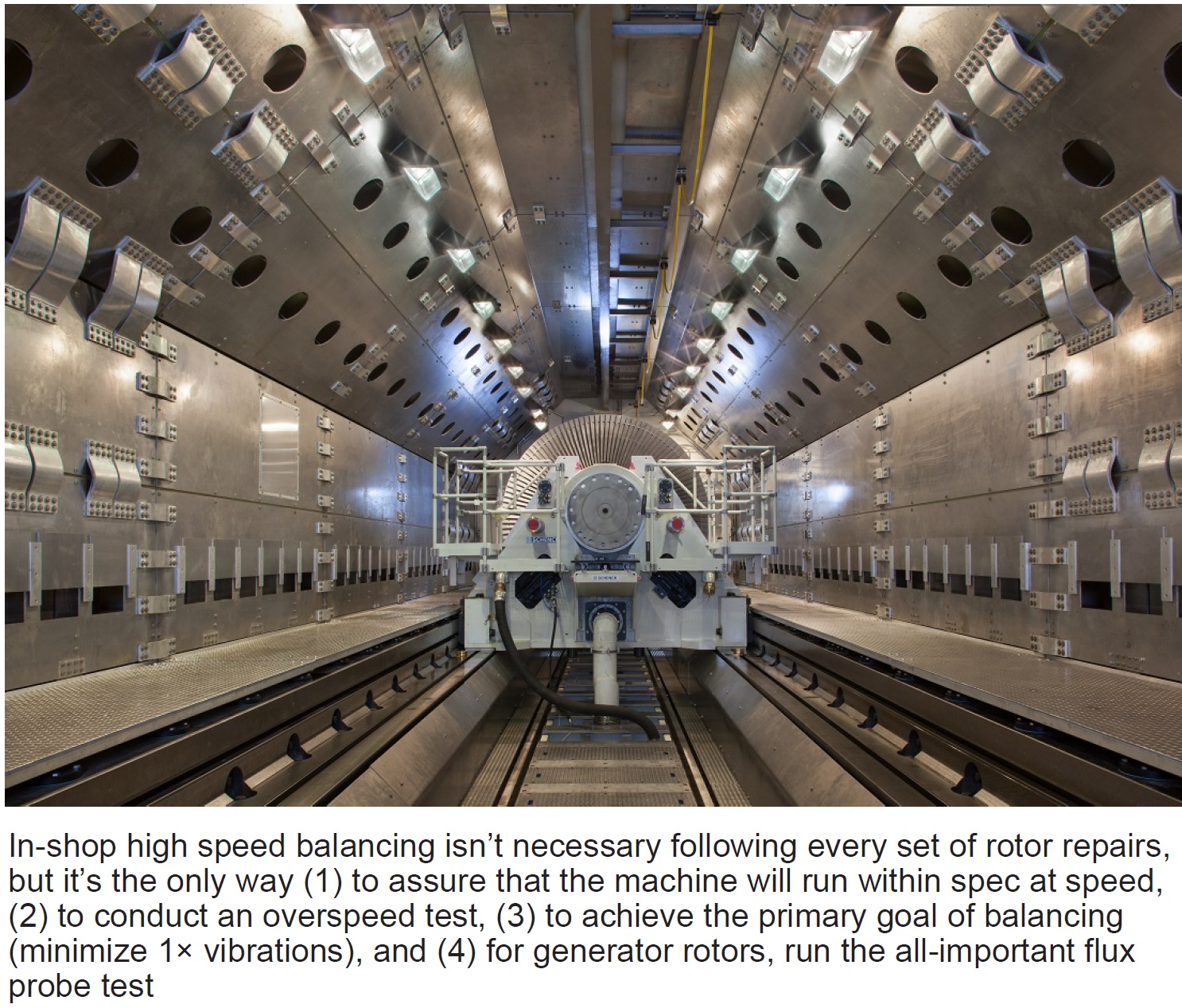

The underlying message of MD&A’s third webinar in its fall 2022 series is that a shop which has invested in a high-speed rotor balancing (HSB) machine (photo) offers the user clear advantages in shortening outage schedules and avoiding the risk of having to transfer the machine from the shop where repairs are made to a shop with an HSB.

Not all rotors require HSB after being repaired, noted MD&A’s Keith Collins, in his presentation entitled, “High-Speed Balance.” If repairs are minor, a low-speed balance (LSB) will suffice, or even an onsite balance. But if the rotor has undergone journal machining, heat straightening, or weld repairs, as a few examples, you should opt for HSB. Ditto if any repairs have altered rotor geometry or local stresses.

For a generator rotor, the big advantage of HSB is the ability to perform a flux probe test, the “only way to guarantee no shorts at startup,” said Collins. Turn-to-turn testing in the shop cannot detect speed-sensitive shorts. “If the rings come off your generator rotor you should do a HSB. This is true for a rings-off inspection or a rewind with new or existing copper,” he stressed.

For all rotors, the HSB also allows for overspeed test and comprehensive vibration analysis.

The bulk of Collins’ slides offer a tutorial of sorts on topics including applicable standards, vibration measurement basics, critical speeds, modal balancing, overspeed test and balance, electrical testing, and heat and stability runs.

During the Q&A, Collins added that an onsite balance should definitely follow an in-shop HSB, with experts present to determine need for additional trim shots. On the subject of whether MD&A “heats up the GT/G or ST/G rotor in the shop for HSB, Collins replied that they typically do not, though other shops do. “We can draw partial vacuum to heat up the blades which transfers heat to the rotor for soaking,” he said.

Regarding the question, “Should you do an onsite LSB after a partial re-blade,” Collins replied “Yes. Do an LSB before and after the repairs.” To a similar question of doing an LSB after replacing all blades in an ST/G rotor, Collins also replied “Yes.”

Access this recording @ https://www.mdaturbines.com/webinar-archive/

The Turbine Inlet Cooling Assn (TICA) announces that its annual awards to owner/operators of GE aeroderivative gas turbines who have demonstrated the successful implementation and use of at least one turbine inlet cooling (TIC) technology will be conferred during the 2023 Western Turbine Users Inc (WTUI) Conference (March 12-15 in San Diego).

One award will be given for each TIC technology. Presentations will be made during the organization’s luncheon on Monday, March 13. Awardees must be present to accept their awards.

Nominations will be evaluated using the following criteria:

- Number of turbines with TIC (20%).

- Total power increase (kW) due to TIC (20%).

- Percent increase in capacity by TIC (20%).

- Ages of TIC installations; older the TIC system, better the score (20%).

- Noteworthy/innovative details of the TIC system or its use (20%).

Each award recipient will receive:

- A plaque for display at the power plant.

- Awardee name and system info posted on the TICA website.

- Awardee name and its system highlighted in a TICA press release to industry publications.

- Complimentary one-year TICA membership.

- $100 VISA gift card.

Deadline for submitting nominations is January 13, 2023.

Instructions: Complete all required information on the nomination form at www.turbineinletcooling.org and submit it to Dharam Punwani, TICA Executive Director at exedir@turbineinletcooling.org.

Advancements and case studies in film-forming-substance chemistry on display for fossil, geothermal, and nuclear generators

By Steven C Stultz, Consulting Editor

As we prepare for the most comprehensive meeting on film-forming substances to date (see above), a recap of the FFS 2022 follows to bring you and your organizations up-to-speed on the latest science and real-world applications of FFS in generating facilities. Co-chairs Barry Dooley, Structural Integrity (UK), and David Addison, Thermal Chemistry (NZ), organized and led this 2022 conference on behalf of The International Association for the Properties of Water and Steam (IAPWS, www.iapws.org).

Their opening greeting: “Welcome to the virtual world of film-forming substances,” a specialized topic in cycle chemistry control of powerplants and steam generating systems.

The focus: Film-forming substances to protect metal surfaces from corrosion through hydrophobicity. It’s part of the larger effort to control corrosion throughout the water/steam circuits of fossil, nuclear, geothermal, and combined cycle/HRSG plants.

One-hundred forty-six paid attendees—a record—logged in from 30 countries to watch, listen, and participate in 21 technical presentations and discussions. Ten suppliers also presented their credentials and technical details. Participating sponsors of FFS 2022 were Fineamin, Kurita, Nalco Water/Ecolab, Reicon, SUEZ (now Veolia), and Waltron.

FFS conferences, which began in 2017, have become well known as a unique and critical opportunity for plant operators/users to raise questions relating to all aspects of film-forming substances. Dooley stressed the IAPWS goal: “To provide information freely and improve FFS guidance for owners and operators worldwide.”

Below are selected highlights related to combined-cycle plants and operations.

Base definitions

In brief, the term “film-forming substances” represents two main categories of chemicals:

- Amine-based film-forming amines (FFA) and amine products (FFAP).

- Non-amine-based film-forming products (FFP).

There remains general confusion on the nomenclature, but these terms introduced by IAPWS in 2016 have quickly become the global standard.

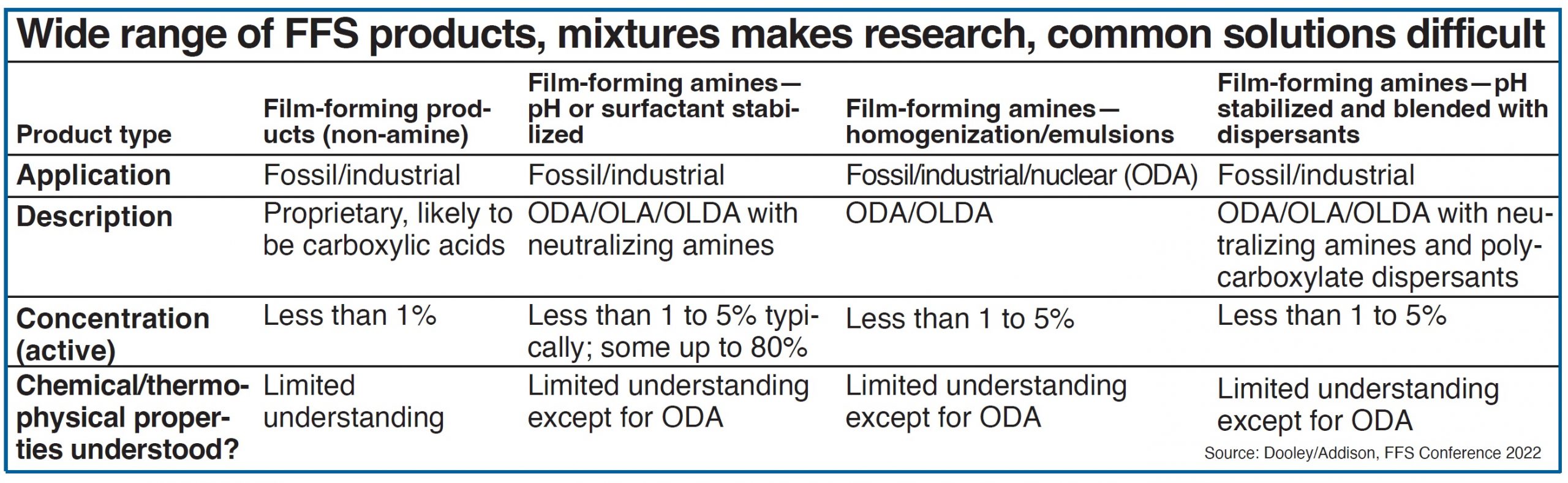

It is important to note here that the wide range of these products and applications make research and common solutions difficult (table).

Current foundation

“Universally,” explained Dooley, “we are seeing reductions in the measurement of feedwater total iron and copper corrosion products through the use of FFS. There are general visual observations of hydrophobic films in the water-touched areas (mainly feedwater and condensate) of plants, and within air-cooled condensers.

“However,” he continued, “film formation and adsorption remain questionable on steam-touched surfaces.” Also important, a lack of visual evidence of hydrophobicity does not necessarily mean lack of protection.

These complexities, and the underlying understandings of oxide growth, protection, and tube failures, as well as the impact on steam turbines and other plant equipment, make this series of conferences critical for owners/operators of fossil and combined-cycle/HRSG plants, among others.

Cycling and layup protection

Ronny Wagner, managing director, Reicon (Germany), launched the technical presentations with Application of film-forming amines for preservation of water/steam cycles with and without air-cooled condensers. Wagner’s overview covered FFS preservation principles for both flexible operation and long-term layup. He focused on ODA as the film-forming amine (FFA) to offer this fundamentals-only guide.

For cycling units with varying schedules, Wagner explained, a steady and continuous FFA injection at low concentration (50 to 500 ppb) should offer the best protection while offline and should have little to no long-term impact on system water quality. FFA should be injected at the suction side of the feedwater system; the condensate polishing system (if provided) can continue to operate. Any conductivity spike during implementation should return to stable.

For long-term preservation of plants with seasonal shutdown or planned outages, a high feed rate of around 2 ppm should be initiated five to 10 days before shutdown. After shutdown, a lower but steady concentration of 50 to 500 ppb then can be used for follow-up injection.

“After the next shutdown,” he suggested, “it is wise to re-preserve at a high rate (1 to 1.5 ppm) beginning three to five days before the following shutdown. Normal injection is at the suction side of the feedwater system, or in the condensate lines after the polisher.”

The polisher should be bypassed because it will remove the amine from the condensate. Water chemistry values will probably be affected during the injection periods.

Again, these are general rules, Wagner emphasized, “The total FFA consumption for preservation is dependent on surface area, and is both plant and product specific.”

Preservation practices for air-cooled condensers (ACCs) are more complex. Most importantly perhaps, common ACC heat-exchange tubing is carbon steel with large internal surface area, typically thousands of square yards.

ACC design also requires long, large-diameter lines from the LP steam turbine outlet to the ACC upper duct (street), to handle the two-phase steam/water mixture. The tube entries within the ACC upper duct become corrosion-active surfaces for flow-accelerated corrosion (FAC), and there is normally high iron concentration downstream of the ACC during and after startup. Thus, high FFA concentrations at the ACC inlet often are necessary.

ACC case history

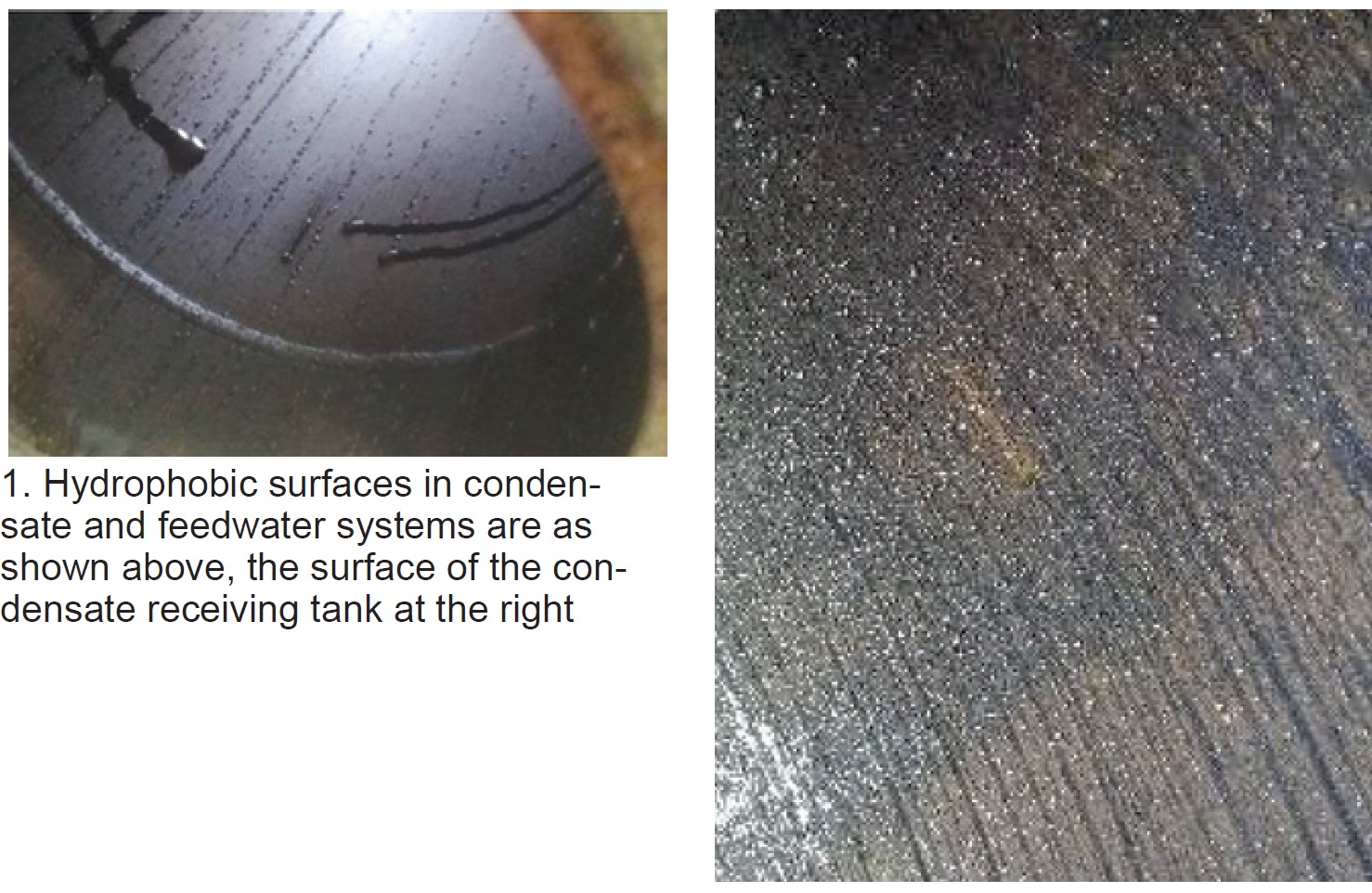

A 70-MW combined cycle completed commissioning, but had to idle because of a delayed grid connection. It was critical to protect the ACC. The solution was injection of FFAP (Odacon®) in front of the ACC. Following application, hydrophobic surfaces were visible in the feedwater system and condensate receiving tank (Fig 1).

After grid connection and during startup, there were no noticeable issues with corrosion.

Wagner took the opportunity here to emphasize the Dooley Howell ACC Corrosion Index for operating comparisons. Having a proper total iron baseline and use of this index for results comparisons are critical analysis tools to assess FFS impact, he explained. For a clear discussion of the DHACI, access ACC.01: “Guidelines for Internal Inspection of Air-Cooled Condensers” at http://acc-usersgroup.org/Reports.

Case study without ACC

Case study without ACC

An 800-MW plant with drum-type HRSG and no condensate polishing unit moved to flexible operation (less time online) and a fast-start requirement. Baseline review showed high iron levels during startup, especially in the IP section of the HRSG.

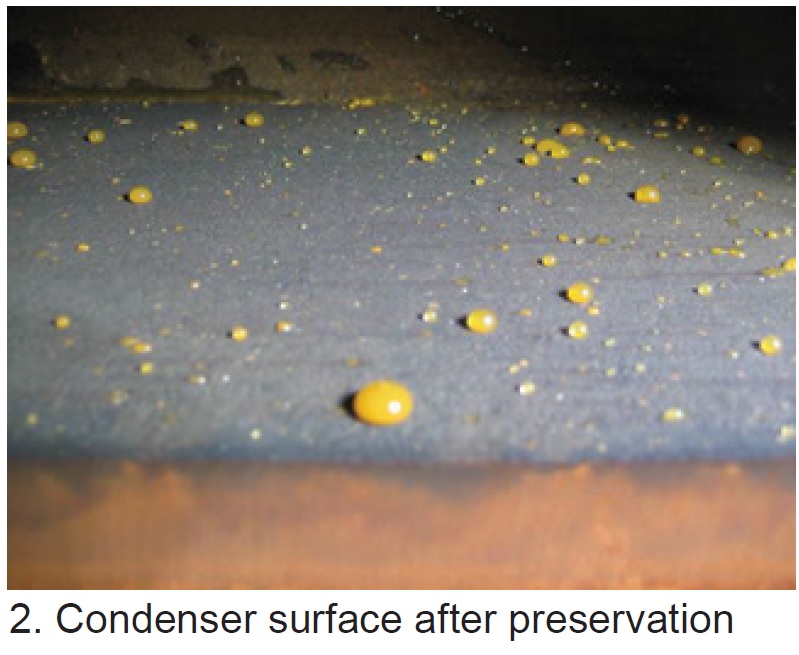

Preservation was performed in several steps beginning with injection of Odacon in the main condensate line after the condensate pump. Inspection showed hydrophobic protection (Fig 2).

Startup time was halved, and iron concentration in the IP section during re-start was reduced by 70%. For the off cycles, previously-applied nitrogen injection for short-term protection was no longer necessary.

In both cases, total iron transport in the water/steam cycle was reduced.

Biofuels

Attention turned to Agata Zietec, Jönköping Energi, and a combined heat and power (CHP) plant in Sweden burning both household waste and a variety of biomass fuels in two fluidized-bed boilers.

The plant experienced feedwater system issues, including blockages, and preheater FAC. Some parts of the plant were in annual seasonal shutdown for up to five months. Traditional treatment included ammonia and phosphate.

Operators selected Odacon, largely because of positive global nuclear plant experience, and began dosing at the feedwater pump.

The required flow was calculated to be minimum rate at full boiler load and maximum rate at lowest load. To prepare for offline protection, continuous FFS dosing (up to 0.3 ppm amine) was performed from February until the end of the run season (three months).

Iron content in feedwater during startup was significantly reduced and many existing deposits were removed from the turbine area. There was no noticeable impact on online instruments. The applications seem to offer effective protection during layup.

Geothermal

Geothermal processes offer unique challenges in scaling and corrosion. Two case studies were presented focusing on Kurita FFS geothermal technology developments in Turkey and Indonesia.

Worldwide, the most common direct use of geothermal energy is district heating. For power generation, uses include dry steam and flash steam powerplants, binary-cycle powerplants, and combined units.

Common corrosion mechanisms are high salinity, high reservoir temperatures, high gas content, and low pH. Scaling issues come from varying mineral compositions, changes in pressures and pH, water cooling in heat exchangers, and other site-specific issues.

Pilot systems reviewed showed good corrosion protection (Organic Rankine Cycle area), including reduced under-deposit corrosion.

Industrial hot water

A New Zealand dairy factory uses a 10-MW industrial hot water system of carbon steel construction with titanium heat exchanger, introduced in 2019. After two years of operation, the system suffered tube metal loss of up to 56%, according to data provided by IRIS Inspection Services. The system was continually saturated with oxygen and iron levels exceeded 160 ppm with a reducing chemistry program.

Following IAPWS TGD11-19 guidelines regarding steam purity, Odacon was dosed at 0.5 to 1 ppm. Pumps and seals were upgraded to reduce oxygen ingress.

Results showed bulk water iron levels reduced below 1 ppm. Using three to four times the recommended saturation volume for heavily corroded systems, there was a 96.8% reduction in corrosion rate after five months.

Photos were shown of the seven-month inspection in this ongoing program.

Next steps will be an online filming amine analyzer (Waltron), reintroduction of sulfite to see if low oxygen levels have an impact on iron chemistry, change to an optical luminescent dissolved-oxygen (DO) sensor, acid cleaning, and 100% IRIS testing of tubes.

Nuclear experience

Multiple presentations focused on FFS application experience (primarily ODA, octadecylamine) at nuclear plants. ODA has been applied to nuclear facilities in seven countries, and one presentation discussed more than a decade of experience with positive results for feedwater iron levels and measurable particle-size reduction.

The two units discussed, pressurized water reactors commissioned in the early 1980s, are good examples of steam-generator replacement (1996-1997) and turbine upgrades (2010-2011) to continue operating well beyond their original service dates. Water quality becomes even more critical.

In another presentation, Efficiency and harmlessness of film-forming amines used as alternative layup method in secondary circuit of pressurized-water nuclear power plants, similarities also were present. The secondary circuit (steam generators, turbine, and condenser) includes carbon and low alloy steels with surfaces covered by magnetite. During refueling or other outages, oxygen and humidity can lead to generalized corrosion and require layup protection.

Traditional protection methods are either drainage and drying to a relative humidity below 40%, or filling with chemically conditioned water. Both are time consuming and can be difficult.

A presentation by EdF explained an alternative method using film-forming amines (ODA) to inhibit corrosion. Detailed background was given for ODA behavior on different oxide samples at different temperatures, methods used to better understand the related adsorption mechanisms of ODA on various surface states (including testing protocols), and simulations of film efficiencies during layup.

Specifics were presented on morphology and contact angle measurement, electrochemical impedance spectroscopy, chemical composition analysis (ATR-IR and XPS), and other methods.

Beyond these three, presentations dealt with gasket and elastomer testing, and corrosion inhibition by anionic surfactants.

J Fandrich, Framatome, gave an update on the IAPWS Technical Guidance Document for FFS application in nuclear powerplants, a current initiative within the Power Cycle Chemistry (PCC) Working Group. The hope is to finalize this at the IAPWS Annual Meeting in November 2022. Fandrich highlighted the differences compared to fossil water/steam cycle materials, design, chemistry, and steam-generator operation.

At the laboratory

Day Two began with a deep dive into air-cooled condensers, important because they can release significant quantities of iron-oxide corrosion products into the water/steam system serving the entire plant (Fig 3). Risks include HRSG evaporator interior tube deposits (and failures) from iron transport (Fig 4).

Andy Howell, EPRI, took attendees to the upper ducts (Fig 5), “where the corrosion rate is high and tube-entry wall thickness is small.” Corrosion-caused leaks here can draw air into the condenser. This leads to costly performance, maintenance, equipment damage, and availability problems.

In the past, reducing iron levels in the system had been through increasing pH.

Howell explained a laboratory approach to simulating the ACC steam-side (two-phase) environment at the heat exchanger tube entries. The main results were:

- Ammonium hydroxide involves simple chemistry and is inexpensive; it has proven suitable for system pH control in many ACCs.

- Properly selected and applied neutralizing amines can reduce corrosion in ACCs compared with ammonium hydroxide, and can be used in conjunction.

- FFPs appear to be very effective at reducing corrosion in ACCs under the right conditions.

XPS and EIS

A takeaway mentioned during a discussion period was that university laboratories and staff can help the industry with advancing sciences related to FFS.

One presentation was a deep dive to the molecular level using x-ray photoelectron spectroscopy (XPS). Rob Lindsay, The University of Manchester (UK), offered empirical insights including trial-and-error discussions.

The key target is FFS interface characterization at the microscopic level. This is part of a Manchester research effort into adsorption thermodynamics and interface characterization.

XPS basics were explained and profiles interpreted. Results hope to offer knowledge-based development of the next-generation corrosion inhibitors.

During discussions, Dooley emphasized: “This helps provide key insights, using XPS, to prove the presence of, but not the continuity of films with potential to move away from the standard hydrophobicity tests. This would be a great future outcome for tube sampling and analysis if it can be proven to work in real operating environments.”

The University of Toulouse (France) came soon after, with Adsorption kinetics of film-forming amines on carbon steel surface using electrochemical impedance spectroscopy (EIS). EIS is used to monitor variations of the electrochemical system over time, and to identify the processes occurring at the metal/solution interface. The presentation focused on experimental protocols using submerged carbon steel with and without the FFS OLDA.

Work continues with in-situ monitoring of FFA barrier formation for representative industrial conditions.

As a concluding comment to these presentations, Dooley offered what he believed to be the key takeaway from the lab studies portion of the program: “For the first time at FFS conferences, basic research is presented on film-forming corrosion inhibitors [oleic-based imidazoline (OMID) and sodium lauryl lactylate (SLL)] in different corrosive environments (HCl, H2SO4) than are found in powerplants using XPS and EIS.

“It is hoped that the insights on how the filming molecules interact with metal surfaces (carbon steel) under severe chemical environments at lower temperatures can provide advancements in the studies of FFS on materials in powerplant environments.”

Field-switching of FFS

As a follow-on to last year’s FFS conference, and providing a long-term outlook, PacifiCorp’s Gary Hoffman presented Switching from non-amine FFS to blend of amine/non-amine FFS at the Hunter Power Station.

The subject is Hunter Unit 3, a 430-MW subcritical coal-fired plant in Utah, designed for baseload service, that began operating in 1983. With the owner’s move to increase solar power’s contribution, Hunter 3 is now cycling with daily swings from full load to 10 to 15%.

The last chemical cleaning was in 2012, when nearly 5000 lb of magnetite was removed, and 400 lb of copper recovered. The full-flow deep-bed condensate polishers have been in service since the mid-1990s. Boiler tubes show some under-deposit corrosion.

Chemistry control strategies are:

- AVT(O) chemistry control, ammonia for feedwater.

- Tri-sodium phosphate and caustic for drum pH control during startup.

FFP history was given at the Fourth Annual IAPWS FFS conference in 2021 after two years of Anodamine FFP feeding. On June 28, 2021, operators switched Unit 3 to SUEZ Polyamine Plus based on economics (significant dosage reduction). The program intent remains protection while offline.

The SUEZ second-generation filming technology acts as a dual filmer (FFA and non-amine FFP) that adsorbs quickly and desorbs slowly.

Monitoring and control currently are provided by:

Monitoring and control currently are provided by:

- Online corrosion product sampler.

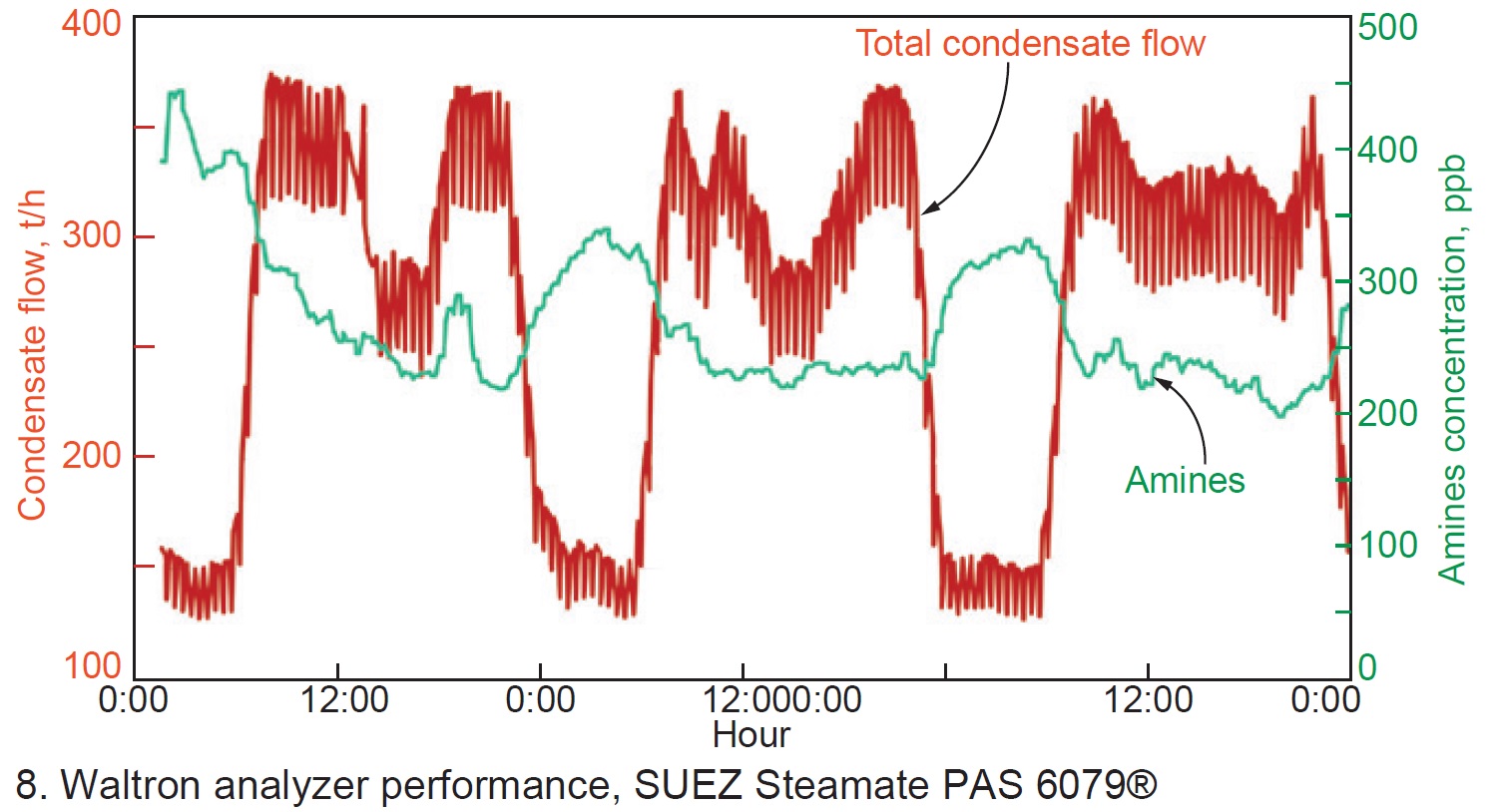

- Online Waltron 3054 amines analyzer (Fig 6).

- Corrosion coupons on the condensate-pump discharge.

- Grab samples for product concentration analysis.

- DCS controlling chemical feed pumps based on megawatt load.

- Inspections when possible.

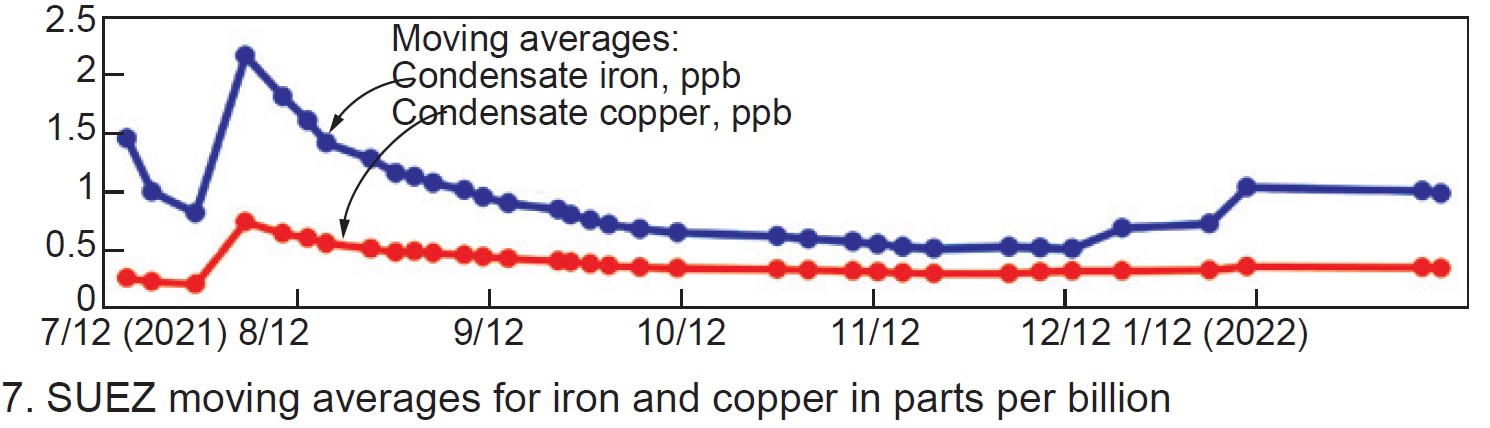

During the first eight months, the unit was subjected to eight trips, eight recorded starts, and four outages of more than one day. Moving averages of iron and copper concentrations are shown in Fig 7.

All testing coupons are sent to Lehigh University (US) for XPS analysis. Results confirm the presence of both FFS actives on the surfaces of the coupons. The summary given by Hoffman notes excellent corrosion results during normal operations, with minimal corrosion spikes at startups. The key result is that there was no noticeable difference.

This is an ongoing project, which will also move to other units within the owner’s system. Work continues to measure results and optimize feed rates (currently 1 to 1.5 ppm total product).

One question during discussions pointed to a need for further industry research. That question: “Did you fully remove the first FFS (non-amine) before using the blend?” The answer: “We do not know.”

Dooley later offered a broader perspective: “Further plant and laboratory studies will help confirm the similarity of film properties and protection formed with the wide range of FFS currently on the market.” He invited participants to consider and encourage additional test sites worldwide. In closing the discussion on this topic, Dooley said, “This information was one of the key results from this conference.”

Instrumentation

Waltron’s Hal Stansfield, chief chemist, presented Instrumentation and FFS: the good, the bad, and the ugly. The content was two-fold: development of instruments to measure and control the applications of FFS, and growing concerns that FFS are having damaging effects on existing instrumentation.

On the positive side, Waltron’s online analyzer is effective at monitoring total condensate flow versus the concentration of amines (Fig 8). On the negative side, FFS are creating issues with ion-selective and pH electrodes, dissolved oxygen sensors, and colorimetric analyzers. There are lab reports of sodium electrode failures.

These issues, and proposed solutions, were reviewed. The conclusions: Instruments must be protected, and improved, because FFS have an important place in water and steam chemistry programs. Research is ongoing.

Baseline, due diligence

As a prelude to planning the use of any FFS, a proper baseline is critical. As stated in IAPWS TGD8-16(2019) p 7, “If plants have not previously made thorough assessments of the chemistry used, the consequences of using an FFS cannot be clearly demonstrated.”

Co-chair Addison stressed attention to detail. “Good planning is absolutely critical,” he emphasized. Failure to do proper due diligence can lead to:

- Suboptimal FFS selection.

- Incorrect application of an FFS.

- Failure to obtain full benefits of an FFS.

- Consequential plant issues including equipment failures.

- Excessive application costs with little or no technical benefit.

The key starting points should always be the IAPWS technical guidance documents, available for download and at no cost. The relevant documents for this discussion are these:

- Instrumentation, TGD2-09(2015).

- Corrosion product sampling, TGD 6-13(2014).

- Steam purity, TGD5-13.

- Film-forming substances for fossil, combined-cycle, and biomass plants, TGD8-16(2019).

- Film-forming substances for industrial facilities, TGD11-19.

Section 8 of TGD8-16(2019) p 18, provides operational guidance for operators/users for the continuous addition of an FFS. Your due diligence should include a review of the following:

- Local regulations and suppliers.

-

- Is the product approved and available in your area?

- How will the product get to you, and are there supply-chain risks?

- Supplier competence and willingness.

-

- Will supplier engage with you technically?

- What are supplier’s technical resources?

- Will supplier support you in testing (coupon bench tests, etc.)?

- Annual cost estimates:

-

- Projected FFS consumption.

- Flexible operation rates (often two to five times greater).

- Dosing required at shutdown.

- Your plan versus what others are doing.

- Robust residual analysis methods: Do they work? (bench tests and online analyzers).

- Does the selection impose any technical/commercial/legal restrictions to your site?

- Can you discuss experiences with others one-on-one or at technical conferences?

- Can you use third-party experts for support?

Many of these concerns were highlighted in the final discussions section of the conference.

Path to needed research

The wide range of FFS products, mixtures, and suppliers make research and common solutions difficult. Much of the current industry work is on metal surfaces rather than the oxide surfaces that form within plants. Fundamental research targets are:

- Effect of FFS on growth mechanisms of iron, copper and chromium oxides in water and steam.

- Effect of FFS on boiler and HRSG tube failures (under-deposit corrosion, corrosion fatigue) and stress corrosion cracking.

- Film formation, kinetics, structure and porosity of water- and steam-touched oxide surfaces, to include changes of FFS.

- Uncertainty of thermal degradation, stability limits, and decomposition products for FFA—and especially FFP—under oxidizing and reducing conditions.

- Uncertainty of adsorption onto oxide surfaces for all FFS (FFA, and especially FFP).

- Protection of superheated-steam surfaces with all FFS (FFA, and especially FFP).

- There is evidence of increased steam-turbine performance for amine-based FFS (ODA), but what about other FFAs and FFPs?

Upcoming conferences

The research needs for film-forming substances are a major topic for the next IAPWS Annual Meeting, Nov 27 to Dec 2, 2022, in Rotorua, New Zealand. Dooley serves as executive secretary for IAPWS, David Addison as chairman of the IAPWS Power Cycle Chemistry Working Group.

Mark your calendar: The Sixth IAPWS FFS International Conference will be held Mar 21 – 23, 2023 at Monash University, in Prato, Italy. Details and registration now available at www.filmformingsubstances.com.

|

|

|

The HRSG Forum, led by Co-chairs Bob Anderson of Competitive Power Resources and Barry Dooley of Structural Integrity Associates, continued its tradition of offering excellent user-driven content in its recent virtual meetings. You can dig deeper by accessing the recordings at https://HRSGforum.com. The HRSG Forum in-person meeting, in collaboration with Power Users for the first time, is scheduled for Atlanta the week of June 12. Details coming soon.

The two user-driven presentations during the eighth virtual HRSG Forum (Apr 5, 2022) took deep dives into issues plaguing combined cycles with high transient operating hours: Drain-line and bypass-piping cracking. The first confirmed yet again that lab metallurgical analysis of failed components is a must, even if it adds a day or two to an outage, while the second revealed the growing importance of data mining in failure assessment.

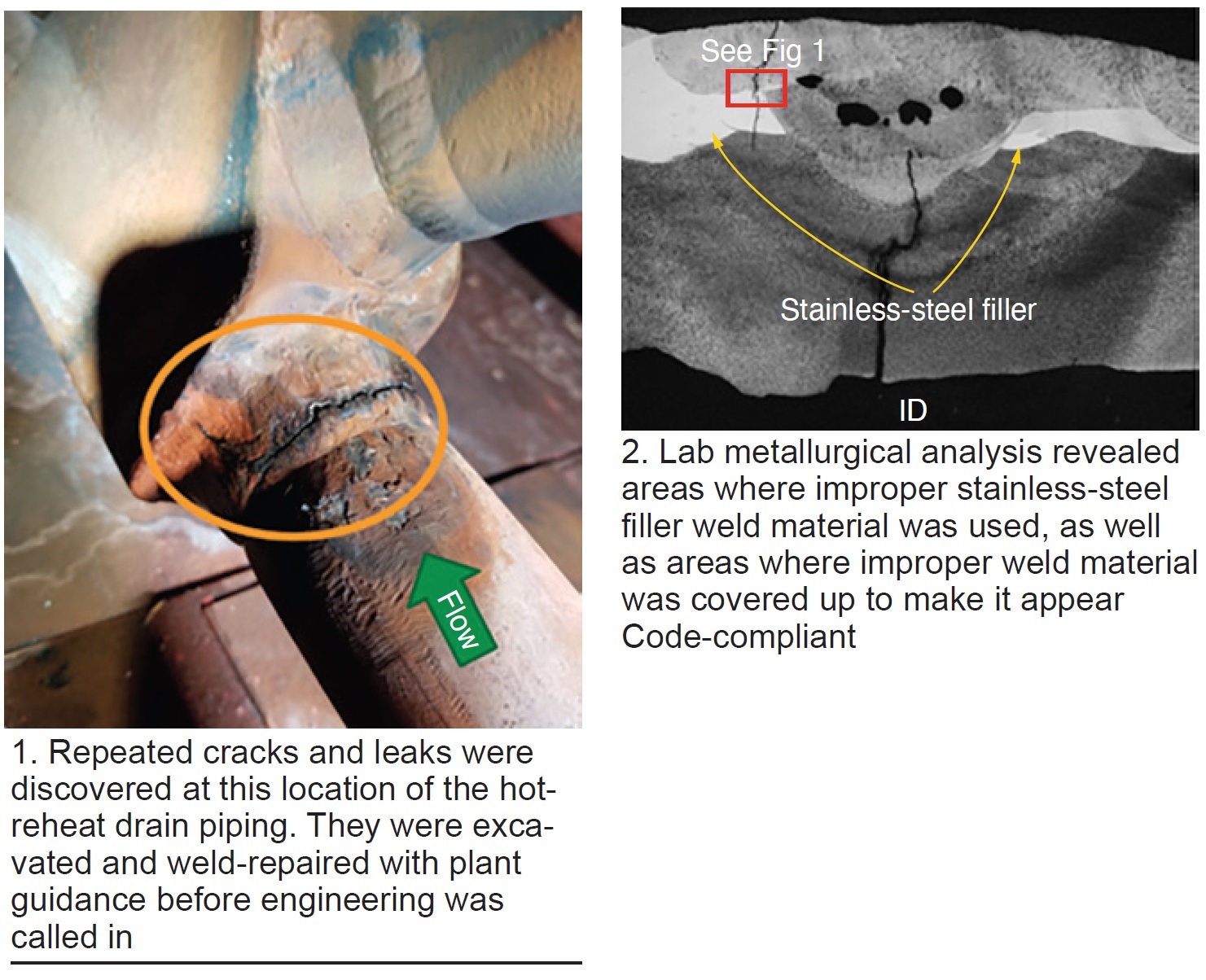

Albert Olszewski, Constellation Energy Generation, titled his presentation “Why Failure Analysis Is Performed,” and the implicit “answer” is, to avoid repeat cracking failures of the same component in the same location. Olszewski’s initial slides showed three crack failures (Fig 3) over a year’s operation of a 2-in., P22, wye-block fitting with a full-penetration weld on an HP evaporator drain line to the blowdown tank. After each discovery, the crack was excavated and weld-repaired by the plant without engineering being involved.

Then the plant replaced the wye-block, only to experience a “terrible crack” right through the weld within a year and a half of operation. Engineering finally was called in. Metallurgical analysis (Fig 4) revealed improper stainless-steel filler material in the field weld, probably from a welder grabbing the wrong filler rod during construction. Remnants of improper weld filler material used since construction seemed to explain the repeated leaks and how often they occurred.

During the post-preso discussion, HRSG Forum Co-chairman Bob Anderson re-iterated that best practice is to always take a sample to the lab for analysis when failures like this one occur. However, he added, such decisions that extend forced-outage durations rarely are taken unless senior management has agreed pre-failure that this is a best practice.

The Q&A was a veritable brainstorming session about other factors which could affect this type of cracking (for example, pipe movement and inadequate supports), ways to obtain additional data (for example, add thermocouples to measure transients), etc—so best to listen to Olszewski’s recording at https://HRSGforum.com. Some experts cautioned that the stainless-steel filler may not be the root cause of the crack.

Most everyone knows that data mining permeates our work and personal lives, but it’s refreshing to see it laser-focused on a specific plant problem common to many combined cycles. Diederic Godin, senior manager, Mechanical and Optimization, at Capital Power, and Valve Doctor Ory Selzer, application engineering manager at IMI-CCI, tag-teamed, with Godin setting the context of the plant design and the failed component, while Selzer focused on analyzing the operating data and details of an improved component design.

Most everyone knows that data mining permeates our work and personal lives, but it’s refreshing to see it laser-focused on a specific plant problem common to many combined cycles. Diederic Godin, senior manager, Mechanical and Optimization, at Capital Power, and Valve Doctor Ory Selzer, application engineering manager at IMI-CCI, tag-teamed, with Godin setting the context of the plant design and the failed component, while Selzer focused on analyzing the operating data and details of an improved component design.

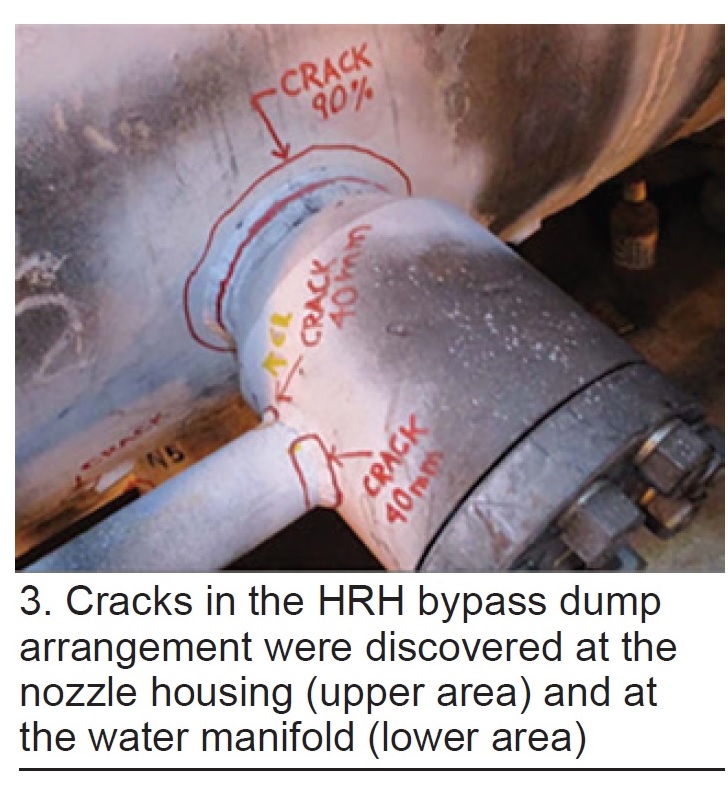

Capital Power acquired its Goreway plant in Ontario, in 2019, about a decade after it went commercial. The failure involved a two-stage, low-noise, hot-reheat (HRH) dump valve system to the air-cooled condenser (ACC)—including a 16 × 24 in. steam pressure-control valve with desuperheater, a 24 × 34 in. second-stage desuperheater, and a 34-in. low-noise resistor ahead of the ACC.

The end plate cap from the first-stage desuperheater also was found liberated, with no evidence in the process data that it was missing. The desuperheater thermal liner posed problems early in life, apparently, and was removed after only a few years of operation under the previous owners.

The external water manifold and nozzle housing are in one “spool.” Cracks were discovered at the nozzle housing to steam-pipe connections and in the manifold (Fig 5). Capital decided to replace the valve and desuperheater with an improved design. But once the upgraded outer pipe spool, nozzles, and manifold for a new desuperheater were purchased, internal erosion damage was discovered on the diffuser, so the upgraded design included a new diffuser. The final unit was being installed literally as Godin was making his presentation.

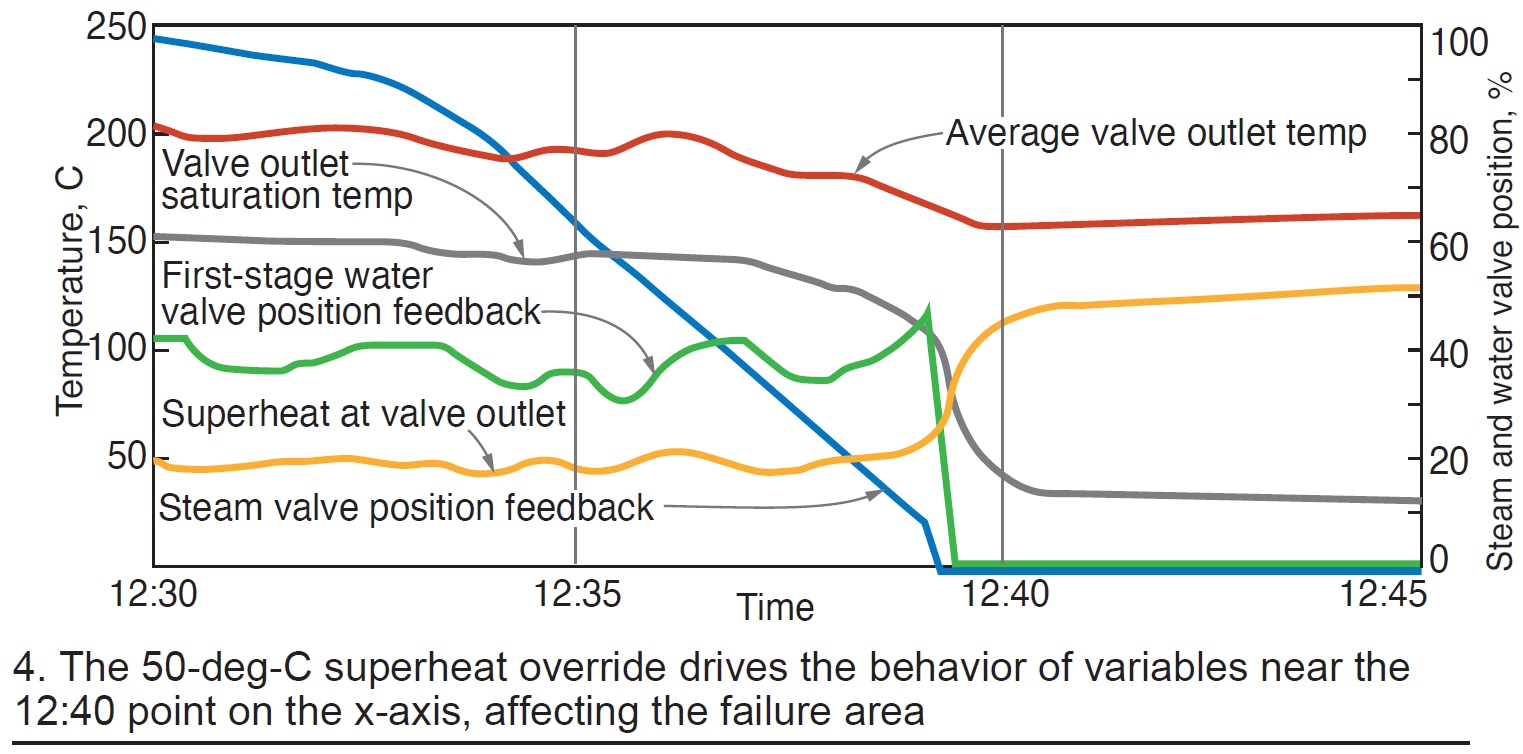

Selzer then turned to the root-cause analysis. IMI Insyt, with specialized data mining techniques, acquired four weeks of operating data in small intervals representing 28 startups across three units, or 25-million data points total. In other words, not an analysis you’d want to attempt using Excel spreadsheets. The startup data important to this component were then overlaid to detect patterns and anomalies.

The “big catch” was a massive quench down to saturation taking place at the desuperheater first stage during each hot start after the bypass (dump) valve opens, a quench that should be taking place at the second stage. This was occurring because of a 500-deg-C minimum superheat override setpoint in the DCS logic (Fig 4). Several other “critical findings” also fell out of the analysis. But you’ll have to get them from the video tape at https://HRSGforum.com. They provide the hardware design modifications and control logic revisions.

Attendees wondered where the end cap was found (just upstream of the ACC) and whether there were any operating “symptoms” suggesting that it was missing (none). Another in the audience suggested that the plant should have seen a change in pressure drop when the end plate was lost. In response to another inquiry, Godin noted that a sample of the liberated end cap was not taken for analysis.

Barry Dooley, who shares moderating duties with Anderson for these forums, asked if the failed component was analyzed metallurgically and the answer was “no.” He then added that reheaters 1 and 2 are typically constructed of T23, one of the worst materials for exfoliation. Godin responded that he would “dig into this.”

Upcoming HRSG Events

|

|

|

The HRSG Forum, led by Co-chairs Bob Anderson of Competitive Power Resources and Barry Dooley of Structural Integrity Associates, continued its tradition of offering excellent user-driven content in its recent virtual meetings. The HRSG Forum in-person meeting, in collaboration with Power Users for the first time, is scheduled for Atlanta the week of June 12. Details coming soon.

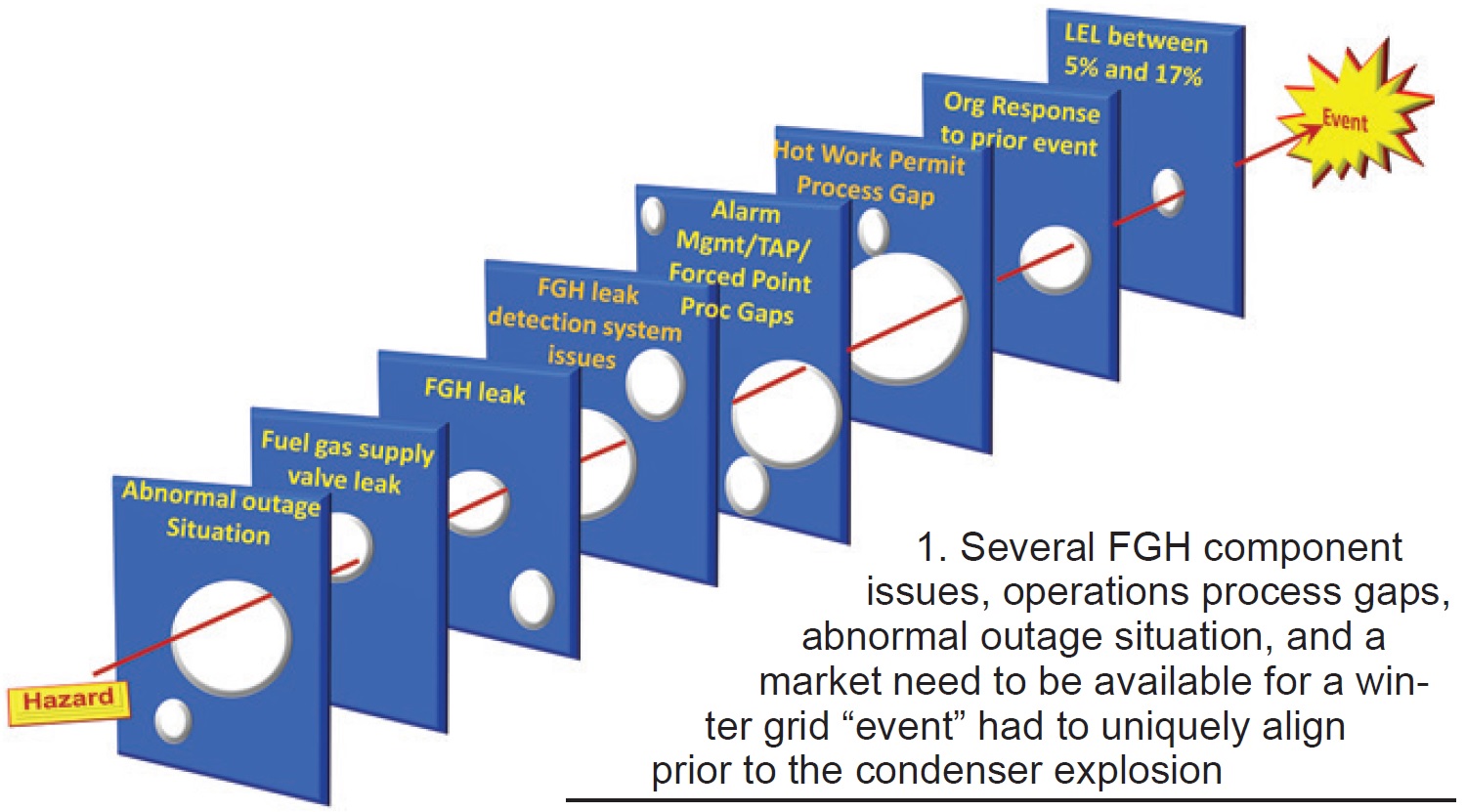

Steve Bates and Steve Harvey shared the details of a catastrophic incident at the 2 × 1 501G-powered Wise County (Tex) Power Plant in which natural gas accumulated in the condenser during an extended outage and exploded when a welder attempted to repair an external pipe. In the opinion of the editors this presentation could be one of the most valuable safety briefs you’ll receive if you have a combined-cycle plant with a fuel gas heater (FGH). An abridged account follows.

As a result of a failure of a main lead in the steam turbine/generator, the facility was in a steam-turbine outage in January 2022 during which the Wise County GTs remained “available” to the grid (with fuel at pressure up to the FGH stop valves). With the plant experiencing numerous issues with the FGH (for example, leaking gas isolation valves) and its leak detection system (prone to false alarms), and other factors, natural gas found its way to the condenser through the IP water-side supply line (the source of heat for the FGH).

The plant was down for 10 days, but with cold weather in the forecast, the gas turbines were started to build up pressure to about 50 psig in the HRSG to prevent freezing. The steam pressure in the HRSG provided the motive force to move the gas that had been accumulating in the IP drum to flow down the steam piping to the condenser.

When a welder arrived to repair a 1-in. pipe connection on the outside of the condenser, the arc ignited the gas and the subsequent explosion blew out six rupture discs on top of the unit, caused bolting threads on the LP steam-turbine cover to fail, and damaged internal structural supports. Rupture-disc parts were found all over the plant site. The explosion was heard and felt throughout the plant.

Mercifully, no one was injured (not even the welder), no condenser tube leaks resulted, and the LP section of the turbine suffered no internal damage.

Bates covered the events (Fig 1) at the plant which had to uniquely align for this incident to even be possible, as well as his company’s fleet-wide assessment and recommendations to avoid a similar incident elsewhere, including the following:

- Eddy current test FGH tube bundles and perform leaking testing at least every six years.

- Utilize more robust inserts when plugging tubes.

- Ease plant staff access to vent valving and instrumentation.

- Establish fleet standard critical preventive maintenance guidelines for FGH systems.

- Perform comprehensive FGH system design review.

- Install permanent redundant methane detectors on air ejectors with feedback to control system.

This presentation is not available online. Those interested in learning more should contact Bates directly.

Upcoming HRSG Events

|

|

|

The HRSG Forum, led by Co-chairs Bob Anderson of Competitive Power Resources and Barry Dooley of Structural Integrity Associates, continued its tradition of offering excellent user-driven content in its recent virtual meetings. You can dig deeper by accessing the recordings at https://HRSGforum.com. The HRSG Forum in-person meeting, in collaboration with Power Users for the first time, is scheduled for Atlanta the week of June 12. Details coming soon.

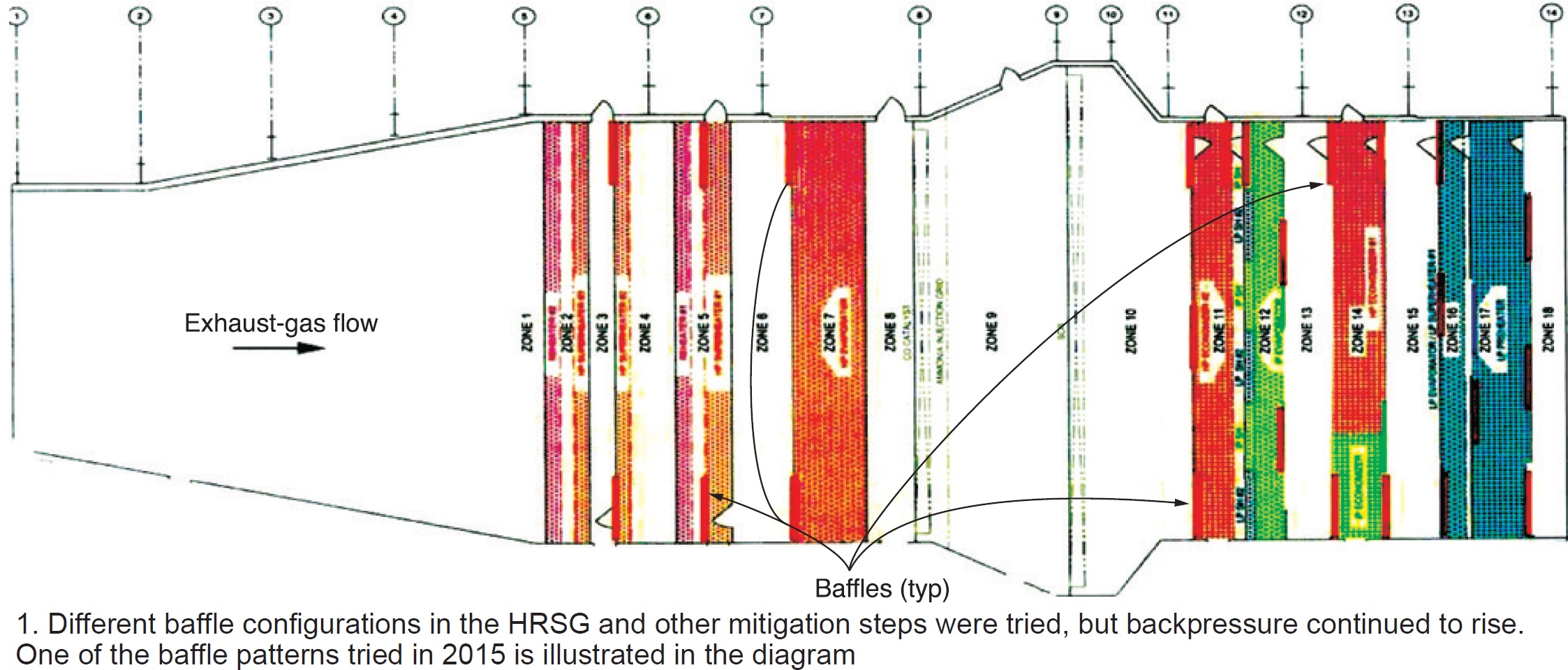

Harold Snyder, PE, of Lakeland (Fla) Electric’s McIntosh Power Plant, began his presentation with a review of a two-decades battle Unit 5, a 1 × 1 501G-powered combined cycle, experienced with high HRSG backpressure (BP) and resultant derating. This facility was commissioned in 2001, one of the plants typical of that era designed for baseload operation but soon pressed into cycling service for many years thereafter.

Almost from the get-go, the HRSG experienced fouling by ammonia salts from the SCR and rust accumulation, most evident in the last tube sections, forcing a gas-turbine (GT) derate of 15 MW.

After years of monitoring pressures, trying online cleaning methods (sonic horns, vibrators on lower headers) and offline cleaning (dry ice, air jets, pressure wave), and dehumidifiers on the GT inlet and LP inlet to the HRSG, McIntosh, beginning in 2008, resorted to adding stiffeners in the HRSG, removed lower baffle plates (Fig 1) in the LP and intermediate-pressure (IP) sections (and trying several different baffle configurations), and adjusted SCR controls and economizer recirculation temperature controls, to increase the allowable BP from 28 to 30 in. H2O.

In the face of continued elevated BP in 2016, McIntosh pursued permanent modifications beginning in 2017 (through 2020) to increase allowable backpressure to 45 in. H2O and address other issues—such as tube leaks. These included doubling the number of stiffening plates in the roof, floor, and walls; replacing the LP economizer, LP superheater No. 1, and LP evaporator tube bundles; and upgrading the expansion joints. Eleven tube rows in the LP economizer were replaced with 15 smaller-diameter tubes, creating a 20 in. cleaning lane between the LP economizer and the LP evaporator/superheater No. 1.

Snyder noted, during the Q&A, that pressure-wave cleaning was by far the most effective, stating that the technique was able to remove about five times as much debris as dry ice. Readers are encouraged to listen to all of the Q&A, available at 2022 Recordings (hrsgforum.com), which generated critical discussion and insight into ancillary causes of the BP issues, consequences of different baffling configurations, and other topics. Slides include detailed diagrams of baffle and stiffener configurations and external photos of stiffeners.

The story may not be over, though. The unit has not been cleaned since 2020 and BP is beginning to rise again, reported Snyder, even though the unit is now operating baseload.

Upcoming HRSG Events

|

|

|

Explore EthosEnergy’s options to repair over replace that save cost and reduce lead times

Perhaps you’re in the middle of a major outage and an issue has cropped up, putting your critical path in jeopardy.

Or maybe you’ve received a technical information letter (TIL) recommending the replacement of L-0 blades, or alerting you to issues with the N2 casing or diaphragms.

Not to mention rotor vibration or bowing which can have serious consequences.

Suddenly, you’re looking at significant expenditure and the potential for extensive lead times.

That’s if you go with traditional replacement options.

Learn more about these solutions, including our unique in-situ blade repair and titanium blade refurbishment, at the link below.

The V Users Group serves owner/operators of both 50- and 60-Hz engines, as noted alongside the logo above. However, at meetings in the US, the focus is on the 60-Hz models of Siemens Energy’s 4000F and 2000E gas turbines. The V fleets here number about five dozen 2000Es and three dozen 4000Fs. Worldwide, the total is about 1000 engines—roughly 80% made by Siemens Energy, the balance by Siemens Energy licensee Ansaldo (50 Hz only).

Siemens Energy has hosted annual in-person conferences here for almost two decades, except for 2020 and 2021 because of Covid-19 concerns. Web meetings filled the void in information transfer until the 2022 meeting at the Hotel Monteleone in New Orleans, August 1 to 4.

This report summarizes content shared with the nearly 50 users participating in the NOLA conference. It is based on notes taken by the editors, Mike Herman, combustion turbine supervisor, Great River Energy (4000F and general sessions), and Scott Wright, technical superintendent, PowerSouth Energy Co-op (2000E), and from presentations by Siemens Energy engineers led by Service Engineering Manager Jonathan Swasey.

Wright is a member of the US steering committee, which also includes Preston Walsh, combustion turbine supervisor at Great River Energy, and J R McKinney, site supervisor, Arkansas Electric Co-op Corp. Communication among V users is facilitated by the organization’s forum, hosted at www.PowerUsers.org.

Dig deeper into the Siemens Energy presentations by accessing the slide decks posted on the OEM’s customer extranet portal at https://cep.siemens-energy.com (users only).

V Users Group 2022

2. OEM and users discuss product lines, common issues

3. SGT6-4000F Fleet Engineering Update

The first in-person meeting of V Users in three years began with a program characteristic of the Big Easy. The only event on the Monday calendar was a vendor-sponsored welcome reception in the early evening, allowing attendees to avoid weekend travel in the ever-crazy post-Covid world. Tuesday began with a social event—golf followed by a group luncheon—giving attendees the opportunity to reconnect face-to-face after about a thousand days of isolation. Product demonstrations, a favorite on this organization’s program, were conducted at the end of the day.

The first in-person meeting of V Users in three years began with a program characteristic of the Big Easy. The only event on the Monday calendar was a vendor-sponsored welcome reception in the early evening, allowing attendees to avoid weekend travel in the ever-crazy post-Covid world. Tuesday began with a social event—golf followed by a group luncheon—giving attendees the opportunity to reconnect face-to-face after about a thousand days of isolation. Product demonstrations, a favorite on this organization’s program, were conducted at the end of the day.

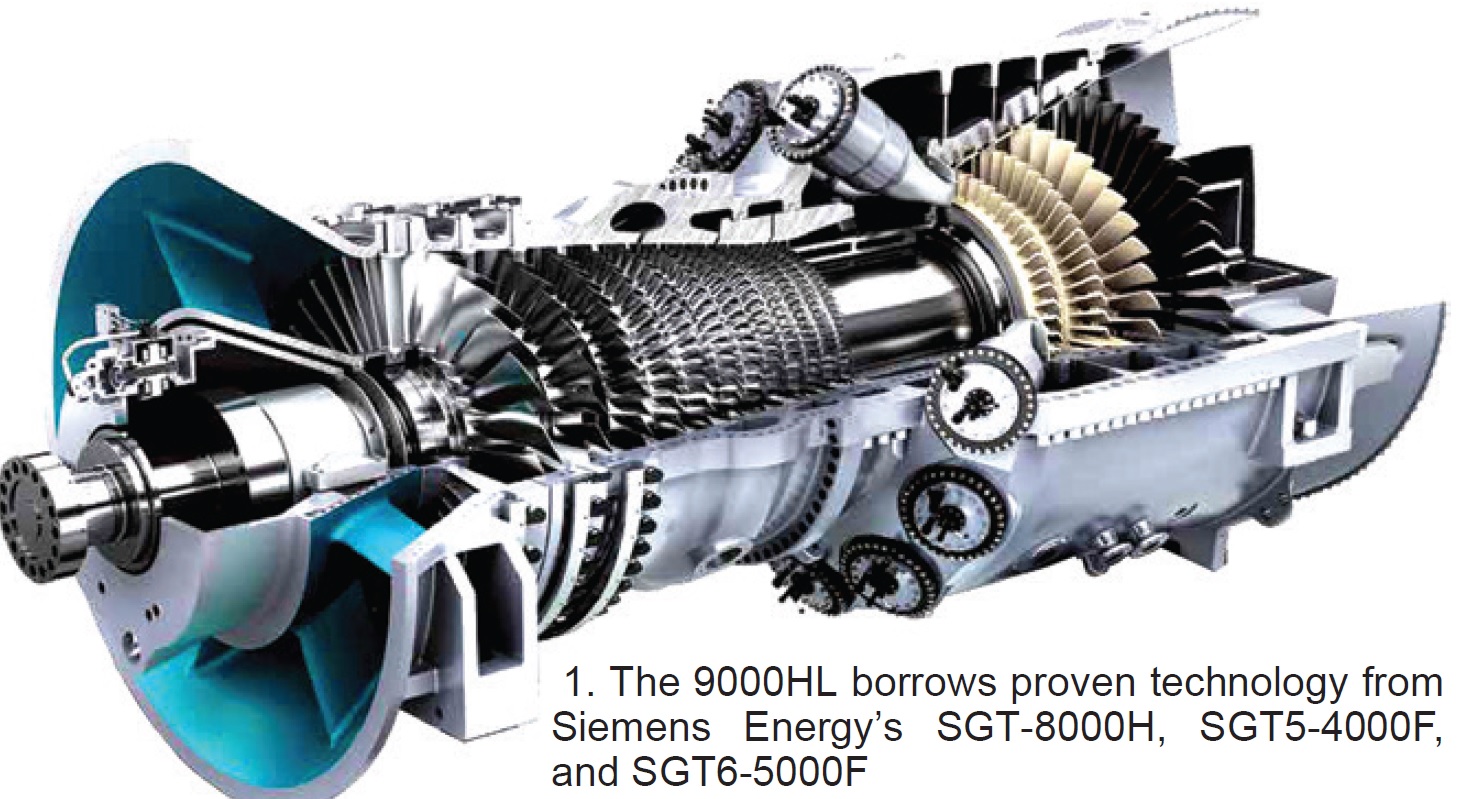

The program picked up steam Wednesday morning with a special session dedicated to the OEM’s progress in commercializing one of the industry’s most advanced gas turbines—the 9000HL. Attendees were told this machine is the world’s largest GT—both in simple-cycle (440 MW at 60 Hz) and combined-cycle (880 MW at 50 Hz) service, as confirmed at US and UK powerplants.

The 9000HL (Fig 1) borrows proven technology from Siemens Energy’s SGT-8000H, SGT5-4000F, and SGT6-5000F, validated over the course of hundreds of thousands of operating hours—including single tie-bolt, Hirth serration/steel rotor, air-cooled four-stage turbine section, and hydraulic clearance optimization.

Eighteen HL-class units reportedly had been ordered worldwide at the time of the meeting. Important features of the new gas turbine include its ability to ramp at up to 85 MW/min and burn gas with up to 50% hydrogen. Combined-cycle efficiency tops 64%.

A one-hour closed session for both 4000F and 2000E owner/operators followed, featuring a presentation by Héctor A Frare, plant manager of Argentina’s Genelba Thermal Power Plant, and by Curtiss Wright on its Readily Accessible Parts Information Directory (Rapid).

A one-hour closed session for both 4000F and 2000E owner/operators followed, featuring a presentation by Héctor A Frare, plant manager of Argentina’s Genelba Thermal Power Plant, and by Curtiss Wright on its Readily Accessible Parts Information Directory (Rapid).

Frare shared details on how his team identified and corrected a combustion-chamber issue on Genelba’s SGT5-2000E gas turbines using a methodology developed in-house. That effort earned the plant, owned and operated by Pampa Energía SA, a CCJ Best of the Best Practices Award for 2022, which was presented at the meeting (Fig 2).

Rapid allows all plants subscribing to its service to see what parts are available through Curtiss Wright, updated daily. The virtual community is said to be used by more than 4500 supply-chain professionals to locate, buy, and sell parts for generation, transmission, and distribution assets. Prices are not included in the data. One participant said he heard that Siemens Energy would “support” the system if “multiple” users joined it.

Closed sessions for 4000F and 2000E users were conducted in parallel until lunch, closing out the morning program. Information shared is incorporated into the closed sessions for those engines on Thursday and is covered later in this article.

A general session for all users and Siemens Energy personnel was conducted in the afternoon, plus dinner offsite. Highlights of the technical program follow.

Field service. A broad-brush view of Siemens Energy’s goals regarding tooling, people, and processes to assure the availability of well-trained, capable engineers and technicians to meet customer expectations. Specific technician skills are identified, standardized outage reports explained.

Some recent process improvements include the following:

- Blade-tip and tile grinders changed from 480 to 120 V.

- Casing installation guide cones for V84.2 bolts eliminate manual guiding when setting the case.

- Compressor-blade removal tool.

- New tile overlays to support V84.3Ax minor inspections.

Compressor bearing damage, caused by an interruption in lube-oil flow, was presented next as a case study that explained how the OEM’s turbine services group corrected the issue. Accident details: dc lube-oil pump came on for nine seconds following a loss of power, turned off for a minute, and then resumed operation. What happened: Elevated active-side thrust-bearing temperatures were experienced.

A hardness check revealed off-spec measurements, suggesting the potential for cracks. The axial bearing surface on the front hollow shaft was machined in-situ to eliminate the hardness. Tooling developed to machine the rotor was a collaborative effort between Siemens Energy personnel in the US and Germany. Positive outcome: Off-the-shelf bearing pads still can be used, but in conjunction with shims to compensate for material loss.

A brief discussion of specific field-service capabilities for V engines—including blower blade tipping, coupling boring machine, collector-ring grinding/polishing, and compressor-seal disc mod for rows 3-5—followed the bearing case history.

Generator update. Recent outages showed a need for further evaluation into stator winding and stator core unplanned outages longer than 10 days to identify their causes. Outages attributed to stator winding/core issues have increased significantly from the January 2017 to June 2022 period compared to January 2021-June 2022.

Siemens Energy’s Global Vacuum Pressure Impregnation (GVPI) technology for generator stators has many advantages according to users sharing their opinions at user-group meetings. However, a big disadvantage of the technology can be the difficulty it causes when a stator rewind is necessary.

This presentation is valuable for the information it shares on the rewinding of generators onsite using Siemens Energy processes for coil removal, laser cleaning, and rewinding with Single Vacuum Pressure Impregnation (SVPI) coils.

Another discussion point during the session: The benefit of dynamic generator cooling control for flexible operation. Reduction of the temperature differential during short standstill durations enables higher load gradients on restarts. Plus, thermal-mechanical stresses on the insulation system are reduced.

The slides on FAST Gen™ generator robotics inspections using new high-resolution cameras should be of interest to plants wanting faster turns on maintenance outages.

Steam-turbine update. Presentation likely will be of value to staff (other than the plant engineer) for its review of the nomenclature/definitions affiliated with turbine performance calculations—including availability, reliability, starting reliability.

Several slides explain Siemens Energy’s TMS (Total Maintenance Services) process. It’s a structured outage planning, implementation, and lessons-learned methodology said to create a win-win partnership between the OEM and its customers. It covers budgeting, communications, planning, identification of resource issues during outages, supply-chain issues, shop machine-time planning, etc.

Two sidebars within the presentation address (1) part kits for fossil steam turbines (HE, KN) to help reduce outage time and (2) upgrade solutions for the SST-5000 to increase efficiency, reduce maintenance cost, and recover degradation.

Finally, the intended benefits of a barrel swap for H steamers are covered. They include outage optimization, efficiency improvement, ease of maintenance, etc.

Omnivise T3000 status update should pique the interest of anyone with controls and/or cybersecurity responsibilities. Migration from ET 200M to ET 200SP is a focus of this slide deck. Options and choices are detailed in the well-illustrated presentation.

A few slides on cybersecurity cover audit awareness and what to do in an audit situation. Primary takeaway: It’s important for Siemens Energy to know whom onsite is responsible for tracking changes for NERC CIP to avoid issues. Contacts in Alpharetta are provided to answer your questions, etc.

Plant flexibility for a changing market. Plant assessments, weatherization, hydrogen co-firing, the value of emerging technologies such as batteries, and solutions for grid stability are all profiled. Two examples of operational flexibility are provided to illustrate how plant owner/operators might reduce unit startup time and cost, increase starting reliability, and improve performance. A case study illustrates a plant upgrade capability assessment with the goal of determining equipment capabilities for proposed upgrades.

CEP and power diagnostics presentation stresses that the Customer Energy Portal is the single gateway for all a plant’s service needs and reinforces the message that Siemens Energy is the owner/operator’s most trusted partner and advisor. The slides walk users through the CEP registration process and illustrate by way of screen shots the unit dashboard, operations KPIs, etc.

Power Diagnostics® services are explained—basic and enhancements. A mobile app with live data feed and visualization connects to key operational indicators and notifies selected personnel of a plant trip. Other capabilities and bells and whistles round out the presentation.

V Users Group 2022

2. OEM and users discuss product lines, common issues

3. SGT6-4000F Fleet Engineering Update

Thursday’s program was intense, with four 90-min sessions conducted in parallel tracks for 4000F and 2000E owner/operators. Each track featured one session on mods and upgrades (M&U), one on engineering, and two closed sessions for user-only discussions. A 30-min skull session allowing Siemens Energy engineers and users to sort out sticking points identified over the four-day conference completed the technical program. A closing reception offsite followed.

Thursday’s program was intense, with four 90-min sessions conducted in parallel tracks for 4000F and 2000E owner/operators. Each track featured one session on mods and upgrades (M&U), one on engineering, and two closed sessions for user-only discussions. A 30-min skull session allowing Siemens Energy engineers and users to sort out sticking points identified over the four-day conference completed the technical program. A closing reception offsite followed.

The mods and upgrades sessions are particularly valuable for those users experiencing operational constraints. It’s often possible to identify solutions to consider for increasing operating hours, reducing emissions, boosting efficiency and availability, etc, by listening to OEM engineers with relevant experience.

The M&U sessions in each track began with a fleet update, good for benchmarking and for seeing how your plant compares to others in terms of equipment capabilities.

Worldwide, Siemens Energy reported, the SGT-4000F fleet (50 plus 60 Hz) had a 12-month rolling average availability of 96.3%, reliability of 99.1%, and 96.6% starting reliability. At the end of 2021, 53 of the 342 operating 4000F engines were in 60-Hz service—more than half that number in the US. This segment had accumulated nearly 5-million equivalent operating hours (EOH) and more than 83,000 starts by year-end.

The SGT6-4000F began life in the US as the V84.3A frame as the 1990s drew to a close. Over the next several years, improvements extended the basic engine’s capability from about 165 MW to nearly 200 MW in 2013 with the introduction of Service Package 6 (a/k/a SP6)—featuring a thermal performance upgrade and improved hot-gas-path parts. SP6 benefits from earlier upgrades, such as 33MAC (33,000-EOH interval), introduced in 2009 with its improvements in coatings and airfoil geometry and cooling.

Business case for the SP6 includes the potential for a GT power increase of up to 16 MW and simple-cycle efficiency increase of up to 0.7%. A combined cycle could gain up to 21 MW, but with an efficiency increase of only 0.4%. The OEM’s CMF++ (compressor mass flow) upgrade, introduced in 2015, squeezed more power out of the machine at higher ambient temperatures than was possible with just the SP6 upgrade.

Next on the list of improvements was the burner upgrade introduced in 2018 to reduce NOx emissions. Designs of the pilot and premix burners were improved to reduce local flame temperatures; premix flames benefitted from improved stability as well. A reduction in cooling-air consumption in the combustion chamber also contributed to lower average flame temperatures.

Part-load optimization was an important part of the presentation and very practical because this analysis makes use of real site boundary conditions—including current load profile, emissions requirements, and gas-turbine, HRSG, and SCR upgrade capabilities.

There were several slides on fuel flexibility—including guidance on the possible addition of liquid-fuel capability to a unit burning only gas. Next came a look at requirements necessary to accommodate burning varying percentages of hydrogen mixed with pipeline gas.

Siemens Energy’s goal of continuous improvement suggested a progress report on the company’s Advanced Turbine Efficiency Package (ATEP), the development of which is currently focused on the SGT5-4000F engine. Its goal is to increase the efficiency of the current machine by up to 1.5% and boost power output by up to 40 MW. Advanced materials and ultra-efficient internal cooling and sealing of critical parts are among the improvements expected to deliver on the ATEP promise. Four ATEP units have been sold for EU deployment, two for Asia. First fire was planned for summer 2022 at the time of the V users meeting.

Update: In September 2022, the first-time application of ATEP at the Enecogen combined-cycle plant in Rotterdam, Netherlands, was completed as planned. Early performance indications show outstanding values, according to Siemens Energy. Data from the extensive measurement campaign are under evaluation. The OEM expects to present results of its analytical work to the 4000F community shortly.

Engineering. The first presentation in the engineering session described Siemens Energy’s efforts to review its global supply chain with the combined goals of identifying opportunities to improve the lead time for repairs, consolidate technologies, and reduce the strain on critical facilities.

Wet compression got attention for its ability to add up to about 12% power output on demand when ambient conditions are “right.” System was tested at one customer site in June 2021, producing a power gain of 25 MW with 101 gpm of wet-compression flow and a compressor inlet temperature of 90F.

aSMC. Next, experience with Siemens Energy’s Advanced Stability Margin Controller was reviewed. It is intended to boost unit reliability and availability while promoting more cost-effective operation. Seven installations at four customer sites (first in June 2015) are credited with preventing unit trips and unloading events associated with combustion stability issues.

Sliding fuel-gas pressure operation, discussed next, likely is of greatest interest to those users desiring more efficient fuel-gas compressor operation. Attendees were reminded that when gas pressure is too low, operators receive a warning before a gas-turbine trip is initiated. Also, that fuel-gas pressure is not required all the time because of varying operating conditions.

These three possible solutions are described in the presentation:

- Probabilistic approach. Fuel-gas pressure set points (warning and protection) are established based on “real” ambient conditions.

- I&C logic upgrade assures reliable operation by automatically adjusting the load set point according to actual fuel-gas pressure.

- “Smart” fuel-gas compressor control based on gas-turbine load.

Experience with the M77 ceramic heat-shield material followed. It is more durable than the M100 material being replaced in some areas of the combustion chamber. The group was told that SiCerm M77 has a higher resistance to hot-gas erosion and subsequent material erosion during engine operation. It is recommended for the last rows in areas susceptible to erosion. Reduced scrap rates and maintenance effort are among the expected benefits. Less material loss in the combustion chamber also reduces wear and tear on turbine-section blades and vanes.

Rotor-Casing Inspection and Evaluation is always a topic of interest at V user meetings. The speaker stressed that RCIE is a customized approach based on unit operating history. Case studies were offered for baseload engines with up to 200,000 EOH and less than 3000 starts and for peakers with less than 6000 starts.

Presentation reviews components affected by long-term operation, the damage mechanisms expected (creep, etc), and fleet experience. Then current solutions for repair/replacement of affected components are identified along with a look at solutions under development.

One of the conclusions of Siemens Energy’s work: “Statistical results have shown lesser need for replacement of casing and rotor components for baseload engines while experience with peaking engines is still limited.” The speaker continued, saying that with changing markets and more demanding operating regimes, findings (and the need for component replacements), may change; also, that the OEM’s programs are updated based on experience and the latest analytical results.

Brownfield engine exchange (BEX) is on the Siemens Energy agenda at many user-group meetings. The idea is to increase powerplant efficiency and operational flexibility, and reduce emissions, by replacing an existing engine with a new one, perhaps performing selected upgrades on other equipment in parallel. The “carrot”: Less than the cost of a completely new plant.

The OEM’s global BEX program has been successful, with 40 units participating in 10 countries—21 of them in Taiwan. BEX is not specific to the SGT6-4000F. In fact, there are no upgrades of this frame on Siemens Energy’s reference list. However, four V94.3x machines have been replaced with 50-Hz 4000F engines.

Exchanges have been done on SGT6-5000F, W501FC, W501D5A, 501FD3, V64, V93, V84.2, and M701F gas turbines. Plus, general plans were presented by the speaker for SGT5-4000F replacements at plants with GE 9FA and Alstom GT26 machines.

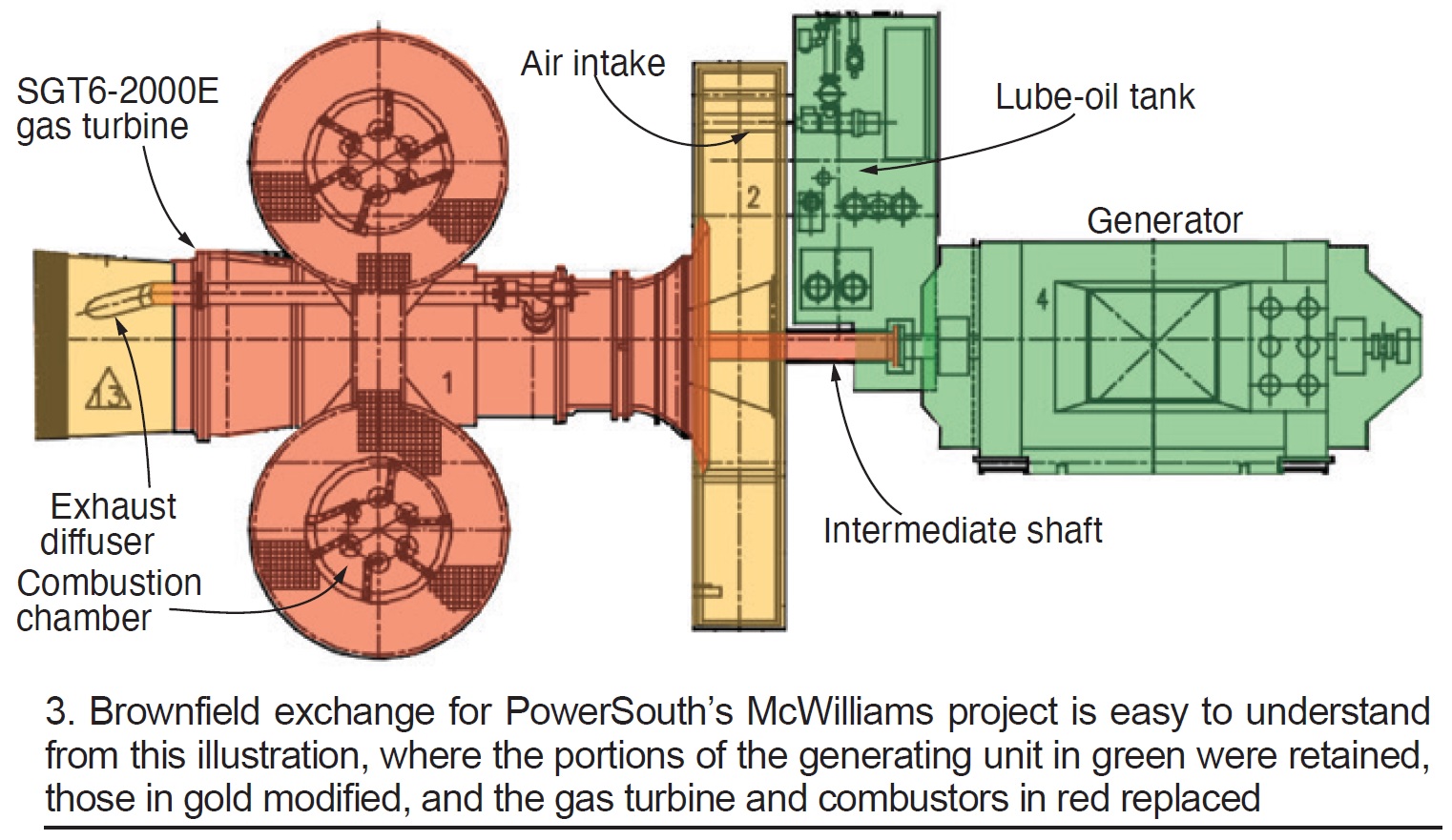

In the US, three exchanges have been made—one a SGT6-2000E replacing a V84.2 engine (Figs 3 and 4) and two SGT6-5000Fs replaced with a later model of the same frame. The first enabled PowerSouth Energy Co-op’s McWilliams Power Plant in Covington County, Ala, to boost the output of its mid-1990s SGT6-2000E(2) from 102 to 114 MW by swapping it out with a new late-model SGT6-2000E(8).

Improvements in the engine’s gross simple-cycle efficiency from about 31% to 35% over the years made replacement more economically attractive than continuing to change parts and do regular maintenance upgrades. Plus, NOx emissions were reduced to 10 ppm from 13-16 ppm.

Major work on this project, the first-of-its-kind here for the OEM, included the design/manufacture/installation of a new intermediate shaft between the turbine and generator, and modifications to the air-inlet house and exhaust diffuser—in addition to replacing the gas turbine, of course. The original generator remained as it was.

Paint update. Final topic on the program was a repair paint, in validation at the time of the conference. Use of the two-component epoxy resin was to address leading-edge coating abrasion on the first few compressor stages. The coating can be applied during a minor inspection.

V Users Group 2022

2. OEM and users discuss product lines, common issues

3. SGT6-4000F Fleet Engineering Update