The first in-person meeting of V Users in three years began with a program characteristic of the Big Easy. The only event on the Monday calendar was a vendor-sponsored welcome reception in the early evening, allowing attendees to avoid weekend travel in the ever-crazy post-Covid world. Tuesday began with a social event—golf followed by a group luncheon—giving attendees the opportunity to reconnect face-to-face after about a thousand days of isolation. Product demonstrations, a favorite on this organization’s program, were conducted at the end of the day.

The first in-person meeting of V Users in three years began with a program characteristic of the Big Easy. The only event on the Monday calendar was a vendor-sponsored welcome reception in the early evening, allowing attendees to avoid weekend travel in the ever-crazy post-Covid world. Tuesday began with a social event—golf followed by a group luncheon—giving attendees the opportunity to reconnect face-to-face after about a thousand days of isolation. Product demonstrations, a favorite on this organization’s program, were conducted at the end of the day.

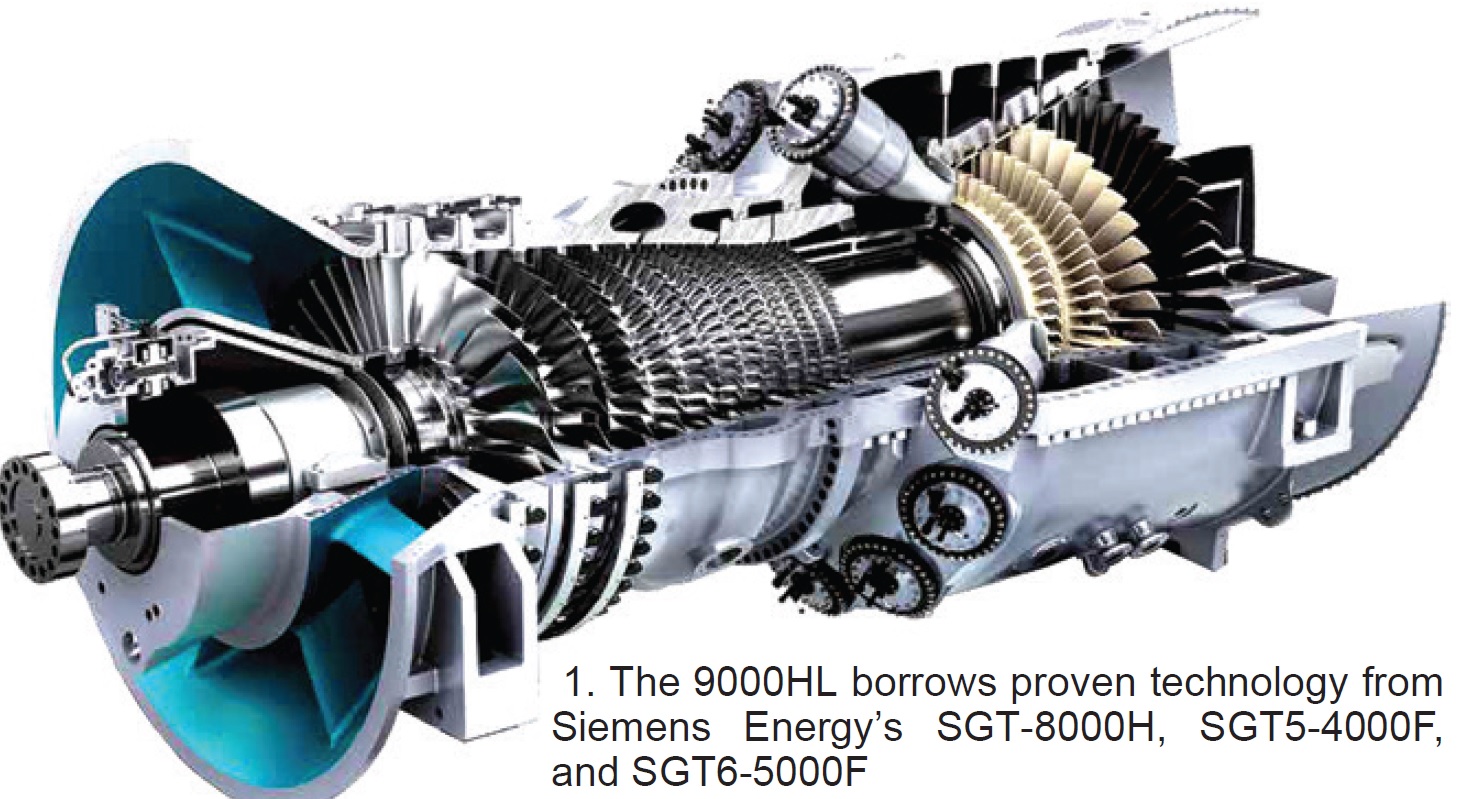

The program picked up steam Wednesday morning with a special session dedicated to the OEM’s progress in commercializing one of the industry’s most advanced gas turbines—the 9000HL. Attendees were told this machine is the world’s largest GT—both in simple-cycle (440 MW at 60 Hz) and combined-cycle (880 MW at 50 Hz) service, as confirmed at US and UK powerplants.

The 9000HL (Fig 1) borrows proven technology from Siemens Energy’s SGT-8000H, SGT5-4000F, and SGT6-5000F, validated over the course of hundreds of thousands of operating hours—including single tie-bolt, Hirth serration/steel rotor, air-cooled four-stage turbine section, and hydraulic clearance optimization.

Eighteen HL-class units reportedly had been ordered worldwide at the time of the meeting. Important features of the new gas turbine include its ability to ramp at up to 85 MW/min and burn gas with up to 50% hydrogen. Combined-cycle efficiency tops 64%.

A one-hour closed session for both 4000F and 2000E owner/operators followed, featuring a presentation by Héctor A Frare, plant manager of Argentina’s Genelba Thermal Power Plant, and by Curtiss Wright on its Readily Accessible Parts Information Directory (Rapid).

A one-hour closed session for both 4000F and 2000E owner/operators followed, featuring a presentation by Héctor A Frare, plant manager of Argentina’s Genelba Thermal Power Plant, and by Curtiss Wright on its Readily Accessible Parts Information Directory (Rapid).

Frare shared details on how his team identified and corrected a combustion-chamber issue on Genelba’s SGT5-2000E gas turbines using a methodology developed in-house. That effort earned the plant, owned and operated by Pampa Energía SA, a CCJ Best of the Best Practices Award for 2022, which was presented at the meeting (Fig 2).

Rapid allows all plants subscribing to its service to see what parts are available through Curtiss Wright, updated daily. The virtual community is said to be used by more than 4500 supply-chain professionals to locate, buy, and sell parts for generation, transmission, and distribution assets. Prices are not included in the data. One participant said he heard that Siemens Energy would “support” the system if “multiple” users joined it.

Closed sessions for 4000F and 2000E users were conducted in parallel until lunch, closing out the morning program. Information shared is incorporated into the closed sessions for those engines on Thursday and is covered later in this article.

A general session for all users and Siemens Energy personnel was conducted in the afternoon, plus dinner offsite. Highlights of the technical program follow.

Field service. A broad-brush view of Siemens Energy’s goals regarding tooling, people, and processes to assure the availability of well-trained, capable engineers and technicians to meet customer expectations. Specific technician skills are identified, standardized outage reports explained.

Some recent process improvements include the following:

- Blade-tip and tile grinders changed from 480 to 120 V.

- Casing installation guide cones for V84.2 bolts eliminate manual guiding when setting the case.

- Compressor-blade removal tool.

- New tile overlays to support V84.3Ax minor inspections.

Compressor bearing damage, caused by an interruption in lube-oil flow, was presented next as a case study that explained how the OEM’s turbine services group corrected the issue. Accident details: dc lube-oil pump came on for nine seconds following a loss of power, turned off for a minute, and then resumed operation. What happened: Elevated active-side thrust-bearing temperatures were experienced.

A hardness check revealed off-spec measurements, suggesting the potential for cracks. The axial bearing surface on the front hollow shaft was machined in-situ to eliminate the hardness. Tooling developed to machine the rotor was a collaborative effort between Siemens Energy personnel in the US and Germany. Positive outcome: Off-the-shelf bearing pads still can be used, but in conjunction with shims to compensate for material loss.

A brief discussion of specific field-service capabilities for V engines—including blower blade tipping, coupling boring machine, collector-ring grinding/polishing, and compressor-seal disc mod for rows 3-5—followed the bearing case history.

Generator update. Recent outages showed a need for further evaluation into stator winding and stator core unplanned outages longer than 10 days to identify their causes. Outages attributed to stator winding/core issues have increased significantly from the January 2017 to June 2022 period compared to January 2021-June 2022.

Siemens Energy’s Global Vacuum Pressure Impregnation (GVPI) technology for generator stators has many advantages according to users sharing their opinions at user-group meetings. However, a big disadvantage of the technology can be the difficulty it causes when a stator rewind is necessary.

This presentation is valuable for the information it shares on the rewinding of generators onsite using Siemens Energy processes for coil removal, laser cleaning, and rewinding with Single Vacuum Pressure Impregnation (SVPI) coils.

Another discussion point during the session: The benefit of dynamic generator cooling control for flexible operation. Reduction of the temperature differential during short standstill durations enables higher load gradients on restarts. Plus, thermal-mechanical stresses on the insulation system are reduced.

The slides on FAST Gen™ generator robotics inspections using new high-resolution cameras should be of interest to plants wanting faster turns on maintenance outages.

Steam-turbine update. Presentation likely will be of value to staff (other than the plant engineer) for its review of the nomenclature/definitions affiliated with turbine performance calculations—including availability, reliability, starting reliability.

Several slides explain Siemens Energy’s TMS (Total Maintenance Services) process. It’s a structured outage planning, implementation, and lessons-learned methodology said to create a win-win partnership between the OEM and its customers. It covers budgeting, communications, planning, identification of resource issues during outages, supply-chain issues, shop machine-time planning, etc.

Two sidebars within the presentation address (1) part kits for fossil steam turbines (HE, KN) to help reduce outage time and (2) upgrade solutions for the SST-5000 to increase efficiency, reduce maintenance cost, and recover degradation.

Finally, the intended benefits of a barrel swap for H steamers are covered. They include outage optimization, efficiency improvement, ease of maintenance, etc.

Omnivise T3000 status update should pique the interest of anyone with controls and/or cybersecurity responsibilities. Migration from ET 200M to ET 200SP is a focus of this slide deck. Options and choices are detailed in the well-illustrated presentation.

A few slides on cybersecurity cover audit awareness and what to do in an audit situation. Primary takeaway: It’s important for Siemens Energy to know whom onsite is responsible for tracking changes for NERC CIP to avoid issues. Contacts in Alpharetta are provided to answer your questions, etc.

Plant flexibility for a changing market. Plant assessments, weatherization, hydrogen co-firing, the value of emerging technologies such as batteries, and solutions for grid stability are all profiled. Two examples of operational flexibility are provided to illustrate how plant owner/operators might reduce unit startup time and cost, increase starting reliability, and improve performance. A case study illustrates a plant upgrade capability assessment with the goal of determining equipment capabilities for proposed upgrades.

CEP and power diagnostics presentation stresses that the Customer Energy Portal is the single gateway for all a plant’s service needs and reinforces the message that Siemens Energy is the owner/operator’s most trusted partner and advisor. The slides walk users through the CEP registration process and illustrate by way of screen shots the unit dashboard, operations KPIs, etc.

Power Diagnostics® services are explained—basic and enhancements. A mobile app with live data feed and visualization connects to key operational indicators and notifies selected personnel of a plant trip. Other capabilities and bells and whistles round out the presentation.

V Users Group 2022

2. OEM and users discuss product lines, common issues

3. SGT6-4000F Fleet Engineering Update