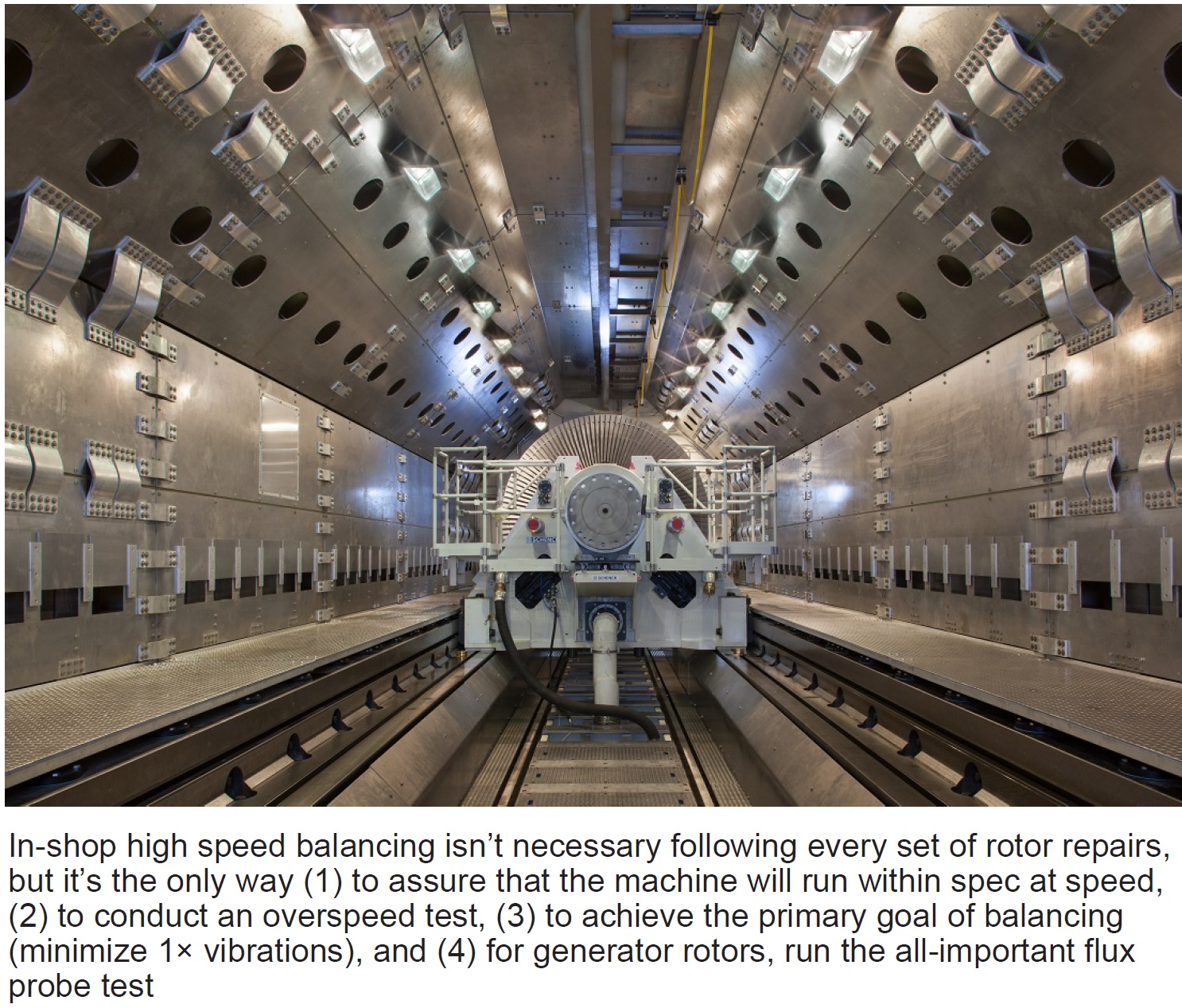

The underlying message of MD&A’s third webinar in its fall 2022 series is that a shop which has invested in a high-speed rotor balancing (HSB) machine (photo) offers the user clear advantages in shortening outage schedules and avoiding the risk of having to transfer the machine from the shop where repairs are made to a shop with an HSB.

Not all rotors require HSB after being repaired, noted MD&A’s Keith Collins, in his presentation entitled, “High-Speed Balance.” If repairs are minor, a low-speed balance (LSB) will suffice, or even an onsite balance. But if the rotor has undergone journal machining, heat straightening, or weld repairs, as a few examples, you should opt for HSB. Ditto if any repairs have altered rotor geometry or local stresses.

For a generator rotor, the big advantage of HSB is the ability to perform a flux probe test, the “only way to guarantee no shorts at startup,” said Collins. Turn-to-turn testing in the shop cannot detect speed-sensitive shorts. “If the rings come off your generator rotor you should do a HSB. This is true for a rings-off inspection or a rewind with new or existing copper,” he stressed.

For all rotors, the HSB also allows for overspeed test and comprehensive vibration analysis.

The bulk of Collins’ slides offer a tutorial of sorts on topics including applicable standards, vibration measurement basics, critical speeds, modal balancing, overspeed test and balance, electrical testing, and heat and stability runs.

During the Q&A, Collins added that an onsite balance should definitely follow an in-shop HSB, with experts present to determine need for additional trim shots. On the subject of whether MD&A “heats up the GT/G or ST/G rotor in the shop for HSB, Collins replied that they typically do not, though other shops do. “We can draw partial vacuum to heat up the blades which transfers heat to the rotor for soaking,” he said.

Regarding the question, “Should you do an onsite LSB after a partial re-blade,” Collins replied “Yes. Do an LSB before and after the repairs.” To a similar question of doing an LSB after replacing all blades in an ST/G rotor, Collins also replied “Yes.”

Access this recording @ https://www.mdaturbines.com/webinar-archive/