If the coronavirus pandemic has taught us one thing, having the ability to access the expert information needed to perform O&M tasks at the highest level without leaving the plant (or home) is vital. With good internet connections generally available at most powerplants, the challenge might be finding the information required. You likely have several preferred websites to search, ones that may have helped you in the past.

If CCJ not one of them consider adding it to your “preferred websites” list. Our online library, keyword searchable on the homepage, can direct you to perhaps unimagined resources on the operation and maintenance of gas turbines and combined cycles. Included among these resources is our webinar library.

At home you might access a service such as Netflix for leisure viewing; at work search CCJ’s webinar library for guidance on how to identify and implement critical O&M solutions capable of helping you and your colleagues improve plant safety, availability, and performance.

To learn more about the library and its value for your facility, please skim the content summaries below of webinars conducted in the last few months and use the links provided to watch one or two. No charge! Note that several more online conferences and webinars are scheduled before year-end—including the 2020 meetings of the 7EA, Steam Turbine, Generator, Combined Cycle, and Power Plant Control Users Groups.

CONCO

Every owner/operator of a plant with an air-cooled condenser (ACC) might benefit from listening to Gary Fischer on the value of an ongoing condition-assessment program and how the experts find performance-robbing leaks quickly. His presentation is fast-moving, easy for both new and experienced employees to understand, and answers the question, “Why do we not want to try doing this with plant personnel?”

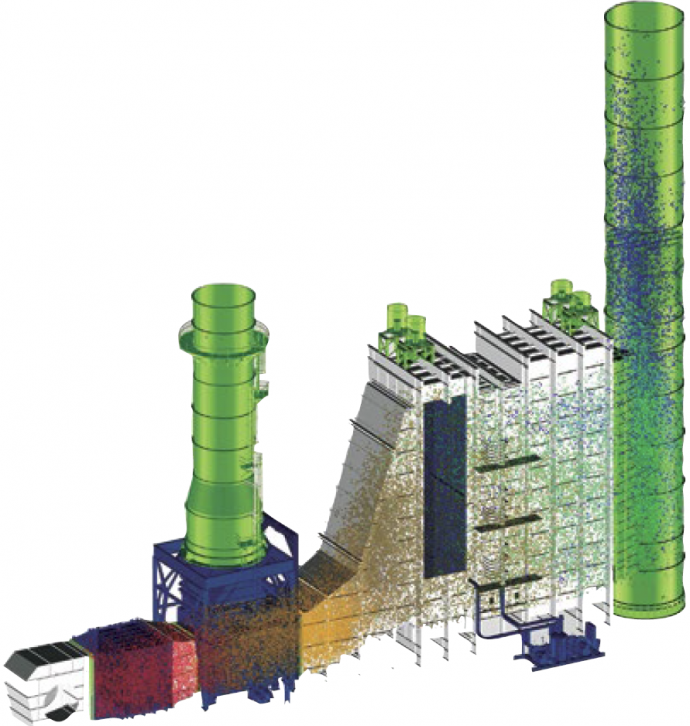

Fischer begins with several slides on the importance of cleanliness, the sources of fouling, and how to remove external deposits (Fig 1). The free flow of air across all heat-transfer surfaces is critical, the chairman of the ASME Heat Transfer Committee reminds. A 20% reduction in air flow because of fouling and debris nestled in an ACC’s finned tubes will increase turbine backpressure by 33%, decreasing electrical output and reducing revenue.

Pushing fans to their maximum to reduce the impact of fouling is not a solution. It only exacerbates the negative impact on financials because auxiliary load increases and you wind up consuming more power at a time when you’re making less money.

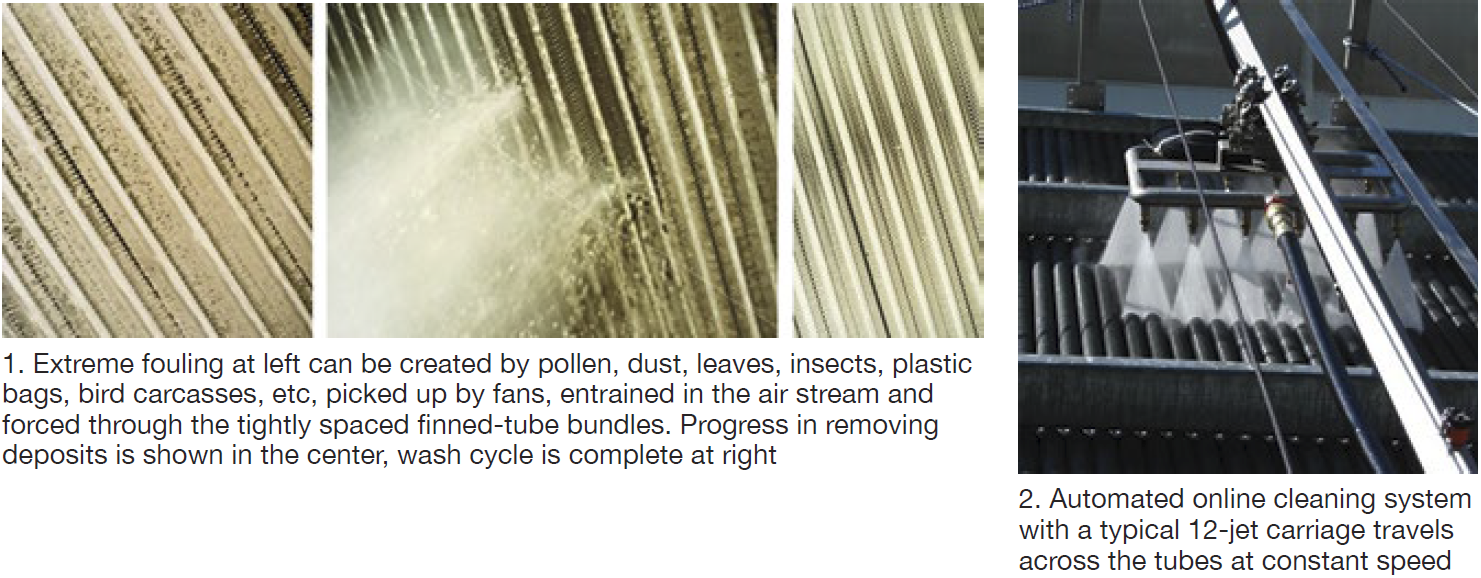

Fischer dismisses the use of fire hoses (too much water, minimal cleaning effect) and high-pressure hand lances (damage to fins and galvanized surfaces) in short order and touts the value of automated cleaning (tight process control, uniform cleaning, no need for scaffolding).

Fischer dismisses the use of fire hoses (too much water, minimal cleaning effect) and high-pressure hand lances (damage to fins and galvanized surfaces) in short order and touts the value of automated cleaning (tight process control, uniform cleaning, no need for scaffolding).

Automated online cleaning systems, such as that shown in Fig 2, have the advantage of delivering a high volume of water at a pressure that will not damage fin and tube surfaces; plus no scaffolding is required. A focused array of water jets mounted on a trolley distributes water deep into the bundle with the opportunity to adjust the jets to optimize the washing effect. The typical carriage holds a nominal one-dozen jets and travels at constant speed across the tubes, assuring effective cleaning in one or two passes.

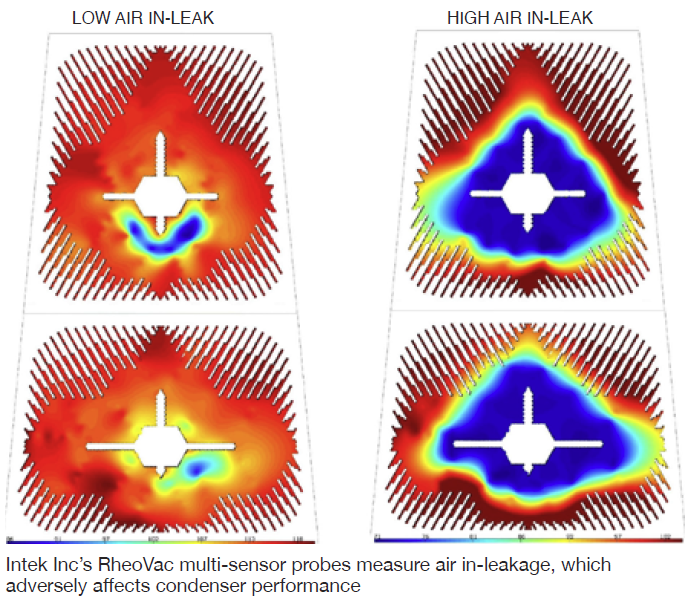

Testing for and minimizing air in-leakage was the focus of the second part of Fischer’s presentation. For identifying the source of air in-leakage, he says non-hazardous helium wins hands-down. Detection is quick and reliable for most leaks at 1 part in 10 million above background (5 ppm). Perspective: Sometimes you’re looking for a leak less than the size of a dime in a surface area equivalent to three or four football fields. Helium can help you find that.

Oftentimes leaks are not where an inexperienced person might believe they are. A leak can be outside the ACC proper and in the hogger or hogger exhaust, the gland-seal drain/trap, the crossover bellows, or at welds in retrofit projects, etc. Don’t be surprised to find an air leak in a new unit, Fischer adds. Indicators of in-leakage are high backpressure, dissolved oxygen, and continuous hogger use.

Concludes Fischer, tracer-gas leak detection is a very cost-effective method for maintaining Rankine cycle efficiency where ACCs are installed.

CECO Environmental

The presentation by Vaughan Watson and Jeff Broderick is suggested viewing by users looking to come up to date on SCR technology and peer into the future of emissions control. The presenters speak to the following technologies and applications from CECO that they consider “next generation”:

-

- Rapid Advantage SCR (RASCR™).

- Urea as an SCR reagent.

- Direct injection.

- EDGE® ammonia injection grid (AIG).

RASCR, Watson and Broderick say, can be adapted easily to an existing plant to maximize SCR performance. It uses fuel as the heat source for reagent vaporization, rather than an electric heater, thereby promoting rapid compliance with permitted NOx emissions during unit starts and transients. Emissions compliance reportedly is achieved within 30 minutes of a gas-turbine start, typically in less than 15 minutes. Natural gas or oil can be used as the heat source for all reagent solutions, including urea.

Retrofits can be installed during a short outage. RASCR integrates with the existing ammonia vapor discharge line and the fuel supply system. Today’s low natural-gas prices typically offer an ROI in six months or less based on the reduction in parasitic power consumption.

Webinar attendees provided these facts related to NOx control at their facilities:

-

- Seventy percent of the participants said their plants have duct burners upstream of the SCR.

- The heat source for ammonia vaporization was electric 59% of the time, gas 28%.

- Fourteen of the plants polled were using RASCR technology, including five on HRSGs.

Reagent options for SCR systems are anhydrous ammonia, 99.95% pure NH3 stored as a liquid under pressure; aqueous ammonia, typically 19% to 29% NH3 by weight and stored as a liquid under pressure; and aqueous urea, a mixture of urea powder and water in solutions containing 32% to 50% urea with storage in an atmospheric tank. Recall that safety risks are associated with ammonia, not urea.

Urea may be making a comeback as a safe alternative to ammonia, the speakers say. If you’re not familiar with the reagent, be aware that it is corrosive and must be stored in tanks made of stainless steel or FRP (double-wall recommended). Piping and pump materials of construction, and seals, also must be compatible with the fluid.

Plants using anhydrous or aqueous ammonia as the reagent for their SCRs can be made more safe by converting to urea. In the case of anhydrous ammonia, the conversion to aqueous ammonia or urea requires addition of a fluid handling skid and vaporizer system. A new storage tank also may be required depending on its condition, capacity, etc. Going from aqueous ammonia to urea will require a stainless steel or FRP tank and possibly changes to the fluid handling system regarding materials compatibility. Plus, vaporizer capacity probably will have to be increased as urea decomposition requires more energy than ammonia vaporization.

Direct injection is a method for supplying ammonia vapor to the SCR system gas path without need for a vaporization system or AIG. Its advantages include lower capital and operating costs, primarily because there’s less equipment. Photos, case history, and data tables presented by the speakers make listening to the presentation beneficial.

EDGE. Participants learned that CECO’s new AIG lance with a square (instead of circular) profile is designed and optimized to provide the desired reagent distribution across the duct to assure expected SCR efficiency and performance. The square cross section promotes better mixing, thereby improving NOx reduction, reducing ammonia slip, promoting longer catalyst life, and reducing the cost of operation. The likelihood of AIG fouling and plugging also is reduced because EDGE provides a place for deposits to accumulate without plugging the nozzles.

Explanatory drawings, lab flow-test results illustrating the degree of mixing achieved, and a case history provided in the presentation attest to the product’s success in the field.

EthosEnergy

You can run longer: What to do when your GE gas turbine is reaching the designed rotor end-of-life limit, Kale Dreymala, gas-turbine rotor project manager, EthosEnergy Group.

If your plant is equipped with a GE industrial gas turbine—Frame 3, 5, 6, 7 (A, B, C, E, EA, and/or F)—and mention of the OEM’s Technical Information Letter 1576, “Gas Turbine Rotor Inspections,” does not strike a responsive chord, obtain a copy today from your plant’s GE representative.

If your plant is equipped with a GE industrial gas turbine—Frame 3, 5, 6, 7 (A, B, C, E, EA, and/or F)—and mention of the OEM’s Technical Information Letter 1576, “Gas Turbine Rotor Inspections,” does not strike a responsive chord, obtain a copy today from your plant’s GE representative.

TIL-1576, released in 2007 and updated in 2011 (1576-R1), identifies the equipment and personnel risks associated with operating gas-turbine rotors beyond 200,000 factored fired (FF) hours (144,000 for F-class units) or 5000 FF starts, whichever comes first, when specific intervals are not defined.

This TIL refers you to GER-3620 for overall guidance on centerline maintenance that the OEM recommends. The latest version of 3620 is Rev N, issued in November 2017. You can obtain a copy with a simple Google search. Rev N is important because it considers the impact of forced cooling on rotor inspection calculations (pages 30 to 35 and Fig 45), replacing the “trip from load factor” in earlier versions of the document.

Kale Dreymala walked webinar participants through the inspection scope recommended by EthosEnergy Group (EEG) for turbine wheels, distance piece/spacers/stub shaft, and compressor wheels. Here’s the lineup of inspections typically recommended:

Compressor and turbine wheels

-

- Visual inspection of all surfaces.

- Semi-automated phased-array ultrasonic (UT) inspection of the bore, web, and rim areas.

- Semi-automated eddy current (ET) inspection of the through-bolt holes.

- 100% ET inspection of the dovetail serrations in the compressor wheels and the fir-tree serrations in the turbine wheels.

Distance piece, spacers, stub shaft

-

- Visual inspection of all surfaces.

- Semi-automated ET inspection of the through-bolt holes.

- Semi-automated phased-array UT of the bore.

Other inspections

-

- Hardness.

- Replication.

- Dimensional measurements.

If these inspections produce no findings, the rotor is reassembled with new bolts and your engine receives a certification for an additional 50,000 FFH (one time only).

If there are findings, the speaker says the OEM is likely to suggest buying a new rotor or possibly a replacement wheel or disc, if that is the life-limiting part.

By contrast, an affordable aftermarket solution suggested by EEG probably would be to obtain a used rotor with a documented history and refurbish it in the shop. The additional life certified (from 50,000 to 200,000 FFH) depends on an engineering review. Note that for peaking units, no extensions are allowed beyond the 5000-starts limit.

Dreymala went on to describe EEG’s capability for manufacture and qualification of new rotor components as might be required during the refurbishment process get the best balance between cost and additional life. Other rotor options also were presented during the webinar, which was not recorded for post-presentation viewing. However, you can write the speaker with questions and/or for a copy of his presentation at kale.dreymala@ethosenergygroup.com.

Nitto

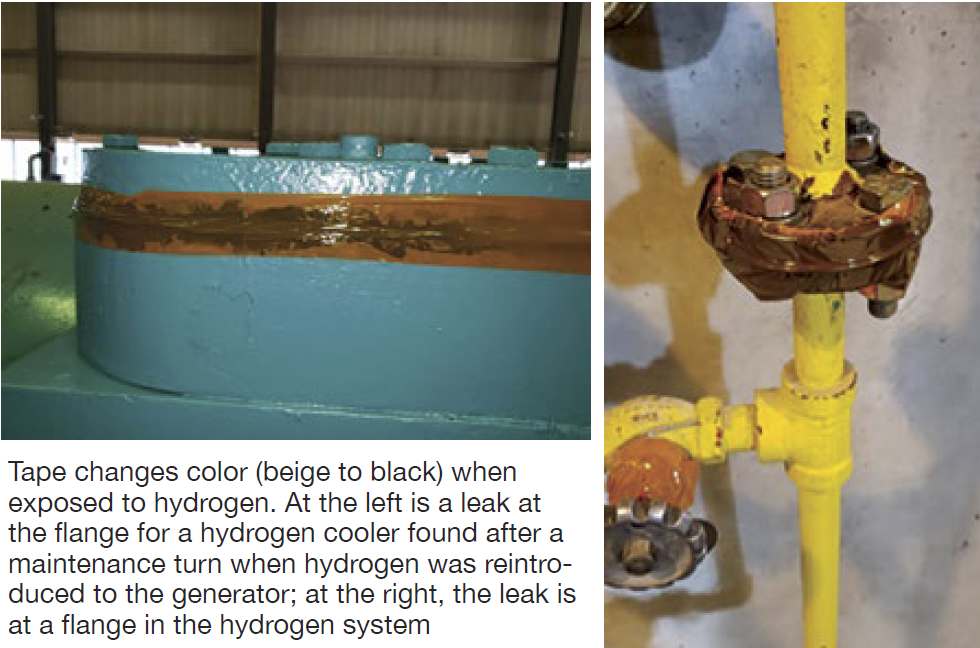

Depending on the type of generator cooling at your plant, and the gas-turbine fuel, a fool-proof hydrogen leak-detection program can be critical to protecting employees, the environment, critical equipment, and the overall business. This presentation presents details, data, and results of field trials of a pipe flange tape, developed for NASA, that changes color in the presence of hydrogen (photos). Thus, it provides a visual indication of a leak because it will not return to its original color once hydrogen gas flow stops.

The presentation shows that soap tests typically used to find hydrogen leaks may not deliver consistent results and provide the confidence that connections/joints are not leaking. In field trials at one utility, 38 flanges were taped. All had been soap-checked prior to using the tape. Once installed, the tape on four flanges changed color within two days. The tape was removed from the flanges and the joints were soap-checked again. Only one of the leaks was large enough to cause bubbling visible to the eye.

Plant personnel concluded that the hydrogen-detection tape worked well as a pre-emptive safety check and has stimulated proactive thinking about previously unrecognized problems. Use of the tape is now part of the plant’s hydrogen-system restoration procedure following generator maintenance.

TRS Services

If you’re involved in gas-turbine repair planning, the editors suggest you listen to the presentation by Greg McAuley and Pete Sobieski, both highly experienced in the planning and conduct of turbine repairs. Each spent a decade or more with a gas-turbine OEM and two or more decades with a major owner/operator before getting back together again at TRS and expanding the company’s mission.

Today, TRS offers turbine component repairs, new-parts manufacture, and consulting services aimed at reducing downtime, minimizing total costs, and enabling new opportunities. The outcomes expected from the company’s work: reduced downtime, fewer unexpected errors, lower costs, and less hassle.

The presenters define repair planning as the process of defining the tasks important to know with a high degree of certainty what components should be retired or repaired, and to achieve the lowest lifecycle cost for parts that should and must be repaired.

McAuley and Sobieski say the five essential ingredients to successful repair planning are the following:

-

- Focus on lifecycle costs.

- Know parts pedigrees.

- Have a fallout plan.

- Choose the right partners.

- Start execution early.

They discussed each of these in turn. For lifecycle cost analysis, the speakers provide calculational examples for repairs to transition pieces and R1 ring segments, with service hours a primary variable. The results might startle you; certainly, they illustrate why this is a very important step in project cost control.

Know your parts illustrates the level of expertise necessary for an accurate evaluation of in-service components. Prior to making a repair decision the speakers say you should know lifecycle costs, hours/starts since last repair, visual appearance, repair history, the OEM’s part expectations, industry experience with a similar part. Of course, your personal experience with the repair of a similar part also is important to the evaluation.

A helpful takeaway tool is the partner evaluation process which offers a price/value comparison across the partner options entered into the equation. A discussion on contingency planning and an action plan to mitigate fallout risk.

EthosEnergy

Improve availability and reduce costs? Your data knows how. . ., Brady Kirkwood, technical services manager for EthosEnergy Group’s monitoring and diagnostics department.

Brady Kirkwood covered short-term (performance analytics) and long-term (advanced predictive AI) methods of how to identify degraded systems and provide quantifiable potential performance gains. Having the tools to evaluate the cost versus benefit of individual system upgrades/repairs to plant systems is critical to improving performance with today’s limited maintenance budgets.

The speaker provides profiles of real events resolved by EEG, including these:

-

- Hidden problem with inlet fogging causing a reduction in plant output.

- An OEM “repaired” bearing oil leak causing compressor fouling.

- Slow degradation in turbine performance during a period of high demand.

- Forced outages caused by lean blowouts.

- Fouling of inlet filters caused by the increased particulate loading attributed to forest fires.

Two goals of the presentation are to identify hidden issues and predict future issues, thereby reducing reactive activities that result in unbudgeted costs. Kirkwood walks you through a plan for reducing reactive maintenance, how to conduct a thermal performance audit to identify underperforming systems, short-term versus long-term solutions, and the financial impacts of unplanned outages and lost generation.

Unfortunately, this presentation was not recorded for post-presentation viewing. However, you can write the speaker for a copy of his informative presentation at brady.kirkwood@ethosenergygroup.com.

EthosEnergy

Decrease cost and simplify outage planning with zero-leak-time components, John Jensen, VP new-product commercialization, EthosEnergy Group.

John Jensen covers the range of flexible EEG solutions geared towards improving the accuracy of your gas-turbine outage plan and reducing the risk inherent in traditional component repair services. Presentation takeaways include the following:

-

- Understand the obstacles to improving outage planning.

- How to remove component repairs from outage planning.

- EEG’s commitment to supporting customers with outage planning and emergency situations.

Jensen says EEG has the depth to effectively and efficiently manage risks in repairs, parts manufacturing, rotor life extension, multi-year maintenance contracts, and plant operations and maintenance. Its capital-parts exchange capabilities eliminate lead-time risk and scope creep of traditional repairs. Repair fallout risk is mitigated by accommodating it outside the plant’s schedule.

This presentation was not recorded for post-presentation viewing. Owner/operators can request a copy of the PowerPoint from john.jensen@ethosenergygroup.com.

“Steam Turbine Repair Planning and Execution,” Bryan Grant, Advanced Turbine Support LLC.

Whether you inspect/repair your plant’s steam turbine or contract out those services, Bryan Grant’s presentation is a valuable reference for O&M personnel, one possibly worthwhile reviewing ahead of your ST inspection/maintenance outages. It’s available on the Power Users website 24/7.

Grant offers tips on repair planning, blade replacement, J-seal installation, when to repair/when to replace nozzles, and final inspections. Plus, he stresses the importance of final FME (foreign material exclusion) close-out inspections prior to unit closure.

One of the speaker’s messages: Be prepared, especially when finger dovetail replacements are involved. Some of the retention pins will hang up during removal, he explained, but most can be persuaded to come out with a hilte or peening gun. Those that remain often must be machined out. This can be a risky operation because it’s easy to damage dovetails.

Risk mitigation during finger dovetail installs demands close attention be paid to the availability of parts and reamers. This entails verifying the sizes of pin holes as designed and to be aware of any oversize holes identified during previous outages. Grant said the lead time for the all-important reamers is upwards of about two months. How many should you order? His rule of thumb is to restrict reamer use to 20 holes. When reinstalling pins, he continued, start at the bottom hole and work your way up.

J seals received significant air time. Not every turbine has them, and all J-seal designs are not the same, Grant went on. Inspections for straightness and crush checks were described. Make sure the J seals are installed correctly with respect to steam flow, he noted. If installed backwards the steam flow acts to pull out the seal. Remember, you want a small gap where the two hemispherical sections of the J straps meet. Photos in the slides show what to look for during J-strap inspections.

Regarding hardware inspections, Grant urged attendees to replace: Never reuse old hardware. Photos described the proper procedure for conducting balance-weight and L-0 mid-span inspections. Staking of balance weights was said to be “incredibly important” to assure weights do not escape during operation. Decisions on diaphragm repair versus replace also were illustrated by way of photos.

“Fluid Film Bearing Visualization,” Dr Lyle A Branagan, Pioneer Motor Bearing Co.

Lyle Branagan is a familiar face/voice at user-group meetings in person and online. His well-illustrated presentations typically cover the design basics of journal and thrust bearings for motors and gas and steam turbine/generators, materials, lubricants and lubrication systems, machine dynamics and performance, installation/operation/maintenance, the importance of quality control, etc.

If you’re new to the business of power generation, listening to or thumbing through the slides in one of Branagan’s presentations is a good way to get introduced to bearings. If you’ve been on the deck plates for several years and haven’t been exposed to bearing work recently, his PowerPoints and videos are a good refresher.

Branagan’s presentation before the 2019 STUG meeting is available in the Power Users library, a video of his 2020 7F Users Group presentation can be accessed at Power Users and in CCJ’s webinar library.

“Failure Modes for Hydraulic Components and Control-Valve Actuators for Steam- and Gas-Turbine Applications and Strategies to Mitigate,” Ralf Bentfeldt and Tom LaCombe, Rexroth, a Bosch company.

This is another presentation available on the Power Users website that you might want to link to for your personal library of troubleshooting best practices. Valve actuators typically are an afterthought until they suffer an operational hiccup or must be removed for inspection and maintenance. [link to article] That probably doesn’t happen more than once a year, so it can be difficult to remember everything you should.

The speakers mentioned that 70% of hydraulic-component replacements are attributed to surface degradation—from abrasive, erosive, adhesive, and fatigue wear—and that 71% of these causes of mechanical wear can be associated directly with hydraulic-fluid condition. That means they are within the user’s ability to monitor and control.

Common fluid issues impacting mechanical wear of hydraulic components are temperature and viscosity, water ingression, air entrainment/cavitation, and contamination. The presenters cover each of these mechanisms individually, offering best practices and rules of thumb to improve outcomes on the deck plates. Example: One chart that illustrates the impact of low viscosity on component wear and the optimal fluid temperature to minimize physical contact between internal parts.

“Benefits of an Alternative Material for In-situ Hardfacing of Valve Seats,” Joerg Schoepp, Power Service Group.

Cobalt chromium hardfacing alloys 6 and 21 have been used to overlay high-wear components—such as steam-turbine valve seats—for decades, protecting against oxidation, impact damage (valve closing), solid-particle erosion, and friction-related wear. Industry requirements that valves be fast-acting while operating at temperatures approaching 1100F in some plants are linked to delamination of the CoCr layer from the high-chrome (9% to 12%) base material. Liberated metal causes downstream damage to components in the steam path.

A buffer layer between the base material and hardfacing has worked in some cases, but it creates additional steps in manufacturing and refurbishment of valve seats, increasing both cost and time. Plus, some recent valve designs have the added complexity of seats that cannot be removed for refurbishment, dictating in-situ seat replacement. Several slides provide key steps for in-situ seat replacement (photos are included) and attest to the challenges of hardfacing in the field.

Joerg Schoepp speaks to the company’s positive experience in using a single layer of Inco 625 for valve seat protection. By eliminating the buffer layer, the company’s general manager of repair services says, “greatly reduces outage duration and variability” while also mitigating the risk of the hardfacing layer to liberate from the base material.

“Technical Considerations for Optimizing Steam Turbine Startups,” Matthew P Scoffone and Thomas R Reid, PE, TG Advisers Inc.

The consultants consider both vintage and modern steam turbines in their presentation. Regarding the former, they identify the following as possible impediments to faster starting for economic benefit: HP/IP creep and embrittlement concerns, solid particle erosion, rotor bow, and casing cracking; for the LP section, stress corrosion cracking and water-droplet erosion.

Modern and retrofit steam turbines are characterized by less accumulated fatigue damage, a more aggressive duty cycle (cycling service, for example), turbine inlet steam temperatures of 1050F and higher.

The presentation [link] offers insights on how vintage rotors age, the importance of correct hold speeds, pre-warm to reduce the mismatch of steam and metal temperatures, clearance considerations for cycling, and startup modifications.

The presenters assure that opportunities exist to safely reduce cold start times without capital upgrades. They are identified by use of recent inspection results, finite-element analysis, and modern fracture mechanics principles. In their experience, cold-start times on legacy turbines typically can be reduced by 25% to 50% while still adhering to critical OEM design parameters and requirements.

“Fundamentals of Steam-Turbine Valve Maintenance,” Mark A Cohen and Scott Cavendish, PE, Independent Turbine Consulting LLC.

Mark Cohen and Scott Cavendish dig into the details of steam-turbine valve maintenance, touching on valve sticking and oxide management, in-service monitoring of valves, extending maintenance intervals, balance-chamber failures, and valve actuators. The presentation is heavily illustrated with meaningful photos. For example, the photos of valve oxide and stuck valves were taken immediately after valve outages where the oxide was not properly removed and the valves had to be taken apart again to correct the failed attempt.

Cohen, a hands-on maintenance expert who probably has forgotten more than many have learned in their careers, is an engaging bareknuckle speaker who maintains your attention with a seemingly inexhaustible supply of anecdotal case histories. Thus, the formal presentation posted on the Power Users website doesn’t cover all that he shared at the meeting. If Cohen presents at the upcoming virtual 2020 STUG conference starting November 11 be sure to tune in.

Restoring design clearances to original dimensions was the first topic. The speakers said 80% of valve sticking incidents is traced to incorrect high-temperature oxide maintenance—such as not honing and using try-bar go/no-go checks. Attendees were warned that grit blasting does not remove oxide, it only polishes surfaces. Reason: Oxide deposits are harder than the grit. When asked about the proper valve maintenance interval, Cohen said it depends on the oxide growth rate. Scale, he continued, is like bark on a tree: It keeps growing until you remove it.

He stressed that oxide removal to bare metal is tough hand work typically using nominal 60-grit bricks; higher doesn’t work, Cohen assured. A couple more best practices shared:

-

- Never change a part unless it really must be changed because you could make an error in replacement and make a good thing bad.

- On bolting up valve connections, stud tightening must be done until you see sealant squeeze out. Leaks on 1960s machines that never existed previously, it was said, testify to today’s lax work procedures.

- In-service operational monitoring can detect only stuck valve, not insufficient clearances caused by oxide buildup.

“Don’t Do That to My Steam Turbine” was the second part of the presentation by Cohen and Cavendish. It focused on operating procedures to avoid turbine damage, including the following:

-

- Adhere to starting and loading temperature matching to minimize life expenditure and avoid cracked shells and distortion of hot parts. Remember that metallurgical life cannot be restored. Example: Cracked shells cannot be fully repaired back to new metallurgy, only temporarily patched. And when shells are patched it’s even more important to temperature-match.

- Quenching during an improper shutdown causes the most damage; it puts metal surface in tension. During shutdowns, avoid low/no-load operation with a hot rotor. On a hot restart, avoid quenching hot parts.

An example of quenching damage to valve parts was presented. Boiler producing 1000F steam tripped with a resultant drop in steam temperature to 750F-800F. Inspection revealed cracking to three valve seats and stems. Keep in mind that the differential expansion of stellite is twice that of the base material.

Some podium time was dedicated to turbine layup and the corrosion damage and stress corrosion that can result if proper procedures are not followed. Avoid moisture entry into the casing and oxygen-induced corrosion with dehumidification, inert gas and sealed casings, heat, and covered storage, the group was told. Periodic rotor rotation and filming amines were among the suggested actions.

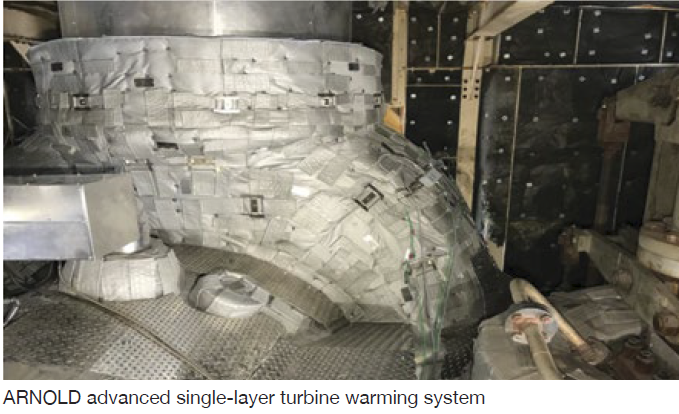

“Advanced Single-Layer Turbine Warming System Improves Startup Flexibility,” Pierre Ansmann and Norman Gagnon, ARNOLD Group.

Pierre Ansmann and Norm Gagnon opened their presentation on “the most advanced turbine insulation combined with a high-performance heating system to improve startup flexibility,” by summarizing its value proposition thusly:

-

- Increased in-market availability.

- Lower startup costs.

- Reduced thermal fatigue and longer mean time to repair for critical components.

- Increased operating flexibility.

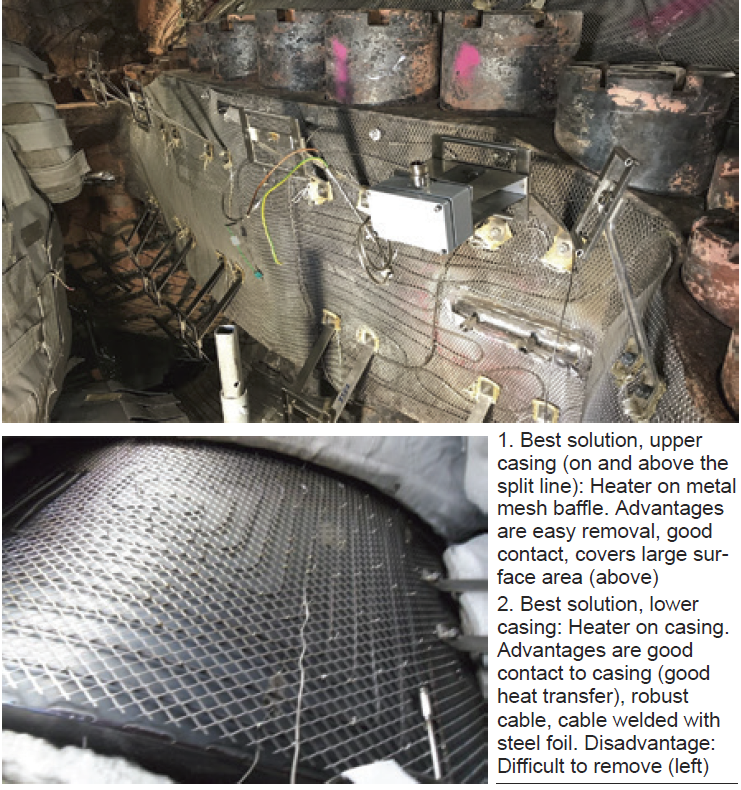

The duo reviewed the different warming-system arrangements, rejecting those integrating the heating circuits in insulation blankets, installing the heater on a thin mattress below the blanket, and using gas-fiber-insulated heating cable. The optimal system for the upper casing, they said, is heater on metal mesh baffle (Fig 1), for the lower casing, permanent mounting of heating cable below the split line (Fig 2).

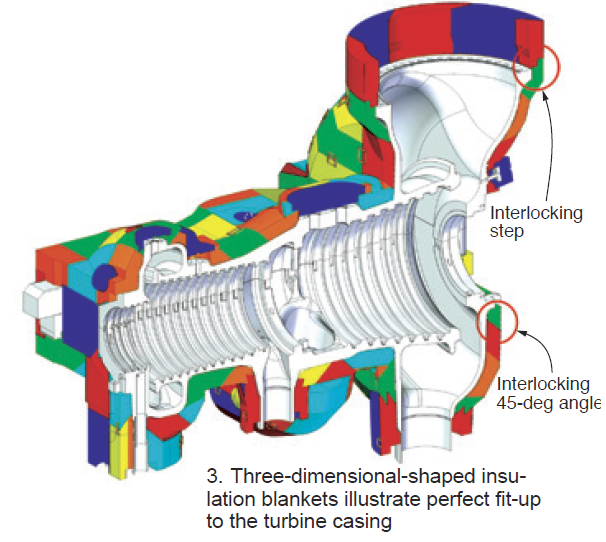

The ARNOLD system features interlocking high-performance blankets which conform perfectly to the turbine surface as shown in Fig 3. High-quality materials and manufacturing, and long-term high-temperature resistance, allow the company to guarantee reuse of its insulation system for 15 outages without a decrease in efficiency. The insulation system for a 330-MW GE steam turbine is on the first page, integrated with the STUG logo.

The ARNOLD system features interlocking high-performance blankets which conform perfectly to the turbine surface as shown in Fig 3. High-quality materials and manufacturing, and long-term high-temperature resistance, allow the company to guarantee reuse of its insulation system for 15 outages without a decrease in efficiency. The insulation system for a 330-MW GE steam turbine is on the first page, integrated with the STUG logo.

More than five-dozen thermocouples, strategically located on the turbine, ensure proper heating. Each of the 18 or so heating zones has t/cs installed on the heating wires to double check if the zone is responding correctly and at the specified temperature. Below every heating zone, multiple t/cs are mounted on the casing to confirm even heating of the turbine.

Ansmann and Gagnon say the ARNOLD warming system can maintain your turbine in a hot-start condition for at least four or five days after shutdown. No preheating of the turbine is required prior to a start within this time period, reducing startup fuel consumption and auxiliary power.

To learn more about ARNOLD’s control system and blanket design, plus, how company technicians would go about custom-designing an insulation system for your steamer, be sure to tune into their 60-minute presentation at the upcoming STUG 2020 Digital Conference on December 9.

The value of user groups continues to grow in the electric power industry as the number of employees on the deck plates shrinks and personnel with deep experience retire.

The plant manager for a 2 × 1 J-class combined cycle under construction told the editors he had received more than 500 resumes in the last two months for about 20 hourly positions at the facility. Two-dozen employees is the total headcount planned. Given that most candidates are not familiar with this gas turbine—only a handful of J engines are operating worldwide and the US fleet leader had less than a year of service time in February 2018—training time likely will focus on the GT because it is the revenue resource. Certainly would make sense.

What about the other equipment? Who is the subject matter expert (SME) on steam-turbine valve actuators, for example? Anyone? Not likely. The editors picked this for illustrative purposes because their Rankine Cycle experience comes from the nuclear and coal-fired plants home to large, hydraulically actuated steam valves and big staffs with SMEs for virtually every piece of equipment.

Before the Steam Turbine Users Group was launched in 2013, the major gas-turbine users groups may have dedicated half a day to steamers. STUG enabled owner/operators to drill down on important steam-turbine (ST) topics, like actuators, that weren’t covered previously because of time constraints.

Actuator inspection and overhaul was on the agenda for STUG 2016 and then again in 2017. If you’re a neophyte and don’t understand why this subject would be discussed two years in a row, by the same company (MD&A), you ask someone on the steering committee.

Here’s what the editors were told by a committee member with decades of GE steamer experience: Back in the days of “big steam,” he said, GE, the dominant turbine supplier, made its own actuators, which might have run for 30 years with little or no maintenance. In the combined-cycle era, Bosch Rexroth AG has supplied the majority of actuators for large steam valves and those must be overhauled every five to eight years.

Some actuator designs have specific issues that require close attention. For example, Rexroth actuators for Toshiba steam turbines are very large and oriented horizontally creating wear points that might not be found in the vertically mounted actuators on GE machines.

In the mind of this committee member, at least, actuators for turbine valves may be the most important “forgotten” component in a steam plant. Many problems, he said, can be traced to water ingress and maintenance inexperience. At his company, in-service failures and numerous servo and solenoid issues that had occurred when station O&M personnel were charged with maintaining actuators in-house have been avoided by contracting the work to a specialty shop.

But, the turbine expert cautioned that there are no guarantees when it comes to actuator reliability. Inspection and soft-parts replacement, which typically are scheduled during steam-turbine minor inspections, are done at intervals of about five years—a long time given the wear and tear traced to today’s demanding cycling requirements.

Because you don’t know exactly what you’ll find when an actuator is dismantled for inspection, be sure the overhaul partner you select can assure the ready availability of parts—unless you have a back-up set of actuators, as some owners do. Scuttlebutt suggests that getting parts from Rexroth, a German company, can be challenging. However, most users are likely to agree that Rexroth has the best actuator on the market today for steam valves.

To learn more about what owner/operators can do to minimize actuator issues, the editors spoke with MD&A’s Anthony Catanese, an engineer on the front lines of the company’s Ohio overhaul shop and the SME invited to speak at STUG 2017.

Actuator performance and lifecycle are influenced most by the cleanliness of the hydraulic fluid and your ability to restrict water ingress, Catanese said. Varnish presents a double whammy: It can plug the 4- and 10-micron filters for the servos, the actuator’s “brain.” Plus, it can combine with oxidation products produced during the degradation of the hydraulic fluid to form rust and varnish that inhibits actuator operation and may reduce spring life.

Given the importance of actuators and how easy they can be to forget in the daily crush of plant activity, consider assigning responsibility for them to one person in the O&M department. There’s not that much to do except keep after the few recommended activities for relatively few valves—eight in the case of a GE D11, an integral part of the OEM’s 2 × 1 and 3 × 1 combined cycles. Those plants typically are equipped with two each stop, intercept, control, and reheat valves.

When scheduling D11 overhauls, Catanese notes that some customers have opted to inspect and refurbish two valves every year to level both cost and outage time on an annual basis. Most often only about a week or two of scheduled shop time is required for the basic “open/clean/close” process and replacement of soft parts for a full set of eight actuators. An incoming inspection report with shop recommendations is generated shortly after actuator receipt. Plant personnel are invited to verify the report’s findings, discuss the recommendations, and witness testing after work is complete.

Of course, the technician assigned responsibility for actuators should be looking at them periodically when out in the plant. One of the first signs of concern often is leakage out of the packing-gland telltale weep hole. If borescope examination of the spring reveals moisture or rust, maintenance should be scheduled soon.

Moisture causes rust which can cause broken springs which, in turn, score the shaft and promote increased leakage. Plus, moisture can accumulate and contribute to the failure of springs on vertically mounted actuators. As a stop-gap measure, consider removing a breather vent and using dry shop air to pressurize the actuator, thereby preventing water/steam accumulation in the spring can.

Given the problems with varnish and moisture ingress that can arise over an actuator’s lifetime, it makes sense to spend time at the design stage to select the optimal hydraulic fluid for the service. If problems arise in service, give thought to replacing the fluid with one better suited to your application.

Finally, when your actuators leave the shop, be sure they are properly crated for shipment and possible long-term storage and secured in an upright position.

The speaker making the first technical presentation at the 2019 meeting discussed damage to the first three stages (blades and diaphragms) of his steamer caused by what he termed “magnetite throw”—a way of describing solid-particle erosion. An attendee mentioned that strainers were added to bypass valves at his plant to protect the turbine against such damage but he couldn’t contribute operational information to testify to the efficacy of this approach.

Trying to get meaningful discussion going early, a member of the steering committee asked attendees: “What’s the correct way to test the emergency overspeed trip?” He said the OEM had over the years assisted in checking the functionality of the overspeed trip. Recently he had heard that GE was writing software into the Mark VI to confirm trip operability without physically shutting down the machine. No one offered a comment.

A participant representing a 2 × 1 combined cycle said one of his plant’s heat-recovery steam generators (HRSGs), on an all-volatile treatment program, was showing high silica readings—and they were increasing over time. An attendee suggested that drain valves might not be operating properly. The affected user was urged to post a question on the HRSG Forum on the Power Users website. That online forum is chaired by Bob Anderson, chairman of the leading user group serving HRSG owner/operators, the HRSG Forum with Bob Anderson.

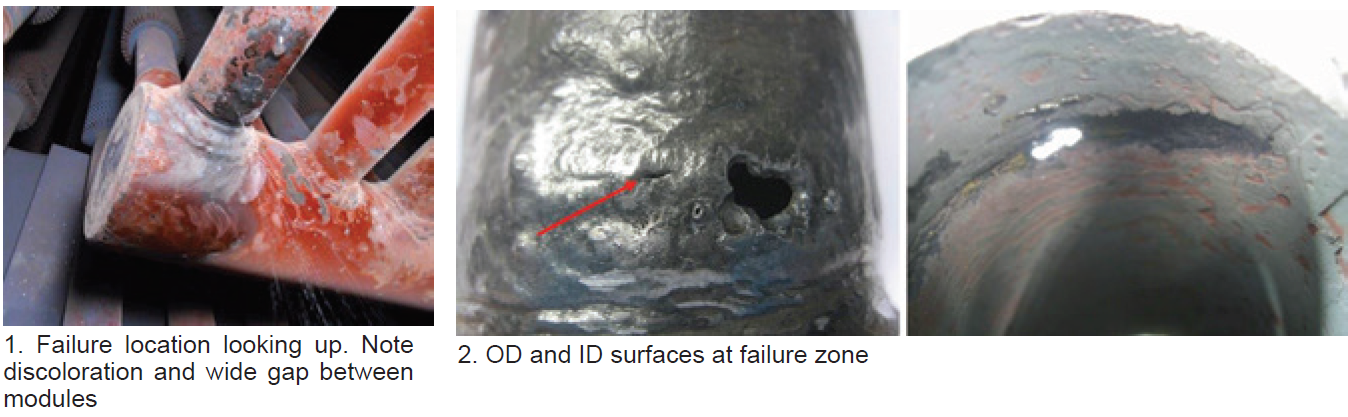

Valve seat delamination. The session moved on to a user describing damage suffered by a 262-MW D11 turbine at a 2 × 1 F-class combined cycle because of seat delamination associated with HRSG steam valves. The clue that something was amiss: Following a routine valve test, operators recognized that throttle pressure had to be increased by 70 to 80 psi above “normal” to maintain desired output—symptoms consistent with possible steam-path fouling or damage.

After weeks of data monitoring and analysis involving personnel from the owner/operator and OEM, a two-week outage was taken. Delamination of stellite from the seats of HRSG steam valves was confirmed by investigators and a borescope inspection of the turbine HP inlet revealed significant damage to the first-stage nozzle block and buckets.

Three run-versus-repair options were considered for the steam turbine:

-

-

Repair now (reliability outage). This lowest-risk option would require extending the current outage by six weeks and would result in significant unbudgeted expenses. Plus, the potential for additional discovery could add to both the time and cost of the outage.

-

Run short and repair when new buckets arrive. This would permit increased time for planning the optimal outage. However, the recommendations by experts would include a reduction in steam pressure (reducing output by about 12 MW) and no cycling of the unit offline. Plus, there is a risk that unidentified cracks might propagate.

-

Run until the major maintenance outage planned for spring 2019. Essentially the same pros and cons of running short, except a higher likelihood of cracking and damage because of the longer time between the outages.

-

Recommendations made to station management was to run until the spring 2019 major and order new buckets and diaphragms from GE for the first four stages of the unit. Important, too, was to monitor the unit for noticeable changes in operation that would indicate additional damage. Also recommended was initiation of a fleet-wide program to inspect and replace similar stellited valve parts and assemblies.

L-0 experience. A user discussing the design, operation, and maintenance of late-model L-0 buckets suggested that plant personnel track blade condition and failure probability over time to answer questions posed by corporate financial staff regarding operational risk. He reported finding indications on six L-0 blades extending from 0.25 to 0.33 in. from the trailing edge. One bucket was found with a 1.25-in crack starting in an area impacted by erosion.

An EPRI presentation complementing this experience urged station personnel to identify and track locations of erosion and to identify the source of the water. The speaker said erosion is heavily impacted by the angle of droplets hitting the bucket. He added that liquid droplet erosion can be found on leading and trailing edges on last-stage blades while operating in normal and off-design conditions.

The speaker encouraged the development online monitoring and inspection tools to identify damage on rotating equipment and to track the progression of LSB erosion. It was said that plants operating baseload can avoid erosion problems by using titanium L-0 titanium blades.

The topic of operating intervals between minor and major steam-turbine inspections was brought before the group. One user said he had two turbines running 80k hours to majors but said this might not be a time-based function for at least some machines. Depending on how your turbine operates, he said, you might want to schedule inspections based on operating hours adjusted by a starts factor. One practical suggestion was to check steam-turbine valves during 32k gas-turbine majors.

More on valves. The steam-turbine main stop and control valve presentation by an offshore user is especially valuable for its thoroughly labeled design and construction drawings and notes on how the valves operate. This introductory material facilitates understanding of the valve problems discussed in the remainder of the presentation. Used alone, the design and construction slides could serve well as a lunch-and-learn presentation and/or as a pre-outage primer for those involved with steam-turbine valve inspections.

Valve problems discussed by the presenter included the following:

-

-

Valve sticking during operation/testing.

-

Control valve closes during test but opens again.

-

Stop valve closes during test but opens again.

-

Turbine rolls off turning gear when stop valve opens.

-

Stop valve over-travels during closing.

-

Possible causes associated with the stated valve problems:

-

-

Oxidation buildup on the bushing/stem section.

-

Oxidation buildup on the balance-chamber section.

-

Valve internal damage.

-

Actuator issues.

-

Sticking problems with steam valves are mentioned frequently in STUG meetings. This user’s data indicate why: He said the number of times control valves did not close below 95% open while performing online daily testing numbered six during a calendar year for one of his turbines, nine for another, and 10 for the third.

He then illustrated by way of several photos the valve dismantling procedure typically used to gain access to address the cause of the sticking problem. For the valve shown, there was oxidation buildup on the balance-chamber section—between the outside surface of the control-valve and the balance chamber.

The measured clearance at one location was 1 mil, not even close to the design clearance of 19 mils. Clearances before and after cleaning were provided at seven points along the disc’s path from close to open and vice versa. Clearances after cleaning were 18 or 19 mils at each location.

The root-cause analysis provided an interesting result. Poor steam chemistry was an early suspect, but all documentation received from the laboratory indicated that steam quality was perfect. What many readers may not know, the presenter said, was that the 12-chrome material used by GE in its steam-turbine valves has a short oxidation life—typically two to three years.

And, as you might have suspected, valve tests were not being performed daily and the valve operated in the full-open position for months—against the OEM’s recommendation and a cause of a more rapid rate of oxide buildup than normal. Daily testing would have helped to break up/remove the oxide layer forming and keep the valve operating freely for a longer period.

Three short presentations with both user and supplier participation addressed various aspects of cyclic-operation effects on stop/bypass valves designed for baseload service. The valves discussed feature a wear-resistant stellite inlay on the stem. Historically they operated reliably (no stem failures) with maintenance intervals of 24k EOH (equivalent operating hours). Stems were replaced at that interval because of erosion in the inlay region and/or bending at the threaded end of the stem that engages the stop-valve (SV) bypass disc.

But the wear and tear contributed by the shift to intermediate/cyclic operation dictated a change from traditional thinking. As a first step, a high-temperature diffusion coating process was implemented to increase the resistance to SPE (solid particle erosion) of the valves, which were manufactured with stellite 6 weld inlay in the erosion region of the bypass disc skirt. The coating increased to 130 hours the service interval for SVBP valves.

Note that service hours here are calculated by adding the SV bypass pre-warm hours and SV bypass online hours. As a frame of reference, consider that in baseload operation the SVBP valves might accumulate about 60 service hours during a 24k EOH maintenance interval, but in cyclic operation, with more hours in full-arc mode (throttling on SVs rather than control valves), that number might increase four-fold.

Manufacturers have responded with upgraded valve designs to improve the resistance of main-steam turbine stop valves to SPE. These would increase maintenance inspection intervals beyond the 130 hours provided by the diffusion coating. A non-OEM supplier presented on its design, compatible with legacy system requirements, noting that a redesign does not eliminate the underlying problem—solid particles released in the boiler—rather it reduces the effect particles have on valve components.

The OEM also offers an improved erosion-resistant design for the D11 fleet of stop valves currently being inspected on an 18-month interval. The design modification, it was said, incorporates a 50-deg seat/disc angle and changes the internal steam flow characteristics to redirect the particles away from the valve stem during throttling and high steam-flow velocities. In the design described, erosion occurs on the valve pressure-seal head assembly, which is hardened and reportedly erosion tolerant.

Given the recent valve developments, the presenter said his company has two cost options to consider:

First, it can perform stop-valve maintenance with outages at 130 SVBP service hours and replace steam-valve wear parts without inspecting the control, reheat, or intercept valves. At the following interval, the valve outage would include maintenance on the steam, control, reheat, and intercept valves. This would involve purchasing a set of spare stop-valve subassemblies and rotating of the spare assemblies into stock as repairable items. The repair of spare SV subassemblies would be done on straight time during off-peak shop hours.

Second, retrofit the stop valves with an improved design that would allow longer maintenance intervals and return to a traditional maintenance cycle with all valves inspected and repaired. Note that the second option eliminates the stop-valve-only outage required by the first option.

“D11 Main-Steam Lead Piping Cracks” is a timeless presentation that all O&M personnel should consider reviewing. The detailed case history begins, as you probably would expect, with deck-plates personnel noticing a small steam leak—in this case, in the HRSG steam supply line at the tee where it splits to go to the turbine’s two main-steam stop valves.

The steamer was taken out of service, insulation removed, and the pipe inspected visually. Cracks were found at the tee-to-reducer weld on one side of the pipe. The 12 × 14 reducer was removed. Then the tee, and the piping on the turbine side of the reducer, were checked visually. Of course more cracks were found: How often do you find only one?

A crack was discovered on the inner wall of the tee at the horizontal-to-vertical transition. It was ground out and a penetrant inspection confirmed it had been removed. While NDE technicians were onsite, PT was conducted at the bottom of the tee, at the low-point drain junction. More cracks were found there. The still more cracks were found in the exposed sections of the steam piping. The result: The tee and 12 × 14 reducers on either side of it were replaced. Still more cracks were found later in several welds, including a couple of through-wall cracks.

An engineering review of system history was conducted. The piping had been exposed to approximately 730 startup/shutdown thermal cycles since COD, plus nearly a thousand transitions from 2 × 1 to 1 × 1—likely more severe transients than designers would have expected.

No PM records having being found, investigators concluded that inspections of main-steam-system welds had not been conducted after plant construction—perhaps because historical industry experience suggested this was a low-risk system. They also concluded that the root cause of the cracking was water intrusion.

Supporting this conclusion was that the steam-seal spray-water control valve and associated automated blocking valve had suffered erosion damage and/or seat degradation. This was already known and the unit was operating with the steam-seal spray-water manual isolation valve closed until an outage opportunity.

The leaking valve allowed water to enter the main-steam piping. During normal operation, the leak-by would have flowed to the steam-seal header, where drains removed it from the system. Erosion across the steam-seal spray control-valve seat likely was the result of excessive cycling. The seat was replaced.

The RCA investigation dug into the details, confirming that the cause of cracking in the main-steam system was thermal fatigue crated by cool water inadvertently entering the pipe while the unit was online or shortly after shutdown. Leaking valves in the steam-seal spray-water system were the source of the water. The investigation also determined that valve operating logic, the PM strategy for the valves, and startup procedures/testing for leaks all required improvement.

Engineers then set about creating a list of action items, as suggested by the RCA, to prevent a recurrence of the problems identified. The list included the following:

-

-

Install skin-temperature thermocouples at select locations and collect real-time operational data to support ongoing analysis.

-

Obtain additional samples from the full circumference of failed pipe to support additional analysis. Also, try to date the failure using the oxide layer.

-

Evaluate the current PM strategy for high-energy piping systems, giving consideration to reducing inspection intervals and expanding the inspection boundaries.

-

Some of the actions taken to date include these:

-

During minor and major steam-turbine outages, a robotic inspection of the main-steam piping adjacent to the valves will be performed.

-

An annual PM will be conducted on the steam-seal attemperator valve to check for leak-by.

-

Other units in the company’s fleet will be inspected similarly. Thus far, some cracks were discovered on another unit at the same site.

-

Finally, the experts believe cracking initiated about seven years before the steam leak was noticed by deck-plates personnel. A similar experience at another plant was reported earlier in CCJ.

“Lessons Learned to Shorten a Steam Turbine Major and Valve Outage,” has value to most, if not all, plant and headquarters personnel assigned to ST outage planning—especially those who haven’t been involved in this exercise previously. It is based on one owner/operator’s experience, so all points made might not apply to your specific situation.

It begins by suggesting both the responsibilities of personnel managing the outage, and the progress reviews and discussions among the parties that should be conducted, to ensure success. Next comes a slide on how/why to perform a steam-plant audit, which focuses on performance losses—recoverable and unrecoverable—attributed to both the thermal and structural condition to the steam path. The audit enables informed decision-making on components/parts that should be repaired or purchased new.

The speaker said that another benefit of collecting data for the steam-path audit is identifying the actual rotor location within the stationary components. This information may prove invaluable later if realignment is necessary.

Other lessons learned/best practices that you might find useful include these:

-

-

If your steamer is a D-11, purchase or repair decisions will be required for dished diaphragms. Suggestion is to purchase ahead of the outage new diaphragms for stages identified with a high risk of dishing (one to five and 12 to 16 in the case presented) and send the dished ones removed to a third-party vendor for restoration and use in a sister unit.

-

Consider using a third-party vendor to supply and install packing and spill strips, and to do laser alignment. For the seal work, a contractor with a portable machine shop to support field fit-up activities might be your optimal choice.

-

Arrange for turbine-deck storage racks and onsite machining to support diaphragm activities. The storage racks optimize floor space and minimize the use of a crane to move diaphragms between the time they’re pulled out of the machine and reinstalled.

-

Install a temporary freight elevator outside the steam-turbine building if one is not available inside and crane access is limited.

-

Consider not flipping over the HP shell and performing necessary repairs with the casing top side up.

-

Shorten your steam-turbine valve outage by having spare valve assemblies onsite. So doing, this user reduced valve outage time from a typical 14 to 21 days to five to 10 days. Spare assemblies help reduce your valve parts inventory as well as the cost of inspection and repair of valve assemblies because they are done off-peak.

-

If there are budget concerns, the speaker suggested a low-cost option for a spare control valve consisting of just the stem and disc; for a spare main-steam stop valve, just the stem, disc, and pressure-seal head. Several drawings and photos presented in the PowerPoint provide details.

-

-

Valve seat: Buy new or lap? For those opting for the latter, recommendations were given for lapping tools.

-

Final advice: Try bars are important.

-

There are several more user presentations from the 2019 STUG meeting that you can access in the Power Users library, including the following case histories:

-

-

HP-turbine blade liberation.

-

Failure of a main-steam control valve to shut on a turbine trip.

-

KN steam-turbine fleet issues.

-

Asset preservation program using data analytics to drive steam-turbine maintenance.

-

Lessons learned during a D11 minor outage.

-

Lessons learned during the major overhaul of a 416-MW GE D8 steamer (LP section) and valve inspection.

-

“Ask an Engineer”—an open forum. This was one of several discussion sessions strategically integrated into the agenda to provide attendees feedback on topics of interest.

There was a great deal of discussion on valves throughout the meeting. In one exchange, the topic of fine-mesh stop-valve strainer baskets was brought before the group. Several users suggested their installation ahead of work planned on the steam path from the boiler outward. They will collect grinding/welding debris. But don’t forget to remove the baskets before the unit is returned to service: They can plug over time, collapse, and go through the machine.

Strainer basket rotation was cited as another problem. The group was reminded that there is a pin for correctly positioning the basket. However, several incidents of pins snapping off because of negligent work practices.

A best practice for seat inspection on a combined control/stop valve: Don’t use a penetrant because you won’t see a crack when the valve is hot.

A user recommended conducting actuator outages every six years or at every other valve outage. At his plant, actuators are removed, crated, transported to the selected shop, overhauled, and returned. Dig deeper into the topic.

Another participant opted to forego a major on his KN steamer at 120,000 hours because several colleagues said their units did not work properly after their majors.

What follows are abstracts of presentations and key points made by suppliers from the 2019 meeting—timeless content not covered previously by CCJ online or in print. The information shared here should help you decide to participate in the 2020 virtual meeting—it takes little effort, costs nothing, and you can learn so much.

To dig deeper on the topics that follow, access speaker PowerPoints on the Power Users website, which are available to registered owner/operators only. If you don’t already have a “library card,” register today. It takes only a few minutes.

“Generator Inspection Outages—Contingency Planning,” Jamie Clark, AGT Services.

Jamie Clark’s message was simple: Increased cycling of ageing gas-turbine (GT) assets, both simple cycle and combined cycle, is causing problems for owner/operators. The proof: Service providers say as much as 60% of their shop effort during outages is emergent work. “We’re running older units harder than ever,” he continued, “harder than they were ever designed to run.”

The speaker recommended that attendees follow the latest guidelines regarding periodic inspections. These have changed recently, he said. One example: The most recent OEM guidance has no reference to field removal unless prior robotic inspections dictates via findings, or operational events—such as motoring, sync out of phase, generator trips, etc—warrant.

He also suggested users do the following before the outage:

-

- Take flux-probe readings.

- Do EMI testing (refer back to the third item in the section above on user presentations).

- Conduct partial-discharge testing.

- Review reports from, and since, the previous outage to review what was not done as recommended.

Clark next discussed the pros and cons of robotic inspection. At the top of the “pro” list is that robotic inspection avoids the cost and risk of field removal/reinstall. However, findings from that inspection might suggest field removal, in which case you pay twice unless it’s possible to postpone work until the next outage.

The speaker called attention to the fact that robotic inspection equipment is a limited resource, especially with competent operators and generator specialists guiding the work. He suggested releasing robotic-inspection RFPs at least six months prior to the outage and ensuring service-provider commitments are in hand within three months of outage start.

Clark then reviewed reasons for pulling the field and explained work that can be done with the field in. The latter seemed particularly helpful to attendees. Here’s what he said regarding the stator: Minor endwinding repairs (tightening, partial-discharge damage, for example) are possible, as is belly-band tightening and possibly even core tightening—provided EL CID validation is possible.

Concerning the field, collector-ring grinding and replacement typically are possible, along with brush-rigging repairs and upgrades. Retaining-ring NDE also can be done, in addition to a few other tasks.

If it becomes necessary to pull the field, Clark reminded, be sure the proper tooling is accessible—including coupling/journal shoes, skid pan, body shoe, slings, turnbuckles, and rigging from stator ends. Don’t overlook the benefits of field extraction platforms—for 7FH2s in particular, and possibly AeroPacs. This is not “incidental equipment, requiring possibly two 53-ft tractor trailers. Cranes are another consideration: A 7FH2 field weighs more than 75,000 lb, a GE 324 field about 50 tons. How close can the crane you need get into your unit? Access is almost always an issue.

Clark continued, “So now your field is out and you’ll be shipping it offsite, what do you need to know?” Come up to speed on permitting procedures and details. Figure it will take a couple of weeks to get a permit and line up trucking for the optimal route. Be aware of the permit time required and on-road time, the speaker said, advising that it’s rarely a good idea for an owner to manage shipping.

Doing field repairs? Figure seven to 10 days minimum, 30 days maximum for these typical repairs:

-

- Main-lead repair usually requires a No. 1 coil (both poles)—a partial rewind. But keep in mind that if you opt for this plan, the remainder of the field is “old.”

- Crossover repairs may require a full rewind.

- Slot armor delamination requires a full rewind.

- Turn shorts usually indicate a global condition: Rewind.

An exchange field might be the best course of action if operating commitments are firm. Keep in mind, the speaker said, that while all 7FH2s and 324s are the same mechanically, they can be different electrically—for example, in numbers of coils and turns per coil, etc. A few points to remember: Only accept an exchange with current high-speed balance and at-speed flux probe data, no turn shorts, high-quality vibration data, and assurance of interchangeability.

If field removal is in your plan, think about what stator repairs are prudent. Clark concludes his presentation with recommendations for rewedging, repairs to endwindings and connection rings, and a complete stator rewind. The last typically takes between 20 and 35 days, but may go to 12 weeks if bars must be replaced and they’re not available off the shelf.

“Rotor Turn Insulation Failure,” Tyler Foutz, EthosEnergy Group.

Tyler Foutz’ short presentation concerned a rotor with 22k hours of run time that was exhibiting intermittent vibrations and flux-probe data discrepancies. Turn shorts were suspected and confirmed. The retaining rings were removed and endwindings inspected. Decision was to rewind. A root-cause analysis confirmed insulation failure and side-wall interference. Repair quality was confirmed by high-speed balance/flux probe.

“What You Need to Know About the New IEEE Standard to Extend the Life of Your Existing Electrical Bus System,” Steve Powell, EBI-Electrical Builders.

Steve Powell, known to users for his insightful presentations at annual meetings, reviewed the design, construction, testing, and performance of bus systems, as established by IEEE C37.23-2015 for metal-enclosed gear. He covered voltage ratings, rated insulation levels, continuous current, rated short-circuit and momentary withstand current, short-time withstand current, and temperature limits.

Powell reminded users that isolated phase bus systems have no backup and if a failure occurs, the plant will be offline until the bus is repaired. He urged attendees to follow the OEM’s recommended service schedule (annually during a normal shutdown or every 18 months) and to confirm what you think you see (or don’t) with EMI testing and thermal imaging. He also discussed the value of periodic offline inspection and cleaning.

“Modification of a Westinghouse Stator from Diamond Coil to Bar Design,” Andrew Adam, PE, EthosEnergy Group, and Caleb Munholand, The High-Voltage Coil Manufacturing Co.

The RFQ for a generator stator rewind stated no changes would be allowed to the nominal 54-MVA (13.8 kV) three-decades-old design except for insulation class (B to F). This stator was one of the largest diamond coils ever manufactured and the OEM and only one vendor still made the component. EEG, currently the OEM for legacy Westinghouse gas turbines and generators with access to original design prints and parameters, was the successful bidder.

EthosEnergy faced manufacturing challenges, as described in the presentation, motivating conversion to a Roebel bar design; design and manufacturing details are summarized in the slides. Because overall performance and output of the generator is largely dictated by the field, the speakers said, overall generator capability remained essentially unchanged. The new winding has the same number of turns as the original, resides in the same core iron, has the same amount of copper (or more), and has equivalent losses.

The stated advantages associated with specifying the three-turn Roebel bar design over the three-turn diamond coil are these:

-

- Elimination of top-strand heating. Temperatures within the winding are evenly distributed because of roebeling.

- Elimination of installation issues associated with the diamond-coil design mitigates significant user schedule and performance risks.

“Fiber Optic Generator Monitoring,” Derek Hooper and George P Dailey, PE, BPhase Inc.

Better techniques and instrumentation for monitoring the performance powerplant equipment are always welcome. The presenters focus on the use of fiber optics for reducing the risk of generator in-service issues caused by high core temperatures and loose wedges. The presentation includes many slides on development history for those interested in how the technology has evolved.

The stated value of the BPhase developments is the following:

-

- The core monitoring system can detect any excursion from normal core operating conditions. The data allows plant personnel to see a core thermal event in progress, enabling a controlled shutdown before serious damage occurs.

- The wedge tightness analysis system allows maintenance personnel to follow the degradation of the wedge package over time, enabling the planning of rewedging without need for disassembly or robotic inspection. This can predict coil wear through mechanical vibration and core damage through slot pounding—as the condition will be detected before significant damage can occur.

While acknowledging that fiber-based systems cannot perform visual inspections, the presenters say they can certainly reduce operational risk from wedge tightness and core-related issues, thereby reducing overall risk during extended operation as necessary.

“Generator Degassing and Purging: Best Practices for Safe Plant Operation,” Christopher Breslin, Environment One Corp.

Hydrogen is explosive, colorless, and odorless, as well as difficult to contain. Yet it has been used widely as a generator coolant since the late 1930s because its windage/frictional losses are less than for air and it has excellent heat-transfer characteristics.

It is essential for plant personnel to know and understand the hazards associated with hydrogen and that all equipment for handling and storing this gas must be certified and maintained in top condition. Finally, because purging is an inherently complicated exercise, and can be dangerous if performed improperly, all personnel involved must be well trained, non-sparking tools must be used, carbon dioxide must be readily available in sufficient quantity, appropriate safety signage must be in evidence in critical areas, and keyed lockouts must be provided for “air” and “hydrogen.”

Chris Breslin, known by users for his practical and valuable presentations, reviews primary elements of the hydrogen auxiliary system, including useful one-line diagrams, provides guidelines for the purging process and best practices for safe plant operation, and reviews requirements/considerations for automated de-gassing. Consider the presentation for a lunch-and-learn session in the plant conference room.

“Comparison of Low- and High-Frequency Partial-Discharge Measurements on Rotating-Machine Stator Windings,” G C Stone and H G Sedding, Iris Power (Canada).

The speakers are among the industry’s top experts in the partial-discharge (PD) testing of electrical equipment. They draw the following conclusions in their relatively short but informative presentation: Low- and very-high-frequency PD detection methods in machines each have very different advantages. For offline applications, it is clear that low-frequency testing is preferred because PD can be better detected regardless of where it occurs in the winding.

For online testing, of transformers for example, the very-high and ultra-high methods are preferred by users because the risk of false indications caused by noise is lower; therefore, test credibility is higher.

“Realities of Global Vacuum Pressure Impregnated (GVPI) Impregnated Generator Stator Repair and Rewind,” W Howard Moudy, NEC-National Electric Coil.

Howard Moudy may have made more presentations at user-group meetings in the last decade than anyone else—in the process covering all types of generator failures and their fixes. At the 2019 GUG conference his topic was the repair and rewinding of a GVPI stator for a 13-yr-old, 100-MVA, air-cooled generator serving a geothermal plant in Indonesia. The unit tripped with damage to the winding and core. Contributors to the failure as determined by a root-cause-analysis investigation included the following:

-

- Endwinding vibration/resonance.

- Core looseness/hot spots.

- Key-bar deterioration at the core exit—ground-wall fretting and thermal deterioration, and strand fatigue.

- Vibration transmitted from the phase-ring assembly.

The owner expressed preference for mechanical removal of the winding despite NEC’s deep experience with the generally preferred water-blasting process. Contract was awarded to a local company with NEC in an oversight role. The local firm did not have appropriate tooling for the job which NEC supplied later to enable job completion. However, other findings created uncertainties in the customer’s mind that led to replacing the entire core. A couple of dozen photos describe the work.

NEC came away from the project with the confidence in its ability to rapidly rewind/rebuild air-cooled GVPI stators anywhere in the world. In this case the time to manufacture a new stator winding and ship it to Indonesia was 38 days.

In his concluding remarks, Moudy acknowledged that the initial cost of GVPI generators is attractive but that there are maintenance concerns and limitations associated with a decision to go with GVPI. Finally, he said that with proper engineering and planning, GVPI generators can be rewound effectively to a coil VPI design that is more easily maintained and conducive to long-term reliable operation.

What follows are abstracts of presentations and key points made by users from the 2019 meeting—timeless content not covered previously by CCJ online or in print. The information shared here should help you decide to participate in the 2020 virtual meeting—it takes little effort, costs nothing, and you can learn so much.

To dig deeper on the topics that follow, access speaker PowerPoints on the Power Users website, which are available to registered owner/operators only. If you don’t already have a “library card,” register today. It takes only a few minutes.

Replacement of bushings. The focus of presentations by owner/operators was near equally divided among stators, rotors, and inspection/testing/general. One concerned the replacement of bushings on a nominal 265-MW (1980 COD) hydrogen-cooled generator that runs only four to five months annually at baseload. The well-illustrated presentation covers testing and repairs conducted to enable decision-making, issues faced during replacement (confined space, terminal plate bonded to the bushing plate, etc), and challenges post replacement—including the loss of hydrogen and a blown isophase connection.

Stator, rotor rewinds. The same user also presented on the rewind of both rotor and stator on a 65-MVA, 13.8-kV generator. Periodic maintenance testing revealed a high dc leakage value (120 microamps leakage at 1.25 times the dc value) and a winding resistance unbalance of more than 5%. Plus, rotor inspection revealed shorted turns and loose blocking.

During the rewind, one of the contractor’s staff got a drop of glue in his eye and the use of goggles was made mandatory. After the rewind, the endwinding was re-blocked. Return to service was not smooth, the unit tripping within one second after start attempts. The gremlin: The shorting cable installed on the CT circuit was not removed after generator testing.

Then issues surfaced in the excitation system. Personnel found one diode wired incorrectly on the rotating diode bridge. It took three days to rewire the diode bridge.

EMI testing. A hot topic in generator circles continues to be electromagnetic interference (EMI) testing to detect failing electrical connections—in particular, those inside generators and bus systems. Two significant presentations were made on the topic at the 2019 GUG meeting, with the dialog continuing at the 2020 conference beginning next week.

EMI has been used since the 1950s, possibly earlier, to locate defects in power lines that cause radio and TV interference. Application to powerplant equipment began in about 1980, motivated by the work of several Westinghouse engineers who found that energy discharges in electrical equipment—such as arcing and partial discharge—produce a broadband high-frequency emission pattern. The radio-frequency (RF) currents produced, the engineers said, flow in the machine neutral connection with a magnitude and spectrum signature that can be recognized and differentiated from other RF signals which may be present.

“EMSA [electromagnetic signature analysis] Training,” the first of the EMI presentations last year, is highly recommended by the editors for the background it provides. A significant portion of the presentation is devoted to work done since 2015 by National Instrument and a major utility to develop an affordable instrument for “continuous” monitoring of EMI in generators and transformers.

Fast forward to today, the utility has installed the instrument developed on more than 80 generators and 120 transformers in its fleet. A full-spectrum reading, taken about every 15 minutes, produces data for trending.

The presentation is particularly valuable for what the utility has learned over the years. Here’s a summary of that experience across the four frequency bands of primary interest:

-

- 30 to 500 kHz. In this region, diode and SCR/Thrystor firing patterns are seen and the following issues can be identified, among others: dirt contamination on diodes, SCRs, and Thyristors; loose excitation cables/connections; missing SCR firing patterns, etc.

- 500 kHz-5 MHz is where issues in the core slots of motor and generator windings likely would be identified—including loose wedges, slot discharge, and back-of-the-core arcing.

- 5 to 30 MHz. Issues associated with motor or generator endwinding structure are likely identified in this frequency band—including loose winding basket, corona in the endwindings, broken strands, etc.

- 30 to 100 MHz. In this frequency band, issues associated with the generator output bus and isolated-phase bus generally are found. Look for cracked insulators, insulator contamination, water intrusion, etc.