Perhaps the best way to think about how to respond to NERC-CIP-9, which seeks to protect the bulk electric system from a coordinated attack on smaller, low-impact assets which can result in a catastrophic event on the interconnected system, is this: Rather than think in terms of complying with the new standard, think about defending yourself in court after a malicious attack through your facility.

The panel of specialists in the second of three NAES webinars on the subject put it a bit more gingerly: What you should do vs what you must do. Example: Regarding remote access by vendors, a site must determine who, how, and where vendors access devices and have a program to document its methodology for remote access controls. What should you do? Suggests the panel, automate the detection of vendor access, alarm occurrences of such access (to the control room, for example), and long and record all sessions in which vendors made changes to the system.

That might not sound so terrible until you realize that some of your primary vendors might have fifty people authorized to access equipment on your site remotely.

Here’s another example: A site must have procedures to disable access to the network boundary (not the device) and physical or electronic methods for removing access. What you should do is:

- Have granular controls per vendor

- Test and validate controls per vendor and cyber-asset

- Have methods for terminating a previously authorized session (even mid-session)

- Form a global access management team with a two-man rule

There are several of these examples available in the recording of the webinar.

The panel concedes that some of the key language in the draft is fuzzy, but NERC will be making modifications during the 18 months owner/operators have to comply. The term asset, for example, is not explicitly defined in 003 (unlike in 002); thus, it is difficult to define the scope a site implementation. Another term, the asset boundary, which experts call a “term of art,” is not a NERC-defined term.

What should sites do know? That’s difficult to say, but be prepared for today’s “shoulds” to become tomorrow’s “musts.”

Access CCJ recaps and recordings of the three webinars here:

Just as plant owner/operators should “be prepared for an ever-changing cybersecurity attack surface, they should also plan to control their own destinies with respect to regulatory compliance,” noted a panel of experts during a webinar hosted by NAES Corporation titled “NERC CIP-003-9: What you need to know about the new requirements and how to comply.”

If you are one of the 72% of organizations who don’t have full visibility into their control-system supply chains, the 47% of organizations who don’t have the internal resources to manage operational technology (OT)/industrial cybersecurity (ICS) incidents, or the 75% of ICS networks successfully attacked by malicious external actors, don’t fret. NAES NERC/CIPS Services, and its partners, Network Perception and ABS Group, also scheduled two follow-on webinars which deep-crawl through the weeds of this latest compliance challenge.

For those of you whose plants are categorized as “low-impact” BES (bulk electricity system) assets and don’t think this latest standard affects you, think again. “NERC is coming for you,” these experts stressed.

One of the major implications of CIP-003-9 is that “plants should no longer rely on their control system OEMs for compliance or security [two different things].” “There are limits to risk transfer,” they say. Owner/operators, and other “responsible entities” (as referred to in NERC language), must now seek full supply-chain visibility.

Why? For one, a malicious actor can attack all users of a specific plant software (that is, many BES assets) by infiltrating the third-party vendor supplying or servicing that software. This looms large when you consider that the vast majority of combined-cycle control systems in America are sourced from only a few gas-turbine vendors and one or two control-system OEMs (along with the skids and subsystems with PLCs and other devices from a variety of vendors networked into the control system).

“You’d be surprised how frequently control system vendors traffic through their remote access points, and how unaware plant staff are,” observed one expert. Section 6.3 of the new standard, approved by FERC in March, requires one or more methods for detecting known or suspected in/outbound malicious communications through vendor electronic remote access points.

This means plants need comprehensive remote access solutions, and perhaps a full network model. “If two hosts haven’t communicated,” you can’t know whether they could have communicated or not.” A model helps you understand what could happen, not what did happen, these experts stressed.

The ninth annual meeting of the Generator Users Group, launched in fall 2015 in Las Vegas, is an important component of Power Users’ 2023 Combined Conference in the Omni Atlanta Hotel at CNN Center, August 28 – 31.

The ninth annual meeting of the Generator Users Group, launched in fall 2015 in Las Vegas, is an important component of Power Users’ 2023 Combined Conference in the Omni Atlanta Hotel at CNN Center, August 28 – 31.

Technical program for the upcoming meeting was developed by the all-volunteer steering committee of engineers and managers identified in the sidebar—many with decades of relevant experience. A preview of the presentations scheduled for the week beginning August 28 follows.

GUG steering committee, 2023

Chair: Jeff Phelps, consulting engineer, Southern Company

Vice Chair: Craig Spencer, director of outage services, CalpineDave Fischli, director of engineering and programs, Duke Energy

Andres Olivares, generator specialist, Calpine

Joe Riebau, director of compliance and electrical engineering, Constellation Power

Jagadeesh Srirama, senior electrical engineer, NV Energy

Doug Coleman, generator engineer, Duke Energy

Expectation is that most of this year’s presentations will be made available to owner/operators through the Power Users website a few months from now—except for those made by GE and Siemens-Energy. Access the GE PowerPoints at https://mydashboard.gepower.com; the Siemens-Energy presentations on the company’s Customer Extranet Portal, https://siemens.force.com/cep.

Slide decks from 2022 and earlier meetings already are accessible to registered users. If you are not registered, sign up now at www.powerusers.org: It’s easy and there’s no charge.

Monday, August 28, begins with a training workshop on stator endwinding support systems, presented by Siemens-Energy, GE, and NEC, which ends with lunch. The afternoon program is dominated by presentations from users and EPRI. Here are the highlights:

- Generator sweep frequency response testing.

- Generator monitoring.

- Generator inspection/data app.

- Case study of a generator ground fault after two years in service.

- Stator winding ground fault: collateral damage from a core-iron hot spot.

- Generator case-history findings.

- Brushless exciter experience.

Tuesday, August 29, features presentations by vendors and consultants until the afternoon break, when owner/operators take over the podium. Yet another preso on endwinding support systems kicks off the program, with Jason Sinkhorn of EME Associates focusing on design, philosophy, and construction. Following Sinkhorn are:

- Brushless exciter system overview by Daniel Besmer and Jacques Leger of Electric Machinery.

- Advances and case study on EMI monitoring by Consultant Kent Smith, representing Cutsforth.

- A rapid 7A6 field rewind case study by engineers from MD&A.

- Turbogenerator rotor rewind: Maximize the value of maintenance, Rob Rettler, Toshiba America Energy Systems.

- Generator fields: Testing, evaluations, and repairs, Jamie Clark of AGT Services Inc.

- Generator high-speed-balance case studies by Keith Collins of MD&A.

- Generator rotor concerns, Howard Moudy, NEC.

- Core restacking in the horizontal position, Rhett Smith of EthosEnergy Group.

- Circulating currents and overheating issues associated with isolated-phase bus ducts, Mohsen Tarossoly, EBI.

Topics of the user presentations are:

- Generator protection auto-trip philosophy.

- NERC compliance challenges.

- Excitation-system upgrade and replacement case history.

Tuesday’s technical program ends at 5 when the three-hour Vendor Fair begins.

Wednesday, August 30, features presentations by Siemens-Energy in the morning and GE in the afternoon.

The Siemens-Energy lineup:

- Issues and maintenance practices for (1) gas (air/H₂) coolers, (2) hydrogen gland seal rings, (3) hydrogen seal-oil systems, and (4) generator bushings.

- Generator additive manufacturing.

- Fleet major findings.

- Changing operating regime

- Stator core inspection and repair experience.

The GE lineup:

- Model 324 phase connection cracking—including TIL-1965/1966 retirement and its replacement with a new TIL.

- Model 390 phase connection cracking, with a focus on RCA progress.

- Collector brush design history and maintenance best practices, plus RCA progress and supply-chain status.

- TIL-2119, “Generator Pole-to-Pole Connection Replacement.”

- Velomitor radio interference.

- CTS hydrogen leakage PSIB: Reinforce replacement of new design.

- RCA of 89SS switch failure.

18Z/21Z aluminum spacer: Risk with potential stator rewind. - Stator-bar putty repair.

- Stator-core integrity/aging factors.

- Fault event investigation.

- Fast stator rewind: Its applicability and benefits.

Thursday, August 31, features user presentations and open discussion. Here are some of the topics identified before press time:

- AeroPac I main lead failure.

- Blocked rotor cooling holes.

- Collector flashover event and related supply-chain issues.

Keep in mind that meeting information is updated regularly on the GUG pages of the Power Users website at www.powerusers.org. Alternatively, come up to date when you register for the conference.

With the 2023 Generator Users Group (GUG) approaching August 28-31 in Atlanta, part of the greater Power Users Combined Conference, reviewing some of the content from last year’s meeting should encourage you to attend or send someone from your organization to experience this valuable content in person. Presentation abstracts below are based on information available only to end users in the slide decks posted at www.powerusers.org. Those seeking deeper dives into specific topics should note the presentation titles in italics at the end of each summary and access the source material on the website.

- See part one of this GUG recap series here.

- See part one of this GUG recap series here.

- See part three of this GUG recap series here.

- See part four of this GUG recap series here.

Considerations in the rewinding of stators

Gary Slovisky, NEC’s director of generator services, began by saying that understanding “why” a rewind must be performed is an important first step. For example, is it because of age/deterioration? Or might it be design weaknesses and/or unit idiosyncrasies?

Understanding “what” also is very important, he said. What design or unit idiosyncrasies are problematic or can be improved? What rewind components are critical to quality and can they be reused or upgraded, or should they be replaced? Slovisky then identifies components generally reused as part of the rewind. Next step: Stator-core testing and requalification using El Cid and Core Loop or Full-Flux tests.

Focus of the presentation is on GE’s 7FH2 generator. The slide deck likely would be of use to anyone with responsibilities relating to stator rewinds. It offers good general information on the following:

- Rewind decision.

- Specific problems—such as dry ties, vibration/resonances, rigid phase leads.

- Endwinding redesign and modification.

- Pros and cons of the various stator ground insulation systems.

- Tangent Delta testing.

“Effectively Rewinding High-Voltage Generator Stators”

Better core monitoring may allow an increase in maintenance intervals

Derek Hooper, president, B-Phase, describes a new technology which promises to give local temperature and stator-bar motion in the slot during operation. Objective is to extend the time between maintenance outages given the availability of more meaningful information. Users may find it beneficial to follow the development of this technology at future GUG meetings.

The challenging nature of recent core issues on H₂-cooled generators

AGT Services’ Jamie Clark, well known to users for his deep knowledge on the nature and repair of various generator issues—such as loose cores and low insulation values on stator and field windings in large hydrogen-cooled machines—opened his presentation at the 2022 GUG meeting with this statement: “The past 24-36 months has been very ‘eye-opening’ with respect to GE’s 7FH2 generator fleet.”

AGT Services’ Jamie Clark, well known to users for his deep knowledge on the nature and repair of various generator issues—such as loose cores and low insulation values on stator and field windings in large hydrogen-cooled machines—opened his presentation at the 2022 GUG meeting with this statement: “The past 24-36 months has been very ‘eye-opening’ with respect to GE’s 7FH2 generator fleet.”

He then discusses why four planned minor outages morphed into majors during the spring 2022 outage season. AGT Services was awarded two of the four projects—each requiring a full stator rewind and field exchange. One reason for the dramatic turn of events is simple arithmetic.

More than 5000 generators (about 60% with GE nameplates) have been built since 1995 with design stator lifetimes of 25-30 years and design field lifetimes of 10-15 years. Do the shop and personnel resources required to test, inspect, and repair, and make new windings, to keep these generators operating reliably exist—especially given the recent retirements of highly experienced engineers and technicians? There are no simple solutions.

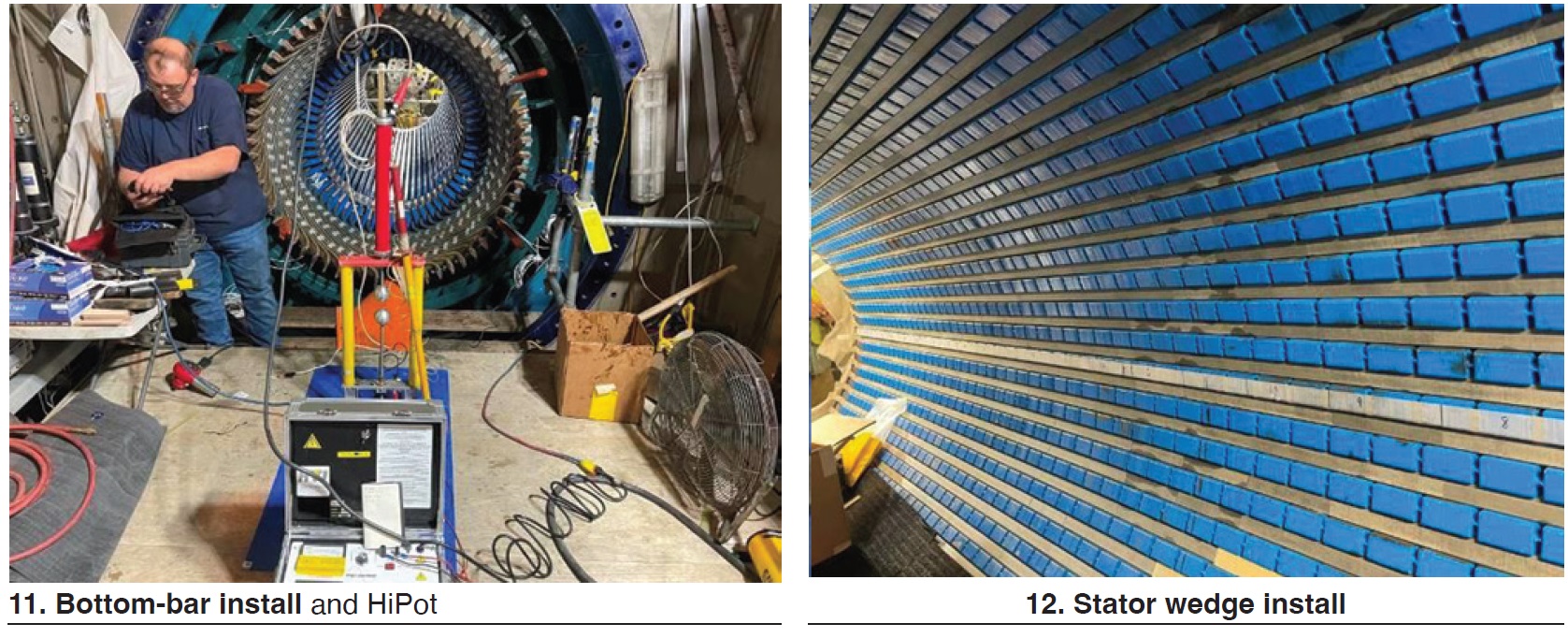

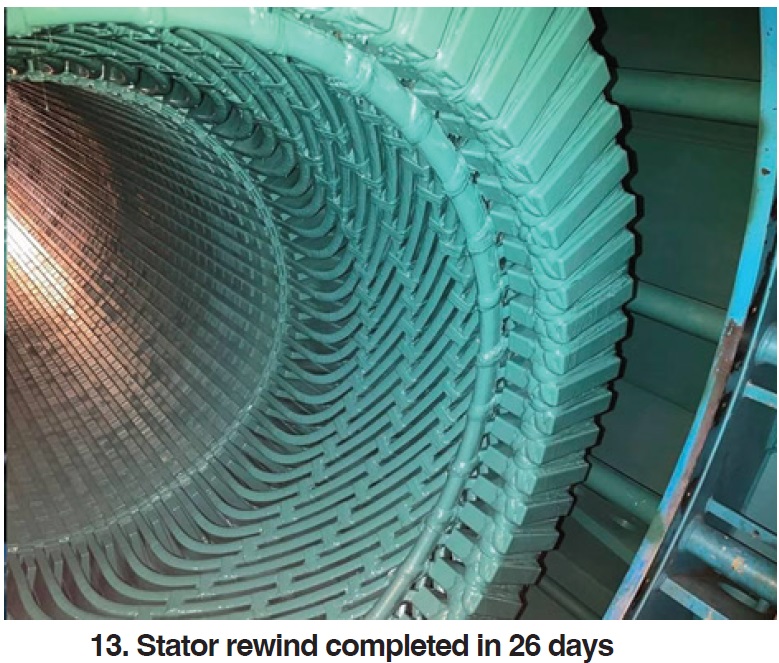

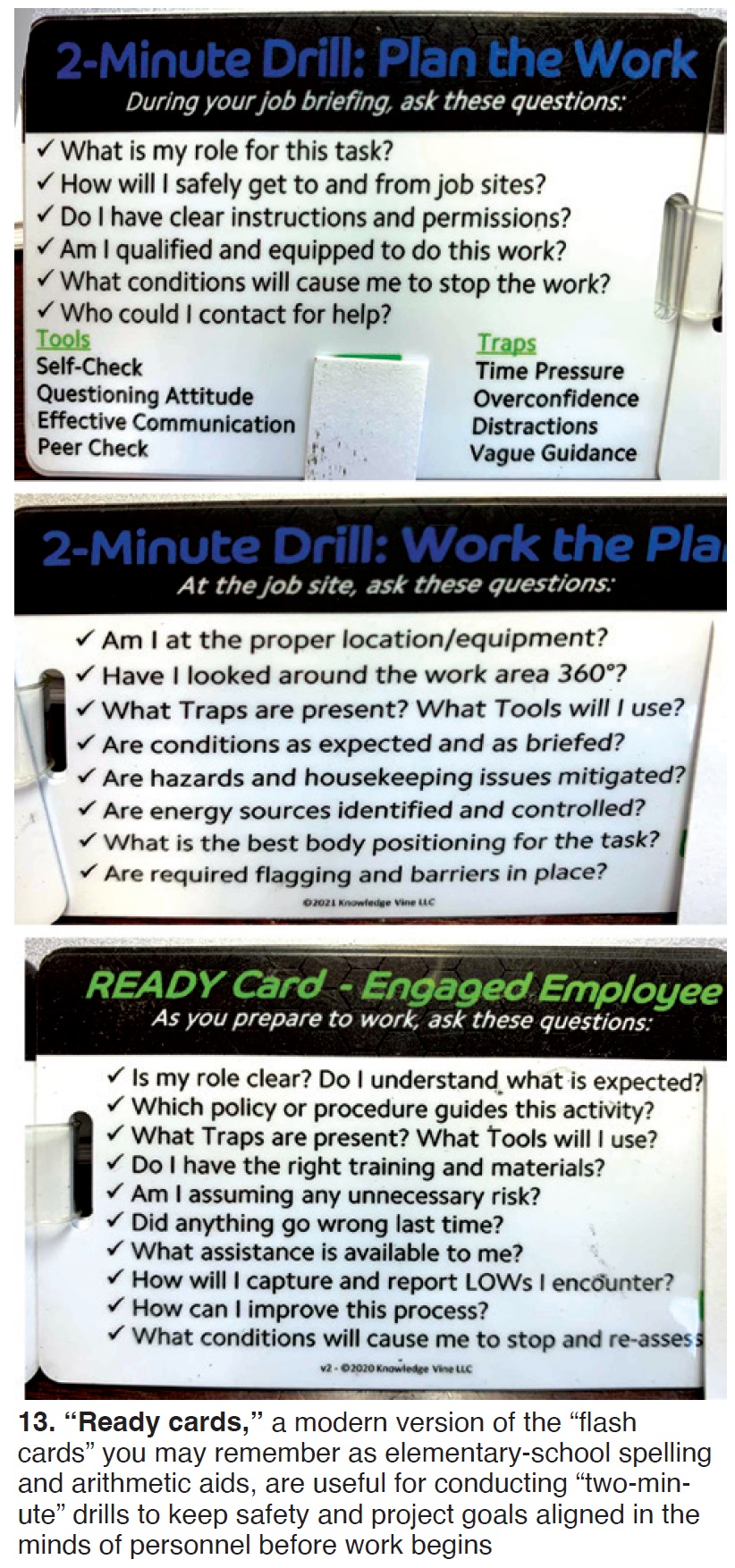

Clark outlines the work scopes for both projects completed by AGT Services and provides many photos to help define both the challenges faced and the repair work done (Figs 10-13). Think of this slide deck as a useful tutorial for those associated with generator maintenance.

“7F Generator Issues – Minors turn to Majors”

Generator literature searches

Jane Hutt’s recent passing leaves the generator community short a guiding light to technical information resources on these rotating machines. Hutt’s presentation at GUG 2022 was her last and quite possibly her best effort on the subject.

By way of background, Hutt was the primary developer, webmaster, and site manager of the Web-based International Generator Technical Community (IGTC), which serves about 6000 member engineers, technicians, and academics worldwide involved in the design, service, maintenance, and reliability of electric generators. Plus, she was an advisor to the board of directors of the Generator Users Group, which operates under the Power Users’ umbrella.

Her slide deck offers a comprehensive, thoughtful guide for conducting an efficient literature search of the internet, industry technical societies, conferences, IGTC, and other sources. It provides excellent guidance on where to look and what information to trust—particularly on the failure and repair of generator equipment.

“An Approach to Performing Time-Efficient Generator Literature Searches”

Other presentations available through the Power Users website cover a sudden excitation increase (field), summary of fleet-wide issues, failure during pre-commissioning, and main lead failure.

With the 2023 Steam Turbine Users Group (STUG) approaching August 28-31 in Atlanta, part of the greater Power Users Combined Conference, reviewing some of the content from last year’s meeting should encourage you to attend or send someone from your organization to experience this valuable content in person. Presentation abstracts below are based on information available only to end users in the slide decks posted at www.powerusers.org. Those seeking deeper dives into specific topics should note the presentation titles in italics at the end of each summary and access the source material on the website.

- See part one of the STUG recap series here.

- See part two of the STUG recap series here.

- See part three of the STUG recap series here.

- See part four of the STUG recap series here.

Steam-path audit essential for restoring performance

Every ST/G major should include a structural steam-path audit as part of the lifecycle maintenance plan, say Neil Jones and Tim Keen, MD&A. The audit is an assessment by experienced steam-path engineers based on visual inspection of the rotating and stationary steam-path components and limited dimensional checks.

The inspection is best performed immediately after blast cleaning, but is not, caution the presenters, a substitute for nondestructive testing. Balance of slides review key inspection areas and typical findings richly illustrated through photos.

“Steam Path Audit and Lifecycle Management”

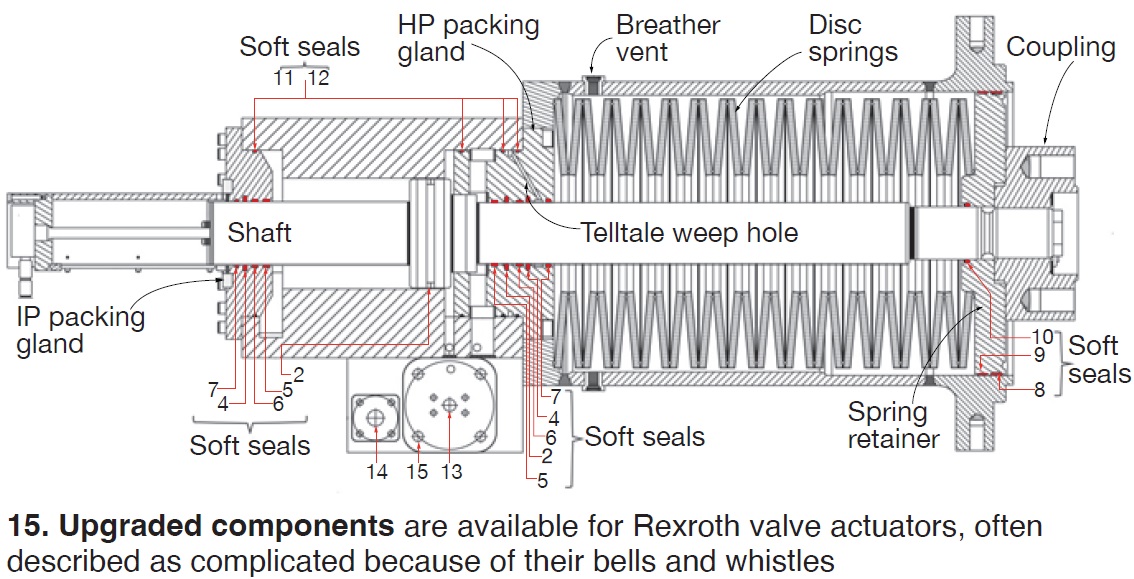

Upgrades, spares available for Rexroth actuator components

MD&A not only stocks over $1-million in spare parts for Rexroth LP-turbine valve actuators (Fig 15), but has designed and implemented upgraded components to solve customer problems and extend operating life. Anthony Catanese’s journey in slides begins with photos of common issues experienced with these actuators, then moves into design modifications for spring can retainers, pistons, packing glands, and disc spring coatings.

“Rexroth Turbine Valve Actuators”

GE addresses recent TILs, top issues

In what GE ST/G owner/operators should probably consider essential information, Matt Foreman and Paul Roche introduced the OEM’s session by addressing what they called the “top issues” (and their associated TILs). In order of appearance, they are:

- L-0 CAE dislodged mid-point sleeves (TIL 2294).

- KA 24 ICS (Alstom) steam-turbine IP rotor cracking (TILs 2052, 2205, 2230, 2315, 2316).

- Regular (daily) control and stop valve testing.

- Annual last-stage-blade inspections, now recommended for all ST/Gs.

- Finger dovetail L-0 cracking (TILs 1847, 1874).

- Critical D11 casing findings (numerous), some of which are “surprising” in units 15-20 years old.

- Moderate-to-severe main-stop/control valve (MSCV) casing cracks in less than 15 years of service.

- N2 packing-head replacement experience (TILs 1627, 1748, 1749) to reduce premature failure of the shell.

- D11 HP/IP horizontal joint leakage.

Slide decks for the Top Issues and TILs identified above are not available via the Power Users website. To access, log into your MyDashboard account on the GE website.

Is poor insulation impacting cooldown?

This is the question GE’s Peter Eisenzopf asked indirectly as he discussed results from a fleet data review of 300 ST/G units. Insulation matters is the abridged conclusion. New insulation installed during an outage may not be “high quality,” he stressed, and encouraged users to request an insulation quality study during their next GE-driven outage. The study confirmed that cool-down performance is improved by replacing current material with world-class insulation. There was not a clear answer when an audience member asked if there is a spec available for “world class insulation.”

“Importance of Insulation and Indicators of Concern” Not available via the Power Users website. To access, log into your MyDashboard account on the GE website.

With the 2023 Combined Cycle Users Group (CCUG) approaching August 28-31 in Atlanta, part of the greater Power Users Combined Conference, reviewing some of the content from last year’s meeting should encourage you to attend or send someone from your organization to experience this valuable content in person. Presentation abstracts below are based on information available only to end users in the slide decks posted at www.powerusers.org. Those seeking deeper dives into specific topics should note the presentation titles in italics at the end of each summary and access the source material on the website.

- See part one of the CCUG recap series here.

- See part two of the CCUG recap series here.

- See part three of the CCUG recap series here.

- See part four of the CCUG recap series here.

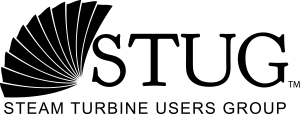

Always an ‘extra mile’ when it comes to safety

Safety is always a popular and critical topic at CCUG, evidenced by a closing presentation with ideas for promoting better work environments, including: drain-valve locations, central first-aid stations, two-minute drills to help workers think about what’s about to happen with a task (Fig 13), “ready cards” for engaged employees and empowered leaders, confined space barriers, hoses colored for service (such as red for air, blue for water), and others.

Black start using battery technology

Black-start grid support was added to this 2013-vintage 2 × 1 combined cycle in the Bay Area. Main goal is to get one of the state’s nuclear plants back online as soon as possible. This is reportedly the second F-class gas turbine site with battery black start (the first is in Louisiana) but the first at a combined-cycle facility.

You can probably imagine all the special regulatory requirements, especially for air emissions, but some of the practical considerations are worth noting, mostly focused on the limited energy that a battery can provide. In addition, this plant has to conduct functional readiness/emergency tests twice annually, and one fully black-start test every three years by Cal ISO, without violating air permits.

The 13.- MW/3.4-MWh/850-V dc batteries supply an instantaneous load of 12 MW to get one gas turbine/generator to 184 MW. Once the turbine/generator is synchronized to the grid, you “can’t go back.” Things have to start quickly, the presenter noted. Capacitors have to energize big equipment like boiler feed pumps and fuel-gas compressors (gas feed line pressure is 250 psig but the turbines require 500 psig). Another wrinkle: Batteries have to be fully charged at all times, limiting their life to five years.

“The GT synchronizes through its 230-kV line so we had to get creative about how to do that,” the presenter said.

“Battery Connected as a Black Start”

What’s keeping your insurance guy up at night?

It’s been a bad past decade for insurers and in recent years the power industry hasn’t been helping. That’s the implicit message delivered by Chris Black, Lockton Companies, who cautioned the audience that insurers will be paying very close attention to steam turbine/generators for which insurers (and owner/operators) have suffered “an unprecedented number of major losses.” Dollar amounts on specific loss events in 2021 and 2022 are listed in one slide.

Specific areas for added scrutiny include avoiding the worst-case scenario, which Black describes as a lube-oil system fire with ST/G overspeed and subsequent fire; overspeed trip testing, sequential trip validation; dc lube oil system design and testing; valve maintenance and testing; and frequency of maintenance.

Black also touched on lingering issues with gas turbines, transformers, hydrogen fuel supply systems, winterization, supply chain, and battery systems. Another cautionary word: “Your word is not always good enough—you will need proof.”

Two aux transformer failures, one plant

A 2002-vintage plant in the southeast US experienced two ST/G excitation transformer failures (two separate units) within 18 months of each other. The first was during startup, the second during baseload operation. Fortunately, spares were available for both occurrences. Presentation reviews post-event inspections, OEM-driven inspections conducted during the next outage, mitigation tools (for example, monitoring), and root-cause analysis questions.

The 10th annual meeting of the Steam Turbine Users Group, launched in Richmond in summer 2014, is a cornerstone of Power Users’ 2023 Combined Conference in the Omni Atlanta Hotel at CNN Center, August 28 – 31. Technical program for the upcoming meeting was developed by the all-volunteer steering committee of engineers and managers identified in the sidebar and accompanying photo—many with decades of relevant experience. A preview of the presentations scheduled for the week beginning August 28 follows.

The 10th annual meeting of the Steam Turbine Users Group, launched in Richmond in summer 2014, is a cornerstone of Power Users’ 2023 Combined Conference in the Omni Atlanta Hotel at CNN Center, August 28 – 31. Technical program for the upcoming meeting was developed by the all-volunteer steering committee of engineers and managers identified in the sidebar and accompanying photo—many with decades of relevant experience. A preview of the presentations scheduled for the week beginning August 28 follows.

STUG steering committee, 2023

Chair: Matt Radcliff, consulting engineer, Dominion

Vice Chair: Mark Johnson, staff ST fleet engineer, FPLEddie Argo, team leader, Southern Company

Jake English, steam turbine program manager, Duke Energy

Jay Hoffman, maintenance manager, Tenaska Virginia Generating Station

Connor Hurst, engineer, Teco Energy

John McQuerry, director of outage operations, Calpine

Lonny Simon, maintenance engineer, OxyChem

Seth Story, director of fleet mechanical engineering, Luminant Generation Services

Brandon Stewart, maintenance team leader, Southern Company

Jared Harrell, production superintendent, OxyChem

Recall that in its infancy, STUG focused primarily on GE A10 and D11 steam turbines; today it covers steamers for combined cycles made by all the leading OEMs.

Many sessions are user only. Non-users wanting to participate in a particular session must be approved by the steering committee to gain admission. Presenting vendors are allowed in the room only when it is their time to present.

Expectation is that most of this year’s presentations will be available to owner/operators through the Power Users website a few months from now—except for those made by GE and Siemens-Energy. Access the GE PowerPoints at https://mydashboard.gepower.com; the Siemens-Energy presentations on the company’s Customer Extranet Portal, https://siemens.force.com/cep.

Slide decks from 2022 and earlier meetings already are accessible to registered users. If you are not registered, sign up now at www.powerusers.org: It’s easy and there’s no charge.

Monday, August 28. The STUG technical program opens with an EPRI seminar, which runs until lunch. Discussion topics for the open forum include the following:

- ST valve diagnostics.

- Lube-oil testing and maintenance.

- The effects of flexible operation on high-/low-temperature steam-path components.

The afternoon begins with the steering committee’s Seth Story of Luminant moderating a roundtable discussion on conference expectations and “knowing our fleets.” A panel discussion on GE combined-cycle steam-turbine valves is next. Participants from three major utilities (Dominion, Duke, and Luminant) discuss historical experience plus valve upgrade options and experience with them. Three user presentations follow. One covers an IP- to LP-turbine crossover failure.

Tuesday, August 29, is all-in on vendor presentations until 4 p.m.—specifically:

- Steam-system metal-bellows expansion joints (Senior Flexonics).

- Return to service following abnormal operating events (TG Advisers).

- Boiler-feed-pump steam turbines—recent issues and challenges (EthosEnergy Group).

- HyFit (Nord-Lock Group) coupling-bolt solution.

- Turbine insulation and warming systems from Arnold Group.

- Advances in EMI monitoring, plus a case study (Cutsforth).

- Using real-time data analytics to improve asset reliability and performance (Black & Veatch).

Siemens-Energy and FPL close out the afternoon with the OEM presenting on the following topics:

- Low-load operation.

- Short-term layup.

- Hydraulic fasteners.

- Steam-turbine modernization options for combined cycles.

- Lessons learned from forced outages.

And the utility explaining major outage findings for an uprated BB-43 steam turbine, plus lessons learned while taking steam-turbine performance measurements.

Tuesday’s technical program ends at 5 when the three-hour Vendor Fair begins.

Wednesday, August 30, opens with a two-hour MD&A session covering the following:

- Turbine outage-management case study.

- Steam-turbine high-speed-balance case studies.

- Outage planning.

GE presents for the remainder of the morning on its Technical Information Letters and top issues, plus turning-gear failure modes, maintenance, and best practices.

In the afternoon, the OEM is at the podium to discuss these topics:

- Interval extensions possible with NextGen Valve and experience to date.

- Updates on Alstom rotating components and structures.

- D-11 turbine-shell findings, repairs, and replacement experience.

- Benefits and methods of improving the start times of combined-cycle plants.

- Improvements in outage execution at combined-cycle plants.

Thursday, August 31, the final day of the conference, morning-only, features presentations by representatives of leading utilities. Only one topic was released to the editors by press time: “LP Gland-Case Replacement on a 57-year-old Unit.”

However, meeting information is updated regularly on the STUG pages of the Power Users website at www.powerusers.org. Alternatively, you can come up to date when you register for the conference.

With the 2023 Steam Turbine Users Group (STUG) approaching August 28-31 in Atlanta, part of the greater Power Users Combined Conference, reviewing some of the content from last year’s meeting should encourage you to attend or send someone from your organization to experience this valuable content in person. Presentation abstracts below are based on information available only to end users in the slide decks posted at www.powerusers.org. Those seeking deeper dives into specific topics should note the presentation titles in italics at the end of each summary and access the source material on the website.

- See part one of the STUG recap series here.

- See part two of the STUG recap series here.

- See part three of the STUG recap series here.

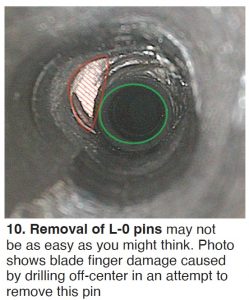

Exercise caution with UT inspections of pinned L-0 buckets

Data in this user presentation clearly reveals that an ultrasonic (UT) inspection of L-0 pins in-situ from one side after sandblasting can be quite different from a UT done in the shop under controlled conditions. How different? The shop inspection identified over 170 pins with indications, the field inspection 725. The discrepancies greatly complicated the outage. The second part of the presentation compared several different methods for removing pins, with a valuable lessons-learned conclusion (Fig 10).

“Pinned L-0 buckets: Variability in UT Inspection Results and Pin Removal”

D11 HP/IP shells: ‘Nightmare of 2013’ and other bad dreams

User’s discussion of observations and lessons learned during the second major of three D11 ST/Gs (commissioned in 2002) includes the “nightmare of 2013,” when weld repair of HP/IP shell cracks (Fig 11) had distorted the shell at the horizontal joint, extending a 49-day outage to 95 days. Other issues present and depicted in the slides are HP/IP shell creep, packing and spill strip replacements, N₂ offset machining and replacement, turning-gear issues, bolting issues, and a rotor-bow incident.

Regarding the last problem, an 11-in. rotor bow was first observed in 2007, but despite the OEM’s repair, the bow returned in 2012, and increased to 21 in. by the second major. User elected a non-OEM shop for a different repair strategy because the first one was not successful.

“D11 Second Major Observations/Lessons Learned, including L-1 Inspection Findings”

L-0 risks illustrated for many makes and models

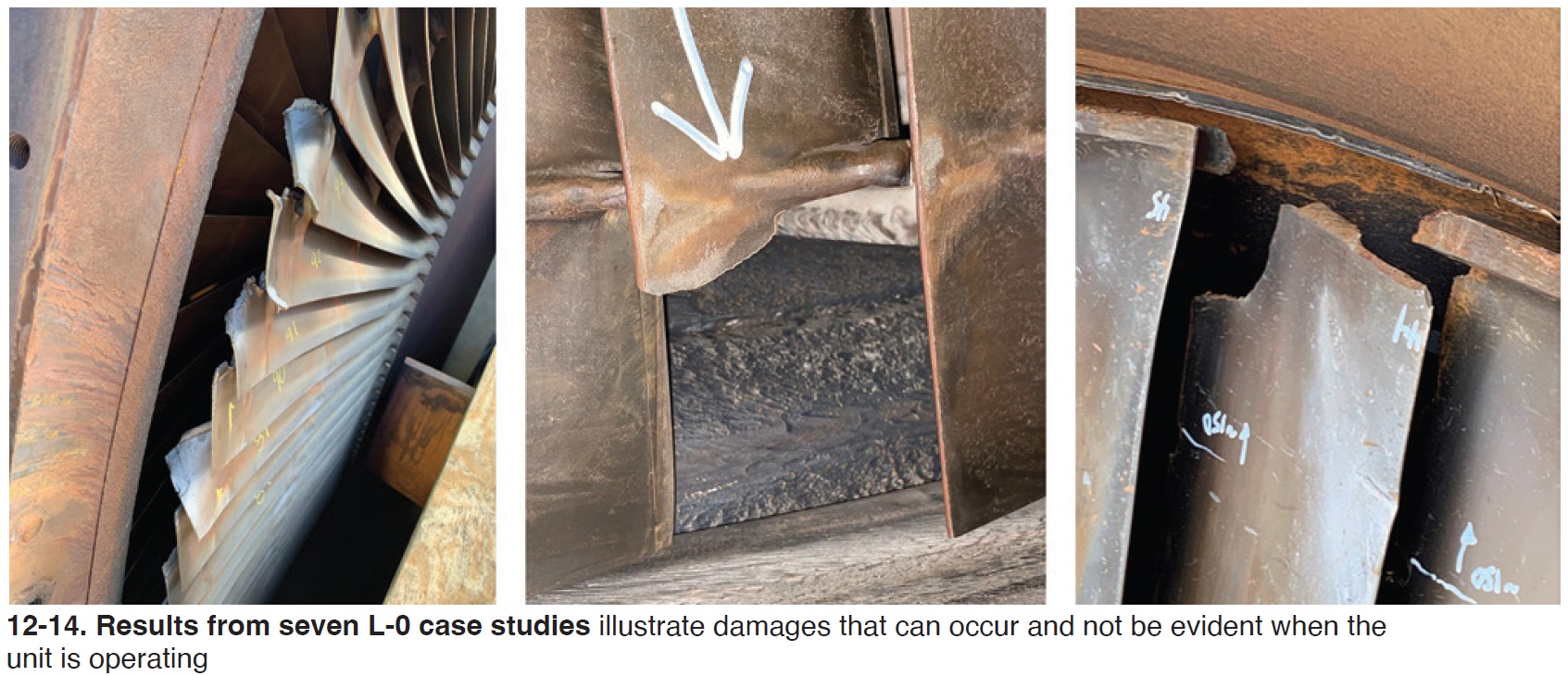

One overriding learning from this presentation is that often there are no indications of problems with L-0 stage blades during unit operation. This is astonishing, really, when you see the types and extent of some of the damage experienced by this owner/operator across a variety of steam-turbine designs, machine ages, operating regimes, L-0 blade materials, rotor attachment methods, and OEMs over the last five years (Figs 12-14).

The seven ST/G L-0 damage case studies examined in this slide deck have varied root causes. Recommendation: Increase inspection frequency! Conduct visual, borescope, and/or dye penetrant inspections during every major outage, especially since they don’t require disassembly of the LP turbine. And pay attention to the OEM service bulletins.

“L-0 History and Concerns Including Recent Outage Experiences”

Refresh on vibration standards

Siemens Energy, in addressing rotor-bearing vibration issues, mostly referred the audience to several standards because there are “inconsistencies” in what is monitored for rotor vibration. The standards are ISO7919-2, “Mechanical Vibration—Evaluation of Machine Vibration by Measurements on Rotating Shafts,” ISO10816-2, “Mechanical Vibration—Evaluation of Machine Vibration by Measurements on Non-Rotating Parts,” and ISO13373-3, “Condition Monitoring and Diagnostics of Machines—Guidelines for Vibration Diagnosis.”

The presenter also listed common and uncommon causes of vibration, some of which are unique to the KN fleet. Mass imbalance, rubs, rotor-support degradation, and misalignment are the common ones. Steam instability (partial arc, steam whirl), bearing instability, and bearing loading are less common.

This presentation, “Rotor Vibration Troubleshooting,” and the other two Siemens Energy presentations made at the STUG 2022 meeting (“Erosion Monitoring and Corrective Actions,” and “Application of the New 8.7-m² Steel Blade for the Existing Titanium L-0 Fleet”) are not available via the Power Users website. Siemens Energy customers can contact steve.radke@siemens-energy.com for access.

With the 2023 Generator Users Group (GUG) approaching August 28-31 in Atlanta, part of the greater Power Users Combined Conference, reviewing some of the content from last year’s meeting should encourage you to attend or send someone from your organization to experience this valuable content in person. Presentation abstracts below are based on information available only to end users in the slide decks posted at www.powerusers.org. Those seeking deeper dives into specific topics should note the presentation titles in italics at the end of each summary and access the source material on the website.

- See part one of this GUG recap series here.

- See part two of this GUG recap series here.

- See part three of this GUG recap series here.

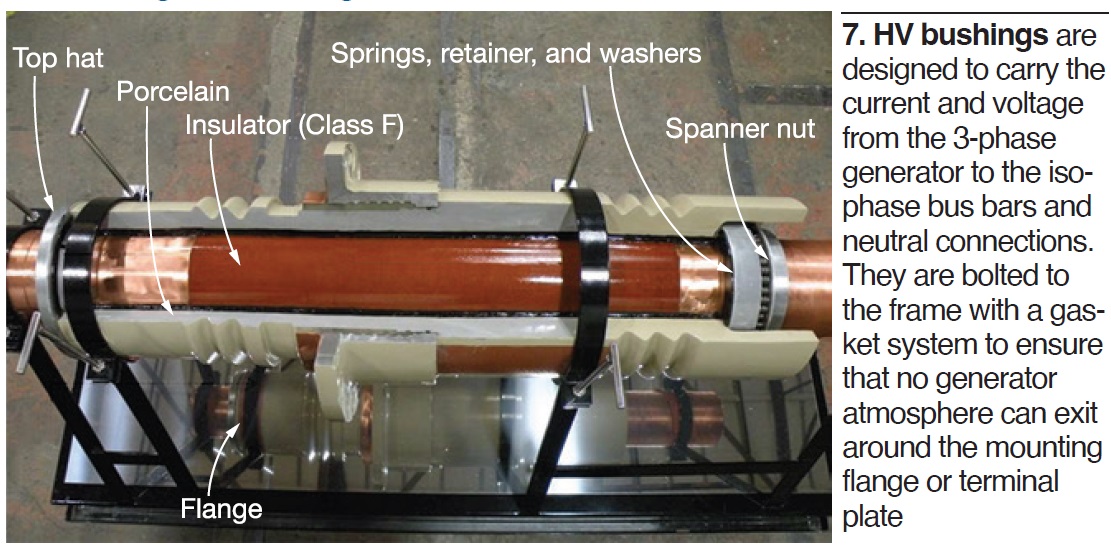

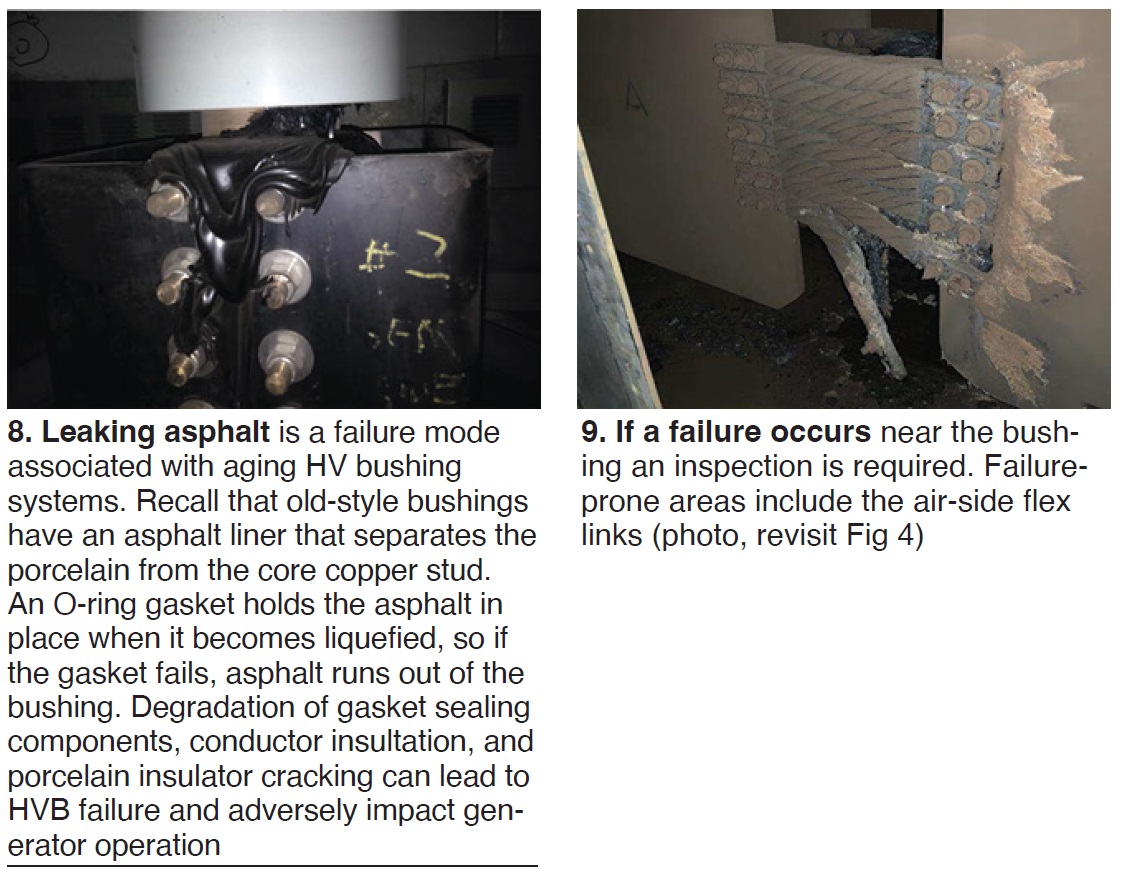

HV bushings—inspection, testing, failures

James Joyce, MD&A’s generator repairs operations manager and a popular participant in user group meetings, presented a comprehensive tutorial on the inspection, testing, and maintenance of high-voltage bushings (HVB) at the 2022 GUG conference. The slide deck is highly illustrated with many excellent photos, such as those in Figs 7-9. The presentation is of value to anyone having HVB responsibilities.

“High-Voltage Bushings—Inspection, Testing, Manufacturing, and Failure Examples”

Bus-duct failure investigation

Case history begins with a review of the basics of isophase bus-duct design, including topics not typically covered in presentations on IBD at most industry conferences—such as induced voltages and resulting current flow in the various types of enclosures: discontinuous or insulated, continuous bonded, and discontinuous bonded housing arrangements.

Inspections were focused on locations where current may flow that it shouldn’t and where current can’t flow that it should.

“Generator Bus Duct Circulating Current Issues”

Focus your attention on the things causing you problems

Sounds like a no-brainer, but the retired former owner’s engineer, who made a career out of fixing problems, offers valuable advice, especially for those new to generator O&M. Consultant Jim Stone began with a few words on viewpoint, noting the following:

- Everyone is trying to make a profit.

- Everyone is short/tight on expertise.

- The less they know/have, the more you must know/have.

- If no one does it, it won’t get done.

Next, he reviews how generators fail—mostly for mechanical reasons:

- Insulation fails from debonding, delamination, voids, cracking organic breakdown, abrasion, and/or contamination.

- Things break, caused by high-/low-cycle fatigue or overload (usually thermal).

- Things loosen.

- Things stick, wear, catch, lose resilience, etc.

The capacity to discern is critical, he says. Someone has to know what’s what and what matters every step of the way. That can be you or someone you hire who does. Or you can rely on supplier experience. Remember: Having someone look who doesn’t know, adds nothing.

The expert also offers his thoughts on the complicated nature of generators, the need for good specifications, the importance of design reviews, inspections and test plans, the value of documentation, commissioning, the perils of nonconformance, and what to track during manufacturing and construction.

“Getting What You Want—that is, Ensuring Quality”

Online diagnostics for generators

Thomas Laird, a principal electrical systems engineer for PSM, begins his presentation with the requisite list of products and services available from his company and its sister firm, Thomassen Energy. Next, he discusses key steps in PSM’s generator major and minor inspections and how the company uses online diagnostics to assist in outage planning.

Focus is on electromagnetic signature analysis (EMSA), using a radio frequency current transformer (RFCT) to assess rotor, excitation, and isophase condition. A flux probe is used to assess field-winding condition.

Anyone involved in outage planning would likely benefit from a review of this slide deck.

“Using Online Diagnostics to Assist in Generator Outage Planning”

With the 2023 Combined Cycle Users Group (CCUG) approaching August 28-31 in Atlanta, part of the greater Power Users Combined Conference, reviewing some of the content from last year’s meeting should encourage you to attend or send someone from your organization to experience this valuable content in person. Presentation abstracts below are based on information available only to end users in the slide decks posted at www.powerusers.org. Those seeking deeper dives into specific topics should note the presentation titles in italics at the end of each summary and access the source material on the website.

- See part one of the CCUG recap series here.

- See part two of the CCUG recap series here.

- See part three of the CCUG recap series here.

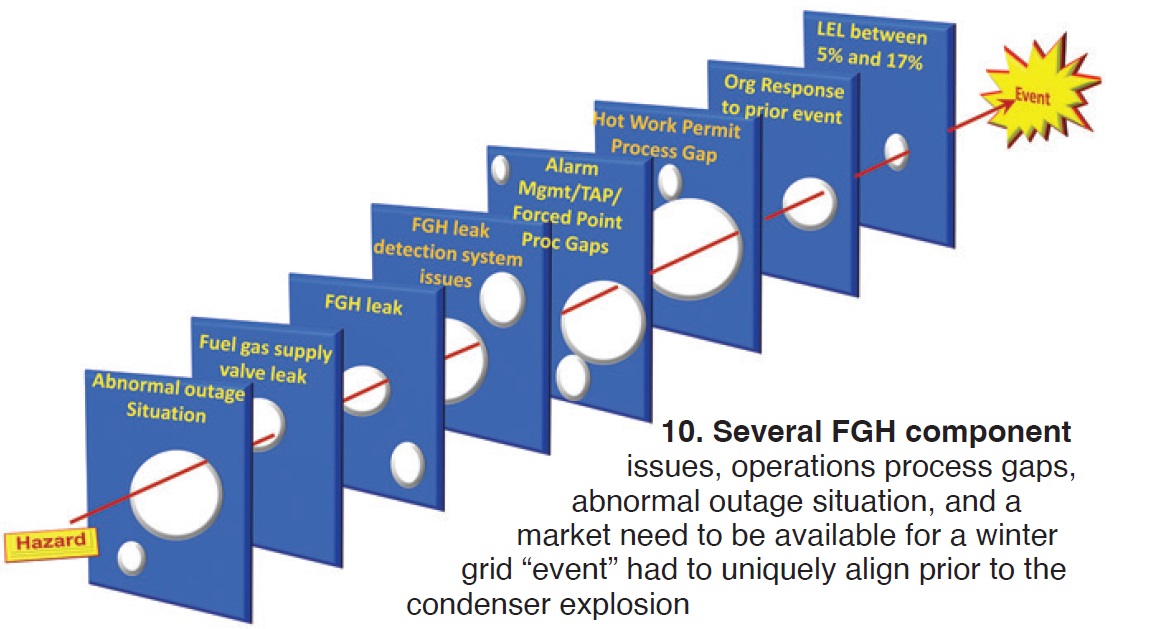

Condenser explosion? Yes, you read that right

During an abnormal plant outage, and precipitated by faulty fuel isolation valves, natural gas accumulation in the steam turbine/generator condenser led to a catastrophic explosion which rocked a 2 × 1 combined cycle but fortunately did not injure or kill anyone, and caused only minimal equipment damage.

Before this event, no one at the plant imagined that fuel gas could build up inside the condenser. And if you can’t either, you owe it to yourself and your colleagues to view the slides.

One of the unique aspects of the 11-day outage was that the gas turbines were being held in a state of readiness to support the grid during a period of extraordinary demand. That meant fuel-line pressure was being maintained up to the fuel-gas heater (FGH) valves. Unbeknownst to the plant staff, one or more of the heat-exchanger tubes were not plugged sufficiently, the heater’s fuel leak detector wasn’t working properly, and the isolation valve leaked (Fig 10).

When a welder came to repair a 1-in line on the outside of the condenser, the arc ignited the fuel in the condenser, six rupture disks on top of the unit blew out (and were later found strewn throughout the plant site), bolting holding the center LP turbine cover failed and the cover lifted about 6 in. The truly unfortunate factor in all this was that the fuel gas accumulated to within the relatively narrow explosive limit range of 5% to 17%.

This presentation should win an “all conference” award, not only for the clarity of the content but the owner/operator’s subsequent efforts to ensure that the learnings permeate the industry. The must-view slide deck will be especially instructive for anyone at plants with gas performance heaters getting the heat from the HRSG’s intermediate-pressure water supply lines.

You’ll be rewarded with a cogent list of a relatively large number of fleet-wide recommendations being undertaken by the owner/operator, which are then tailored to each individual plant—surely an excellent starting point for the many other plants with similar design features.

There’s gold in them thar gaps!

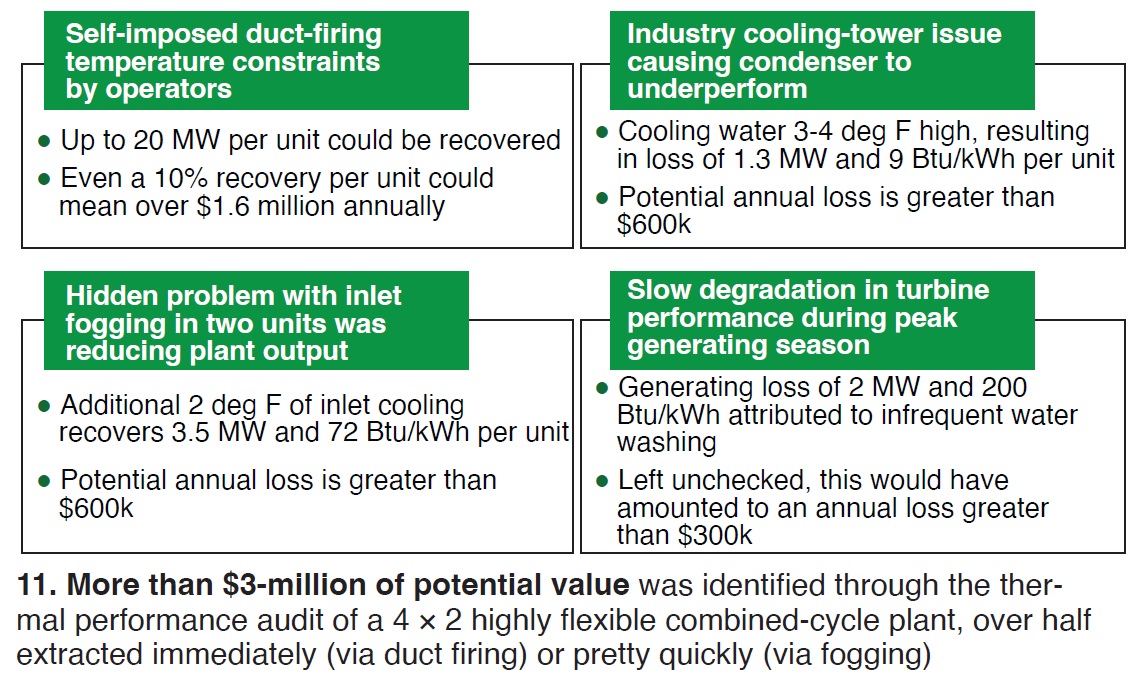

Hidden value can be unlocked through a thermal performance audit and addressing gaps to restore performance, stressed Jeff Schleis, EthosEnergy. Case study results reveal valuations from $300,000 to $1.6-million annually (Fig 11) by undertaking the modest actions recommended in the report issued to the client. Assessment is based on interviews with plant staff, six months of operating data (with remote access to the historian), and plant design data.

“CCGT Performance Is Key to Net Zero”

ST/G valve issues, repair strategies

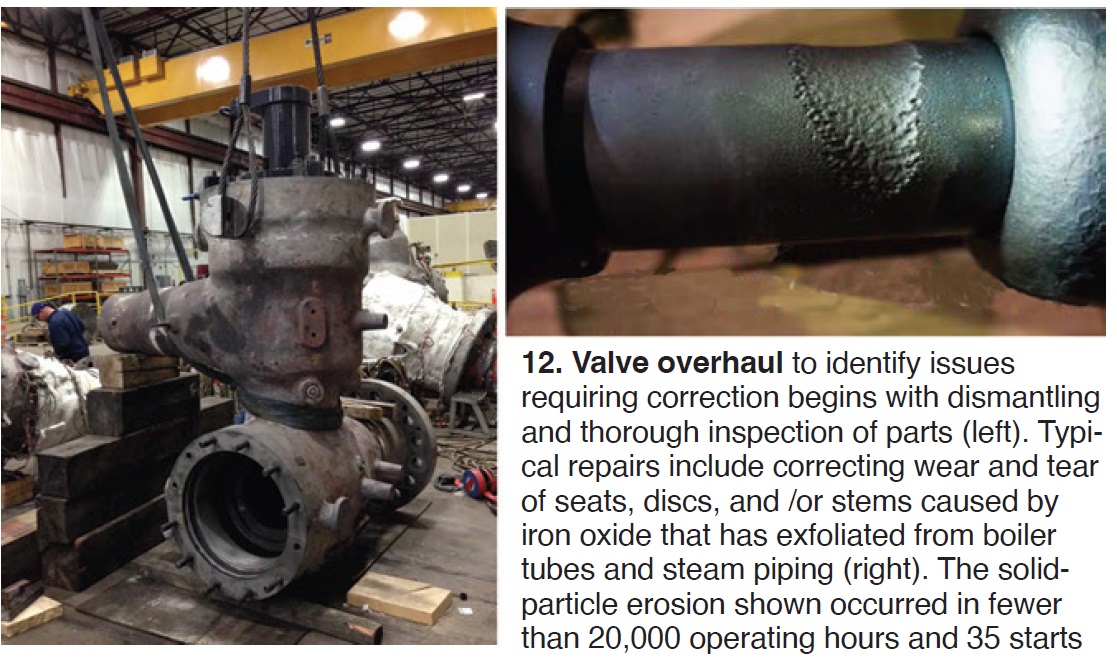

If you have main steam valves approaching three to five years in age, or 25,000 hours of operation, MD&A’s minimum recommendation for inspection and repair, you owe it to yourself to view these slides presented by Dale Gould and Dean Casey. This is especially true if you are past the first five years of plant operations, when valve issues begin to rise. There are no industry or independent maintenance practices, only OEM guidelines, for these valves in combined-cycle facilities, making presentations like this one even more valuable.

Generally, inspection and repair are targeted at: restoring clearances to OEM specs—such as bushing removal and replacement, hardened inserts, and scale removal; achieving concentricity, so that the valve operates precisely on its centerline; sealing and resurfacing to ensure no steam cutting; and attending to foreign-object barriers, such as strainer baskets. Case studies replete with photos drive home main points.

“Steam Turbine Valve Common Issues”

HGP parts—understanding, mitigating risks

All hot-gas-path (HGP) components for life extension have associated risks, Mechanical Dynamics & Analysis’s Jose Quinones, stressed, whether they are OEM new, OEM repaired, third-party repaired, third-party new, or originating from other users. His overriding message is that there are options to evaluate and mitigate these risks, illustrated with “quick” case studies showing how three third-stage blades from three different GT models were assessed, and how two led to successful life extension and one (not cooled internally) did not.

“Unintended Reliability Risk Through Part Replacement/Obsolescence”