With the 2023 Combined Cycle Users Group (CCUG) approaching August 28-31 in Atlanta, part of the greater Power Users Combined Conference, reviewing some of the content from last year’s meeting should encourage you to attend or send someone from your organization to experience this valuable content in person. Presentation abstracts below are based on information available only to end users in the slide decks posted at www.powerusers.org. Those seeking deeper dives into specific topics should note the presentation titles in italics at the end of each summary and access the source material on the website.

Perfect storm, but the lightning was arc flash

When someone lists operator error, equipment failure, instrument failure, hardware and software issues, and acts of God/nature as causes, you know the plant had a bad day. In fact, “perfect storm” doesn’t do justice to the human and equipment failures which preceded the potentially catastrophic arc-flash event on the 230-kV transmission line at an outdoor plant in the Northeast with no black-start capability.

Fortunately, no one was injured—just a 10-in. hole in the ground below the T-line (Fig 6)—and there was no collateral damage to the plant but the ensuing outage lasted more than half a day. But the industry should be collectively grateful that these are the kinds of good people who volunteer to present at CCUG to help others learn from their experiences.

An accident at the commercial warehouse facility next door caused the loss of the T-line when a worker on a manlift was attempting to change out some street lighting bulbs near the line. Operator and crew, who had just recently qualified in the powerplant control room, made some errors (not helped by unclear procedures) starting the emergency diesel/generator (EDG) and a three-minute sequence turned into 15. But the normal feed breaker had failed to open on loss of ac power, so the EDG couldn’t synch to the 480-V bus. The list goes on.

The recommendations following this event are a veritable safety minute expanded. Among the measures taken here:

- Install physical barrier 20 ft on either side of the T line with hazard signage.

- Revise procedures to include what to do if the normal power breaker does not open.

- Change EDG controller layout to eliminate sequence confusions.

- Remove light poles under the T-line.

“Plant Trips and Lessons Learned”

40 is the new 30—extending the life of your HRSG

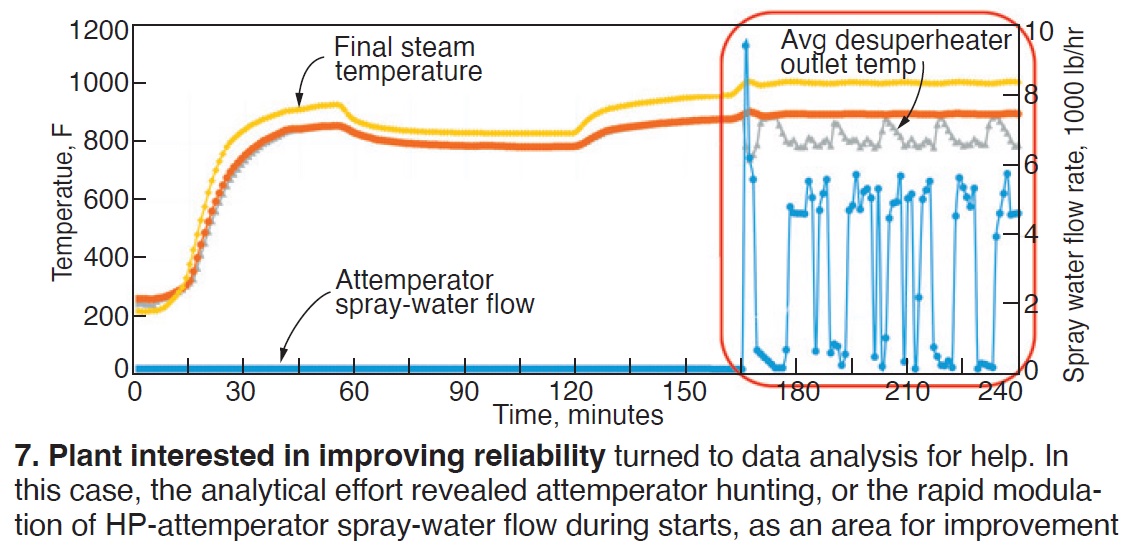

The primary message delivered by Anand Gopa Kumar, HRST, is that the life of an HRSG can be extended to 30+ years, and even up to 40, with good O&M practices driven by data analysis. Kumar reviews HRST’s assessment process, then applies it in several case studies focused on (1) impacts from attemperator hunting as illustrated in Fig 7, (2) HP-evaporator feed pipe stress, (3) creep life assessment of an HP superheater, and (4) recurring and economizer failures. Findings are ranked based on priority and a criticality score of 1 to 100.

“HRSG Life Extension and Long-Term Planning: A Data Driven Approach”

Field testing, remote monitoring of critical pumps

Pump performance degrades over time as components wear and clearances erode. So you should periodically field-test your critical pumps at full-load conditions (Fig 8), advocates Jay Marchi, ProPump Services LLC, to optimize efficiency, identify issues, plan for maintenance, and keep availability high and costs at a minimum. New technologies are available for field testing and assessing pumps and drivers, and “they are only going to get better.” Users experiencing loss of expertise or budget pressures should also consider remote monitoring to “bring the experts to your rotating equipment.”

“Advantages of Periodic Field Testing of Critical Pumps”

Up your game in filters

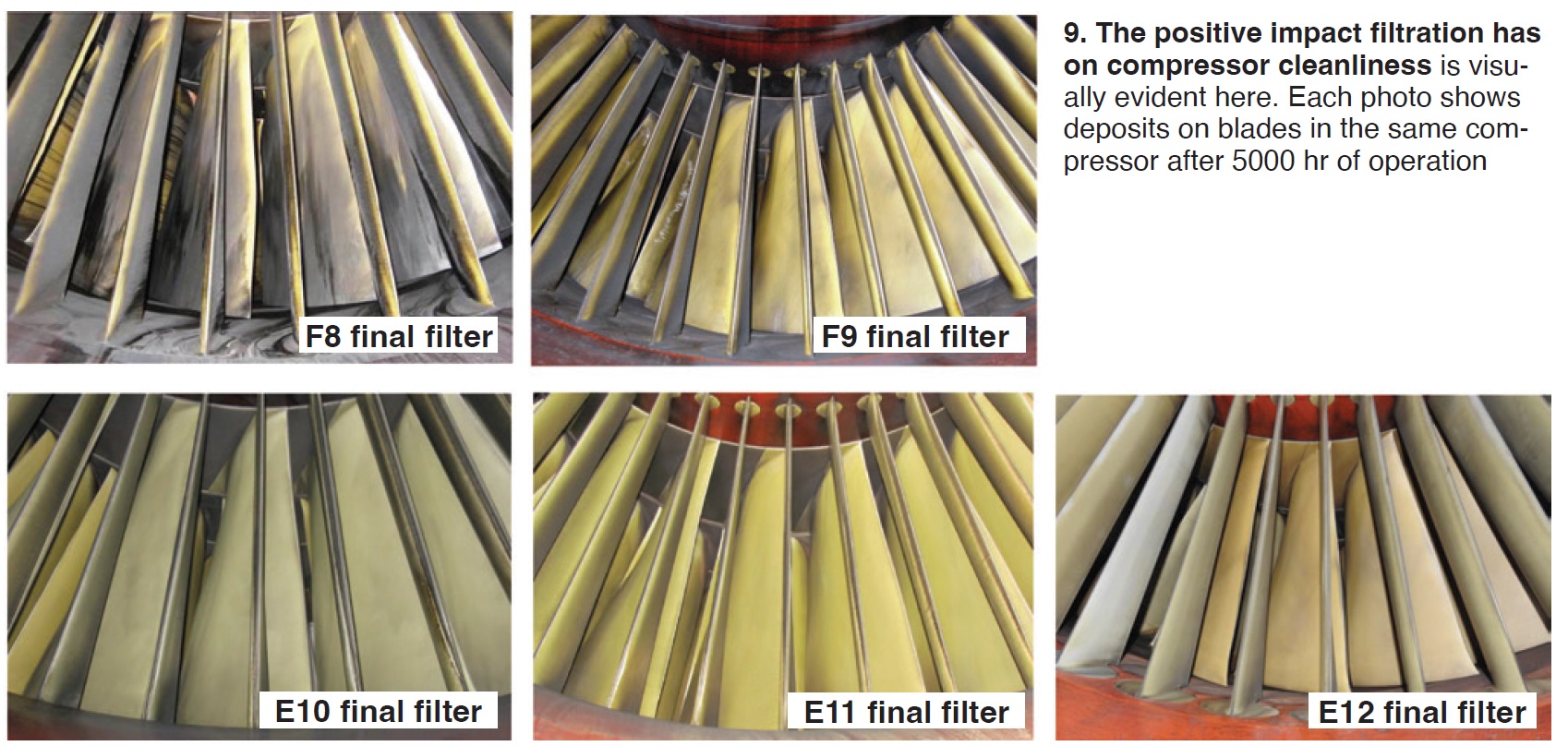

By no means should users think that an E10 final filter is “the maximum filter class” for a gas turbine, says Florian Winkler, EMW filtertechnik GmbH. Winkler illustrates his message with extensive ISO 29461 test data comparing E10, E11, and E12 HEPA filters running on a W501F gas turbine for 5000 hours (Fig 9) for a range of parameters. “Better filtration always pays off,” he concludes.

“Better Filtration Pays for Itself – The Impact of (H)EPA GT Filters”