With the 2023 Steam Turbine Users Group (STUG) approaching August 28-31 in Atlanta, part of the greater Power Users Combined Conference, reviewing some of the content from last year’s meeting should encourage you to attend or send someone from your organization to experience this valuable content in person. Presentation abstracts below are based on information available only to end users in the slide decks posted at www.powerusers.org. Those seeking deeper dives into specific topics should note the presentation titles in italics at the end of each summary and access the source material on the website.

- See part one of the STUG recap series here.

- See part two of the STUG recap series here.

- See part three of the STUG recap series here.

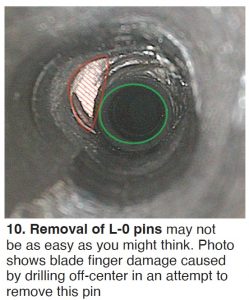

Exercise caution with UT inspections of pinned L-0 buckets

Data in this user presentation clearly reveals that an ultrasonic (UT) inspection of L-0 pins in-situ from one side after sandblasting can be quite different from a UT done in the shop under controlled conditions. How different? The shop inspection identified over 170 pins with indications, the field inspection 725. The discrepancies greatly complicated the outage. The second part of the presentation compared several different methods for removing pins, with a valuable lessons-learned conclusion (Fig 10).

“Pinned L-0 buckets: Variability in UT Inspection Results and Pin Removal”

D11 HP/IP shells: ‘Nightmare of 2013’ and other bad dreams

User’s discussion of observations and lessons learned during the second major of three D11 ST/Gs (commissioned in 2002) includes the “nightmare of 2013,” when weld repair of HP/IP shell cracks (Fig 11) had distorted the shell at the horizontal joint, extending a 49-day outage to 95 days. Other issues present and depicted in the slides are HP/IP shell creep, packing and spill strip replacements, N₂ offset machining and replacement, turning-gear issues, bolting issues, and a rotor-bow incident.

Regarding the last problem, an 11-in. rotor bow was first observed in 2007, but despite the OEM’s repair, the bow returned in 2012, and increased to 21 in. by the second major. User elected a non-OEM shop for a different repair strategy because the first one was not successful.

“D11 Second Major Observations/Lessons Learned, including L-1 Inspection Findings”

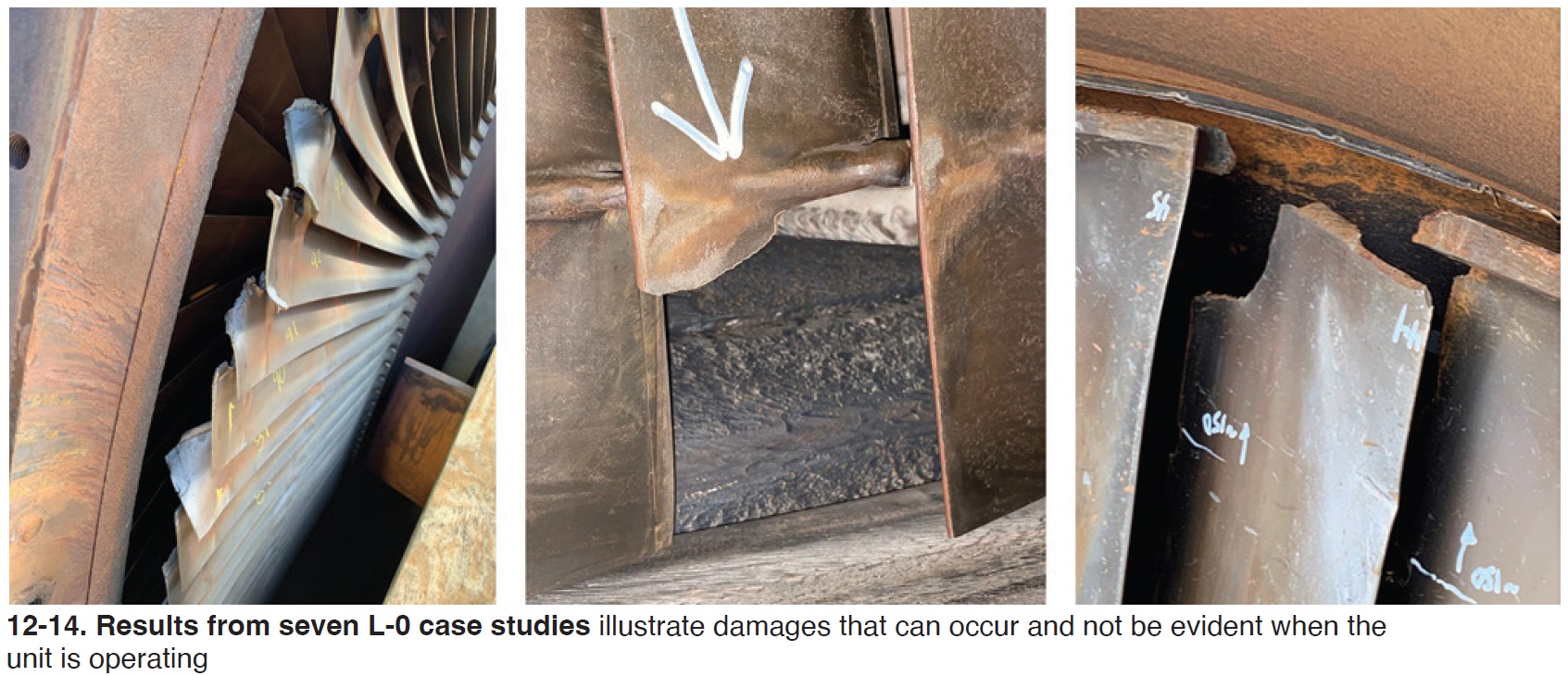

L-0 risks illustrated for many makes and models

One overriding learning from this presentation is that often there are no indications of problems with L-0 stage blades during unit operation. This is astonishing, really, when you see the types and extent of some of the damage experienced by this owner/operator across a variety of steam-turbine designs, machine ages, operating regimes, L-0 blade materials, rotor attachment methods, and OEMs over the last five years (Figs 12-14).

The seven ST/G L-0 damage case studies examined in this slide deck have varied root causes. Recommendation: Increase inspection frequency! Conduct visual, borescope, and/or dye penetrant inspections during every major outage, especially since they don’t require disassembly of the LP turbine. And pay attention to the OEM service bulletins.

“L-0 History and Concerns Including Recent Outage Experiences”

Refresh on vibration standards

Siemens Energy, in addressing rotor-bearing vibration issues, mostly referred the audience to several standards because there are “inconsistencies” in what is monitored for rotor vibration. The standards are ISO7919-2, “Mechanical Vibration—Evaluation of Machine Vibration by Measurements on Rotating Shafts,” ISO10816-2, “Mechanical Vibration—Evaluation of Machine Vibration by Measurements on Non-Rotating Parts,” and ISO13373-3, “Condition Monitoring and Diagnostics of Machines—Guidelines for Vibration Diagnosis.”

The presenter also listed common and uncommon causes of vibration, some of which are unique to the KN fleet. Mass imbalance, rubs, rotor-support degradation, and misalignment are the common ones. Steam instability (partial arc, steam whirl), bearing instability, and bearing loading are less common.

This presentation, “Rotor Vibration Troubleshooting,” and the other two Siemens Energy presentations made at the STUG 2022 meeting (“Erosion Monitoring and Corrective Actions,” and “Application of the New 8.7-m² Steel Blade for the Existing Titanium L-0 Fleet”) are not available via the Power Users website. Siemens Energy customers can contact steve.radke@siemens-energy.com for access.