With the 2023 Steam Turbine Users Group (STUG) approaching August 28-31 in Atlanta, part of the greater Power Users Combined Conference, reviewing some of the content from last year’s meeting should encourage you to attend or send someone from your organization to experience this valuable content in person. Presentation abstracts below are based on information available only to end users in the slide decks posted at www.powerusers.org. Those seeking deeper dives into specific topics should note the presentation titles in italics at the end of each summary and access the source material on the website.

- See part one of the STUG recap series here.

- See part two of the STUG recap series here.

- See part three of the STUG recap series here.

- See part four of the STUG recap series here.

Steam-path audit essential for restoring performance

Every ST/G major should include a structural steam-path audit as part of the lifecycle maintenance plan, say Neil Jones and Tim Keen, MD&A. The audit is an assessment by experienced steam-path engineers based on visual inspection of the rotating and stationary steam-path components and limited dimensional checks.

The inspection is best performed immediately after blast cleaning, but is not, caution the presenters, a substitute for nondestructive testing. Balance of slides review key inspection areas and typical findings richly illustrated through photos.

“Steam Path Audit and Lifecycle Management”

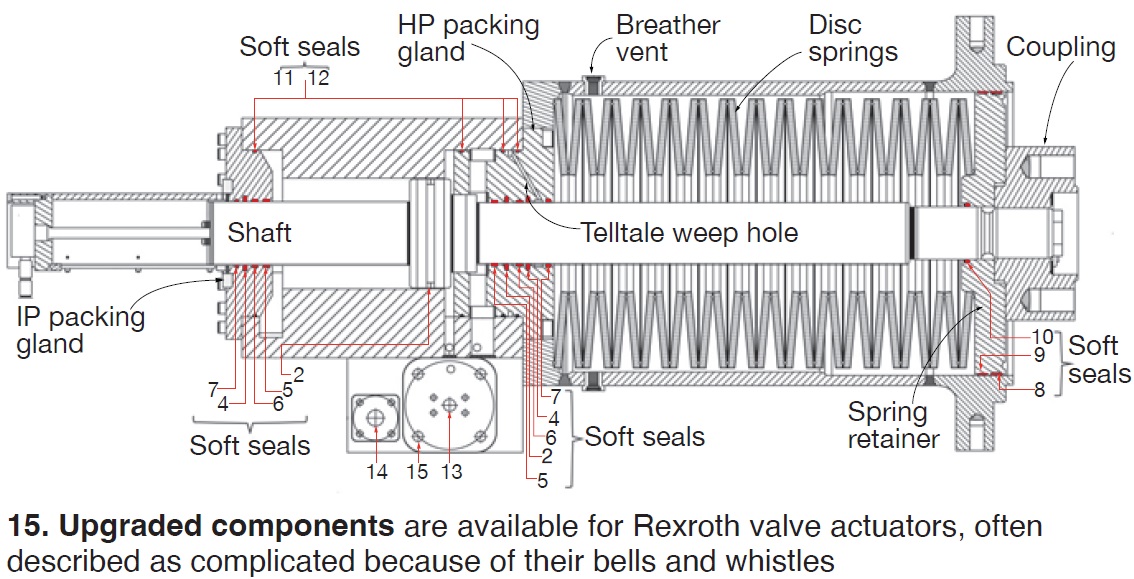

Upgrades, spares available for Rexroth actuator components

MD&A not only stocks over $1-million in spare parts for Rexroth LP-turbine valve actuators (Fig 15), but has designed and implemented upgraded components to solve customer problems and extend operating life. Anthony Catanese’s journey in slides begins with photos of common issues experienced with these actuators, then moves into design modifications for spring can retainers, pistons, packing glands, and disc spring coatings.

“Rexroth Turbine Valve Actuators”

GE addresses recent TILs, top issues

In what GE ST/G owner/operators should probably consider essential information, Matt Foreman and Paul Roche introduced the OEM’s session by addressing what they called the “top issues” (and their associated TILs). In order of appearance, they are:

- L-0 CAE dislodged mid-point sleeves (TIL 2294).

- KA 24 ICS (Alstom) steam-turbine IP rotor cracking (TILs 2052, 2205, 2230, 2315, 2316).

- Regular (daily) control and stop valve testing.

- Annual last-stage-blade inspections, now recommended for all ST/Gs.

- Finger dovetail L-0 cracking (TILs 1847, 1874).

- Critical D11 casing findings (numerous), some of which are “surprising” in units 15-20 years old.

- Moderate-to-severe main-stop/control valve (MSCV) casing cracks in less than 15 years of service.

- N2 packing-head replacement experience (TILs 1627, 1748, 1749) to reduce premature failure of the shell.

- D11 HP/IP horizontal joint leakage.

Slide decks for the Top Issues and TILs identified above are not available via the Power Users website. To access, log into your MyDashboard account on the GE website.

Is poor insulation impacting cooldown?

This is the question GE’s Peter Eisenzopf asked indirectly as he discussed results from a fleet data review of 300 ST/G units. Insulation matters is the abridged conclusion. New insulation installed during an outage may not be “high quality,” he stressed, and encouraged users to request an insulation quality study during their next GE-driven outage. The study confirmed that cool-down performance is improved by replacing current material with world-class insulation. There was not a clear answer when an audience member asked if there is a spec available for “world class insulation.”

“Importance of Insulation and Indicators of Concern” Not available via the Power Users website. To access, log into your MyDashboard account on the GE website.