User-group meetings afford the opportunity to expand your knowledge of gas and steam turbines, and generators, and their controls, auxiliaries, etc. Virtual conferences on these topics are especially convenient and economical for staff training. They allow participation by everyone in the plant, not just the select few who would attend an in-person meeting. The best part: No charge for the education.

Presentations by Arnold Group at the 501F Users Group meeting last week, and at the upcoming Alstom Owners Group (AOG) meeting (March 1-5), illustrate the level of detail you can expect from most vendors discussing their areas of technical expertise.

Presentations by Arnold Group at the 501F Users Group meeting last week, and at the upcoming Alstom Owners Group (AOG) meeting (March 1-5), illustrate the level of detail you can expect from most vendors discussing their areas of technical expertise.

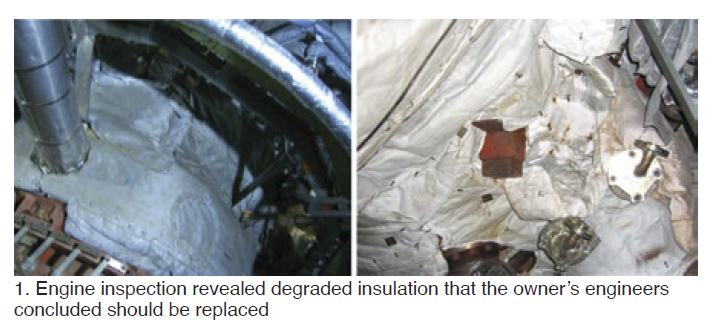

It’s possible to learn a great deal by simply listening. Consider your turbine’s insulation system—an afterthought at many plants until the package temperature exceeds best practice, someone inadvertently comes in contact with very hot metal, etc.

-

-

- How would you inspect your unit’s insulation to determine if it is beyond its useful life and replacement with an upgraded system would improve both performance and safety?

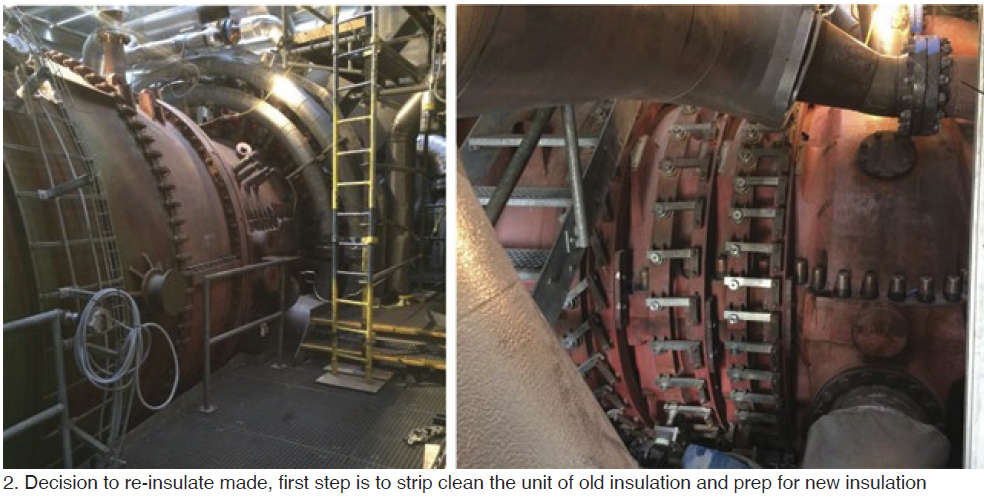

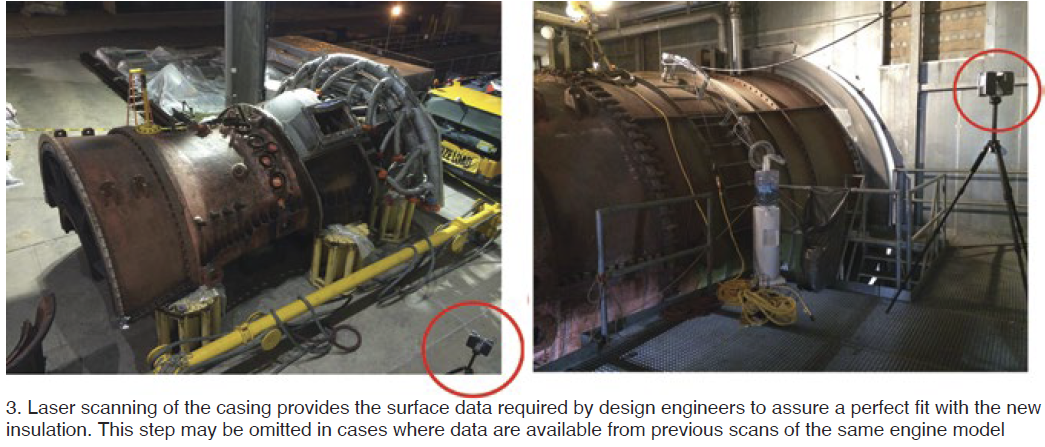

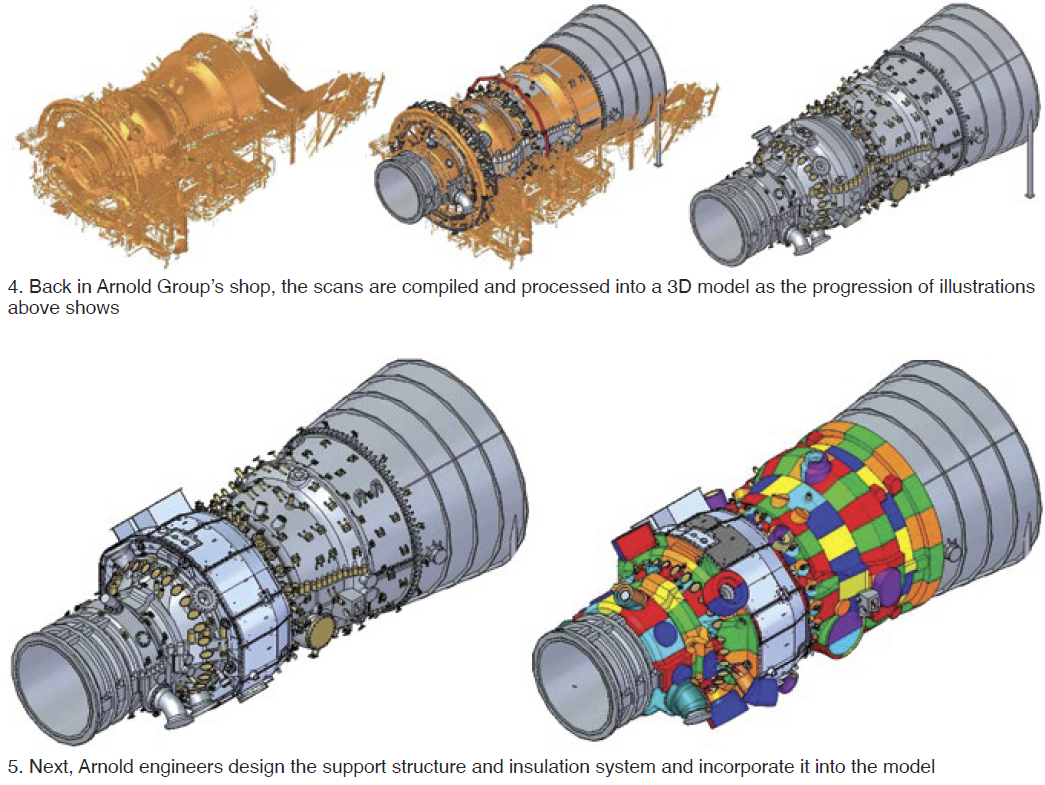

- What are the key steps in the replacement process?

- How long does the project take from inspection to determine current condition to restart after installation?

-

You’re sure to have other questions as well—most of which can be answered during the Q&A session after the presentation or when visiting the supplier’s virtual booth at the end of the conference day.

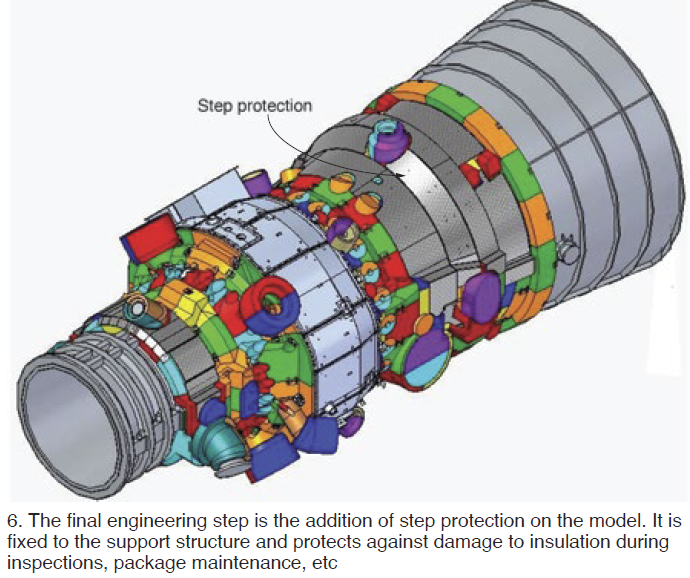

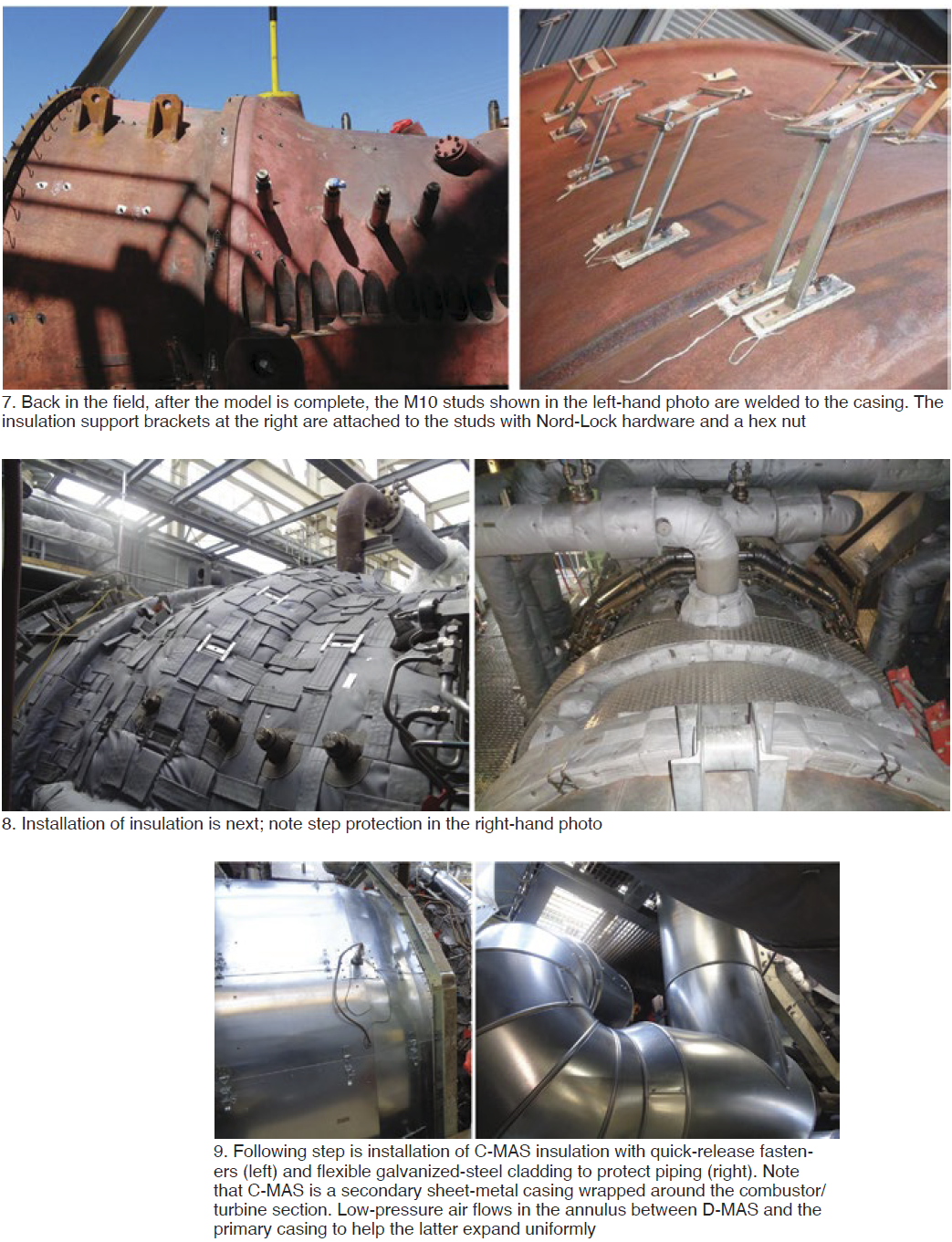

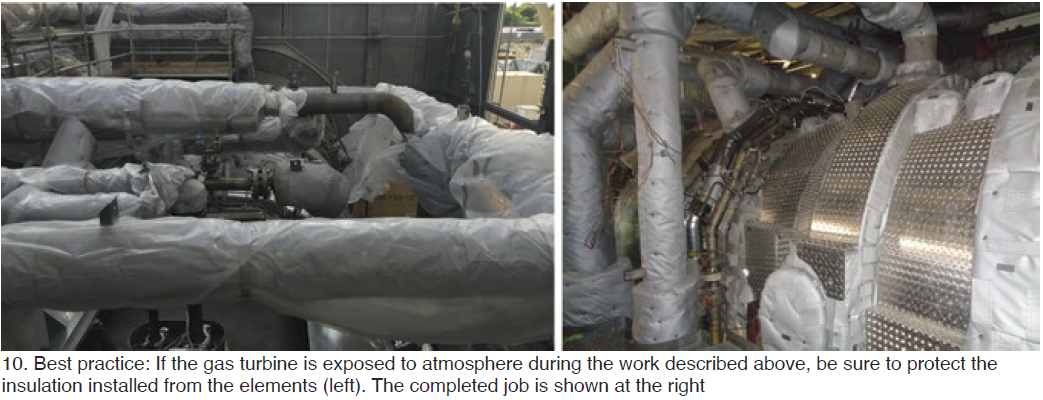

The photos below walk you through the re-insulation of a GT24, a process similar for all frames. Spending a few minutes looking at the images will likely raise questions in your mind about things you want to know more about to make better decisions for your plant in the future. Pierre Ansmann will be presenting for Arnold Group at the AOG conference. Listen to him in the 7:30 to 8 a.m. time slot on Thursday, March 4.

Replacing turbine insulation—a 10-step process