Among the gas-turbine OEMs participating in the week-long 501F Users Group conference at the Hilton West Palm Beach Hotel in February 2020, PSM provided what at least some users considered the most comprehensive technical program. PSM conducted its portion of the meeting at the company’s nearby US headquarters campus.

Attendees were bussed to the Jupiter facility on February 11 for lunch, an overview of 2019 milestones, presentations on plant flexibility upgrades, shop tour, and special sessions on rotors and cases and on the exhaust manifold. An evening event closed out the day’s activities.

PSM’s focus clearly was on engine flexibility, to assure owner/operators the optimal return on their generation investments. In fact, the company’s latest product offering for the 501F is all about flexibility. By combining its new digital FlexSuite package with the latest combustion and turbine innovations of the FlameSheet™ and GTOP (Gas Turbine Optimization) programs, 501FD2 users gain significantly improved flexibility over a wide range of operating conditions— from extended turndown to increased output.

The leading presenters on these topics were Katie Koch, product manager; Greg Vogel, manager of technology programs; and Hany Rizkalla, director of combustion engineering.

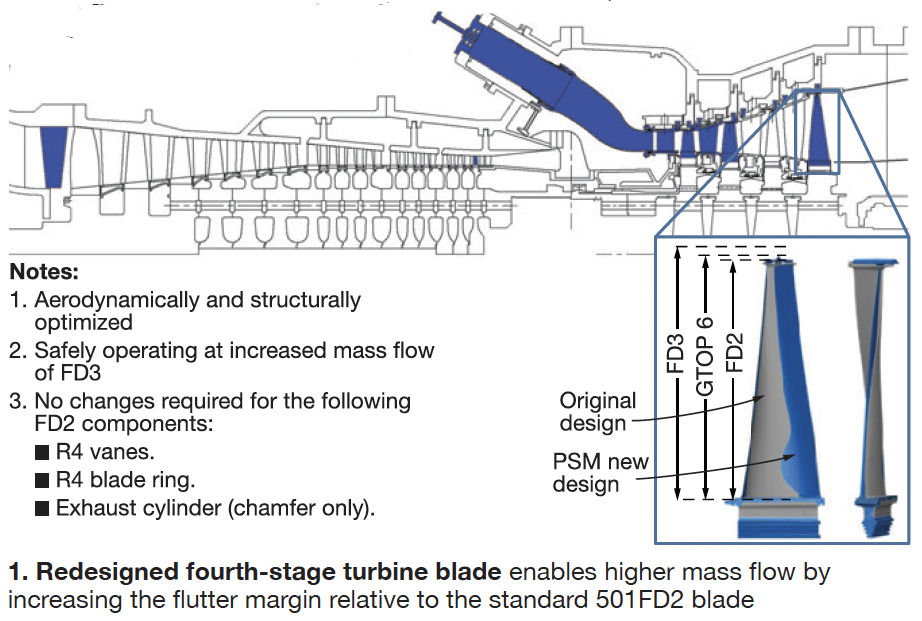

PSM’s effort to provide extended operational flexibility for the 501FD2 began in 2012, early in the development of the frame’s GTOP program—specifically GTOP6. The upgrade package is designed to “unleash” the original performance potential of the gas turbine by enabling operation at higher mass flow. This is achieved via a change in the control of the inlet guide vanes (IGVs), combined with upgraded last-stage compressor and turbine components.

The speaker said PSM’s upgrade comes at a fraction of the cost of Siemens’ 501FD3, which is comparable in performance. The key component in PSM’s solution was said to be a redesigned Row 4 (R4) blade (Fig 1) which is compatible with the existing turbine R4 vane, blade ring 4, and diffuser, and provides the following benefits: longer to enable higher mass flow, yet more robust than the original design given its increased flutter margin. A new aerodynamic shape provides an optimized exit flow velocity distribution that improves both pressure recovery in the turbine diffuser and overall unit efficiency.

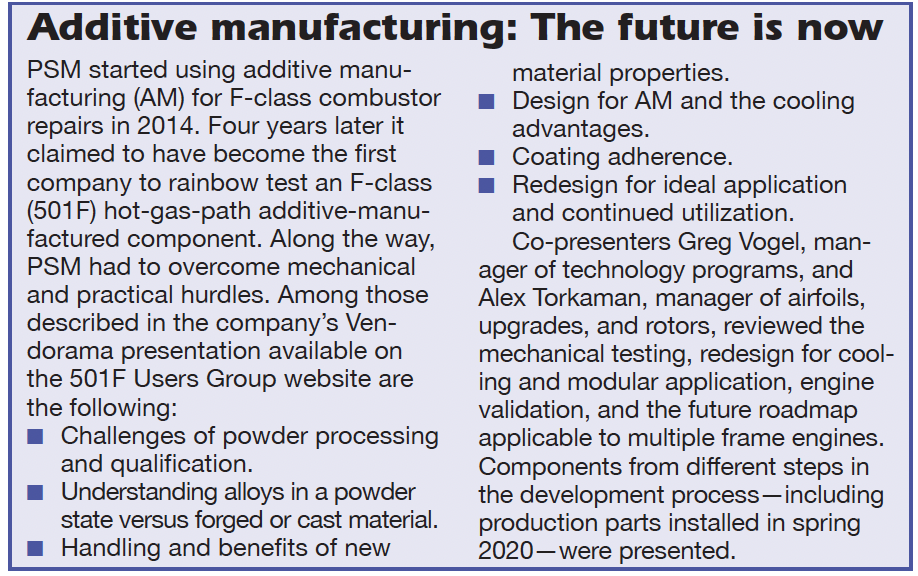

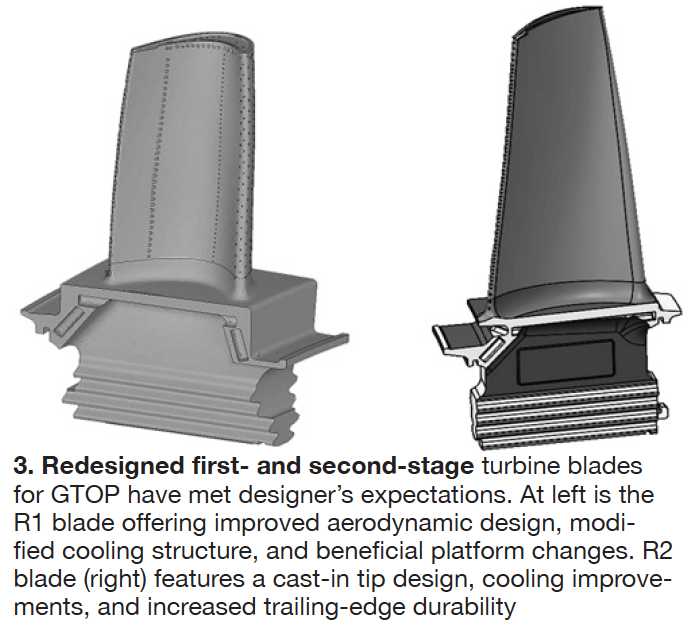

For a given combustion technology limiting any rise in firing temperature, increased unit output can be achieved by reducing the amount of cooling air used by the first-stage turbine vanes to increase turbine inlet temperature. However, use of this “knob” is limited by component durability and traditional manufacturing techniques. The latter limits the degree of cooling- circuit intricacy possible to achieve the level of cooling required.

PSM turned to additive manufacturing (AM, Sidebar) to improve on the cooling of first-stage vanes (Fig 2). Recall that AM often is referred to as 3D printing because it involves making components by building them up in layers. The company leverages this technology in the GTOP program to make components of exceptional durability with superior cooling capability.

Improved design of the R1 vane made possible the reduction in cooling air flow. In effect, the new design redistributed cooling air to where it was needed most. A proprietary nickel-based superalloy and improved coating contribute to longer life of the vital airfoil.

By understanding the metallurgical differences between additive-manufactured parts and traditional cast or forged metals, Team PSM realized the vane assembly itself required re- engineering. The company redesigned the vane assembly and also developed its own proprietary powder alloy and unique production process. In 2018, PSM demonstrated and validated its technological advancements in a commercial engine.

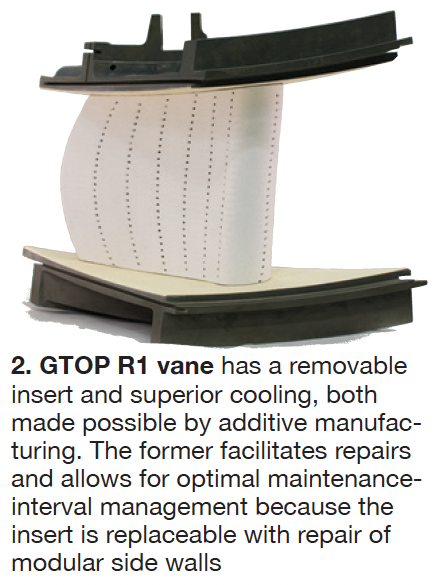

The latest GTOP package (GTOP7), includes elements of GTOP6 and the redesigned AM first-stage vane as well as redesigned first- and second-stage blades (Fig 3). The latter have improved aerodynamic and internal cooling arrangements to extract greater benefit.

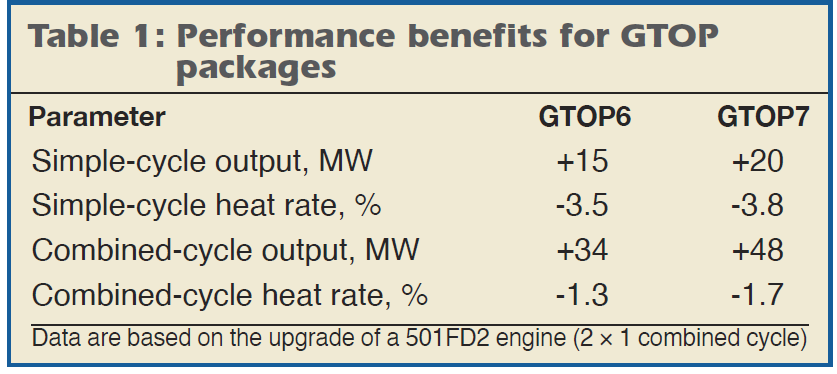

Performance benefits for the different GTOP packages are presented in Table 1. Keep in mind that results may vary from unit to unit depending on plant arrangement. The speaker suggested to attendees that if more accurate numbers are required they should contact their PSM representative.

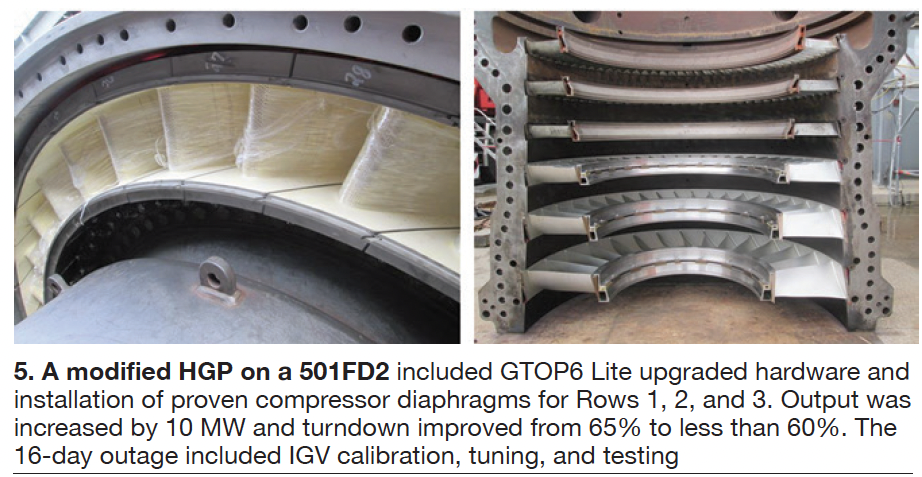

In the last two years, PSM has upgraded more than ten 501F engines with GTOP6 or GTOP7 (Fig 5). The speaker said the company also has the ability to tailor the GTOP program for a given site with what it calls “Lite” packages or changes in combustion and/or logic controls depending on specific requirements (Fig 6).

The GTOP elements described above mainly help in extending the upper band of unit operation. But there’s also a need to extend turndown capability as well. This is where PSM’s FlameSheet™ product comes in, the speakers said. Working together, GTOP and FlameSheet expand the operating profile by increasing both output and turndown.

Turndown has been a primary design initiative for FlameSheet since the first prototype was tested in a 501F engine in 2005. At that time, the goal was to guarantee a low turndown point within emissions compliance where the gas turbine could be “parked.” However, as the market penetration of renewables grew, the ability to maintain emissions compliance across the load range became more important. Later design refinements of FlameSheet ensured performance with improved emissions reductions from baseload to low turndown points, providing operators greater benefit from the product.

Key elements for turndown in combustion systems are low emissions and low flammability margin. The FlameSheet combustor is capable of turndown to low loads and to low emissions. High flammability margin is a key enabling factor to achieve low emissions and combustion stability (no flameout) during low-load operation.

How it works. In today’s installed fleet, FlameSheet relies on four fuel circuits to enable a “combustor within a combustor” design for advanced flame staging. This simplistic arrangement has two unique aerodynamic stages and relies on a trapped vortex flame to provide wide stability margin. The pilot and main stages are effectively two independent combustors, each with its own robust flame stabilization mechanisms. This allows for either combustor to be operated with the other one off, thereby providing significant operational flexibility.

In 2015, commercial installation of FlameSheet began in a variety of F-class gas turbines. Today, the innovative combustion system is operating in seven 7FAs and one 501F. GTOP7 also was integrated into the latter unit.

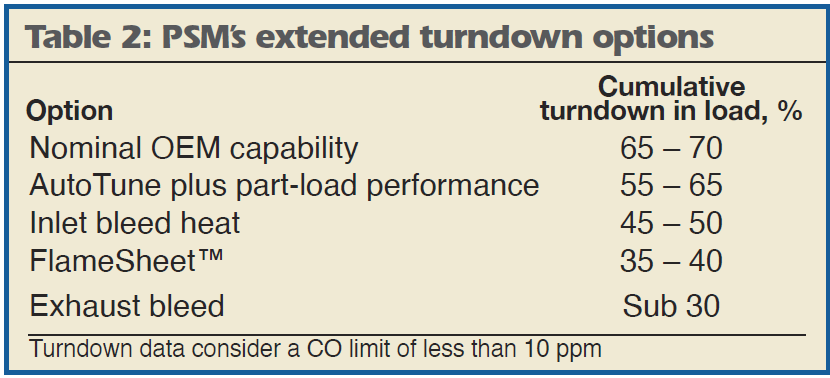

As Table 2 shows, when FlameSheet is coupled with PSM’s AutoTune, part-load performance option, and inlet bleed heat, turndown can be extended from the 65% to 70% capability of the OEM’s standard combustion system to 35% to 40% from baseload. Adding the company’s exhaust bleed system extends turndown to as low as 25% to 30%.

For users interested in increasing the operational flexibility of their gas turbines, the PSM speakers said they would evaluate total plant needs and recommend the optimal arrangement of hardware and digital packages to meet the specific requirements. Example: For a combined cycle, the plant startup profile would be reviewed—including HRSG limitations, steam-turbine output, exhaust temperature, etc—with PSM experts advising on startup optimization in consideration of the desired changes. In one case where a 7FA was retrofitted with GTOP and FlameSheet the startup time was cut in half.

In closing, the speakers touted what they believed to be a unique aspect of PSM’s digital suite of products: Compatibility with almost any control system, thereby eliminating the need for a controls retrofit. Digital services, such as AutoTune and/or FlexSuite modules, were said to be available with or without the company’s hardware upgrade packages. This is of benefit to plants between outages that want to evaluate optimization of their gas-turbine operations.

501FUG: 2020 Conference Review

501FUG: Presentations by Owner/Operators

501FUG: Special Closed Sessions – Doosan

501FUG: Special Closed Sessions – GE

501FUG: Special Closed Sessions – Mitsubishi Power Americas

501FUG: Special Closed Sessions – Siemens Energy

501FUG: Vendorama

Nord-Lock Group solution mitigates 4-way joint leakage

PSM Shop Tour for 501F Users