Ammonia-tank level monitoring contributes to high plant availability

Best Practices Award

Lea Power Partners LLC

Owned by FREIF North American Power I LLC

Operated by Consolidated Asset Management Services

604-MW, gas-fired, 2 x 1 combined cycle located in Hobbs, NM

Plant manager: Roger Schnabel

Frequent calls to the ammonia supplier were required in order to communicate the tank level and projected refill date and time. If the call to refill the tank were made too early, the potential existed to have inadequate space in the tank to offload the entire shipment. Conversely, if the call to dispatch a truck were made too late, the plant would need to make provisions with a third party to add totes of ammonia to the tank in order to avoid a forced de-rate or shutdown.Challenge.  Lea Power Partners LLC uses one 9000-gal aqueous ammonia tank for control of NOx emissions from two M501F gas turbines. During typical operation, the ammonia tank is refilled every four or five days, when the tank level is low enough to receive a full shipment of ammonia (approximately 6000 gal).

Lea Power Partners LLC uses one 9000-gal aqueous ammonia tank for control of NOx emissions from two M501F gas turbines. During typical operation, the ammonia tank is refilled every four or five days, when the tank level is low enough to receive a full shipment of ammonia (approximately 6000 gal).

Solution. Working with the local Airgas distributor, the plant installed a tank level transmitter that communicates real-time ammonia level with the delivery dispatcher (Fig 1). This transmitter also communicates directly to the plant DCS system, allowing the system operator to actively monitor and trend ammonia usage and tank levels to accurately schedule deliveries. Efficient scheduling of bulk ammonia deliveries eliminates the unnecessary risks to personnel of ammonia-tote transfer.

Results. After installation of the remote tank level transmitter, the plant noticed immediate efficiency of ammonia deliveries. All guesswork has been removed, eliminating last minute scheduling of ammonia deliveries while saving the plant from paying expedited trucking costs. Possible forced de-rates or shutdowns caused by ammonia shortages have also been eliminated. Plant personnel are no longer required to handle totes of ammonia, eliminating risks associated with their storage and transfer.

John Texter

Roger Schnabel

Adam Rogge

Richard Shaw

Roger Henderson

Tom Motley

Todd Witwer

Hydrogen system modification improves safety, balance sheet

Best Practices Award

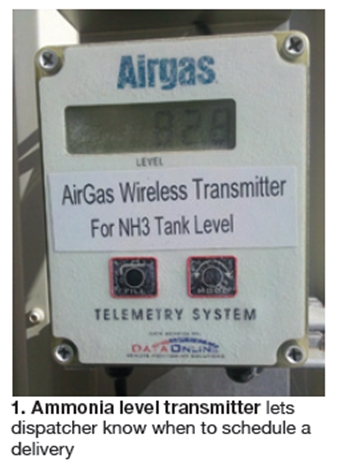

Challenge. The hydrogen supply system for cooling the generator driven by Lea’s steam turbine was commissioned as a 20-station compressed-gas cylinder rack(Fig 2); it required an additional 20 cylinders for system makeup. As designed, the system required manual intervention by a plant operator to replace each exhausted cylinder—a daily task. Frequent manipulation of compressed-gas cylinders exposed plant personnel to the risks of back injury associated with lifting.

The additional cylinders necessary to maintain system makeup also caused the facility to incur high cylinder rental/delivery fees. Plant personnel began to explore the options available to reduce the risks associated with cylinder handling.

Solution. Plant personnel worked with the local Airgas distributor to install a low-pressure bulk hydrogen storage tank to work in parallel with the existing compressed cylinder distribution system (Fig 3). The bulk hydrogen tank piping was coupled to the existing cylinder rack piping to eliminate the need for daily cylinder manipulation and handling. In addition to eliminating the need for daily cylinder management, the bulk tank replaces the weekly hydrogen cylinder delivery with a monthly bulk hydrogen delivery. The existing compressed-gas cylinder racks are still used as a backup system.

Results. After the hydrogen bulk tank installation project was complete, the facility began to see immediate advantages to the new arrangement. Operator man-hours required to receive hydrogen delivery has been reduced by 70%, while the operator man-hours required to handle full compressed-gas cylinders between deliveries have been eliminated. An added advantage to the bulk hydrogen tank system is during scheduled generator purges; additional hydrogen cylinders are no longer needed, eliminating additional cylinder manipulation by plant personnel.

The bulk hydrogen tank also saved money—$27,600 in the first year of the project. With a project cost of $31,900, the payback is a little over one year; annual savings will continue through the life of the facility.

Project participants:

Roger Schnabel

John Texter

Adam Rogge

Tom Motley

Carlos Sanchez

Todd Witwer

Wastewater reclamation project produces big cost savings

Best Practices Award

Challenge. Although operating within design specifications since COD in 2008, Lea Power Partners LLC had been burdened with excessive wastewater disposal costs. The existing treatment plant was unable to process an adequate volume of water to manage evaporation pond levels, forcing the plant to contract trucks to haul wastewater offsite to an approved disposal site.

The cost of hauling and offsite disposal was much greater than that anticipated for wastewater management. The added cost of operating and maintaining wastewater equipment also accounted for more man-hours than initially anticipated. Plant personnel began to explore different options available to reduce the costs and time needed to operate the plant wastewater treatment stream effectively.

Solution. Working with the state department of water quality, the plant applied for and was granted a land-application discharge permit. It allows the plant to discharge wastewater to evaporation ponds, which act as holding tanks, then permits wastewater reclamation by center pivot irrigation.

Coordinating with a local land owner adjacent to the plant property, a center pivot was installed to provide beneficial-use irrigation for 80 acres of farm land. Plant wastewater is now used to supplement irrigation water to raise various beneficial crops in the local semi-arid climate. Operation of the center pivot is controlled through the plant control room through coordination with the local land owner.

Results. After installation of the center pivot, the facility began to see immediate results. The 2012 budget for wastewater treatment was reduced to 5% of the 2011 budget. The project cost for the center pivot irrigation system was returned within five months of use. While the plant raw water use did not increase in 2012, chemical and maintenance costs towards the wastewater treatment facility have been almost eliminated, providing additional dramatic chemical cost savings and increased operator availability for other maintenance tasks.

Project participants:

John Texter

Roger Schnabel

Adam Rogge

Tom Motley

Todd Witwer

Carlos Sanchez

Richard Shaw