Essential monitoring for quickly identifying and repairing air in-leak sources

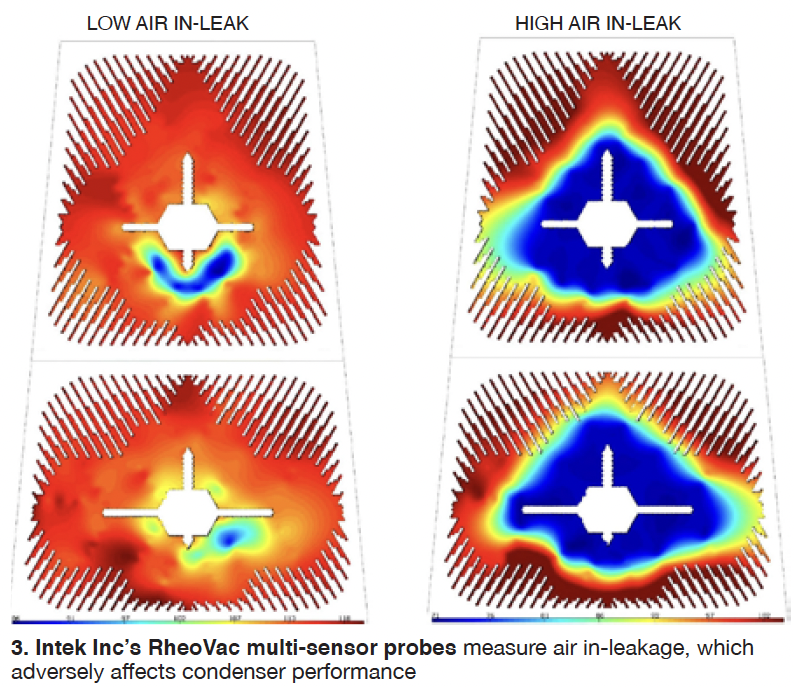

The recording of Collin Eckel’s presentation focuses on presentations of case studies highlighting a new process that combines repair of air in-leaks—identified through a condenser helium leak audit—and condenser vent-line air in-leakage measurements using the company’s Multi-Sensor Probe (Fig 3).

Recall that the presence of helium at the condenser exhausters indicates a leak. Intek’s MSP, installed in the vent line between the condenser and exhauster, measures and continuously calculates the condenser’s total air in-leakage rate.

Data from the MSP allows users to narrow the search areas for potential leaks, thereby increasing the success rate for finding and repairing them, and reducing the time for doing so. As air in-leaks are repaired, the MSP’s air in-leak value indicates the size of the leak eliminated by subtracting the new value from the total air in-leakage rate recorded before the repair was made.