Tenaska Virginia Generating Station

Tenaska Virginia Partners LP

Challenge. A well-conceived fall protection program begins with identification of all fall hazards in the workplace.

Solution. The safety committee implemented the plant’s Continuous Improvement Process to identify and improve safety relating to fall protection. Continuous improvement is one of Tenaska’s core values and is integrated into the management and operational fabric of the company. The simple approach to continuous improvement is a three-step process that defines, measures, and improves.

Our process improvement team, applying the three-step process to improve our fall protection program, focused on measures and processes and sought out interaction and consensus among the process owners, users, suppliers, and customers:

1. Identify fall hazards:

- Plant fall-hazard areas were identified where work was actually performed, the frequency, and the risk was recognized. Discussion with various disciplines helped the team to understand the work being performed using a risk matrix to determine the priorities.

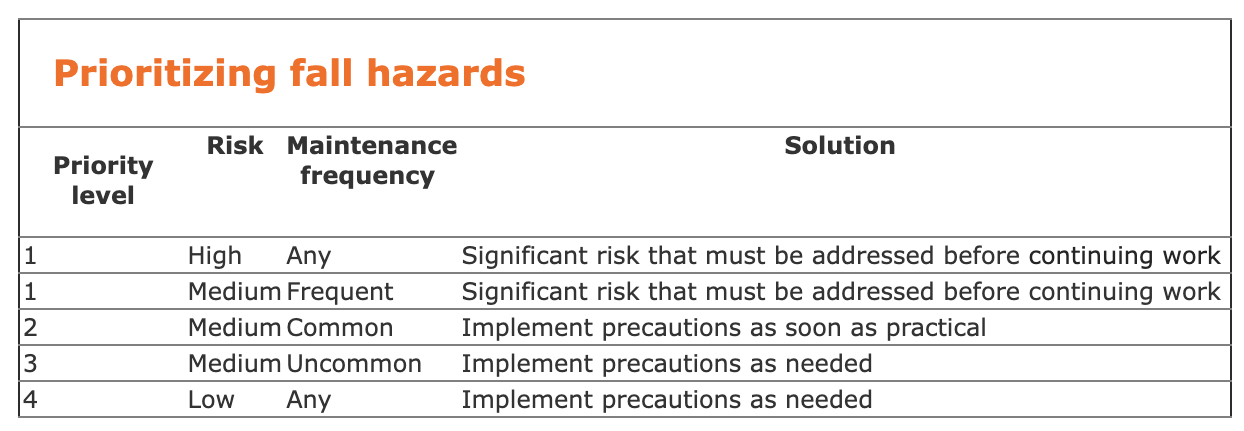

- Priorities were determined to identify the areas where employees were placed at higher risk or where employees were placed at risk more often (table).

2. Solutions to the fall hazard areas:

- The facility has miles of heat tracing because it is dispatched in cold weather. Heat tracing runs along the top of the mezzanine level. Based on our priority table, the risk of possibly falling is considered “high” and the frequency of maintenance is “any.” The facility installed lifelines designed to be used for tie-off points as part of our fall protection program. A 100% tie-off policy is enforced on this area (Fig 1).

- The fiberglass cooling tower was another difficult area for fall protection. There is a significant amount of manpower needed to perform the required upkeep, and there was a small level of comfort when you need to tie-off while working inside (Fig 2). The cooling-tower manufacturer was contacted and came to the site to provide training and documentation regarding the structural design of the tower and ways to enhance our fall protection program.

Maintaining the solutions even after the project is complete is a high priority. When the higher risk items are corrected the facility begins the next round which starts with another evaluation and priority system being developed.3. Establish procedures and training:

- Improvement in safety or any other aspect of powerplant operation is a constant system of self evaluation and improvement. Training is incorporated for all employees and communication lines among management, safety committee, and employees are used to ensure all safety concerns are addressed.

Results. The overall safety program improved during this process. Like all systems, a successful fall protection program is only as good as the personnel who implement the program. Employees’ safety concerns are valued and innovative solutions were provided by all involved to ensure a safe worksite. OSHA VPP benchmarked our fall protection program.