Heating blankets, startup agility package enable faster starts

Challenge. Colusa Generating Station is an F-class 2 × 1 combined cycle in PG&E’s asset portfolio. A company goal is to remain on the leading edge of renewables integration, which demands that conventional generation assets be as flexible as possible to compensate for the relative unpredictability of renewables.

With this goal in mind, engineers were challenged to enhance the flexibility of combined-cycle assets—in particular to reduce their startup times to base base or minimum load, thereby enabling the plants to follow the real-time needs of the generation market.

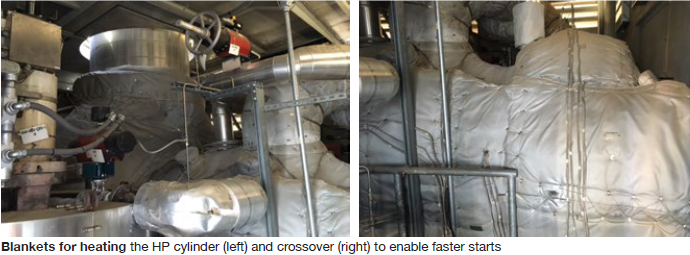

Solution. Colusa implemented the OEM’s OpFlex startup agility package and steam turbine/generator (ST) heating blanket. The plant’s agility package features improved startup automation—including advanced control software to enable fast, reliable, and repeatable ST hot, warm, and cold starts. Benefits include the following:

- Improved capability to meet start-time commitments.

- Reduced gas-turbine (GT) startup fuel costs and emissions.

- Lowered the risk of overstress conditions, vibration trips, and radial and axial rubs.

- Improved operator interface with modified and new HMI screens.

- Enabled ST rapid starts following an overnight shutdown (when the HP bowl upper metal temperature is at least 880F).

- Provide true ST “push-button” auto start in which the operator selects load and decides when to start. The ST control system then automatically executes the entire start.

- Allows combustion turbines to achieve emissions compliance before loading the ST if the startup dispatch/sequence requires it.

- Reduces combined-cycle overall start time to achieve the desired load—approximately 25 to 30 minutes.

For the ST heating blanket, a power console is designed to provide individually controlled zones of low voltage, high current outputs to resistance heaters. There are 24 zones of control on the shell to provide the necessary stable temperatures required to ensure even heating for all three sections of the turbine:

- HP end section (heating starts at 650F).

- Inlet/barrel section (heating starts at 975F).

- IP end section (heating starts at 550F).

Results. The OpFlex startup agility improvements for the ST have been extremely beneficial. We’ve coordinated weekly calls between the OEM’s agility team and the Colusa O&M team to discuss the previous week’s starts and worked to fine-tune starting processes and to streamline ST roll and forward-flow permissives.

Times when we’ve seen the heating blanket come into service we’ve maintained sufficient shell temperatures to begin the approach for a hot start rather than warm, further reducing time to base load. This has reduced our startup time to the point that the steam turbine is no longer our limiting factor to base load; GT emissions requirements are now “critical path” on a hot or warm start. Some tangible benefits of these enhancements include the following:

- Reduced hot/warm start times from 81 minutes to less than 60.

- Allowed faster loading of the ST, reducing the ramp time by approximately half.

- Saved an average of 66 million Btu in fuel per start.

- Reduced CO emissions by an average of 52.5 lb per start.

- Reduced NOx emissions by an average of 75 lb per start.

Project participants: Entire O&M staff with special recognition to our advanced powerplant technicians who coordinated the implementation process with the OEM: Jon Bohn, Earl Giffin, Chris McMains, Dean Linville, and Mike McLellan.

Colusa Generating Station

Pacific Gas & Electric Company

668-MW, gas-fired, 2 × 1 combined cycle located in Maxwell, Calif

Plant manager: Ed Warner