A few years ago, Frame 5s generally were viewed as gas turbines without a future in the generation sector of the US electric power industry. But increasing reliance on intermittent renewables has restored their value in many locations as a reliable resource when the wind stops blowing and/or the sun stops shining. An example was provided by Mike Moore, senior VP for optimization and upgrades in Wood Group GTS’s Power Plant Services business unit, who called the CCJ editorial offices to share information on an upgrade project that delivered a rapid return on investment.

The Frame 5P, a nominal 25-MW machine located at an Ohio coal-fired plant, was relegated to black-start service until a recent market opportunity justified investment in the engine to provide grid ancillary services. Wood Group was awarded a contract to install a water injection system on the distillate-only unit to reduce NOx emissions from 119 ppm to 65 ppm and satisfy permit requirements for the intended service.

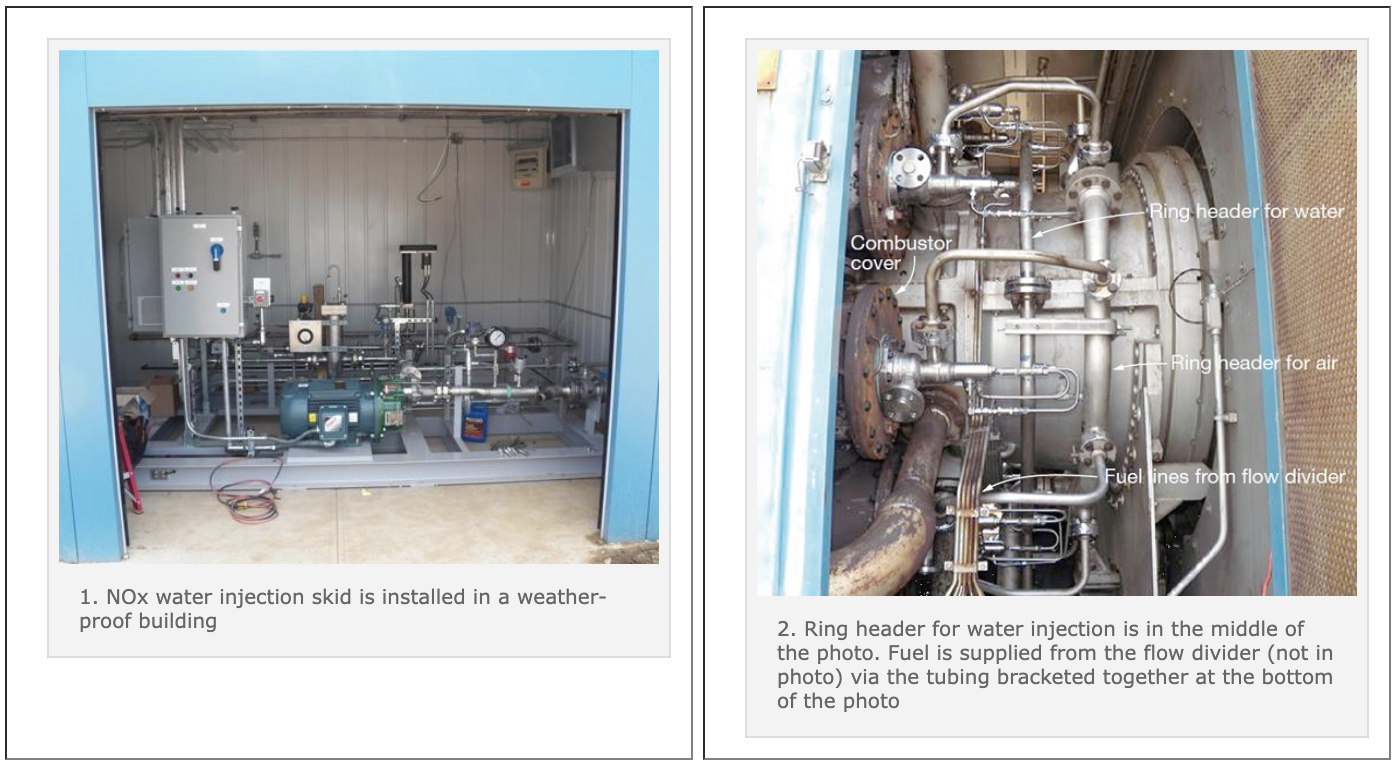

The scope of work included supply and installation of the following new equipment: (1) water injection skid and shed (Fig 1), (2) ring manifold for NOx water, as well as all the tubing and fittings connecting the ring to individual combustors (Fig 2), (3) WG fuel nozzles and liner caps, (4) flame scanner that does not require water cooling, and (5) electric fuel metering valve to improve starting reliability. The project was completed within a 10-day planned outage.

The engine’s controls also were upgraded. That project involved Emerson Process Management, which replaced the original system with its Ovation DCS. The coal-fired unit onsite was equipped with Ovation controls and the availability of technicians and parts made it a wiser choice in the utility’s mind than Wood Group’s PLC-based control solution installed on many GE gas turbines.