Armstrong Energy

ENGIE North America (NA)

640-MW, four-unit, dual-fuel, simple-cycle peaking facility located in Shelocta, Pa

Plant manager: Matthew Denver

Improved, expanded GT fire protection system

Challenge. When the gas turbine/generators were designed in 2002, the OEM provided rationale for excluding fire protection for the collector cabinet and load tunnel. Over the last 13 years, though, various insurance carriers have sited this design as inadequate and requested that fire protection be added to these compartments to minimize possible damage in the event of a fire.

Solution. A few options were considered by the plant staff before the decision was made to install high-pressure (HP) CO2 systems which would work in conjunction with the original low-pressure CO2 system. The installation of this equipment required an upgrade of the existing control panel to provide ample capacity for additional detection, notification, and control modules.

The original fire-protection configuration separated the turbine equipment into four zones:

- GT/gas compartment.

- 2 bearing area.

- Accessory module.

- Liquid fuel/atomizing air.

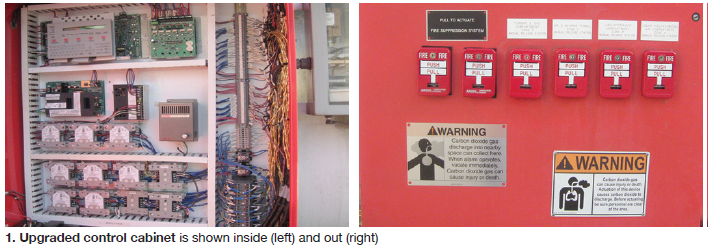

The upgraded CO2 control cabinet (Fig 1) accommodated addition of two new zones to protect these areas (Fig 2):

- Load tunnel.

- Collector cabinet.

Using NFPA 12 for guidance, HP CO2 systems were designed and installed. Additionally, several more changes were made:

- Relays were added to provide automatic shutdown and Mark VI control logic was modified to signal the operator.

- The generator automatic-hydrogen-dump logic was connected to the system to provide additional safety margin.

- Two sensors were installed to initiate evacuation of the hydrogen charge.

- CO2 concentration tests were performed to validate effectiveness of the system design parameters (in accordance with NFPA 12).

- Dampers were installed to effectively isolate air flow.

Results. The load-tunnel compartment was tested to 84% concentration, and required only minimal adjustments to the doors in order to completely seal the compartment.

The collector cabinet doors and soft-patch gaskets required more attention, and the excitation lead box required sealing to reach the required concentration.

Michael Field, ENGIE NA’s VP for the PJM/NY region, stated, “With these successful test results, Armstrong Energy has achieved equipment protection and personnel safety standards that other plants will want to emulate. The project was very complicated and needed to adhere to NFPA 12 as well as standards set by ENGIE engineering and the plant’s insurer. This will serve as the pilot program for our other plants.”

According to Armstrong Plant Manager Matthew Denver, “What we accomplished at Armstrong will pave the way for other ENGIE plants. Superior effort went into this project, which was confirmed by successful test results on the first attempt. This installation will help to further protect our equipment and staff in the event of a malfunction.

“Peter Margliotti, Armstrong’s combustion turbine (CT) specialist and the project’s overseer and subject-matter expert, researched standards and reviewed prints and documentation in advance to ensure safe and timely project completion.

“From design and installation of project changes to the creation and incorporation of new HMI screens, his depth of knowledge, flexibility, and relentless determination were instrumental to seeing the project to its timely and successful completion.”

Margliotti stated, “When this project was first envisioned, I wanted the ability to remotely monitor the gas-turbine fire suppression system, and to also upgrade the systems to current standards. By integrating the fire detection sensors, GT control system, and O&M building fire alarm panel, we have enabled our operators to pinpoint the exact location of a fire and respond appropriately. As a result, our personnel, equipment, and site are now better protected. The next step is to roll out this upgrade to our other plants, and capture the personnel safety and equipment protection benefits across our fleet.”

Project participant: Peter Margliotti, CT specialist

Armstrong continues to salute veterans

Armstrong Energy held its 12th Annual Charitable Golf Event benefitting the Wounded Warrior Project and Team Red White & Blue. The event, held on Sept 11, 2015, brought in more than 130 golfers from the local community. What better way to say “thank you” and honor all the brave men and women who serve and have served on behalf of our country. The site alone has five employees who are former US military. Armstrong Energy and ENGIE NA donate 100% of all registration fees and supporter dollars directly to the charities. Last year $55,000 was raised.