Value proposition: September 16-20

The fall user-group meeting calendar opens with CTOTF’s Fall Turbine Forum and Trade Show at San Diego’s Rancho Bernardo Inn Golf Resort & Spa, September 16-20. The Combustion Turbine Operations Technical Forum, which has been serving gas-turbine owner/operators longer than any other user group, offers a plant-wide technical perspective in its conference agenda, while incorporating non-technical subjects—such as regulatory and compliance programs—which have direct impact on successful plant operations.

Chairman Bob Kirn of TVA says a goal of the organization is to serve as an extension of individual-company technical services departments. “Our active presentation library offers an immediate source of information, industry contacts, and problem solutions,” he notes. “CTOTF’s renowned conference roundtables have been enhanced with technical training delivered by industry experts through the group’s CT-Tech program, shop tours, service-provider presentations, and a robust vendor fair,” Kirn continues.

CTOTF meetings are content-rich and the information flow is relentless. To illustrate: The Fall Turbine Forum will have 15 roundtables totaling 74 hours of presentations and discussion, 10 meals and social functions for informal sharing of information, and a trade show. If you want to know more about the subject-matter experts who develop and conduct the various roundtables, access the org chart at www.ctotf.org and click on the person’s name for an abbreviated resume.

The following list of roundtables scheduled for San Diego illustrates the breath of coverage of a CTOTF meeting, including presentations and discussion of engines made by all the major OEMs:

- Industry issues.

- O&M and business practices.

- GE F-class machines.

- Alstom gas turbines.

- Solar engines (includes a shop tour).

- Pratt & Whitney FT4s and FT8s.

- GE E-class and legacy machines.

- Combined cycle.

- Siemens V and H gas turbines.

- Regulatory and compliance.

- GE Aero engines.

- Mitsubishi machines.

- Siemens legacy gas turbines.

- Generators, high-voltage electrical, and I&C.

- Siemens F- and G-class engines.

Details for each of the roundtables are directly accessible via the program overview at:

http://www.combustion-turbine-operations-technical-forum.org/ConferenceFall/UsersWeekOverview.html

Top sponsors for the CTOTF conferences in 2012, called Super Champions, are the following: Allied Power Group, Combustion Parts Inc, Dresser-Rand Turbine Technology Services, EagleBurgmann EJS, Hy-Pro Filtration, NAES Corp, PSM, Sulzer Turbo Services, Universal Plant Services, Young & Franklin Inc.

ACC Users Group to meet in Gillette: September 24-26

The Air-Cooled Condenser (ACC) Users Group, chaired by Andy Howell, a senior systems chemist for Xcel Energy, opens its 2012 meeting in Gillette, Wyo, September 24, with a welcome reception at the Chophouse Restaurant from 5 to 6:30 p.m. Other members of the steering committee who will be on hand are Dave Rettke, NV Energy; Hoc Phung, PG&E; and Barry Dooley, Structural Integrity Associates Inc.

The program for the organization’s fourth annual conference, September 25-26, at the Cam-Plex includes prepared presentations, open discussion sessions, and tours of ACCs at two plants in the area. Details are available at www.acc-usersgroup.org.

Gillette is the global center of excellence for ACC operation and maintenance. It’s probably safe to say that if the engineers and technicians at the seven dry-cooled plants within 10 miles of Gillette—Simpson 1, 2; Wyodak; Wygen 1, 2, 3; and Dry Fork—haven’t experienced a particular ACC issue, no one has. These people will be at the meeting to share their experiences.

Dry cooling got its start in Gillette and the technology has matured there. Consider the following:

- Simpson 1 is equipped with the first ACC installed in North America.

- Wyodak, which had the largest ACC in the world for more than two decades, was the first plant to completely replace the heat-transfer modules on its ACC.

- Dry Fork is the most recent ACC-equipped powerplant to begin service in North America.

If you are considering participation, bear in mind that the Gillette airport has a limited number of flights and when those are filled the only practical options for most attendees would be flying to Rapid City or Casper—both a two-hour drive from Gillette. You may want to make travel arrangements before registering. Chairman Howell assures there will be a seat available (and food) for everyone who can get to Gillette.

Host generating companies are Basin Electric Power Co-op, Black Hills Power Inc, Black Hills Electric Generation Inc, Cheyenne Light Fuel & Power, Montana-Dakota Utilities Co, PacifiCorp Energy, and Wyoming Municipal Power Agency.

Sponsors for this year’s meeting are Baldor Electric Co, Conco Systems Inc, Evapco-BLCT Inc, GEA Power Cooling, Howden, Johnson Controls Inc, and SPX Cooling Technologies.

No-frills CCUG focuses on formal presentations, open discussion: October 16-18

The Combined Cycle Users Group (CCUG), chaired by Larry Small of Calpine Corp, opens its 2012 Annual Conference at the Buena Vista Palace Hotel & Spa in Lake Buena Vista, Fla, (adjacent to Disney World) October 16 with a welcome reception from 5 to 6:30 p.m. The formal meeting will be held October 17 and 18. A preliminary program is posted on the organization’s website at www.ccusers.org.

The CCUG’s meetings are dedicated to formal presentations and attendee-driven discussion sessions focusing on the design, construction, operation, and maintenance of the integrated plant. Additional topics addressed include NERC and other regulatory impacts on plant operation, environmental rulemakings, plant mods to achieve performance goals, safety initiatives, professional development, skills training, etc.

Prepared presentations and discussion this year focus on the following:

- Reliability and strategic planning—including cycle design improvements to improve performance, reduction of costs and emissions, emerging technologies, challenges associated with integrating renewables.

- High-energy fluid systems/equipment—including valve and piping issues, boiler-feed pumps.

- Issues on the minds of attendees.

- Challenges of modern control and electrical systems—including cyber security, remote monitoring, instrumentation, alarm management, DCS, startup and shutdown automation.

- Performance monitoring and assessment of gas and steam turbines and heat-recovery steam generators.

- Operating challenges and changing paradigms of combined-cycle plants.

- Water management, chemistry, and corrosion control for the steam/water cycle and cooling and makeup water.

- Safety management—including OSHA VPP, fire protection, arc flash, job hazard analysis, manual of change, work permits, culture, process safety management.

- Best practices, lessons learned, and knowledge sharing.

Thought leaders include Chairman Small, Vice Chairman Robert Mayfield of Tenaska Inc, TVA’s Mike Hoy and Daniel Noles, Steve Royall of PG&E, Andy Donaldson and Dan Sampson of WorleyParsons, Phyllis Gassert of Dynegy Midwest Generation Inc, Performance Specialist James Koch, and Calpine Corp’s Tony Wiseman.

Sponsors for this year’s meeting are AAF International, A&R Turbines, Emerson Process Management, MRG Inc, Toshiba Power Systems Co, and URS Corp.

Shop tour adds value to meeting: October 23-25

The 7EA Users Group, chaired by Pat Myers, plant manager of AEP’s Ceredo Generating Station, announces that the first day of the organization’s annual conference, October 23-25, in Greenville, SC, will be devoted to presentations by the OEM and a tour of GE’s manufacturing facilities. The meeting will be held at the Embassy Suites Greenville Golf Resort and Conference Center.

A vendor fair is scheduled for Wednesday evening, October 24. No other details were available through the user group’s website at the CCJ’s deadline.

Members of the steering committee in addition to Myers are Michael Johnson of Turlock Irrigation District, Guy LeBlanc of First Energy Corp, Ray Lathrop of Corn Belt Power Co-op, Jim Beveridge of Utah Associated Municipal Power Systems, Amy Alix of Progress Energy, and Lane Watson of FM Global.

Ovation Users’ Group recognizes Calpine’s Carville Energy Center

Presentation of the Ovation Users’ Group’s awards to power and water projects for their contributions in the development and implementation of controls solutions to improve performance, reduce O&M costs, and increase security and safety is a highlight of the organization’s annual meetings.

At the awards luncheon Tuesday, July 28, only a few days before this issue went to press, Calpine Corp’s Carville Energy Center was honored as the Power Project of the Year by the user group’s executive board. The award presentation was made by Bob Yeager, president, Emerson Process Management Power & Water Solutions, to Calpine’s Arthur L Mayclin, PE, manager of I&C engineering (corporate), Carville IC&E Tech Shane Lowe, plus Richard Johnson and Ralph Owens (Fig 1).

Lowe was involved with logic issues during the conversion, as well as with system commissioning. He also compiled some of the documentation required in support of the bid. Mayclin worked with the plant engineer to produce the technical specifications. He also participated in the review of proposals and other project tasks.

Carville, a 450-MW 2 x 1 combined cycle powered by GE 7FA.03 gas turbines, began commercial operation in 2003. Alstom heat-recovery steam generators and an Alstom steam turbine complete the power block. Plant manager is Reg Jones.

While Carville’s equipment lineup is a relatively standard configuration, the fine print revealed three different primary control systems: Mark VI for the GTs, Advant for the steamer, and Teleperm-XP (better known as TXP) for balance-of-plant. As the years passed, the O&M challenges associated with operating and maintaining three systems proved challenging.

Initially, the plant’s goal was to replace the Advant system. Reasons included the relatively high cost of parts and service, difficulties encountered in obtaining critical parts, and limited onsite staff for troubleshooting upsets and/or implementing control and graphics modifications.

After the award was issued to replace the Advant system, the decision to retain the TXP system was revisited because of cost and parts/service availability concerns. An Ovation migration emerged as a logical and economical decision. Important to note is that by using an Ovation-to-ET200M I/O interface, the plant realized considerable cost saving because the TXP I/O modules did not have to be replaced.

In sum, by converting the Advant and TXP systems to one DCS, Carville Energy Center benefits by having one common platform, a reduction in spare-parts inventory and personnel training, and a smaller network and workstation footprint.

City of San Diego’s Metropolitan Biosolids Center received the user group’s Water Industry Project of the Year Award for its Ovation migration without a plant shutdown. The live migration of 41 WDPF (Westinghouse Distributed Processing Family) controllers and 23 Solaris workstations to an Ovation system running Windows XP, while combining the facility’s three data highways into one, was accomplished without any overtime.

The City’s Ian Harris, PE, who accepted the award from Yeager (Fig 2), told the group that Emerson mitigated the risk of accidentally knocking the huge plant offline while cutting over from WDPF to Ovation by installing the new system in parallel with the old. Harris explained how this was done using the plant’s three digesters as an example. The first digester to be migrated to Ovation was put in manual while the other two continued to operate in auto on the WDPF system. When the first migration was complete, the second digester was put in manual and migrated, and so on.

The order of the cutover plan was modeled during the factory acceptance test to be sure the migration sequence was correct before any field work was done. Also, to streamline the migration, the converted graphics were reviewed by Harris and City staff online.

The overall Award of Excellence went to Indianapolis Power & Light Co’s controls replacement project at its coal-fired Petersburg Units 1 and 4 (Fig 3). The boiler controls, burner management system, data acquisition system, turbine controls, etc, for these generating units all were at the end of their useful lives: They had limitied functionality and obsolescence issues, and parts and services were hard to obtain.

Today, both units have better response times for dispatched load changes, as well as rundowns and runbacks in the event of a process upset, plus:

- Expanded alarming and notification capabilities.

- The ability to make process changes and/or track operating parameters to comply with new environmental and NERC/FERC regulations.

- A Global Performance Advisor to provide plant personnel the information needed to operate at top efficiency.

- A significantly improved turbine operations protection scheme.

Precision Iceblast on network TV

Keith Boye, VP of Wisconsin-based Precision Iceblast Corp called CCJ’s editorial offices to report that PIC was featured on the World’s Greatest TV show in late July (Fig 4). Eight companies are profiled in each half-hour segment of the weekly show, which has been running for six years.

World’s Greatest Production Manager Josh Kessler told the editors that PIC was selected for the interesting work it does and for its “stellar reputation” among customers in the industries served. He said development teams consisting of producers, writers, and researchers continually

scour the nation’s myriad industries for interesting products, services, etc. Suppliers selected for further review are investigated and evaluated. The leading candidates then are interviewed and a company is selected for inclusion in the show. A script is prepared and film crew typically spends a day in the field shooting the company segment.

The profile demonstrating how HRSG tube bundles are cleaned was filmed at an F-class 2 x 1 combined cycle in March 2012 (Fig 5).

Yet another use for dry ice: Painting prep

Donaldson Company Inc’s Barry Link, a familiar face at user group meetings, told the editors that his company and Precision Iceblast Corp (PIC) had teamed up to offer upgrade and rehabilitation services for gas-turbine air inlet systems. Deterioration of metal surfaces is relatively common in air inlet houses because painted carbon steel is the material of choice for filter and evap-cooler structural members among parsimonious owners, and the environment typically is high-moisture. Rusting metal contributes to wear and tear of compressor airfoils because oxide continually flakes off and flies downstream at high velocity into the unit.

Theoretically, just about any maintenance person can wire-brush away rust spots and hit them with paint. But that won’t cut it in the air inlet house. Rusting is virtually sure to continue under the glob of paint and the next flake that comes off will be bigger, heavier, and do more compressor damage.

Donaldson always offered customers painting services where required, typically using sandblasting equipment to prep surfaces after removing filters and evap-media fill. Cleanup always was a painful part of the job, recalled Link. Every bit of grit and all the paint it removed had to be swept/vacuumed up and removed prior to painting. No one wanted that material being swept downstream into the compressor.

PIC had an idea: It could remove rust, lose paint, etc, with high-pressure CO2 blasting, leaving only rust and paint chips for the clean-up crew. Plus, the company had crews trained in powerplant practices from its work cleaning HRSG heat-transfer surfaces, as well as the scaffolding to access all surfaces requiring treatment. Finally, PIC had coatings experience from work in other industries (Figs 6, 7).

Here’s the way a typical evap-cooler restoration project works for an F-class installation: Donaldson crew removes the evap media on the first day; PIC does the scaffold erection, installation of curtains downstream of the cooler, CO2 blast, coating (12 mils of an epoxy designed for marine environments), curtain removal/scaffold breakdown, and cleanup over the next four days; Donaldson crew reinstalls media (previous or new) in two days.

The editors called a couple of customers. One plant manager with four 7EAs and one 7FA—all peakers—said he had a real corrosion problem with his big machine and hired Donaldson to correct it. Coating lasted less than a year. Surface preparation by sandblasting was inadequate he said. Next attempt was by a Donaldson/PIC team. “Seems to have worked well,” the PM added, “More than a year later, the evap cooler still looks OK.” Evap coolers on two of the 7EAs were overhauled the same way last fall; success. Coolers on the remaining two units will be restored this fall.

The second user contacted said he hired Donaldson to replace filters (plant gets about five years on a set of filters) and evap media (nominal 10-yr life) and to restore the evap-cooler framework. He knew PIC from previous HRSG work and embraced the partnership for his project. Final assessment: The two teams worked seamlessly, quickly, and efficiently.

A back-of-the-envelope calculation suggested that the plant could repaint the evap cooler as often as every two years and still be less expensive than retrofit with a stainless-steel frame. Cooler condition is checked annually.

Also, this user took the opportunity to make a small modification to the evap cooler as suggested by Donaldson: Installation of drains at the ends of the water distribution header to eliminate packing of debris and promote better distribution of water across the media. Better performance resulted.

Register today, Early Bird rate expiring soon

Register today, Early Bird rate expiring soon

www.doble.com

2012 Revolutionary Machines: Electrical Plant Reliability and Rotating Machinery Seminar September 10-13, San Francisco

This well-respected annual seminar is designed for O&M personnel at electric generating plants, refineries, pulp and paper mills, and petrochemical plants, as well as for the equipment/services firms, EPC contractors, consulting firms, and insurers serving these owner/operators. Learning modules include the following:

- Machine reliability analysis

- Motor theory and principles; motor design and construction.

- New and repair specifications development

- Machine failure analysis

- Generator design and construction

- Electrical balance-of-plant testing

Questions: Write events@doble.com or call 617-926-4900

Association news

TICA, the Turbine Inlet Cooling Assn, Naperville, Ill, announces the availability of a complimentary online forum for gas-turbine users, webinars on turbine inlet cooling (TIC) technologies, a database of TIC installations, and bibliography of technical papers. Owner/operators must register for TICA membership (no charge through end of September) to participate in the forum. Go to www.turbineinletcooling.org.

TICA’s first webinar in its complimentary series, “An Overview of Turbine Inlet Cooling,” presented in late June, was a success, Don Punwani, the association’s executive director, told the editors. Next webinar, “Wetted-Media Evaporative Cooling Technology,” will be conducted August 22. Register for this and future webinars on the website. Refer questions to Punwani at exedir@turbineinletcooling.org or call 630-357-3960.

Powerplant news

Dean Motl, plant manager, New Harquahala Generating Co LLC, announces the eighth annual Joe Lopez Memorial Golf Tournament, September 24, at the Raven at Verrado Golf Club in Buckeye, Ariz. Last year the plant raised more than $20,000 for the Muscular Dystrophy Assn; the 2012 goal is $25,000.

Competition is an 18-hole, four-person scramble. Greens fees, range balls, cart, and lunch are all provided by New Harquahala. Donations are not required to participate. RSVP by September 4. Registration is at 6:45 am, on September 24, shotgun start at 7:30, lunch and awards at 12:30. The game-within-the-game includes a hole-in-one contest, beat-the-pro hole, and putt-for-dough contest. Refer questions to Motl at dmtol@harqgen.com, 623-810-1346.

Contracts

MPS Canada Inc, a wholly owned subsidiary of Mitsubishi Power Systems Americas Inc, receives an order for two M501GAC gas turbine/generators from the TransAlta Generation Partnership for the Sundance 7 power generation facility in Alberta. Mitsubishi has received orders for more than 75 M501G engines worldwide, half that number for service in North America.

Siemens AG reports POSCO Energy of Korea has ordered three single-shaft H-class combined cycles for service in summer 2014. Each unit is rated over 420 MW at 61% gross efficiency and designed for 250 annual starts. Full power can be achieved in 30 minutes on a hot start.[LINE SPACE]

Puretec Industrial Water, Oxnard, Calif, renews contracts for ultrapure water with Arizona Public Service Co and Salt River Project for another five years.

Company news

NAES Corp, Issaquah, Wash, adds a combustion turbine services group with over two centuries of experience to its Houston-based Turbine Services Div. The new group is led by Darron Pruitt, who joins NAES as director of turbine field services. Other key appointments: Jimmy Cassel, operations manager; Technical Advisors Glenn Hogan and Roger Howell; Andy Hill, field engineer; Field Services Supervisors Paul McCraw, Jeff Townley, Todd Nessmith, and Billy James; and Ryan Pruitt, project control engineer.

“The addition of this team solidifies our position as the premier third-party turbine services provider,” says Butch Kimbrell, VP/GM of the company’s Turbine Services Div. “We are well equipped to address customer needs in the growing combustion-turbine market with the right mix of tools, technical knowledge, supervisory skills, and labor.

Advanced Filtration Concepts Inc, Los Angeles, re-launches its website at www.advfiltration.com, making it more user-friendly and far more comprehensive in its offerings. It offers details on air filtration options, service capabilities, installation, delivery, etc.

Membrana-Charlotte, a division of Celgard LLC, expands its Liqui-Cel® membrane contactor store at the request of customers wanting to purchase a greater variety of degassing products online. Shop now at http://store.liqui-cel.com.

GP Strategies Corp is the new name for General Physics Corp. GP Strategies previously was simply the name of General Physics’ publicly traded parent company. Only the company name changes: The Energy Services Group remains a full-service provider of workforce development and performance engineering solutions.

Analysts Inc, Hawthorne, Calif, moves its Southeast operations to Suwanee, Ga, and expands its lab there to nearly 16,000 ft2. The company provides oil, coolant, and fuel analysis services to the power generation and energy-intensive process industries.

Dresser-Rand Co acquires certain intellectual property assets, including patents and trademarks, from Energy Storage & Power LLC and Dr Michael Nakhamkin. The company is now able to provide the smallest to the largest compressed-air energy storage projects to meet specific grid-scale requirements.

Products/services

ESCO Tool, Holliston, Mass, offers a full line of cutter blades and locking cutter heads for its welding end-prep tools that can bevel, face, and bore simultaneously,

while improving weld surfaces (Fig 8). Millhog® cutter blades, available for any angle of prep from 37.5 to 10 deg, are able to produce a thick chip without cutting oils. They are suited for stainless steels, P-91, and other hard tube and pipe materials from 0.5 to 36 in. OD.

while improving weld surfaces (Fig 8). Millhog® cutter blades, available for any angle of prep from 37.5 to 10 deg, are able to produce a thick chip without cutting oils. They are suited for stainless steels, P-91, and other hard tube and pipe materials from 0.5 to 36 in. OD.

Portable welding end-prep tool features a variable-speed 14-amp motor for applications where compressed air is not available (Fig 9). Wart Millhog is an ID clamping tool suitable for machining highly alloyed stainless steel pipe and tube from 0.75 in. ID to 4.5 in. OD without cutting oils.

Millhog Dictator, an ID-clamping welding end-prep tool features extra-wide clamps for rigidly mounting inside pipes from 4.5 in. ID to 18 in. OD (Fig 10). Powered by a pneumatic motor, tool develops 4000 ft-lb of torque. A hydraulic motor is an option. Tool eliminates the need for hand grinding and the use of complex clamshell tools.

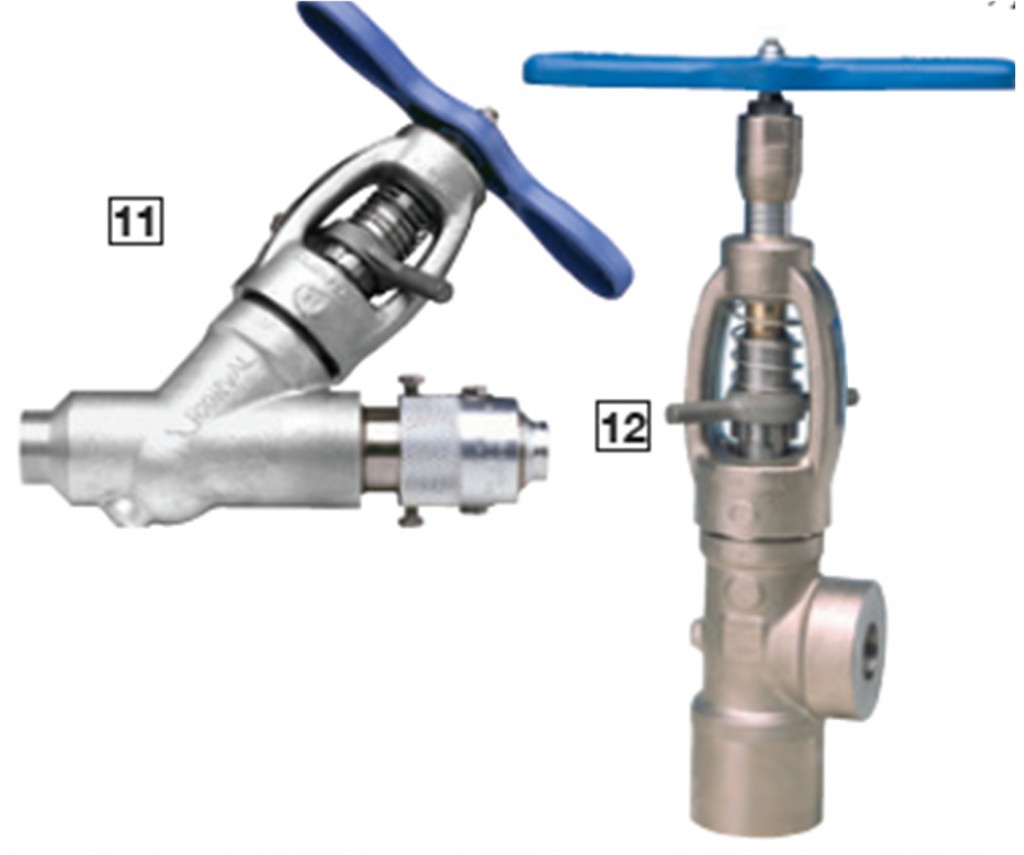

Conval Inc, Somers, Conn, announces an easy-to-retrofit, single-weld, OSHA-compliant safe vent drain for its Clampseal® Y-pattern forged globe valves (Fig 11). SaVD safe vent drain is available in 0.2 to 2 in. sizes, through ASME 2500 pressure class with NPT, butt- or socket-weld ends. Standard materials include a range of stainless steels and F22.

Clampseal forged throttling valves for severe-service applications assure repeatable flow control and dependable shut-off (Fig 12). Valves are available in sizes from 0.5 to 4 in. and in pressure ratings from ASME Class 900 to Class 4095. Materials include Type-316 stainless steel, F91, F92, and SA 182 F22. Catalog with engineering data can be accessed at www.conval.com.

Oil Filtration Systems, Boerne, Tex, announces the availability of oil reclamation, purification, and oil flushing field services. Periodic high-velocity hot-oil

The company also has developed a line of filters and coalescers to remove particulates and water from diesel oil and other gas-turbine fuels (Fig 14). The two-step fuel-cleanup process works this way: First, high-efficiency particulate filters remove particulates down to 1 micron; next, high-efficiency coalescers and separator elements remove free water to less than 50 ppm.