Worthington Generating Station

Owned by Hoosier Energy Rural Electric Co-op Inc Operated by NAES Corp

174 MW, four simple-cycle LM6000 natural-gas-fired peaking units, located in Greene County,

Ind, and connected to Hoosier’s 138-kV transmission line

Plant manager: Robert VanDenburgh

The benefits of upgrading package lighting to LED

Challenge. The S&S packages for Worthington’s gas turbines have two lights that when working properly will illuminate the entire engine space. However, these incandescent lamps constantly fail and are extremely unreliable. Inevitably, technicians have to replace the compartment lights prior to completing their assignments.

This can be dangerous and extremely time-consuming, requiring fall protection given the locations of the bulbs and a LOTO to eliminate the shock hazard. The challenge presented to the safety committee was how to improve the longevity, dependability, and reliability of package lighting. Better lighting would greatly reduce the amount of time technicians spend donning fall protection and working under the lighting LOTO clearance.

Solution. The safety committee discussed several compartment lighting options and made the decision to install industrial LED bulbs. Staff purchased the bulbs and hired an electrician to inspect the wiring and selector switches. Plant technicians removed the old light bulbs from each of the compartment light fixtures and replaced them with the new LED bulbs.

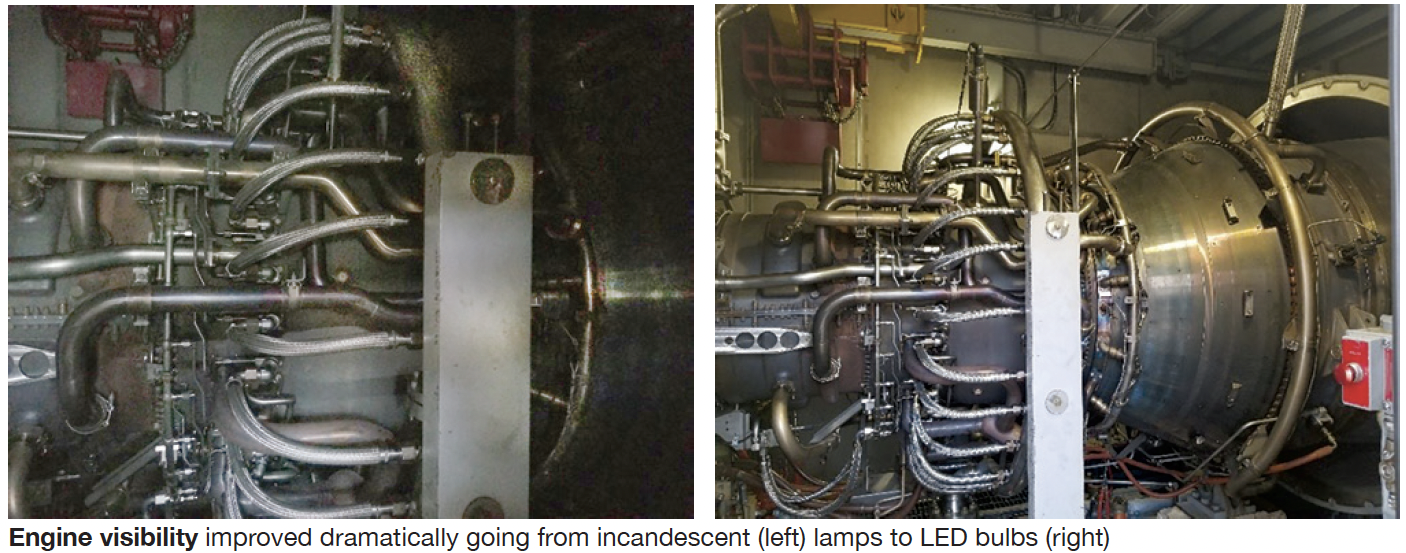

Results. The LED lights are extremely reliable. Turbine compartment visibility has improved dramatically (photos). The selector switch on each side of the package is reliable. LED lamp longevity will both reduce the number of LOTOs needed to replace lamps and time spent in fall protection. Upgrading package lighting significantly decreased the amount of time needed to complete PM work in the package.

Project participants: Matthew O’Hara, OMT

Jason Robertson, O&M/ICE tech William Hooker, OMT