Reducing turbine lube-oil varnish potential extends fluid’s useful life

Challenge. Lea Power Partners’ (a/k/a Hobbs Generating Station) combined cycle is equipped with two M501F gas turbines and a D11 steam turbine. The GTs have 5000-gal lube-oil reservoirs, the steamer a 3600-gal tank. After eight years of service, the varnish potential of GT lube oil, based on the Membrane Patch Colorimetric Test (MPC) results, ranged from 46 to 50, the ST fluid was more than 20.

Plant’s goal was to reduce the varnish potential and safely extend the life potential of these reservoirs, thereby deferring the cost of replacement oil to coincide with a future planned outage.

Solution. Working with Hilliard Corp’s HILCO Div, plant personnel and lube-oil experts developed a plan to recover the reservoirs to acceptable varnish-potential levels as quickly as possible to prevent further oil degradation and not disrupt Lea’s operations. The solution was to treat the reservoirs by using a temporary, portable oil-conditioning unit with a remediation dosage of dry-resin ion-exchange media in a kidney-loop arrangement.

Concurrently, Lea’s staff repurposed HILCO oil conditioners no longer required by a sister plant to maintain low varnish-potential levels going forward with a much smaller amount of ion-exchange media once the higher-capacity conditioning unit had removed the bulk of the varnish.

Plan was to run the bulk treatment unit on each reservoir for four weeks and then commission a permanent maintenance unit to run continually. The portable unit then would be moved to the next reservoir for bulk treatment.

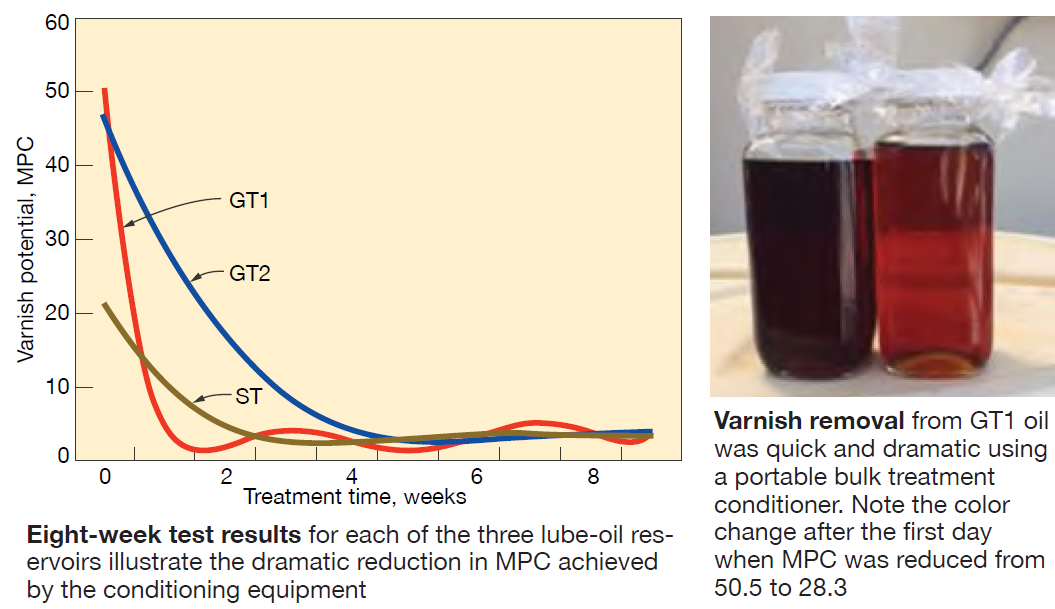

Results were immediate and impressive. After only 24 hours of operation of the bulk treatment conditioner on GT1, a substantial improvement in the appearance of the oil samples was observed (photo). Varnish potential was reduced from 50.5 to 28.3 MPC. Similarly, after GT2 had one of the 3.5-gpm repurposed oil conditioners hooked up for 24 hours, samples showed a reduction in varnish potential from 46.1 to 34.9 MPC.

Clean up of GT1 oil using the portable bulk treatment conditioner took less time than expected, allowing staff to switch to the permanent smaller conditioner in only three weeks. The bulk treatment conditioner then was moved to GT2.

Long-term results: During the eight-week monitoring period, the varnish potential on GT1 turbine lube oil was reduced from 50.5 to 3.7 MPC, on GT2 from 46.1 to 3.8 MPC, and on the steam turbine from 21 to 2.7 MPC (figure).

The reduction in varnish potential allowed the plant time to arrange for lube-oil replacement consistent with a future planned outage, thereby deferring the purchase of new oil until the expense could be budgeted. Note, too, Lea saved $15,000 by recommissioning conditioning equipment no longer needed at a sister facility.

Project participants:

Richard Shaw, O&M supervisor

Carlos Sanchez, engineering manager

Tyler McCoy, Guadalupe Garay, and Kelvin Mendenhall, I&E technicians

Cesar Garcia, senior operations technician

Roger Schnabel, plant manager

Lea Power Partners LLC

Western Generation Partners

Operated by Consolidated Asset Management Services (CAMS)

604-MW, gas-fired, 2 × 1 combined cycle located in Hobbs, NM

Plant manager: Roger Schnabel