Ensure a reliable, sufficient supply of quality water to support generation assets

By David Addison and Judy Weir, Thermal Chemistry Ltd

The purpose of any water treatment plant (WTP) for this industry is to produce a reliable and sufficient supply of product at the quality required by the host plant to support generation operations. Organizations such as EPRI and the International Association for the Properties of Water and Steam have long advocated the need to maintain strict quality limits for both makeup and the steam/water cycle to avoid issues such as boiler tube failures and steam-turbine deposition and corrosion.

Power generators call their WTPs by different names, some of which refer only to a specific part of the total system—such as deionization or pretreatment. For this presentation, the term WTP refers to all treatment processes used in the production of demineralized makeup from the raw water supplied to the plant.

Pretreatment refers to that segment of the WTP producing clarified and/or filtered water for downstream demineralization. It can range from simple chlorination and physical filtration of the water supply to chemical clarification and flocculation followed by sand or multimedia filtration.

The demineralization plant refers to the system that removes dissolved ions and produces water of very low conductivity (less than 10 uS/m) and silica (less than 10 ug/L) for boiler makeup, gas-turbine NOx control, etc. The technology may be membrane-based—like reverse osmosis (RO) followed by continuous electrodeionization (CEDI)—or ion exchange, using resin beds.

Quality, quantity, and reliability are interlinked, and often the issues impacting one—such as changes in feedwater quality, plant operation, and/or maintenance—affect all. It is difficult to talk about one of these variables without referring to the others.

Quantity is important because the WTP is designed to produce a certain amount of product consistent with the quality and variability of the incoming water. For example, with ion-exchange demineralization, each resin bed is capable of producing a certain quantity of final product water depending on the amount of resin in the bed, how many free sites this volume of resin has to exchange its hydroxyl and hydrogen ions, and the concentration and types of ions present in the feed water.

A change in the quality of incoming water—such as a higher concentration of total dissolved solids (TDS), increase in fouling potential, and/or regeneration problems are common reasons why a given resin bed does not achieve the desired amount of product water between regenerations.

A similar change in the quality of water flowing through RO and CEDI units also causes a decrease in product quality if the plant is left unmonitored. However, if output is reduced within design limits then the desired quality sometimes can still be maintained.

Unless there is a significant amount of redundancy built into a WTP—uncommon in today’s “cost-optimized” projects—and any of the subsystems fail to produce their design output at the required water quality, demin water quality and/or quantity always is affected. Sometimes a new WTP is installed at significant expense to produce more water when a review and optimization of existing plant design and operations is all that’s necessary.

The quality of demineralized water produced is important because the dissolved ions in this water ultimately will enter the heat-recovery steam generator (HRSG) and the steam path. Out-of-spec operation of the demineralizer is conducive to deposition and corrosion in both the boiler and steam turbine.

Sometimes, must-run requirements may “force” demineralizers to remain in service even when they are producing off-spec water. While this action might seem like a good idea at the time, it should not be allowed under any circumstances. The issue merely moves from the WTP to the boiler where it can be very time-consuming and expensive to correct. Also, keep in mind that the further water quality is out of spec, and/or the longer it is out of spec, the faster damage occurs and the worse it is.

Quality parameters are easily measured using the preferred and most-accurate technique of continuous online monitoring, or by grab sampling and manual testing. Problem with the latter is that it could be just that one time during the day when water quality is acceptable. Most probably not, but you just don’t know for sure.

Important, too, is that the testing procedure be applicable to the concentration range of the parameter being tested. For example, using a high-level dissolved-silica test method would be suboptimal for testing silica in the low range of 5-20 ug/L.

Also, when testing demin water, it is very important to avoid sample contamination, which can be challenging when grab samples are involved. Just allowing carbon dioxide to dissolve into an open grab sample will elevate its conductivity prior to testing in the laboratory.

Reliability. There is limited value in having a WTP that can produce quality water in the required quantity if it can’t do it every time makeup is required. Often, the size of tankage within the WTP, or downstream of the demineralizer, will determine the criticality the plant owner places on system reliability.

For plants with oversize demin tanks, reliability may not be an issue, given that required repairs or maintenance can be completed before the critical water level is reached. An industry standard is for sites to have 24 hours of makeup storage at the normal usage rate.

The main concerns often affecting the availability and reliability of the WTP to produce in-spec makeup 100% of the time it is required are the following:

- The lack of, or even identification of, critical spare parts for a plant that must produce water of a given quality 100% of the time it is needed.

- The lack of priority given to correction of issues. For example, small leaks left weeping or temporarily repaired until they became larger, more critical problems.

- Less-than-satisfactory plant and/or process design, which means water production is limited by, or relies on, a single or unspared component, or has suboptimal equipment and/or materials.

- An inability to understand the reliability status of the plant—such as in the absence of a plant-wide condition monitoring system and/or the amount of chemical monitoring via online or grab-sample analysis is limited.

- Operational practices and managerial decisions that allow out-of-spec water to enter the WTP when the design basis of the plant clearly states it is unable to process, without issue, water of such low quality.

Optimize WTP performance. A performance monitoring program (PMP) is essential for assuring that your water treatment plant is well-operated and –maintained. It is site/plant specific and gathers information on all of your facility’s water-treatment processes and equipment. Interestingly, despite their obvious value, such programs are not in use at many sites.

The PMP simplifies fault-finding related to quality and/or quantity shortcomings because critical areas are monitored continually and the data are collected and analyzed. Problems identified should be corrected quickly to maximize WTP availability.

After the initial work involved in implementing a performance monitoring program, and the important parameters are identified and documented, the ongoing operational commitment to monitoring and record-keeping does not require great effort. Large capital outlays or increases in WTP O&M budgets normally are not necessary.

A well-designed program is capable of identifying when potential problems may occur and suggest the most cost-efficient time to replace major cost items like membranes, resin, pumps, and vessels. The program also provides the mechanism for the communication of well-informed and –justified O&M decisions. Specifically, an effective performance monitoring program should include the following:

•A description of the overall water-treatment process and plant.

•A functional description of each component within the WTP.

•Details of persons accountable for the WTP.

•Performance criteria and action limits.

•Monitoring requirements and routine operational practices.

•Maintenance activities.

•Reporting and record-keeping.

•Plant-specific troubleshooting information.

•References to site-controlled procedures.

One dedicated WTP operator or technician per shift should be trained by a chemist on how to conduct minor, but meaningful, tests. Operators also should be trained to have a good technical understanding of the water treatment plant so decisions they make will be informed ones. This will help assure both production of high-quality water and a reliable plant. It is the WTP operator’s job to record observations and monitored parameters during walkdowns, take action on observed issues, review plant alarms and data trends, and respond appropriately when action limits are reached.

Calibration and maintenance of all instrumentation is essential if the WTP is to run efficiently. Without this effort, the quality and/or quantity may not be what the owner believes it is. A calibration regime is developed by reviewing current practices and producing a schedule. Maintenance checks and routines for mechanical, electrical, and chemical plant components should be documented. As part of this effort, critical spares should be identified and their immediate availability for breakdown repairs ensured.

Finally, the performance monitoring program should be a living document and the information it contains communicated to all relevant site personnel and followed to the letter.

Case history A: Poor product-water quality, reliability

Site A is home to a chemical process plant, constructed in 2004, which originally used all of its demineralized water for producing steam in two coal-fired boilers. The steam plant was a small, but critical part of the much larger process.

Two ion-exchange trains produced the demin water from town-supplied potable water. The facility had no chemist, or anyone else onsite with sufficient knowledge of water chemistry to understand the implications of sending poor-quality water to the boilers.

In 2010, the company initiated a site expansion that included installation of a combined-cycle cogeneration system capable of selling excess power to the grid. The new HRSG operates in parallel with the original coal-fired boilers as well as with a third identical coal-fired boiler added as part of the expansion.

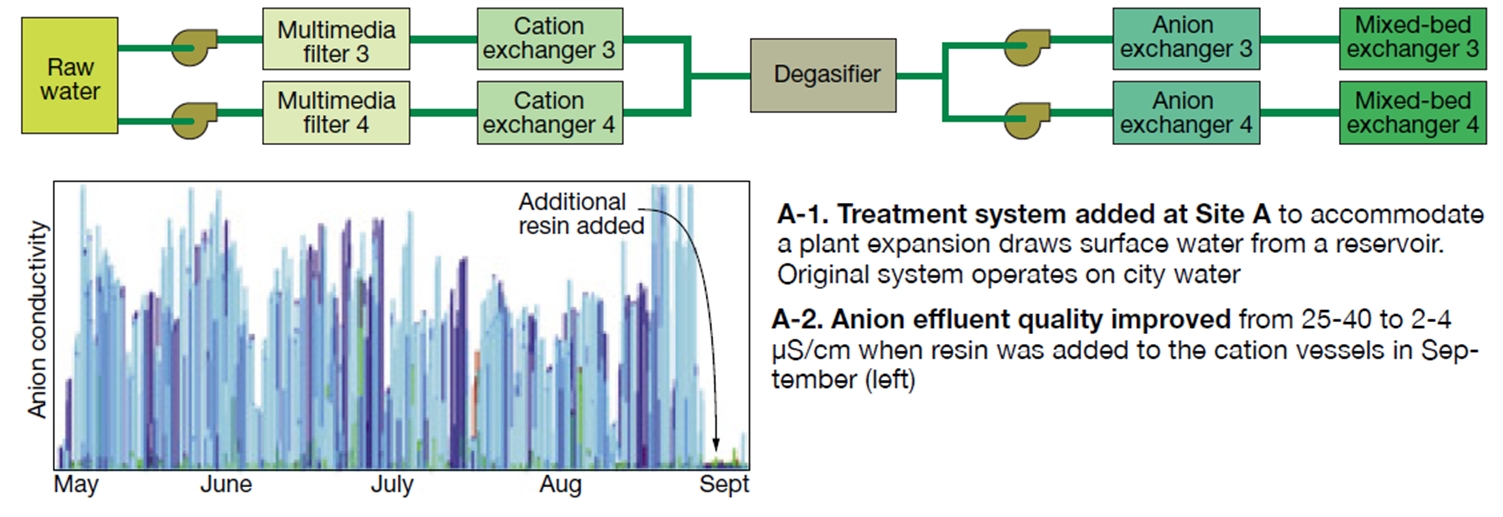

A second water treatment plant (called Stage 2) was added to supply the demin water required for the new boilers. The two-train system shown in Fig A-1 is identical to the original Stage 1 except that its water is supplied from a reservoir rather than from the city system.

As the block diagram shows, raw water first passes through a multimedia filter to reduce turbidity. It then flows through the demin train consisting of a cation vessel, a degasifier serving both trains, an anion vessel, and a mixed-bed exchanger. Stage 2 shares the acid and caustic regeneration system built for Stage 1. Regeneration is of the counter-current type.

Report card. When Site A was audited in 2011, several problems were noted. Most glaring, perhaps, was less-than-minimal monitoring of the water treatment process. Plant operators were unaware of the following:

•The quality of raw water received by the plant.

•Product-water quality (only conductivity was monitored).

•What was occurring within the WTP and inside the ion-exchange vessels.

Bowing to commercial pressures during a period of high demand, the plant owner (1) allowed out-of-spec raw water to enter the WTP and foul demineralizer resin and (2) permitted off-spec demin water to enter the HRSG and coal-fired boilers.

Absence of redundancy was another major issue. There was only one regeneration system for the four demin trains and only one train could be regenerated at any given time. This means that if a failure were to occur in the common system, resin regeneration would not be possible. Water availability would become a major concern if the regeneration system were not returned to service within 24 hours.

Also, with only one degasifier per stage, its contamination would adversely impact both trains of that stage. This makes troubleshooting of the problem train difficult. Online monitoring of the cation effluent, with appropriate chemical limits to trip the demineralizer train, was a simple and effective solution.

Auditors gave the site an unsatisfactory grade for its maintenance practices and absence of critical spares, inability to record process and equipment data for analysis following an upset or failure, and poor training for WTP operators.

Yet another issue: Since installation, the primary cation and anion beds had never been able to consistently rinse down to the required <7 uS/cm setpoint in the rinse recycle step of the regeneration process. The mixed beds from Stage 2 could achieve <0.2 uS/cm, so the train was meeting its quality and quantity requirements specified by the HRSG manufacturer.

However, it was not meeting its reliability requirements, because the mixed beds were regenerating three to four times more frequently than the original design basis. With the demineralizer train being regenerated six times a week, four-hour mixed-bed regenerations were occurring weekly in Stage 2 instead of every two months. This meant that Stage 2 trains were unavailable for eight hours more each week than they were designed to be. A consequence was that there were times when water having a conductivity greater than 0.2 uS/cm was forwarded to the makeup tanks.

The fixes. The first critical step in fixing the problems was for the plant owner to bring a chemist onboard. The new hire convinced management to stop allowing the WTP to accept off-spec (very high turbidity) water and to stop sending out-of-spec demin water to the makeup tanks. To remove particulate matter that had worked its way through to the anion resin beds, the chemist initiated a regular backwashing program to remove it from the cation and anion resin vessels.

The second step was to introduce more monitoring around the plant for relevant chemical parameters—including turbidity and chlorine ahead of, and after, the multimedia filters, differential pressures across the resin beds, regeneration flows, and chemical concentrations.

Today, when monitors detect feed-water turbidity higher than the design basis of >10 NTU, management switches to the more expensive town water to supply Stage 2 trains until turbidity drops below the design value.

Because the Stage 2 demin-plant supplier filed for bankruptcy, the problem with the cation/anion rinse down was not resolved until after the audit. During the ensuing outage, the manhole plate on the cation vessel was removed and an inspection conducted. The resin was clean, but its level was significantly low. The combination of the loss of inert resin, which increased the freeboard volume, and the low regeneration flows used during the first step of the regen process, meant that the bed was fluidized during regeneration instead of being compacted.

Problem was addressed by adding more strong-acid cation resin to the vessel. Fig A-2 charts the results. Follow-up actions included the replacement and addition of inert resin, as well as installation of resin traps on each vessel to detect any future resin losses.

Although the plant owner still does not have a complete performance management program in place, WTP performance has been improved by monitoring more parameters, conducting more inspections, and assuring accountability and communication of important issues.

Case history B: A success story

Site B was equipped with a 20-year-old conventional coal-fired plant and a new, small simple-cycle gas turbine requiring demineralized water injection. Planning for a 400-MW combined-cycle addition was underway. The site had experienced chemists and dedicated operators for the water treatment plant.

Demineralized water was monitored for conductivity and silica and the plant had a good history for recording problems and such operating information as train throughput volumes, resin change dates and volumes, and water consumption. The WTP had significant redundancy and operated the way designers had intended.

However, the owner had stopped detailed chemical monitoring of raw water supplied to the facility. And O&M parameter monitoring—for example, pressure drops across resin beds, rinse-down times, and instrumentation calibration—was poor. Resin maintenance practices (such as anion brine cleaning) had become ad hoc and an activity of last resort.

The owner reported an increasing number of problems with the plant which demanded a greater amount of troubleshooting time. Coincidentally, as the number of problems increased, plant maintenance was given a lower priority and there often was a backlog of work.

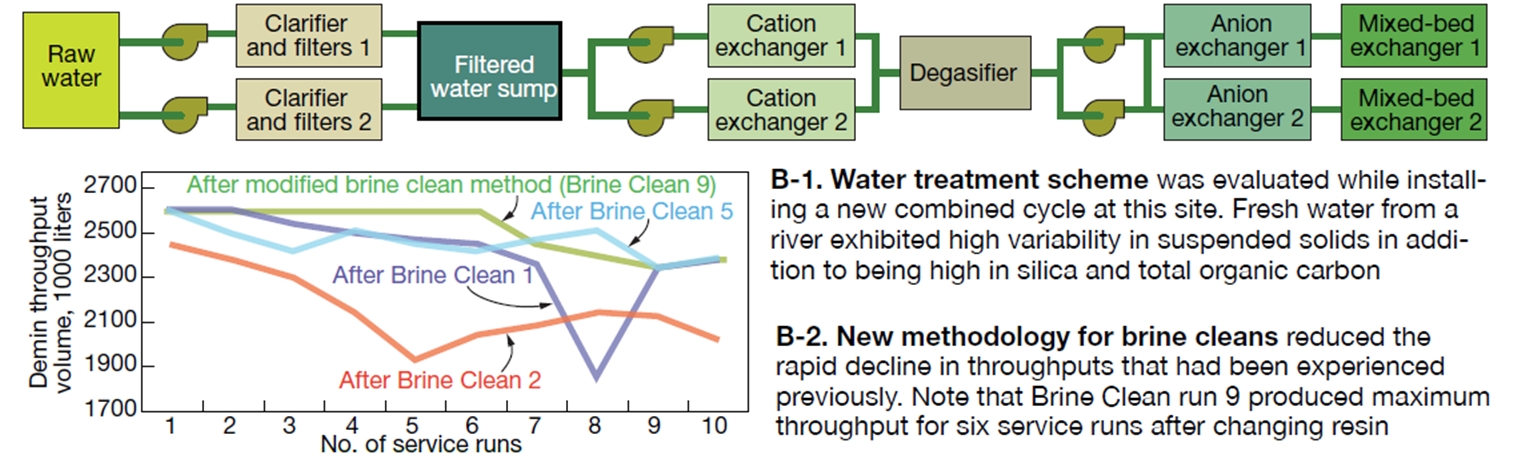

While site preparations were underway for the new combined cycle, WTP capabilities were reviewed. Site B clarified and filtered raw water from a freshwater river supply and the product was fed to two co-currently regenerated demineralization trains—each consisting of cation, stratified anion, and mixed-bed vessels.

The single degasifier serving both trains was located between the cation and anion vessels (Fig B-1). River water had significant seasonal variations in suspended solids as well as high levels of silica (about 20 mg/L) and total organic carbon (TOC, about 5 to 7 mg/L).

A benefit of the WTP review was implementation of a performance monitoring program. The owner started monitoring recommended chemical and operational parameters and began regular resin maintenance and testing. A reliability-centered maintenance (RCM) review was performed with the outcomes from that process used to improve WTP maintenance and reliability.

The PMP has reduced both the number of problems and troubleshooting activities, allowing plant personnel more time for process optimization efforts. Here are a few of the improvements implemented based on PMP results:

- Installation of a TOC analyzer at the outlet of each anion vessel (to help optimize brine-cleaning frequency) and mixed-bed vessel (to measure TOC in makeup water).

- Installation of sodium analyzers on the cation-vessel outlets to help identify the source of high-conductivity events from outside the anion vessel.

- Optimization of brine cleaning methodology.

Regarding the last point, review of historic data indicated that after each brine clean, demineralized water production would increase for one or two service runs and then begin to decline again. Resin testing initiated as part of the PMP revealed that the weak base anion resin was only 41% regenerated after a brine clean.

Using this information, plant management changed the methodology for brine cleans and has successfully reduced the rapid decline in throughputs after each cleaning cycle. Fig B-2 shows declining throughput for runs 1, 2, and 5 immediately after the brine clean. However, after process modification, illustrated by run 9, maximum throughput was achieved for six service runs. CCJ