American Surface Modifications LLC, www.asm-llc.com, On the nature of coatings for F-technology components, Purush Sahoo, Francis Dinh, and Randall Martin.

Degradation of hot-section components can be problematic for owner/operators and result in financial penalties associated with downtime and loss of efficiency. Coatings are critical for mitigating degradation mechanisms—including high-temperature oxidation and hot corrosion. Speakers shared operating experiences of different types of coatings by way of case studies.

Buffalo Pumps, www.buffalopumps.com, Evolution of Buffalo Pumps on the GE 7F turbine package, Scott Lombardo.

Presentation focus was the design evolution of lube-oil pumps for both gas and steam turbines. Extending the interval between thrust-bearing replacements has been one of the company’s primary goals over the last several years. First phase of this program was a redesign of the bearing housing to accommodate a 16,000-hr interval. All pumps sold since 2004 are so equipped. For the installed base, the company developed a complete drop-in replacement pump end which can be installed in the field or in the factory.

Donaldson Company Inc, www.donaldson.com, Understanding the ASHRAE 52.2 filtration efficiency testing standard and other key factors that should be considered when evaluating inlet filtration options, Bill Goodson and Barry Link.

Donaldson Company Inc, www.donaldson.com, Understanding the ASHRAE 52.2 filtration efficiency testing standard and other key factors that should be considered when evaluating inlet filtration options, Bill Goodson and Barry Link.

Plant personnel may not have a say in the selection of inlet-air filters for new peaking and combined-cycle plants, but they certainly are involved in choosing replacements. The Donaldson presentation was valuable for updating users’ understanding of important variables and key filter performance data—including ASHRAE 52.2 test reports. It began with a review of the different types of media, discussed particle removal efficiency, explained dust holding capacity, and addressed filter life.

Of particular value to 7FA owner/operators in attendance was the importance of understanding your specific application. Goodson and Link pointed out that an air filter performs differently at different air flows and in different configurations. They said that the configuration of the inlet system and the air flow a filter module handles can have a major impact on its performance.

The speakers compared a variety of designs offered by Donaldson for 7FA service—including vertically mounted self-cleaning cylindrical filter elements, self-cleaning conical/cylindrical filter element pairs mounted horizontally, static conical/cylindrical filter element pairs mounted horizontally, and Wave™ panel filters of varying depth.

The presenters then reviewed factors that can impact filter performance and life. They started with location/ambient environment, commenting on relative humidity, liquid water (fog and rain), snow and frost, hydrocarbons, concentration of ambient dust, varying environmental conditions.

Another factor they discussed was the gas turbine’s operational profile: The number of hours your engine operates can impact filter selection.

The importance of ASHRAE 52.2 to users for comparing the performance of alternative filter offerings was stressed. The standard guides determination of an air filter’s resistance to air flow and its ability to remove contaminants from the air stream. Goodson and Link explained how filter performance is evaluated with a standard dust and how the MERV (Minimum Efficiency Reporting Value) is determined. A sample test report was explained and provided to attendees.

Users unable to attend the Donaldson presentation can get a copy of the paper prepared especially for the meeting by emailing filterinfo@donaldson.com.

D-R Leading Edge Turbine Technology Services, www.dresser-rand.com, Latest technical solutions for F-class component repair and refurbishment, Greg Snyder.

Snyder provided insights into D-R LETTS’ latest technical solutions for F-class component repair and refurbishment. A description of the company’s new F-class rotor shop, which will add to the comprehensive line-up of repairs and services already offered, was included. The state-of-the-art addition will increase shop lifting capability to 80 tons and 50 ft under hook, with provision for future growth (Fig 20).

F-class rotors require a fully equipped world-class facility, engineering capability, and top technology to successfully resolve the unique issues associated with these high-tech designs. Dresser-Rand’s available resources and commitment to excellence are driving the development of alternative service and repair solutions that few others can provide, Snyder told the group.

These same capabilities also can help owner/operators better manage their rotors up to—and possibly beyond—the original design lives of those components. Successful continued operation can be achieved through a combination of inspections, high-end analyses, and repair and parts solutions.

The enhanced capability offered by the new facility will help DR-LETTS provide the user community access to a high-tech one-stop shop. By adding parts, field service, and control offerings to our existing engineering solutions, Snyder said, we continue with the company’s commitment to provide the industry very attractive low-cost alternatives.

Gas Turbine Efficiency, www.gtefficiency.com, Automation of gas turbine performance, Chris Soileau.

Soileau followed up on a 2009 presentation to the 7F Users Group by a team of engineers from Entegra Power Group LLC (CCJ, 3Q/2009) that described how Gas Turbine Efficiency’s ECOMAX™ gas-turbine optimization system allowed them to improve performance and increase power output without exceeding OEM design limits.

He said that ECOMAX allows continuous tuning of the gas turbine without external operator intervention. Predefined selectable parameters, determined by the plant operator, allow flexible matching of turbine performance with operational goals. Experience of several natural-gas-fired 7FA Model 7241 turbines equipped with the system, has been favorable, Soileau added. Benefits include: more power, tighter control of combustion and emissions, and elimination of seasonal tuning and tuning following combustion and hot-gas-path inspections.

Software add-ons for enhancing turbine operation were part of the presentation. These included firing-curve adjustments to OEM preset limits, turndown, and startup emissions optimization.

HRST Inc, www.hrstinc.com, Quenchmaster: The solution to desuperheater overspray, Amy Sieben.

Sieben began by reminding users that low-load operation can be detrimental to the health of their HRSGs. Reason is that for some gas turbines—such as the 7FA—exhaust temperature increases at low loads. More specifically, the exhaust from a 7FA can be as high as 1200F at loads from about 30% to 70% of rated output.

Operation in this range can cause over spray in interstage desuperheaters as the control system calls for more water to reduce excessive steam temperature. Over spray is conducive to fatigue damage in large-bore piping downstream of the desuperheaters if the pipe undergoes a large, sudden temperature drop associated with the over-spray event.

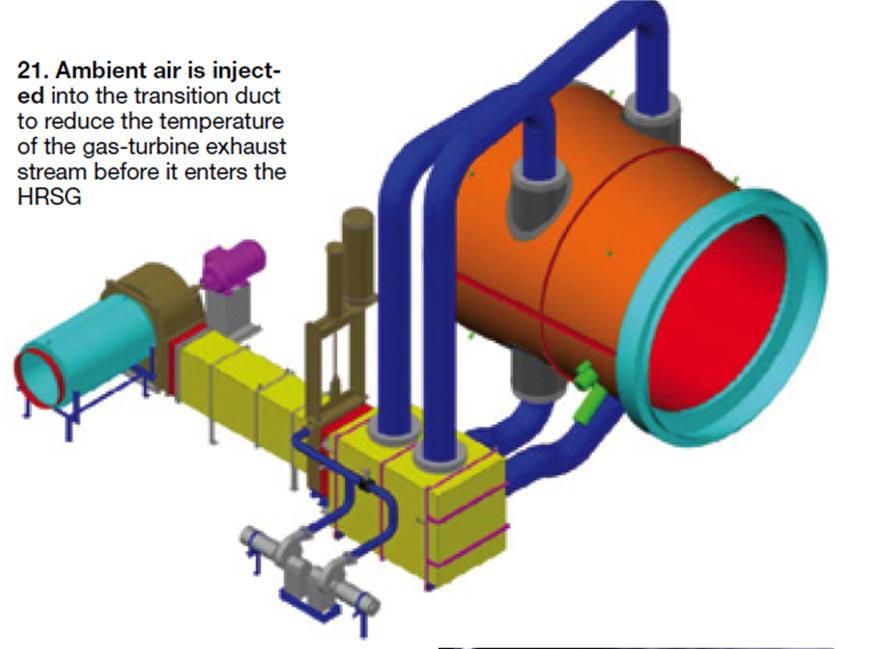

Sieben suggested air attemperation as a means of reducing GT exhaust temperature before the gas enters the HRSG’s high-temperature harps. Here’s how HRST’s QuenchMaster™ works: Significant amounts of ambient air are injected into the transition duct between the gas turbine and the HRSG inlet duct to reduce the temperature of the exhaust stream entering the boiler (Fig 21). The amount of air flowing into the system is adjusted to maintain a specific range of superheat for both main and reheat steam.

Sieben suggested air attemperation as a means of reducing GT exhaust temperature before the gas enters the HRSG’s high-temperature harps. Here’s how HRST’s QuenchMaster™ works: Significant amounts of ambient air are injected into the transition duct between the gas turbine and the HRSG inlet duct to reduce the temperature of the exhaust stream entering the boiler (Fig 21). The amount of air flowing into the system is adjusted to maintain a specific range of superheat for both main and reheat steam.

The temperature of the air/exhaust gas mixture is set to maintain acceptable metal temperatures in the HRSG and steam turbine, and the interconnecting piping, within a “safe” range without having to use water for attemperation. Access “Air attemperation protects HRSGs against damage at low loads,” 1Q/2011, at www.ccj-online.com.

Mee Industries Inc, www.meefog.com, Inlet fogging on GE 7F gas turbines, Thomas Mee.

Fogging has become a popular evaporative technology over the last decade because it is capable of cooling gas-turbine inlet air to its wet-bulb temperature, making the technique more effective than wetted media (evap coolers). Although fogging has been associated with compressor wear and tear at some plants (erosion of blades in particular), in virtually all instances this was said to have occurred because of poor design, fabrication, and/or installation, and/or improper O&M of the fogging system.

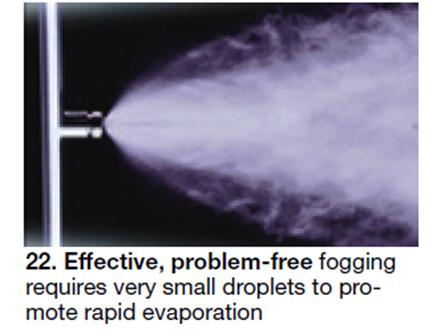

Mee began with a brief discussion of factors critical to the design of an effective fogging system. Droplet size is of primary importance, he told the group, because small droplets evaporate quickly (Fig 22). Those too large to evaporate in less than two seconds—the approximate time it takes air passing through the inlet filters to reach the compressor—will either fall out on the duct floor or enter the compressor.

Mee began with a brief discussion of factors critical to the design of an effective fogging system. Droplet size is of primary importance, he told the group, because small droplets evaporate quickly (Fig 22). Those too large to evaporate in less than two seconds—the approximate time it takes air passing through the inlet filters to reach the compressor—will either fall out on the duct floor or enter the compressor.

Location and arrangement of the fog nozzles was another discussion point. He noted that the OEM-recommended placement for fog nozzles, at least on older machines, generally does not allow sufficient time for droplet evaporation and can lead to flowing water at the compressor inlet.

Mee illustrated the point with a CFD plot to show the large variation in air velocity across the inlet ductwork. The message: Velocity must be considered by designers in the placement of nozzles to avoid localized over-saturation. Translation: More nozzles are required in high-velocity areas than in low-velocity regions of the ductwork.

Mee continued with recommendations for positioning (1) gutters and drains to minimize the probability of free water gaining access to the compressor and (2) trash screens to prevent condensation of fog and the formation of large droplets close to the compressor inlet. To learn more, access “To fog or not to fog: What is the answer?” 3Q/2008, at www.ccj-online.com.

Meggitt Sensing Systems, www.meggittsensingsystems.com, Microwave blade-tip monitoring system, Tom Holst.

Blade-tip sensors monitor blade vibration and tip clearance in real time, enabling meaningful machinery diagnostics and identifying the optimal time for maintenance. Blade vibration is derived from high-resolution blade-tip timing measurements taken by multiple microwave blade-tip sensors. Long-term tracking of individual blade resonance frequencies and magnitudes facilitate blade health monitoring. Changes in blade resonance, Holst said, clearly identify degrading stiffness characteristics caused by an increasing level of damage.

He added that this technology is particularly well suited to measuring 7FA R0 and R1 blade damage through changes in measured natural frequencies of blades. Such capability helps plant personnel optimize the unit’s inspection schedule and minimize the chances of a catastrophic failure. Also, it can help avoid rubs on restarts.

National Electric Coil,www.national-electric-coil.com, A review of critical generator issues for outage planning, Howard Moudy.

Moudy ran through a checklist of items owner/operators should consider prior to scheduling a maintenance outage. Owners’ priorities of cost, outage time, and long-term reliability can be satisfied with proper inspection and planning. Typical concerns regarding air-cooled generators include the following:

- Stator and rotor. Contamination and insulation deterioration.

- Stator. Partial discharge (PD) and spark erosion (SE), slot wedge looseness, core issues, looseness/movement, endwinding resonance/looseness.

- Rotor. Conductor and joint issues, main lead/connectors (pole to pole).

A series of photos enabled users to differentiate between stator PD and SE (early and advanced stages), see rotor and stator contamination, identify and correct slot wedge and endwinding looseness, identify blocked ventilation passages, locate shorted turns, etc.

Planning, performing, and documenting generator outages was Moudy’s next topic. The generator expert called for a proactive effort on the part of owners and operators. This included the following:

- Identifying qualified vendors and establishing blanket terms and conditions. Be prepared for sticking points in the areas of indemnification, limitation of liability, warranty, termination.

- Bone up on design of your machine and its maintenance requirements. Document and trend generator information. Talk to user-group colleagues with the same generator about their experiences.

- Develop performance-based specifications.

- Plan, plan, plan to assure a successful outage. This includes planning for emergencies and the unexpected.

Power Engineering Services & Solutions Inc, www.pessweb.com, Increasing profitability of the MS7001FA gas turbine through thermal optimization, Miguel Sernas.

Sernas explained concepts related to instrumentation, thermodynamic design, control system philosophy, and degradation mechanisms to help plant operations personnel keep their units running at top efficiency.

Pratt & Whitney Power Systems,www.pw.utc.com,Advanced 7FA component repairs proven from standard work developed for commercial and military aero repairs,Andy Lutz, Mat Gartland, and Jose Quinones.

Pratt & Whitney Power Systems,www.pw.utc.com,Advanced 7FA component repairs proven from standard work developed for commercial and military aero repairs,Andy Lutz, Mat Gartland, and Jose Quinones.

PWPS differentiates itself from repair facilities that merely “fix” parts. Its representatives stressed both an approach to engineering of repairs to address the root cause of field problems and facilities having the tools to implement advanced repair schemes (Fig 23). The company pursues design improvements with the goal of providing refurbished parts that are “better than the original,” where possible, the speakers said.

The collaborative process of continual component improvement involves (1) identification of issues based on field experience, (2) re-engineering and modeling of improved parts, (3) laboratory validation, and finally (4) field validation. Examples of successful advanced repair engineering and execution were provided.

PSM, www.psm.com, 7FA+e compressor durability upgrade package offerings, Tim te.Riele.

Focus of the presentation was the company’s design evolution for its 7FA compressor upgrade. It was designed to show owner/operators what PSM has identified as the OEM’s field issues and how they can be eliminated with the company’s R0 upgrade and its S0-S4, S13-S16, and S17/EGV package upgrades.

Dozens of sets of PSM R0 blades—both flared and unflared designs—are installed at customer sites and many more are on order. Rigorous field validation was said to confirm the ability of these airfoils to operate without restrictions regarding fogging and online water washing. No periodic leading-edge dental molds are required.

The PSM R0 design is said to offer the following design enhancements over the OEM’s airfoil without changing aerodynamic performance or adversely impacting engine performance:

- Higher-strength alloy material.

- Undercut attachment to address fretting concerns.

- Modified airfoil thickness to retune the blade.

- Blade frequency increased above the machine’s operating range to reduce its vibratory stress response by more than 50%.

- Regarding the problematic S0-S4 compressor stators, PSM now offers these rows for flared 7FA+e machines on commercial terms. The company says it has upgraded the S0-S4 design to prevent the lock-up of ring segments experienced by many users, thereby reducing the potential for high-cycle fatigue and the possible liberation of some stator vanes. Enhancements include smaller carrier segments, addition of a groove in the carrier to accommodate tooling that facilitates disassembly, and a switch to a higher grade alloy to reduce the potential for corrosion and lockup. Plus, non-uniform spacing of vanes has been incorporated into the S0 and S1 stator rows to reduce the vibratory response of R0 and R1 rotor blades.

Tetra Engineering Group Inc, www.tetra-eng.com, HRSG performance analysis: Impact of low-load GT operation, Frank J Berte.

Berte alerted owner/operators to “flexible plant” operational impacts on heat-recovery steam generators. He began by defining “flexible” as extended turndown of the gas turbine while maintaining required emissions levels; faster startups, shutdowns, and ramp rates; and extended duct-burner range and turndown. An expert in boiler design and operational modeling, Berte talked about impacts on steam temperature control, flow stability, changes in gas-side flow, range limits on control valves, etc. The speaker suggested that users consider evaluating their HRSGs under possible future operating scenarios, and if current capabilities are not compatible with requirements predicted for tomorrow, to begin looking at what mods would provide the flexibility required.

Veracity Technology Solutions, www.veracityts.com, Mitigating the risk of compressor failures through the use of advanced nondestructive inspection methods, Kevin McKinley.

McKinley described advanced nondestructive examination techniques as a core component of the company’s 7FA inspection program designed to identify and mitigate operational risks. CCJ