Suite of V84.2 durability improvements extends outage, inspection intervals

Best Practices Award

Challenge. V84.2 machines require a hot-gas-path (HGP) inspection every 25,000 equivalent operating hours (EOH) or every six years and a major inspection every 50,000 EOH or every 12 years. Units that run well with low capacity factors will reach the calendar-based interval much sooner than the operational interval. As such, the inspections are likely to reveal little wear and tear. However, the propensity for the compressor to oxidize is great, hence the calendar-based criteria. After 12 years of service the Holden units each had accumulated about 10,000 EOH.

Solution. Implementation of reliability and durability upgrades would permit extension of calendar-based maintenance intervals. Summary of upgrades implemented on AECI Holden Unit 12 in fall 2013:

- Compressor coating. The entire compressor, both rotating (Fig 1) and stationary (Fig 2) sections, and IGVs were completely coated with Sermatel 5380DP to prevent compressor oxidation and eliminate the need for inlet dehumidification.

- Flame-tube F-ring upgrade. The standard F-ring tends to oxidize, scale, and liberate material under normal operating conditions. It was machined back to expose unblemished material. An Inconel overlay was welded onto the machined surface then machined back to specified diameter. Inconel will provide better oxidation and wear resistance.

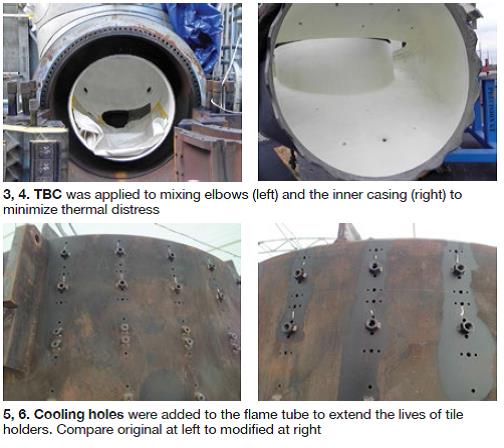

- Full TBC on all combustion components. A ceramic thermal barrier coating was applied to bezel rings and segment plates, mixing elbows (Fig 3), and inner casing (Fig 4). TBC provides increased resistance to thermal distress in the hottest areas of the unit.

- Chromium carbide coating on all mating surfaces in the combustion section. Hard-facing minimizes wear as parts expand and contract against each other during thermal cycling.

- Flame-tube cooling holes. Additional cooling holes were drilled in the flame tube behind the A-row tiles. The improved cooling in this area is expected to extend the lives of tile holders by reducing oxidation and erosion (Figs 5, 6).

The same upgrades will be implemented on Units 11 and 13.

Res ults. It is impossible to report the true results of the upgrades since they were implemented in fall 2013. However, from a planning standpoint, AECI currently is considering to extend the interval for a HGP to at least 10 years and the interval for a major to 20 years.

ults. It is impossible to report the true results of the upgrades since they were implemented in fall 2013. However, from a planning standpoint, AECI currently is considering to extend the interval for a HGP to at least 10 years and the interval for a major to 20 years.

Project participants:

Dave Shirley, senior combustion turbine specialist

Joel Wilhite, senior combustion turbine specialist