‘Arc flash’ NFPA 70E site implementation

Selkirk Cogen

Owned by Selkirk Cogen Partners LP, Operated by GE Contractual Services

345-MW, gas-fired, combined-cycle cogeneration facility with two power blocks. Phase 1: 80-MW 1 × 1 combined cycle. Phase 2: 265-MW 2 x 1 combined cycle

Plant manager: Brian Connolly

Key project participants: Bob Keute, maintenance supervisor Bill Slaver, controls and reliability specialist Phil Muller, I/E technician Tom Nolan, operations supervisor

Challenge.

Plant personnel conducted their first arc flash study in 2001 when data were collected for breakers, relays, and transformers from around the site. On the basis of that initial study, the required PPE was purchased and equipment labeled as recommended.

In 2009, NFPA issued an updated version of NFPA 70E with a requirement that either the calculated incident energy or the level of PPE must be listed on the arc-flash warning labels. Plant personnel decided it was necessary to update our current arc-flash program to meet these new requirements.

Solution.

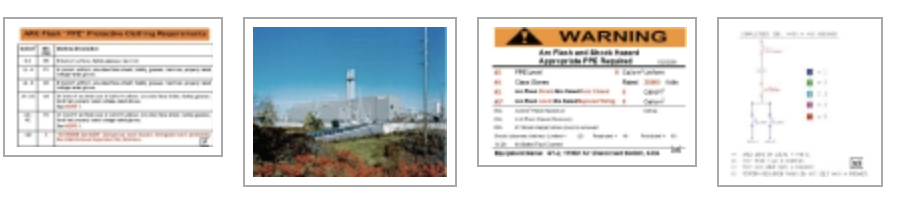

The site maintenance team redesigned the arc-flash warning labels for all the electrical equipment 120 V and above for the entire site. All labels clearly listed the PPE requirements for the different potential incident energy levels (Figs 51 and 52).

The team also had the electrical one lines for the site redrawn with color-coded separation that identify minimum PPE requirements for a particular system (Fig 53). The site also installed several arc-flash reduction modules to reduce the flash potential on certain pieces of equipment.

Results.

O&M personnel participate in annual high-voltage refresher training which brings about improved communication between the operations and maintenance teams when any high-voltage work is being performed. Increased effort in job planning and in-depth pre-job briefings has improved the overall safety mindset onsite.

With the implementation of this best practice by the maintenance team, all employees are now aware of the safety concerns around high-voltage work because of our site’s deeply engrained safety culture. Our site has a first-class safety record and efforts like this continue to keep it that way.