Plant Rowan, Owned and operated by Southern Company (Southern Power)

985-MW, gas-fired, one 7FA-powered 2 × 1 combined cycle and three simple-cycle units located in Salisbury, NC

Plant manager: Chris J Lane

Training videos promote shop safety

Challenge. Following an extensive maintenance-shop overhaul and retooling at Plant Rowan, staff was challenged by management and the site safety council thusly: How do we ensure everyone operates and maintains the equipment according to our company safety policy, common industry practices, and manufacturer equipment procedures?

Plant operators may only use a certain piece of equipment infrequently—such as during outages. The lack of daily use concerned staff because proficiency conceivably could be lost during periods of low maintenance.

Solution. The management team, together with the site safety council, provided direction for the creation and implementation of a series of Just-in-Time (JIT) “refresher” videos. A primary goal of the effort was to keep the videos short, each averaging only about five to six minutes per piece of equipment, but including as much information as possible.

The belief was that in this amount of time an experienced operator could demonstrate safe and effective operation or maintenance of a given piece of shop equipment with adherence to all company safety policy and equipment procedures. Equipment covered included pedestal bench grinders, horizontal band saw, drill press, various machining coolant systems, etc.

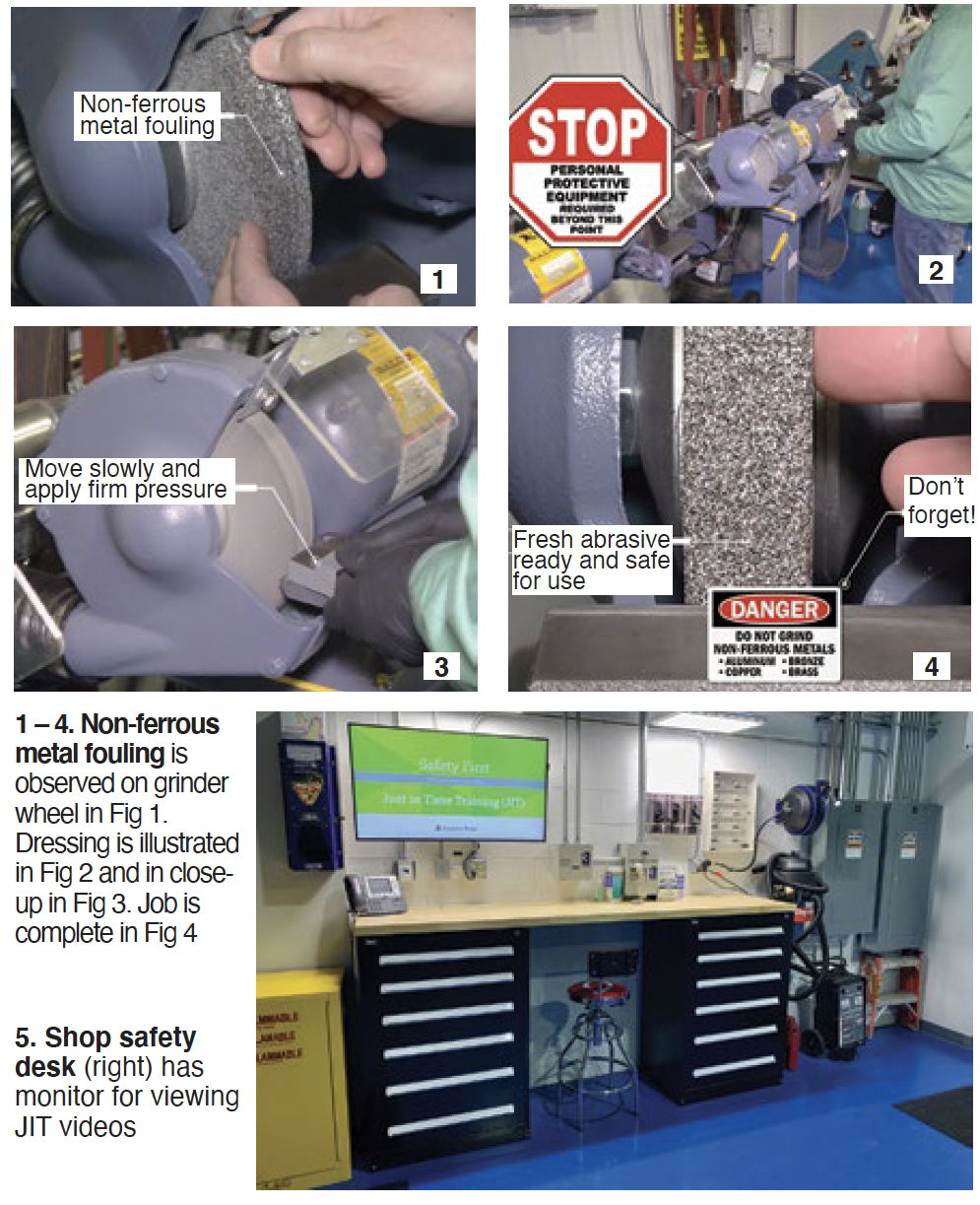

No narration was used; narrating the videos was deemed time-prohibitive at Plant Rowan. Instead, video editing software was used to add detailed on-screen “pop-ups” during final editing. This included pertinent information and hazards at each step of the equipment’s operation. Examples: When PPE is required and what type; tips for safe operation; hazards and examples of improper operational practices, etc.

Once completed, the videos were loaded on a 40-in. wall-mounted LCD monitor located in the maintenance shop for anyone to access prior to equipment use and as part of their pre-work job safety analysis.

Representative examples relating to the video on dressing a fouled pedestal grinder wheel are presented in Figs 1-4. Fig 5 shows Plant Rowan’s shop safety desk with monitor for viewing JIT videos.

Results. There have been significantly fewer occurrences of improper tool/equipment use—such as non-ferrous metal fouling on bench-grinder wheels, prematurely worn metal band-saw blades, and less wear and tear on equipment. There also have been no safety issues.

Project participants:

Shaun R Lynch, operations technician III

Dan Leone, maintenance team leader

Rebecca Young, compliance team leader