Upgraded stack for cooling-tower fans facilitates maintenance

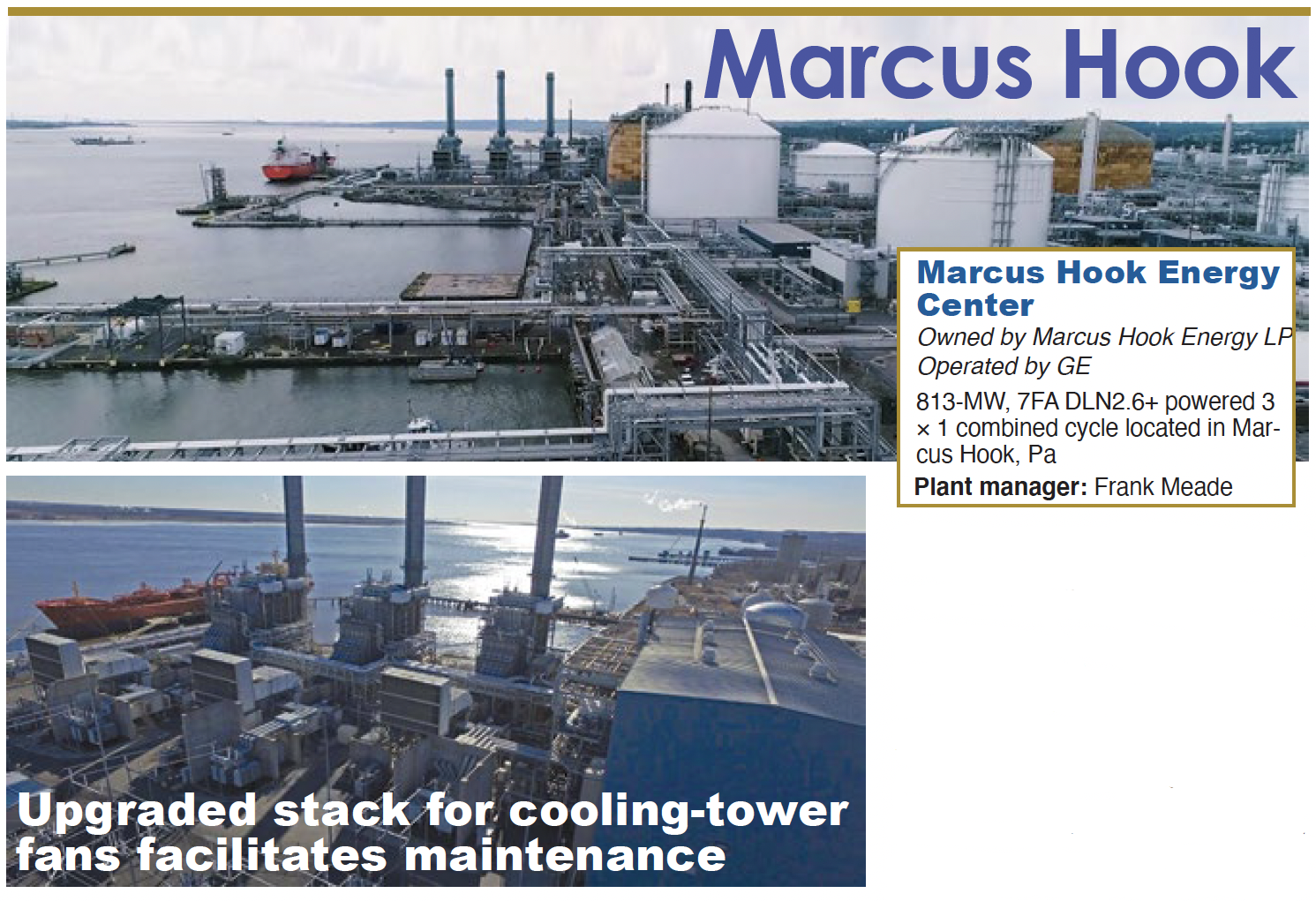

Challenge. Marcus Hook Energy Center has a 12-cell mechanical-draft counterflow cooling tower with multi-speed fans. Blade-tip-to-stack contact was causing wear on both components. The original stacks were made of molded fiberglass, with only vertical ribbing (Fig 1). It was constructed in sections through-bolted together on the inside. If hardware loosened while in operation, a confined-space entry and extensive scaffolding would be required to replace or tighten.

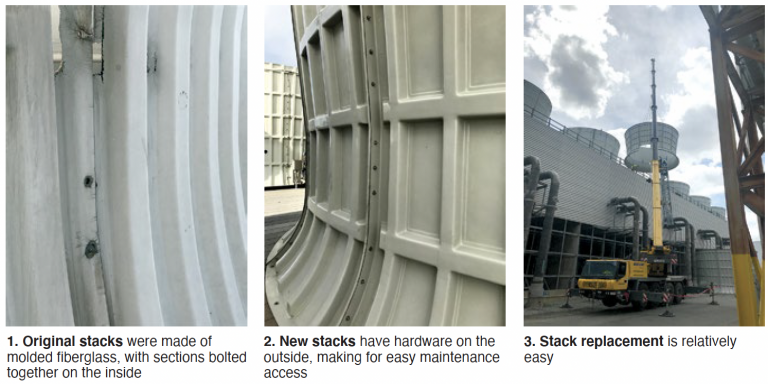

Solution. The new stacks have ribbing in both the vertical and horizontal directions, making this design less susceptible to flexing and reducing the probability of blade-tip-to-stack contact. This also lessens the chance of hardware coming loose. The new stacks connect sections with a completely exterior face-to-face flange (Fig 2), allowing the tightening of all hardware from the outside. This contributes to safer, less expensive, and more effective routine maintenance.

Results. Increased fan-stack rigidity allows use of gear reducers with standard output shafts—typically more readily available and less costly than the original gear reducers. This allows the blades to be located lower in the stack—hence closer to the sidewall—increasing cooling efficiency by decreasing tip vortex. The plant has replaced several of the OEM stacks with the improved design and will continue to do so over the next few years until all cells are retrofitted with the new stacks (Fig 3).

Project participants:

Keith Vickers, GE Gas Power, maintenance specialist

Chris Mahalik, FieldCore, Maintenance production technician

Brian Mozzoni, FieldCore, Maintenance production technician