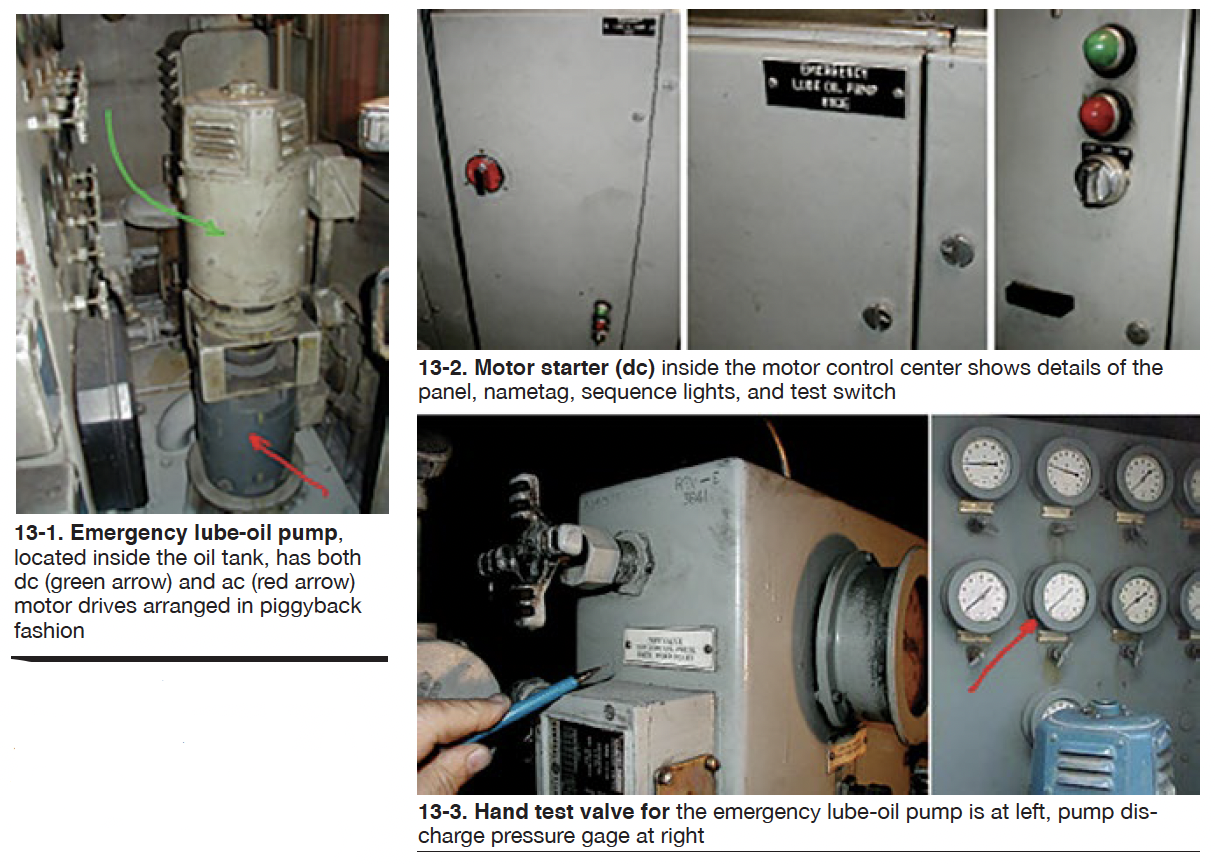

Two operators are required to perform this test, both equipped with compatible communications devices. Operator 1 is in the accessory compartment facing the test valve and gage panel (Fig 13- 3). Operator 2 is inside the control room facing the motor control center (Fig 13-2). The turbine is running at full-speed no load (5100 rpm); the generator can be synched to the grid and operating under load, or not.

- Step 1: Operator 1 slowly opens the hand bleed valve to drain oil under pressure past the adjacent inline orifice. Oil pressure appears to drop, although this action fools the system. The operator observes the dc oil pump turning and producing a pressure of about 25 psig.

- Step 2: Operator 2 confirms that the dc motor has started, not the ac motor. An alarm on the annunciator panel flashes, indicating that the dc pump is running.

- Step 3: Operator 1 puts his hand on the dc motor to see if it gets warm and is operating. He then closes the bleed valve, observing that the dc pump stops.

- Step 4: Operator 2 resets the alarm and clears the annunciator drop.