By Neil Kilpatrick, GenMet LLC, and James Michalec, J R Michalec Consulting LLC

The negative impact of moisture on electrical equipment has been a serious concern since the beginning of the industry. Most senior plant personnel have had experiences with low insulation resistance (IR) and low polarization index (PI) values that have extended an outage.

One example concerned a large outdoor generator alongside a major river in the South. The unit’s rotor was removed in August and on the turbine deck.

A retaining-ring inspection was being conducted to check for the possibility of stress corrosion cracking (SCC). Water was found coming out from under the ID of the retaining rings. The rotor appeared dry and had not been exposed to rain. The root cause was condensation on the rotor surfaces, but primarily water stored in the capillaries formed by the winding components.

Water storage in capillaries is a complicated phenomenon, one studied by a major OEM while investigating SCC of certain retaining-ring steels (sidebar). The findings relating to moisture collection in capillaries are the focus of this article.

The basics of capillary action

Capillary action is not well understood by many power-industry personnel. Without a strong background in related studies, the intuitive explanation of capillary action almost certainly will be guessed wrong. Capillary action occurs because water molecules want to stay close together. The resulting adhesion causes the molecules to be attracted to each other but also to adhere to other substances.

In a small tube, or a set of parallel plates that are sufficiently close together, this adhesion will cause a force on the liquid at the edges and result in a meniscus which turns upward. The surface tension acts to hold the water surface intact. Capillary action occurs when the adhesion to the walls is stronger than the cohesive forces between the liquid molecules. The height to which capillary action will take water is limited by surface tension, the diameter of the tube (or plate spacing), the relative humidity, and fuel viscosity. The same effect occurs with both horizontal and vertical capillaries.

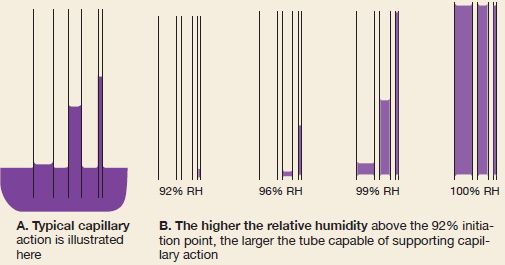

A moist atmosphere (dew point temperature approaching the equivalent of 92% relative humidity) will allow capillary action to take place. Fig A illustrates capillary action in three tubes of different diameter; Fig B illustrates the effect relative humidity has on capillary action.

The conditions under which filling occurs are peculiar. With dry air (no humidity) at the end of the capillaries, the tubes contain only air; there is no capillary action. With the humidity increased to the point of moisture condensation, water starts to condense inside the smallest tube. This phenomenon only begins to occur at about 92% relative humidity (RH).

Increase the humidity further and water starts to condense in the next larger tube; meanwhile, the smaller tube has taken on more water. With nearly saturated air at the end of the capillaries, water starts to condense in the largest tube; the smaller tubes have taken on more water. Under saturation conditions, 100% relative humidity, the capillaries continue to fill toward maximum.

Where water collects in rotating machines. Water will accumulate on any surface of the machine if that surface reaches dew-point (100% relative humidity) temperature. Water also will be stored anywhere a capillary exists. On the stator, capillaries would include the spaces between layers of tape on conductor insulation, between conductors and core, and between core laminations. On the rotor, capillaries exist between field winding turns, between turns and ground insulation, between wedges and field body, and in any cracks that may have occurred in the metallic parts.

Impact of moisture on electrical insulation. The primary negative impact of moisture is reduction of integrity of insulating materials—that is, a reduction in IR and PI. If these values are low there is risk of insulation failure when operating voltages are applied to the windings. Because insulation failure is likely to lead to costly forced outage, impacts of moisture accumulation can become extremely important.

Moisture contamination. Preventing moisture accumulation on component surfaces and in capillaries is not necessarily easy to accomplish, nor are the prevention requirements necessarily easy to understand. Relative-humidity control alone is insufficient to assure that components do not become contaminated by moisture.

It is necessary that both dew-point temperature and component temperature be known. Keeping the temperature of the components about 20 deg C higher than the dew-point temperature will assure that contamination is unlikely to occur. Otherwise, abrupt changes in atmospheric conditions may result in contamination. Outdoor storage will, of course, be more vulnerable to rapid condition changes.

Learn more from our featured solutions provider

Preventing moisture accumulation. During generator operation, moisture accumulation normally is not an issue because of the machine’s inherent heat generation and ventilation activity. An example of an exception might be a cooler leak spaying raw water directly onto insulation; however, such exceptions are not considered here.

During shutdown, two conditions may exist: machine assembled and machine disassembled. For the assembled condition, there also are two conditions: hydrogen-cooled and air-cooled. For the former, it is necessary only to maintain a positive hydrogen pressure with dry gas.

For air-cooled generators, the challenge is much greater. Many designs incorporate heaters, and if they are functioning, and of sufficient size, moisture accumulation is unlikely. If not, moisture accumulation is likely to occur unless corrective action is taken—for example, forced ventilation with heated air, forced ventilation with dehumidified air, or a combination of both.

When a machine is disassembled and the rotor removed from the stator, preventing the ingress of moisture becomes more complicated. For the stator, on designs where the end covers can be replaced by temporary (plastic sheet or wood) covers, forced ventilation with heated and/or dehumidified air should be adequate.

For the rotor, on high-speed generators—for example, 2-, 4-, or 6-pole machines—an enclosure should be provided. This may be as simple as a temporary plastic sheet enclosure or a more complex transportable enclosure (Figs 1 and 2). In every case where humidity can be controlled using dehumidifiers and/or heaters (and cleanliness assured), it should be done. On low-speed units, such as large hydro-generators, control of humidity (and cleanliness) can be challenging.

Drying wet insulation. Because moisture contamination of insulation has been a major problem on rotating machines, manufacturers typically have provided drying instructions with their service manuals. But a few comments are in order:

- In order to dry the machine components, they must reach a bulk temperature higher than the surrounding dew-point temperature.

- Moisture on machine surfaces is relatively easy to remove once exposed to warm dry air.

- The nature of capillary action is such that removal of water from a capillary is difficult once accumulated.

- Perhaps the easiest way to remove moisture is by machine rotation. The windage loss provides heat and rotation provides ventilation. This method, of course, is not effective on a closed ventilation machines—such as hydrogen-cooled generators.

- At standstill, drying can be accomplished by supplying dry air and/or heat. This may become rather complicated and may take several days to accomplish necessary moisture removal to reach satisfactory insulation resistance and polarization index.

Wrap-up. Moisture contamination of insulation systems can have highly negative effects on the insulation. Surface moisture can be removed rather easily, but moisture that has accumulated in capillaries is inherently difficult and time-consuming to remove. In general, it is far better to keep insulation dry than to allow moisture ingress and the need for a costly drying operation.

Acknowledgement: Clyde V Maughan contributed to this article.