Contaminants introduced into your liquid fuel during transportation can require a substantial cleanup effort if foreign material remains in the oil for a prolonged storage period. Reason: Some contaminants will catalyze the fuel degradation process, compounding the problem.

Having a filter ahead of the storage tank capable of trapping large quantities of water (particularly saltwater, the largest single source of sodium contamination so detrimental to HGP parts) and sediment before they enter the tank is important. Also critical to fuel quality is periodic—read weekly—bleeding of water from the bottom of the tank. This is especially true in warm, humid regions of the country. Remember that oil tanks are vented and they breathe.

Plants monitoring the condition of their backup fuel sometimes are surprised by the poor quality of oil at the bottom of their tanks—say the last 5 ft or so. This generally is not problematic given the floating suction systems typically in use today—that is, until you have to burn the dregs. It doesn’t take much sludge-type material to cause a failure to start or to trip a high-performance gas turbine. The financial penalties could be significant.

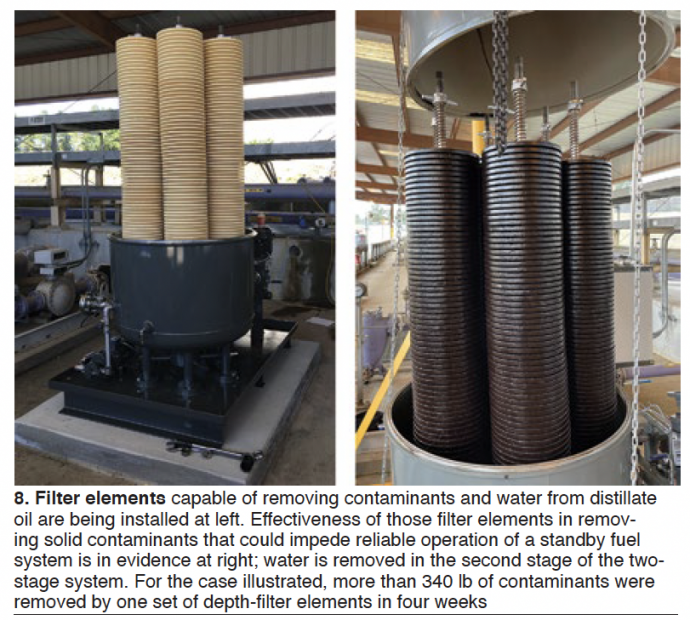

C C Jensen Inc’s Technical Manager Axel Wegner, expert in the cleanup of turbine lube and hydraulic oils, has been promoting at user-group meetings for several years the idea of using similar technology to maintain backup-oil quality with a slipstream treatment system on the storage tank. Results from the first two installations (one on a 1-million-gal tank, the other a 4- million-gal tank) at gas-turbine peaking and combined-cycle sites, just in, are encouraging (Fig 8).

Wegner told CCJ that, based on current experience, an appropriate cleanup system for a standby oil tank might turn over the inventory once a month to maintain the fuel quality desired. A plant burning only diesel (no gas) the system probably should be designed to process oil at 110% of the consumption rate, he added.

One user told the editors that he received only two responses to his RFQ for a diesel-fuel cleanup system, purchasing one each from C C Jensen and Hy-Pro Filtration. CCJ