By Barry Dooley, Structural Integrity Associates, Charlotte, NC (bdooley@structint.com), and Bob Anderson, Competitive Power Resources, Palmetto, Fla (anderson@competitivepower.us)

This article compiles information from one-day assessments of heat-recovery steam generators (HSRGs) focusing on cycle chemistry and thermal transients. The primary goal of the work was to help operators become proactive in the identification of key drivers for cycle-chemistry- and thermal-transient-induced failure and damage mechanisms.

Regarding the former, the assessments addressed key factors for flow-accelerated corrosion (FAC), under-deposit corrosion (UDC), and pitting. For the latter, they addressed thermal fatigue and creep fatigue. In each area, the assessments provided a clear picture of exactly where the weaknesses in the approaches were. Based on their findings, the authors are not surprised that the current ranking order for HRSG tube failures essentially has remained static for the last 10 years.

The article also outlines successful approaches for optimizing (1) cycle chemistry to avoid FAC and UDC, (2) the operation of attemperating systems, and (3) the configuration of drain systems to avoid the thermal-transient-driven damage mechanisms. These important messages easily can be applied by operators to change the current mindset of “waiting for failure to occur.”

The mechanisms that cause unreliability of HRSGs worldwide are mostly well-known. The leading HRSG tube failure (HTF) mechanism is flow-accelerated corrosion (FAC), followed by thermal fatigue. FAC involves the single- and two-phase variants1 and is found predominantly in low-pressure (LP) economizers/preheaters and LP evaporators (tubes, headers, and risers). An increasing number of incidents is reported in intermediate-pressure (IP) circuits (tubes and risers)1. All HRSG components within the temperature range 100-2500C (212-4820F) are susceptible.

Thermal fatigue occurs in superheaters and reheaters, primarily at header/tube connections because of undrained condensate and attemperator overspray during startup2. Creep-fatigue examples are increasing at the same locations in HRSGs operating at steam temperatures above about 565C (1050F)—particularly in circuits containing dissimilar metals at the header/tube connections (T/P 91 and T/P 22)3. Thermal fatigue also is observed in LP economizer circuits because of steaming and quenching of the condensate inlet section during startup4.

The third most important area of failure/damage involves the under-deposit corrosion (UDC) mechanisms in high-pressure (HP) evaporator tubing. As the name implies, this mechanism first requires a deposit on the inside surface of an HP evaporator tube and then some contaminant, or the use of an incorrect cycle-chemistry treatment, that is allowed to concentrate within the deposit and cause increased corrosion, loss of tube wall, and eventual failure.

The most important of these mechanisms, by far, is hydrogen damage which relates to the concentration of chloride (from contaminant ingress, such as condenser leakage) within and beneath the deposit. However, evaporator chemical treatments using acidic phosphates, phosphate blends, or excessive levels of sodium hydroxide also can concentrate and cause damage. Pitting tube failures can occur in any HRSG circuit as a result of repetitive inadequate, and in nearly all cases, non-existent shutdown procedures5.

Over the last year the authors visited 11 combined-cycle plants around the world to conduct assessments of the cycle chemistry and thermal transient aspects of the HRSGs. A primary goal of these assessments has been to help the operators identify and address proactively previously undetected problems. This is based on the authors’ strong implicit belief that the HRSG tube failures and damage mechanisms mentioned above are so well understood that the key drivers (or root causes) can clearly be identified and eliminated prior to inception of serious damage and failure.

These assessments have made it clear that there are common features associated with cycle chemistry operation and thermal transient drivers—most independent of the HRSG type or manufacturer. These repeating or continuing features rarely are identified by plant personnel, but if allowed to continue without remediation, eventually will lead to failure or damage5. There is very little variation in experience across the global HRSG fleet. In some respects, this is fortunate because it should allow operators to review the information presented here and commit to making the necessary changes knowing they can mitigate the drivers commonly present and active.

Solutions to the cycle chemistry influenced areas are much more mature than those for the thermal transient issues. But both are now sufficiently established to allow operators to specify the necessary features to eliminate these drivers in new plant designs, and to take corrective action in existing plants. The authors already are implementing solutions for operators worldwide. One of the most important conclusions of this effort is that organizations should be proactive with plants that haven’t already experienced failure. For HRSGs, it is never acceptable to sit back complacently because incipient damage hasn’t yet manifested itself as failure.

Tube failure prevention program

It is very common for organizations to assume the cause of a unit’s first tube failure is “a bad weld.” Sometimes this may be true, but most often the actual root cause is an undetected cycle chemistry shortfall, design feature, or operating practice that has repeatedly inflicted corrosion, corrosion fatigue, or thermal-mechanical fatigue damage in the failed tube and its neighbors.

None of the plants assessed has a program or policies in place that ensure actual root cause will be determined when a failure occurs. Not surprisingly, 64% of the plants assessed already have experienced failures, or display obvious symptoms of severe thermal-transient damage in the superheater, reheater, or economizer (Table 2).

The only way to be sure that the corrective actions taken will prevent a tube failure from recurring is to remove the failure site, have the actual failure mechanism identified via a metallurgical laboratory analysis, then determine the root cause of the failure.

Taking the additional forced outage time to remove the failed section of tube is not a trivial matter. However, failing to do so is gambling with the unit’s future reliability and maintenance costs. A tube failure prevention plan should be developed and implemented early in the unit’s life—hopefully prior to any tube failure.

The time for plant mangers, asset managers, operations directors, general managers, and executives to objectively agree on the relative priorities of long-term unit reliability and maintenance cost versus short-term revenue and power production needs is before failures occur and the unit is operating well—not during the forced outage when the unavailability and lost-revenue meters are running.

Such a plan need not be complex, but should include the following key elements to be executed during each tube failure event:

- Prior agreement, throughout the management chain, that a material sample containing the failure site will be removed from the HRSG for metallurgical analysis.

- Root cause, as contrasted with apparent cause or failure mechanism, must be determined for each tube failure event.

- Each failure location within the HRSG must be precisely recorded using an unambiguous orientation scheme. Failure-site orientation (up/down, gas flow direction, etc) should be recorded and retained.

- A modest supply of spare HRSG tubing in appropriate sizes and materials, including a few bends, should be placed in inventory and kept in good condition.

Cycle chemistry, corrosion, FAC

There are several cycle chemistry issues important in preventing pressure-part failures in multiple-pressure combined-cycle systems. Among these, two major areas of concern that are influenced by the cycle chemistry treatment regime are FAC and UDC.

FAC. Both single- and two-phase FAC can occur equally in horizontal and vertical gas path (HGP and VGP) HRSG tubing, headers, risers, and the LP drum. During an assessment, it is important to recognize exactly which type of FAC can occur in each circuit because the potential solutions are different for each. A recent review of FAC in combined-cycle plants1 included numerous examples of the different types of attack and morphologies common in HRSGs. Regions of concern include the following:

- Economizer/preheater tubes at inlet headers.

- Economizer/preheater tube bends in regions where steaming occurs.

- Vertical LP evaporator tubes on HGP units, especially in the bends near the outlet headers.

- LP evaporator inlet headers which have a tortuous fluid entry path and where orifices are installed.

- LP riser tubes/pipes to the LP drum.

- LP evaporator transition headers.

- IP economizer inlet headers.

- IP economizer outlet headers, especially in bends near the outlet headers in units prone to steaming.

- IP riser tubes/pipes to the IP drum.

- IP evaporator tubes on triple-pressure units that are operated at reduced pressure.

- LP drum internals.

- Horizontal LP evaporator tubes on VGP units, especially at tight hairpin bends.

UDC occurs exclusively in HP evaporator tubing. The three UDC mechanisms— hydrogen damage, acid phosphate corrosion, and caustic gouging—all require heavy deposits and a concentration mechanism within those deposits. For hydrogen damage, the concentrating medium is usually chloride, which enters the cycle through condenser leakage.

Acid phosphate corrosion relates to a plant using phosphate blends which have sodium to phosphate molar ratios below 3:1 and/or the use of congruent phosphate treatment using one or both of mono- or di-sodium phosphate.

Caustic gouging involves the concentration of either NaOH used above the required control level within caustic treatment or the ingress of NaOH from regeneration of ion-exchange resins.

Deposition and the UDC mechanisms occur in HP evaporator tubing in both vertical and horizontal HRSGs. On vertical tubing the deposition concentrates on the ID crown of the tube facing the GT. It nearly always is heaviest on the leading HP evaporator tubes in the circuit because these have the areas of maximum heat transfer. UDC mechanisms occur in exactly the same areas.

On horizontal tubing, both deposition and the UDC mechanisms occur on the ID crown facing towards or away from the GT. Damage usually occurs on the side facing away from the GT when poor circulation rates, steaming, or steam blanketing occur. These can lead to stratification of water and steam and subsequent heavy deposition in a band along the top of the tubing.

While the FAC and UDC mechanisms occur at opposite ends of the plant, they are linked by the corrosion products generated by the corrosion/FAC mechanisms in the LP sections of the HSRG. Corrosion products subsequently deposit in the HP evaporator tubing and form the basis of the under-deposit corrosion damage mechanisms. This link forms the main focus of the cycle chemistry assessments in the plants, which identify the precursors or active processes if left unaddressed, will eventually lead to failure/damage by one or both mechanisms. Acting proactively can mitigate the risk for both.

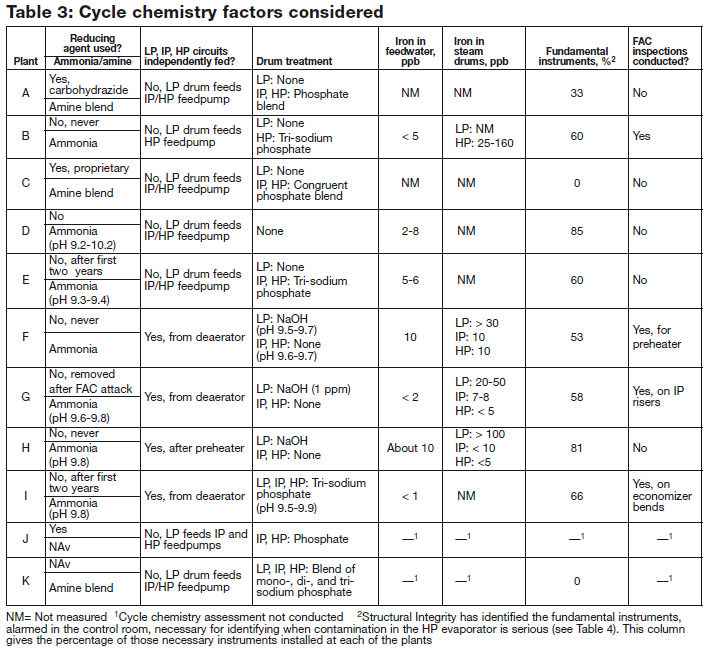

Analysis of Table 3, which presents the cycle chemistry treatments and key indicators for the diverse group of plants assessed, identifies the predominant factors for FAC and UDC.

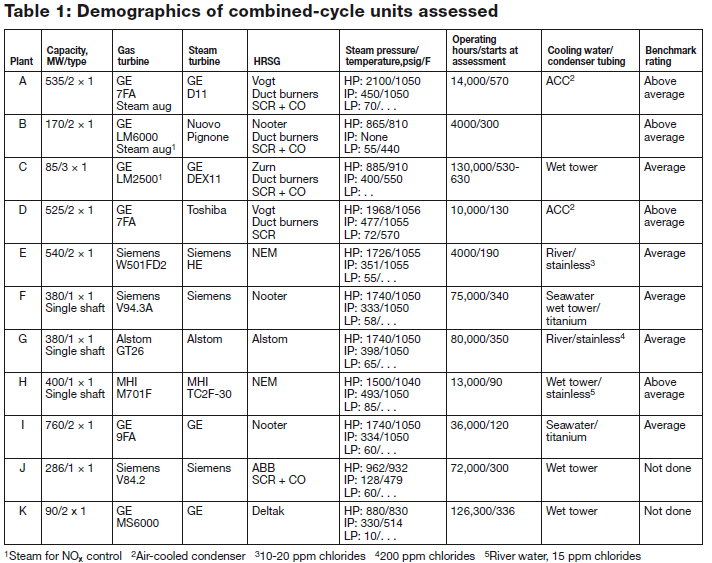

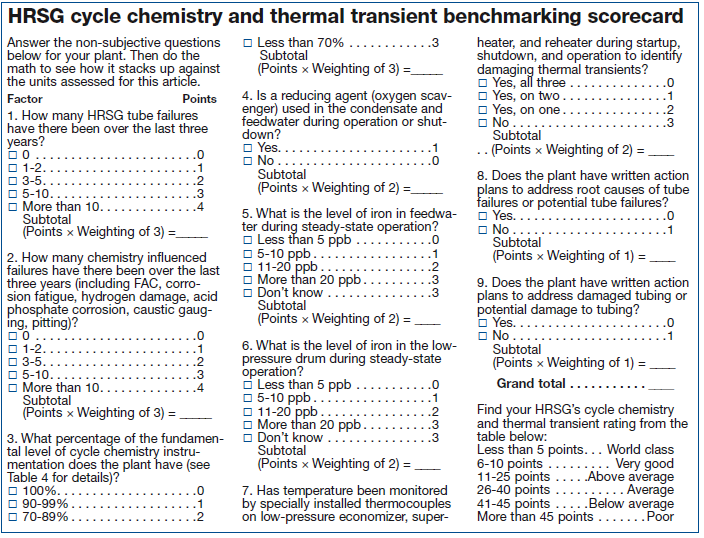

Assessment process

Table 1 shows the diversity of plants assessed. They include units with equipment from seven HRSG, four gas turbine (GT), and six steam turbine manufacturers, and have a wide range of operating experience in terms of hours and starts. Cooling systems vary with the location and include use of river water, seawater, air-cooled condensers, and wet cooling towers.

The last column of the table provides an objective HRSG cycle chemistry and thermal transient benchmark rating that is independent of unit type and manufacturer. The benchmarking process was introduced in 2004 to permit ranking HRSGs on a worldwide basis6. A scorecard for use at your plant, presented in the sidebar, enables you to see how your facility stacks up against the units assessed for this article.

The assessment process is conducted during a one day visit by the authors to review the design, construction, operation, and cycle chemistry of the combined cycle and HRSG. On the cycle chemistry side, review and assessment of the following take place:

- Heat-balance diagrams for the plant.

- Arrangements of the HRSG tubing circuits.

- Cycle chemistry treatments for condensate and feedwater, and for each drum—including the actual chemicals used. Operating and shutdown conditions are included in the review.

- Installed online instrumentation and how close it comes the Structural Integrity’s “Fundamental Level of Instruments,” and whether they are alarmed in the control room. More detail on this later.

- Review of any HTF influenced by cycle chemistry.

- Close review of the FAC potential for the unit, which includes the materials identification and operating temperatures of the LP and IP circuits susceptible to FAC1.

- The monitored total iron levels in the feedwater and drums.

On the thermal transient side, review and assessment of the following are conducted:

- Superheater and reheater: dimensions, materials and arrangement of tubes, headers, interconnecting pipes, attemperators, HP steam pipe, cold-reheat pipe, drains, and flash tank.

- LP economizer: dimensions, materials and arrangement of tubes, headers, interconnecting pipes, drains, and condensate pipe.

- For both lead and lag units in 2 × 1 plants: historical DCS plots of GT load, speed, and exhaust temperature, HP steam flow, HP drum pressure, HP superheater outlet temperature, attemperator inlet and outlet temperatures, HP spray-water valve position, and superheater drain valve positions for a typical cold start, hot start, and normal shutdown. Equivalent DCS points for the reheater system are also required for units with reheaters.

- For both lead and lag units in 2 × 1 plants: operating procedures used for cold starts, hot starts, and normal shutdowns.

Flow-accelerated corrosion

FAC is the leading cause of damage and failure in HRSGs. Its control in combined-cycle/HRSG plants usually requires a three-pronged approach that includes the following:

- Operating with an oxidizing chemistry. This requires an all-volatile treatment—oxidizing AVT(O)—or oxygenated treatment (OT) to control the single-phase component.

- Operating at elevated pH (at least 9.8) to control the two-phase component.

- Monitoring (specifically, analyzing the total iron concentration in the condensate, feedwater, and in each drum) to verify/confirm whether the treatment program is successful.

The 11 detailed assessments of the plants profiled in Tables 1-3 have revealed these important findings:

1. Reducing agents (oxygen scavengers) are used in 37% of the plants. This figure is reduced from previous surveys which indicated that about 50% of HRSGs were using reducing agents5.

2. Of the plants assessed, 37% have the LP evaporator/drum independently fed and not feeding the IP and HP circuits. This affords operators the flexibility of addressing single- and two-phase FAC uniquely by increasing the pH and adding a solid alkali such as tri-sodium phosphate (TSP) or NaOH.

3. About 40% of the LP circuits add TSP or NaOH.

4. Four of the 11 plants assessed do not know the iron levels in the condensate/feedwater and eight do not know the levels in the LP drum. In many cases where iron levels are measured, the organization uses a technique that is either only applicable for soluble iron or does not have sufficient low-level capability for total iron measurement.

5. Few plants (37%) have made any detailed NDE assessments of FAC in the lower-pressure circuits; those that had concentrated their assessments on individual circuits where failures or damage had been identified previously.

6. Many organizations, including those within these assessments, try to address both single- and two-phase FAC concurrently despite strong evidence that the optimum process is to address each individually1—this because they are controlled by different parts of the cycle-chemistry envelope.

Do plants have single-phase FAC under control? What indicators are used during the assessment for single-phase FAC?

To answer these questions requires giving proper attention to the following two factors:

- Ensure that a reducing agent is not used in the cycle during any period of operation or shutdown. It has been well established for about 20 years that single-phase FAC in HRSGs is controlled by the oxidizing-reducing potential (ORP) of the condensate and feedwater. In HRSGs, the potential always should be oxidizing; this means operating without a reducing agent1.

- Identify whether sufficient oxidizing power is available to passivate all the single-phase locations. The indicators the authors look for are: (1) the actual level of oxygen at the condensate pump discharge (CPD) and in the feedwater at the feedpumps, and (2) the color of the LP and IP drums.

Many plants with HRSGs have excellent air in-leakage control, with only 5-10 ppb oxygen being identified at the CPD. The oxygen level would, of course, be much lower after a deaerator if one were installed ahead of the LP economizer/preheater, and in the feedwater if the feedpumps are fed by the LP drum (which may include an integral deaerator).

At some plants there clearly is inadequate passivation of the LP drum (and sometimes the IP drum as well). When there is inadequate passivation, the drum(s) will have a “patchy” red appearance and the grey/black magnetite showing through it usually is associated with low levels of oxygen (2-6 ppb). This means there is still magnetite exposure with incomplete conversion to red FeOOH and associated higher iron levels.

The level of low oxidizing power (low oxygen) may not be able to satisfactorily passivate all the single-phase flow locations in the economizer circuits as well as the LP and IP evaporator circuits and drums. The possibility of increasing the level of oxygen may require investigation—this to provide better single-phase protection while being cognizant of oxygen levels in other areas of the HRSG.

Possible methods include closing deaerator (if included in the cycle) vents or actually adding controlled amounts of oxygen at the deaerator outlet (boiler feedpump suction). However, if high levels of oxygen in the condensate occur intermittently, this would preclude closing of deaerator vents. In such situations, an aggressive air in-leakage solution is needed.

Best practice: Monitor iron to be sure that the level of oxygen in the LP drum is adequate to provide full single-phase FAC protection. Experts have determined the monitoring of total iron in the LP (and IP) drum(s) is the main indicator of the extent of passivation, with the target being total iron levels of less than 5 ppm. This is in agreement with the “Rule of 2 and 5” for corrosion products—that is, less than 2 ppm total iron in the condensate/feedwater and less than 5 ppm in each drum.

Do plants have two-phase FAC under control? What indicators are used during the assessment for two-phase FAC?

Two-phase FAC cannot be influenced by oxidizing power (oxygen level), so it is important to identify first the areas where two-phase steaming and streaming flows can occur; secondly, if pH can be increased locally in these areas. Once a plant is satisfied that the single-phase flow areas are adequately passivated—as indicated by the LP and IP drums having an even red surface color below the water level—the monitored total iron levels can be assessed in terms of two-phase FAC.

For the units investigated that exhibited two-phase FAC, total iron values in the LP and IP drums typically were greater than 20 ppb; one was as high as 100 ppb. The areas affected by two-phase FAC usually are the following:

- Preheater/LP economizer bends or areas where steaming occurs.

- LP evaporator bends near the outlet header where two-phase flow occurs.

- LP risers to the LP drum.

- IP economizer bends or areas where steaming occurs.

- IP risers to the IP drum.

- Hairpin bends in horizontal LP evaporator tubing in VGP units.

- LP drum internals.

Steaming easily can be identified in these areas by installing thermocouples at the appropriate locations. In only two of the units assessed had the HRSG manufacturer “armored” some of these areas with chromium-containing tubes and pipes (typically 1-1.25% Cr alloys); the usual areas are LP and IP evaporator outlet tubes with bends, and the risers.

In cases where the single-phase areas have been passivated by oxidizing treatments but monitored total iron levels remain high, two options are available with the potential to reduce and control the two-phase FAC chemically: (1) Increasing the pH of the condensate/feedwater in steps up to 9.8 with ammonia, and/or (2) Elevating the LP and IP drum pH to 9.8 by controlled additions of TSP or NaOH.

Another option, one related to (1), is to use an amine for increasing pH. But this requires very careful monitoring of steam to ensure that the steam turbine manufacturer’s cation conductivity limits are maintained.

Also keep in mind that option (2) only can be adopted for the LP drum in cases where the IP and HP drums are not fed by the LP drum. Further, if option (2) is adopted using increased levels of NaOH in the LP and/or IP drums, you must monitor steam sodium (saturated and HP/IP); plus, the total carryover from the drums should be measured as discussed below. Whichever option is used, monitoring of total iron is the main indicator with the goal being to meet the “Rule of 2 and 5.”

Be aware that optimized cycle chemistry treatments alone cannot always address the combination of single- and two-phase FAC in HRSG circuits. If after addressing single- and two-phase FAC separately and conducting the well understood sampling, chemistry, and monitoring steps suggested above, the iron levels do not approach the “Rule of 2 and 5,” then the only options remaining are a combination of inspection/NDE and replacement of tubing/piping in the susceptible areas with that containing 1-1.25% Cr1.

Under-deposit corrosion

One of the most important proactive items for plants is to ensure that the HP evaporator does not experience one of the under-deposit corrosion mechanisms—especially hydrogen damage. This takes on added importance when the plant is cooled by seawater or other sources with high levels of chloride (more than 10 ppm)—such as many river, reclaimed, or lake waters—and no condensate polisher in the cycle. In the assessment process, particular attention is given to the two key areas for hydrogen damage: (1) deposits in the HP evaporator, and (2) ingress of contaminant (chloride) into the HP evaporator under conditions when serious deposits are present and the HP evaporator chemistry treatment is inadequate.

The 11 detailed assessments conducted revealed the following with respect to UDC:

1. Only about one-third of the plants knows the iron levels in their HP evaporator/drum and, therefore, whether they meet the “Rule of 2 and 5.”

2. None of the plants has taken HP evaporator tubing samples from the hottest row for analysis of internal deposits.

3. Most plants do not have an adequate level of “Fundamental Instruments” alarmed in the control room to alert operators when contamination in the HP evaporator is serious.

So, are plants proactively addressing the possibility of under-deposit corrosion? Are indicators being used to determine if a plant has adequate instrumentation coverage?

Obviously, no. None of the plants was trying to correlate the total iron level in its LP circuit to the level of deposit in the HP evaporator. None had taken HP tube samples for metallurgical examination and chemical analysis to assess the level of internal deposits, their morphology and their composition.

It was suggested at each plant that tube samples be taken from the lead (hottest) tube row of the HP evaporator section as near to the outlet of the circuit as possible. On units with vertical tubing (HGP) a secondary location is near the bottom of the lead tube row. If possible, samples should be taken from a tube adjacent to a side wall, or adjacent to the gap between side-by-side modules, where exhaust-gas bypassing results in greater heat transfer.

One of the authors has been developing a database of deposit analyses from a much wider suite of HRSGs worldwide to better understand how deposits in HP evaporator tubes are related to the operating cycle chemistry. Particular attention in developing this database has been given to these three aspects: (1) the “normal” deposit density (mg/cm2), (2) optical metallography to determine the porosity and morphology of the deposits as well as the indigenously grown magnetite, and (3) elemental mapping across the deposits to determine if any reaction/corrosion products are being formed within or beneath the deposit.

This information will be published soon. But as expected for some time, it is already clear that deposits are minimized when optimum chemistry control is maintained. This is defined as chemistry that achieves the following objectives:

- Controls single-phase FAC in the condensate/feedwater and LP evaporator with an oxidizing treatment—AVT(O).

- Controls two-phase FAC in the same locations by using either TSP or NaOH in the LP drum, if allowed, as mentioned earlier (four of the units assessed, refer to Table 3).

- Adds nothing to the HP drum or a minimum amount of only TSP or NaOH.

It is also very clear that deposits are made worse (thicker) when an HRSG is operated outside of this envelope by the addition of reducing agents and amines in the condensate/feedwater, and mixtures of phosphates (other than TSP) and NaOH to the HP drum. It is important to know as early as possible—particularly in plants cooled by seawater—the deposition rate on the internal surfaces of HP evaporator tubes by sampling those tubes and analyzing their deposits. This helps to assess the risk of UDC in case of contaminant ingress and, more importantly, allows the HRSG to be cleaned at the optimum time.

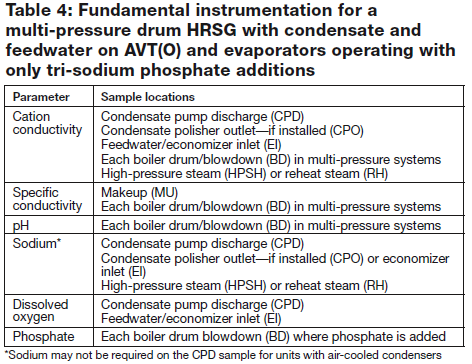

Assessments focus on the fundamental level of instrumentation needed for every plant because of its importance in addressing the UDC mechanism. It refers to the minimum number and type of instruments required to identify cycle chemistry problems on a particular combined-cycle/HRSG unit. Table 4 shows an example of the fundamental level of instrumentation for a multi-pressure HRSG operating with an AVT(O) oxidizing treatment in the condensate and feedwater and only TSP being added to the drums.

It was quite alarming to record in Table 3 the relatively low level of needed instrumentation on some units. Remember that this instrumentation assures adequate, or increased, protection to the HRSG—especially the HP circuit—in the event of contaminant ingress. A key instrument for phosphate-treated units is a phosphate analyzer on the HP drum. It helps keep this circuit optimized continuously, as opposed to infrequently by grab sampling.

To clearly identify a specific contaminant-ingress situation it is imperative to have cation conductivity monitoring of the HP drum. Global experience confirms that relying solely on a pH monitor to record a pH depression in the HP drum to warn of a contaminant situation does not provide sufficient security when only small condenser “weepers” occur. In many cases, weepers go undetected; in others, operating decisions are made to continue operating the unit with ongoing contamination which has been “corrected” by chemical addition.

Best practice: Seawater-cooled plants without condensate polishing can lower their risk of UDC by installing more than the fundamental level of instrumentation—specifically, by addition of an online chloride analyzer on the HP drum for added security. None of the assessed plants has this feature.

Another item on instrumentation noted during the assessments is the disturbing trend of plants relying heavily on grab samples. It is increasingly common to see a large number of grab-sample analyses conducted every shift, every day, or every week or two by the operating or chemistry staff. Much better continuous control of cycle chemistry is possible by installing the fundamental instrumentation recommended by Structural Integrity—such as the example provided in Table 4. A further benefit of using online instrumentation: The time it took operators to take the grab samples can be used more productively.

Other important cycle chemistry items

Carryover from the HP, IP, and LP drums. As Table 3 illustrates, none of the organizations has comprehensive programs for monitoring carryover; in fact, the percentage of total carryover from any drum was not known by any organization. To protect the steam turbine, it is vital to know the amount of carryover from each drum.

Measurements should be made semiannually to ensure the integrity of steam separators and operational drum levels. The test is simple—one requiring concurrent sampling for sodium in the drum and in the saturated steam. Details of the process are provided in a recent IAPWS technical guidance document7. If TSP or NaOH is added to the drums then it shouldn’t be necessary to add any more sodium to conduct the test.

Shutdown protection. Another item included in the assessment process is whether the plant protects its HRSG(s) and steam turbine during shutdown periods. Most of the units within the current assessment have facilities to nitrogen-blanket the HRSG(s) to prevent the initiation and growth of pits on internal surfaces. However, only one of the units has an operating dehumidified air system to protect the steam turbine during shutdown periods.

Most combined cycle/HRSG owner/operators should give serious consideration to installing dehumidified air for the LP steam turbine: This is the most effective method for preventing failures in the machine’s phase transition zone (PTZ)8. This takes on added emphasis if the number of long shutdown periods (more than three days) is increasing year after year.

Thermal transients in HRSGs

Thermal transients are unavoidable if the HRSG is started and stopped, as it must be. This presents no problems provided:

- The OEM accurately anticipates the number and severity of thermal transients to which the HRSG will be exposed.

- The HRSG is competently designed and fabricated to withstand the anticipated transients.

- The OEM, EPC contractor, and/or owner/operator do not introduce features or operating procedures that result in significant unanticipated thermal transients.

HGP HRSGs are constructed with tubes arranged vertically in “harps.” These harps are rigid structures requiring that adjacent tubes remain at similar temperatures to avoid severe thermal-mechanical fatigue damage and premature failure. Even with the use of advanced high-creep- strength materials, HRSGs operating at high pressure and temperature must be equipped with HP drum, HP superheater, and sometimes reheater outlet headers and piping, with sufficiently thick walls that require careful management of heat-up and cool-down rates to avoid internal cracking.

VGP HRSGs are arranged with banks of serpentine tubes, positioned horizontally, and supported along their length by tube-support plates. This tube arrangement is considered by some to be more flexible than the harp arrangement used in HGP HRSGs. While this may be true in some cases, VPG HRSGs are not immune to thermal-transient-induced tube failures. Discussion of these failures and their root causes are beyond the scope of this paper since the current assessments did not include any VGP units.

As with cycle chemistry, there are many thermal transient issues that must be managed effectively to avoid excessive thermal-mechanical fatigue damage. Among these, three stand out as having caused a large number of tube failures, or have a high potential to cause cracks in thick-walled components: (1) inadequate drainage of superheaters and reheaters, (2) interstage attemperator overspray, spraywater leakage, and erroneous operation, and (3) quenching of economizer/preheater inlet sections.

Table 2 shows the indicators of ineffective or incomplete drainage, damaging attemperator performance, LP economizer quench, and operating practices known to cause damaging thermal transients in thick-walled pressure parts for the plants assessed. Analysis of this table identifies several key factors that predominate in the three areas of concern.

Superheater, reheater drains

HP superheater and reheater drain-system designs and operating practices that do not remove all condensate prior to initiation of steam flow during cold, warm, and hot startups are unable to protect the superheater and reheater tube-to-header connections, header bores, and nozzle-to-header connections from severe thermal fatigue damage. Such damage has resulted in many premature tube failures, and can be expected to cause header bore cracking and/or nozzle-to-header weld failure.

A large quantity of condensate forms in the superheaters and reheaters during the prestart purge when these heat-transfer sections behave like large air-cooled condensers. It is critical to drain this condensate as fast as it forms; do not allow it to accumulate. For all types of startups, superheater tubes heat up to near exhaust-gas temperature during the time between GT light-off and when steam begins flowing though the tubes.

Undrained condensate will migrate selectively through some tubes as steam flow is initiated, quenching (and shrinking) them. Shrinkage of these tubes, relative to still hot neighboring tubes, results in a large bending stress at the tube-to-header connection and severe thermal fatigue damage. After shutdown, thick-walled headers and steam piping remain hot for long periods. During hot starts, condensate carried by steam flow will enter and quench the still-hot upper headers and steam piping. Cracks in the header bore and outlet nozzle-to-header welds may result from such quenching.

Analysis of data gathered during the 11 assessments reveals the following:

1. All but one of the plants assessed have drain pipes that are too small to remove the quantity of condensate formed during the purge cycle in the time available prior to substantial steam flow beginning. Detailed calculations to determine condensate formation rates in superheaters and reheaters under various startup conditions, and the drain pipe sizes required to remove that amount of liquid, have been made over the years for several HRSG designs. The authors use this information in assessing drain-pipe size. As an example, each final superheater harp in a typical F-class HRSG requires the equivalent of three 2-in.-diam (5-cm) drain pipes to effectively remove the condensate.

2. Nearly all plants (91%) assessed have their flash tanks positioned at an elevation above the lower headers and none have drain pipes routed with a continuous downhill slope to the tank. During cold and warm starts from zero pressure it is impossible for condensate to flow uphill to the tank or through upwardly flowing sections of drain pipe. By the time sufficient pressure is generated to do so, and if cascading bypass valves are opened early to steam cool the reheater as they should be, steam flow has already moved the accumulated condensate through the superheater and reheater.

3. All plants have drain pipes from superheater or reheater sections that are interconnected and operate at different pressures9. This arrangement is ill-advised: When steam is flowing, the pressure in the primary superheater (the superheater upstream of the attemperator relative to steam flow) must be higher than that in the secondary superheater (the superheater downstream of the attemperator relative to steam flow).

If the drains from these sections are interconnected prior to entering the flash tank, condensate will flow from the primary superheater into the secondary superheater. While some condensate from the primary superheater may also flow to the flash tank (if its elevation is not too high) the secondary superheater will not drain and often has its condensate level rise.

Changes to the ASME Boiler & Pressure Vessel Code in 200711 mandate that interconnection of drains from superheaters or reheaters of different pressures must not be prevented from flowing, or back-flowing, because of backpressure in the common manifold, flash tank, etc. While useful for helping operators purchase new units with more effective drains, thoughtful attention to drain and flash tank arrangement is required if the desired results are to be realized.

4. None of the plants assessed are equipped with a reliable means of determining when condensate is actually present in the superheater/reheater and when drain valves should be open. Neither can they detect when the superheater/reheater has been successfully drained and drain valves should be closed. Plus, 55% of those assessed have no automatic means of drain operation.

At plants with some form of automation, half use thermocouples installed in drain pipes to determine when to close drain valves, and half close the valves at predetermined pressures. While these methods might work as intended during startups from one initial-pressure condition, neither can accomplish effective draining over the wide range of initial-pressure conditions from which a cycling HRSG must be started.

A significant challenge in effective drain control stems from needing very large drain pipes to remove condensate fast enough during starts initiated from zero pressure when only gravity head is available to move the water, and avoiding excessive release of steam through these large pipes during starts initiated from high pressure. For example, drain-pipe thermocouples might be effective during a startup from zero pressure, when it is possible to leave the drain valves open prior to and during the purge, then close them when the thermocouple detects superheated steam passing through the pipe. However, during a start from initial high pressure the drain valves can’t be left open throughout the purge without risk of depressurizing the HP system (if the drain pipes are large enough to work at zero pressure).

Drain-pipe thermocouples are useless for controlling the drain valves during the critical pre-start and purge periods since condensate and steam are both at the prevailing saturation temperature. If the drain valves are not opened until the GT is fired and the drain-pipe thermocouple can be used, there is a good chance that the accumulated condensate will not have completely drained before steam flow commences. The preferred method of controlling drain valves during starts initiated from any pressure is through the use of a level detecting drain pot on each superheater and reheater section that operates at a different steam pressure4,10.

5. None of the plants assessed has drains located near the ends of the superheater and reheater headers. When new, and when in the cold condition, most harps hang straight with their lower headers level. However, after years of operation lower headers may become tilted as harps are distorted. During hot starts, lower headers become “humped” because of the top-to-bottom temperature differential (condensate laying in the header cools the bottom, shrinking it, relative to the top)4.

These conditions result in condensate being unable to reach a drain positioned in the center of the header. Such trapped condensate will migrate up adjacent tubes when steam flow commences, regardless of drain-pipe size and operating procedures. The addition of a drain near each end of the header prevents condensate from being trapped.

6. Six of the plants assessed open drains prior to initiating startup to assure superheaters and reheaters are dry. Of these six, five plants open the drains during the purge to drain condensate as it is forming. Waiting until the GT fires to open drain valves, as the other plants do, significantly increases the time required to remove all condensate and increases the risk that some condensate will remain when steam begins flowing.

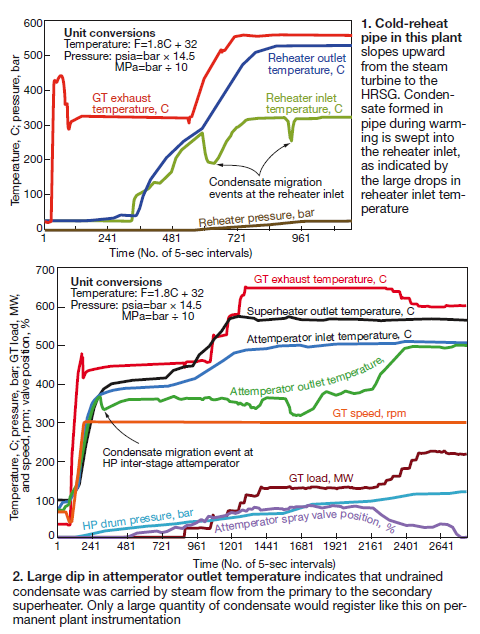

7. Of the plants assessed that have reheaters, 29% are equipped with cold-reheat piping that slopes uphill in the direction of steam flow from HP turbine to HRSG. This arrangement is conducive to having undrained condensate passing from the cold-reheat pipe into the primary reheater4 as Fig 1 illustrates.

Are superheaters and reheaters being drained effectively?

Migration of undrained condensate normally cannot be monitored with the kind of instrumentation typically installed at combined-cycle plants. Permanent steam-temperature sensing elements are relatively slow to respond to sudden temperature changes. Small slugs of condensate pass these temperature elements too fast to register a change in temperature.

Unfortunately, such fast-moving slugs of condensate do cause significant changes in the temperature of the relatively thin-walled superheater and reheater tubes, and to the inner surfaces of hot headers. It is usually necessary to install several temporary tube-temperature thermocouples in the superheaters and reheaters to confirm the presence of condensate migration and quantify its severity12. Only very severe condensate migration events last long enough to register on the DCS steam-temperature instrumentation.

More than three-quarters of the plants assessed showed evidence of condensate migration on DCS plots of permanent thermocouples located near the attemperator. Figs 1 and 2 show two such DCS data plots. The dip in temperature at the attemperator outlet in Fig 2 indicates severe condensate migration between the primary and secondary HP superheaters. Likewise, the dip in temperature at the reheater inlet in Fig 1 indicates a large quantity of condensate passing from the cold-reheat pipe into the primary reheater.

Assessment: It’s not necessary to install temporary tube-temperature thermocouples in these HRSGs to conclude that significant amounts of condensate remain in, and migrate through, the HP superheater and reheater during startups and that at least some of this condensate passes into the main-steam and hot-reheat piping.

Finally, seven of the plants assessed reported failures at superheater/reheater tube/header connections, stretched tubes caused by quenching, and/or spalling of external tube oxide from high strain at the tube/header connection.

Attemperation systems

The distribution of heat-transfer surface area among the primary and secondary superheaters and reheater, the type of GT, performance of the attemperator control system, quality of attemperator hardware installed, and the attemperator piping arrangement are all critical for obtaining acceptable attemperator performance13.

The introduction of unvaporized spray water into downstream harps causes damaging thermal transients. This is called over spray and defined as an attemperator outlet steam temperature of less than 50 deg F (28 deg C) above the prevailing saturation temperature.

The 11 detailed assessments revealed the following:

1. Only 18% of the plants perform routine inspections or preventive maintenance on their attemperators. Desuperheaters are notoriously unreliable and subject to severe thermal transients. At least annually, remove/inspect/repair the spray nozzle, control valve, and block valve, and do a borescope inspection of the thermal liner and its attachment points.

2. Nine of the 11 plants assessed have attemperator piping arrangements that allow unvaporized, or leaking, spray water to flow directly into harps during low (or zero) steam-flow conditions. If this occurs while the harp is hot, severe thermal-mechanical fatigue damage, and sometimes immediate tube failure, results13. Changes to the ASME Boiler & Pressure Vessel Code in 200711 no longer permit undrained attemperator pipe arrangements10. Existing plants with such arrangements can benefit from the addition of a second spray-water block valve and tell-tail drain to reduce the risk of undetected block valve leakage.

3. Four plants assessed are equipped with spray-water control valves internal to the spray-nozzle assembly. This configuration has proven very unreliable in cycling service and is no longer offered by most HRSG OEMs.

4. Three plants use simple steam-outlet-temperature feedback loops for attemperator control. All have difficulty avoiding over-spray conditions and/or maintaining outlet steam temperature within design limits—or manually control the attemperator setpoint in an attempt to compensate for the automatic control’s inability to perform adequately4.

Manual set-point manipulation and manual spray-valve positioning are dangerous workarounds. The thermodynamic complexity, the very long time delay for steam-temperature changes to register on DCS readouts, and the speed with which temperature changes occur place consistently safe manual attemperator control beyond the ability of even the best operator without creating over-spray conditions.

The preferred attemperator control scheme uses two cascaded controllers with real-time enthalpy calculations performed around the attemperator, and a feature to prevent spray down below 50 deg F (28 deg C) of superheat at the attemperator outlet. Plants equipped with GE 7FA/9FA GTs also find it useful to add an anticipatory feature by incorporating GT fuel demand or inlet-guide-vane position into the attemperator control scheme.

5. Two plants experienced attemperators coming into, and going out of, service multiple times during startup. Intermittent attemperator operation exposes attemperator hardware, piping, and superheaters/reheaters to avoidable and undesirable thermal transients. GT load and exhaust-temperature controls (ETM on GE 7FA/9FA units), and attemperator controls, should be coordinated to avoid the need for desuperheating until GT exhaust temperature can no longer be held below 950F (510C).

Once the attemperator is placed in service it should stay in service until no longer needed. New units should be designed to have desuperheaters remain in service continuously at minimum spray water flow to minimize thermal-fatigue damage to attemperator hardware.

Special consideration for attemperation in plants equipped with GE 7FA/9FAs. HRSGs equipped with 7FA and 9FA GTs demand significantly more performance from their attemperator systems because of their unique exhaust-gas temperature (EGT) characteristic. At minimum GT load, EGT is about 950F (510C) unless the exhaust temperature matching (ETM) feature is engaged to lower it to 750F (399C).

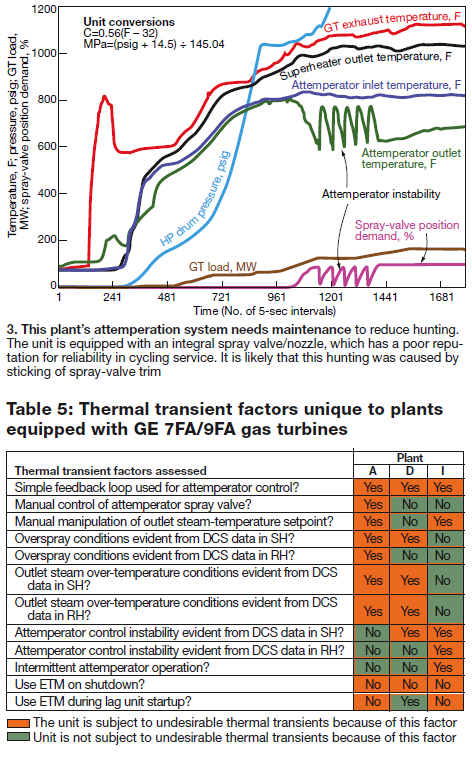

In addition, when the GT load is increased above minimum load EGT rapidly increases to 1250F (677C) (called the isotherm) and remains there until GT load reaches about 60%. This rapid increase in EGT to such high temperature early in the startup process, when steam flow through the superheater is low, creates additional challenges for the attemperator’s hardware and controls4. Table 5 shows the indicators for damaging attemperator performance, and operating practices known to cause damaging thermal transients unique to plants equipped with 7FA/9FAs.

Detailed assessments of the three 7FA/9FA plants have revealed the following:

1. High-quality attemperator equipment, well-tuned cascaded anticipatory attemperator controls, use of ETM during all startups, holding the GT at minimum load until more steam flow is available, and holding pressure steady while increasing GT load through the critical load range with EGT at the isotherm all may be required to (1) maintain stable, automatic attemperator control, (2) avoid over-spray conditions and (3) prevent over-temperature excursions at the superheater/reheater outlet.

Superheater arrangements with more than about 25% of the total surface area positioned downstream of the attemperator (in the secondary superheater) have greater difficulty avoiding overspray conditions with GE units while at the same time preventing outlet steam temperature from exceeding design limits. As the proportion of total superheater surface located in the secondary superheater approaches 50%, it becomes unlikely that both over spray and over temperature can be avoided, even when all of the approaches listed above are used.

2. All of the 7FA/9FA plants assessed are equipped with simple steam-outlet-temperature feedback-loop attemperator controls. This single shortcoming is a significant contributor to poor attemperator performance experienced by this group of plants. Other 7FA/9FA plants, familiar to the authors but not included in these assessments, that are equipped with cascaded anticipatory control schemes deliver acceptable attemperator performance.

3. Two of the GE 7FA/9FA plants manually manipulate attemperator control setpoint or manually position the spray-water valve in an attempt to avoid excursions of steam outlet temperature above design limits. As previously noted, this is a dangerous practice and very likely to result in over-spray conditions.

Are attemperators being operated effectively? Here’s what the assessment results say:

1. Twenty-two percent of the plants assessed experience over-spray conditions during startup as indicated in DCS plots. Not surprisingly, all of these plants are equipped with 7FA/9FAs.

2. Twenty-nine percent of the plants assessed experience an excursion of the HP or RH steam outlet temperature above design limits during startup. Again, all are the 7FA/9FA-equipped plants. Over-spray conditions inflict significantly more thermal-mechanical fatigue damage in the superheaters and reheaters than the creep damage caused by brief periods of over-temperature operation.

Optimize operating procedures, controls, and attemperator hardware to possibly avoid both of these undesirable consequences. However, when faced with the choice of over-spray versus limited over-temperature operation during startup, the priority should go to avoiding all over-spray events.

3. Four plants assessed experience attemperator control instability during startup. Two are equipped with integral spray-valve/nozzle assemblies. Regarding controls, two have simple controls (on the 7FA/9FAs), the other two more sophisticated controls—possibly pointing out the need for additional focus on spray-valve maintenance and control tuning. Fig 3 shows a DCS plot from one unit with significant control instability during a cold start.

Economizers

There have been many failures at tube/header connections in HRSGs attributed to “inlet quench.” During startup, prior to initiation of feedwater flow, the LP economizer feedwater-inlet section heats up close to around 280F (138C)4. In plants not equipped with thermal deaerators, or other means of warming the incoming feedwater above ambient temperature, the LP inlet header and tubes adjacent to the inlet nozzle undergo a large quench when the feed valve is first opened. Since the flow rate often is very low during the initial feed, water only passes through the few tubes closest to the inlet nozzle—thereby creating large tube-to-tube temperature differences.

These very low flow rates (trickle feed) also can lead to flow instability and flow reversal in tubes near the gas-path walls and the gap between side-by-side modules where end tubes pick up more heat from bypassing exhaust gas4. LP economizers that incorporate bent tubes in the inlet pass, and “cross-flow” harps (baffles inside the headers force water to alternately flow up some tubes and down others as it progresses across the harp) generally suffer more from inlet quench than parallel-flow harps with straight tubes9. LP economizer harps with inlet nozzles located on the upper header experience more flow instability and flow reversal than ones with bottom-feed inlets, because down-flowing water has to overcome increasing buoyancy as it is heated.

The 11 detailed assessments revealed the following:

1. More than half (55%) of the plants have economizer drains arranged with a single small-bore inboard isolation valve for each harp and a common, larger downstream isolation valve. This arrangement promotes severe quenching in tubes located immediately above the drain connection in the hotter harps because of water bypassing through the drain pipe when more than one of the small-bore valves develop seat leakage9. This risk is avoided by the installation of tandem small-bore isolation valves for each harp.

2. Forty-five percent of the plants assessed have cross-flow economizer harps.

3. Nearly three-quarters (73%) of the plants use a thermal deaerator or LP economizer recirculation system during startup to minimize inlet quench. LP economizer recirculation systems generally are designed for increasing feedwater inlet temperature above the acid dewpoint during low-load operation and during oil firing. Some operators place these systems in service prior to startup to warm the water in a portion of the condensate piping, hopefully reducing the severity of inlet quench. The additional flow in the LP economizer created by recirculation also may reduce flow instability and flow reversal during trickle-feed conditions. Plant-specific pipe routing and recirculation-system flow capacity will determine how effective this practice is.

Are damaging economizer thermal transients being avoided?

Twenty-seven percent of the plants assessed report economizer tube/header connection failures, which are attributed to stretched tubes caused by quenching.

Thick-wall pressure parts

The HP steam drum, the hottest and thickest HP superheater headers, and the hottest and thickest reheater headers require care during startup and shutdown to avoid initiating thermal-mechanical fatigue cracks caused by overly aggressive heating and cooling rates2.

1. Six plants assessed reported being given a maximum cool-down ramp rate for the critical superheater/reheater headers by the OEM, or had the unit evaluated to determine the maximum safe ramp rate for a normal shutdown. The others are “flying blind” on this potentially expensive issue. All other things being equal, cooling a thick-walled pressure part too quickly causes significantly more thermal-mechanical fatigue damage than does heating it too fast2.

2. Twenty-seven percent of the plants assessed have been given a maximum heat-up ramp rate for the critical superheater/reheater headers by the OEM, or had the unit evaluated to determine the maximum safe ramp rate to be used during startup2.

3. All but two of the plants have been given a maximum heat-up ramp rate for the HP drum by the OEM, or had the unit evaluated to determine the maximum safe ramp rate to be used during startup.

4. Five plants use shutdown procedures that steam-cool the superheaters and reheaters during normal shutdown2. Rapid unloading of the GT during normal unit shutdown leaves superheaters and reheaters near rated steam temperatures. After firing ceases and the GT is coasting down, or during a spin-cool, exhaust air temperature often falls below the prevailing saturation temperature inside superheater and reheater tubes.

When this occurs, condensate forms in the tubes and trickles into the lower headers. If the headers have been shut down hot, they undergo a severe quench. Slower unloading of the GT (at a rate that results in decreasing EGT at the maximum cooling rate determined safe for the critical superheater/reheater header) is suggested to avoid a damaging condensate quench after shutdown.

Recommendation: Unloading the GT (and using ETM on 7FA/9FAs) until outlet steam temperature is about 90 deg F (50 deg C) above the prevailing HP saturation temperature, then holding at that load for few minutes to let the header’s through-wall temperature gradient equalize before shutting down the GT, will avoid the damaging condensate quench after shutdown.

5. None of the 7FA/9FA plants assessed use their ETM feature to control steam-temperature ramp rate during normal shutdown. The exhaust temperature characteristics of these GTs result in very aggressive steam-temperature ramp rates when shut down without using this feature.

6. One of the 7FA/9FAs uses its ETM feature to control exhaust temperature during startup of the “lag” HRSG in 2 × 1 plants. GE intended the ETM feature be used to match steam temperature from the “lead” HRSG to the steam turbine’s requirements during startup of a cold steam turbine.

During cold starts, the lead HRSG typically is warmed up slowly and well within its HP drum and critical superheater/reheater-header temperature ramp rates. Failure to “voluntarily” use ETM for startup of the lag HRSG typically exposes the critical superheater/reheater headers to excessive heat-up ramp rates.

Are thick walled pressure parts being protected from excessive thermal-mechanical fatigue damage?

1. Five plants assessed routinely exceeded prudent temperature ramp rates for their critical superheater/reheater headers during both startup and shutdown. These plants are not likely to obtain design fatigue life from these expensive headers unless corrective actions are taken before too much damage is done.

2. Twenty-seven percent of the plants assessed routinely exceed prudent HP drum temperature ramp rates during startup. These plants are likely to find thermal-fatigue cracks in their HP drums before the HRSG reaches the end of its nominal design life if changes to operating procedures are not implemented to slow the startup-temperature ramp rate.

Concluding remarks. Assessments of 11 combined-cycle/HSRG plants around the world provide an indication of how proactively operators are addressing the known failure/damage HRSG tube failure (HTF) mechanisms, and the potential for damage in thick-section pressure vessels. The two most important aspects have been reviewed: cycle chemistry and thermal transients. In the former, the assessments have addressed the key factors for flow-accelerated corrosion, under-deposit corrosion, and pitting; in the latter, thermal fatigue and creep fatigue.

This effort offers a clear picture in each area of exactly where the weaknesses in the approaches are occurring, and it is not surprising that the current ranking order for HTF has remained virtually static for the last 10 years. Hopefully, the key messages presented in the article easily can be applied by operators to improve the current situation.

Acknowledgements. Much thought and discussion were provided by three other members of the HRSG team: Kevin Shields, Steve Shulder, and Mike Pearson. These colleagues reviewed the assessments of each plant and in many cases provided calculations and important insight. Diane Dooley helped with the word processing and development of some of the tables. ccj

References

1. R B Dooley. Flow-Accelerated Corrosion in Fossil and Combined Cycle/HRSG Plants. PowerPlant Chemistry, 2008, 10(2), pp 68-89. Paper is available at: http://www.structint.com/literature/FAC%20Review%20in%20PPChem%20031008.pdf

2. J M Pearson and R W Anderson. Influences of HRSG Design and Operation on the Durability of Two-shifted HRSGs. European Technology Development Conference on HRSG Technology, London, November 2003.*

3. R W Anderson. Special Workshop Explores P91/T91 Issues. Combined Cycle Journal, 3Q/2005, pp 3-10.*

4. J M Pearson and R W Anderson. Measurement of Damaging Thermal Transients in F-Class Horizontal HRSGs. ETD: International Seminar on Cyclic Operation of Heat Recovery Steam Generators (HRSGs), June 2005, London, UK.*

5. R B Dooley, K J Shields, and S J Shulder. How Repeat Situations Lead to Chemistry-Related Damage in Conventional Fossil and Combined Cycle Plants. PowerPlant Chemistry, 2008, 10(10), pp 564-574. Paper is available at: http://www.structint.com/literature/Repeats%20PPChem%20102708.pdf

6. R B Dooley and R Tilley. Tube Failures in Conventional Fossil Fired Boilers and in Combined Cycle/HRSGs. PowerPlant Chemistry, 2004, 6(12).

7. IAPWS Technical Guidance Document: Procedures for the Measurement of Carryover of Boiler Water into Steam, September 2008. Also published in PowerPlant Chemistry, 2008, 10(10), pp 600-605. Document is available at www.IAPWS.org

8. G Engelhardt, D D Macdonald, Y Zhang, and R B Dooley. Deterministic Prediction of Corrosion Damage in Low Pressure Steam Turbines. 14th ICPWS, Kyoto, Japan, August 2004. Also published in PowerPlant Chemistry, 2004, 6(11).

9. J M Pearson and R W Anderson. Root Causes of Transient Tube Temperature Anomalies Measured in Horizontal Gas Path HRSGs. EPRI International Conference on Boiler and HRSG Tube Failures and Inspections,” Phoenix, Arizona, November 2001.*

10. HRSG User’s Group Steam-plant Workshop Focuses Owner/Operators on Best Practices—of Drains and Other Challenges. Combined Cycle Journal, 1Q/2006, pp 48-49.*

11. American Society of Mechanical Engineers, 2007 ASME Boiler & Pressure Vessel Code, Section I, “Part PHRSG Requirements for Heat Recovery Steam Generators,” Part PHRSG-1, pp 151-153, specifying the requirements for superheater and reheater condensate removal and including the superheater and reheater desuperheater drains

12. R W Anderson and J M Pearson. Quantifying Thermal Transients in Heat Recovery Steam Generators. EPRI Boiler Tube and HRSG Tube Failures and Inspections International Conference, San Diego, Calif, November 2004*

13. S A Wambeke. Avoiding Desuperheater Problems with Quality Equipment, Proper Installation, Tight Process Control. Combined Cycle Journal, Fall 2008, pp 13-17.**

* Access from Publications Page at www.CompetitivePower.us