Rethinking water cycle yields big saving at Gila River

Best of the Best Award

Challenge. Minimizing water consumption is particularly critical at Gila River Power Station because of its desert location. The 2200-MW facility with four 2 × 1 F-class combined cycles also is challenged by a permit that prohibits the discharge of process water from the site. The only alternative to reuse or evaporation is a plant shutdown.

As designed, Gila River was equipped with the following systems to satisfy the discharge restriction:

- Three evaporation ponds to retain process water onsite. Note that the plant was not permitted to pump water from these ponds for any purpose.

- A zero-liquid-discharge (ZLD) system to process wastewater, by way of brine concentrators, into distillate and a concentrated waste stream. Distillate is recycled as makeup water for the plant; the waste stream is discharged to the evap ponds.

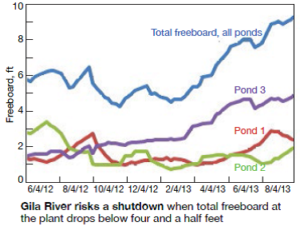

When the ZLD plant is offline, process water is discharged directly to the evaporation ponds. In 2012, the amount of water discharged to the ponds was so high that there were periods when there was less than 4.5 ft of vertical space available to hold water (so-called freeboard). Without adequate space to discharge the water during a ZLD upset or maintenance, the facility risked a forced shutdown (figure).

When the ZLD plant is offline, process water is discharged directly to the evaporation ponds. In 2012, the amount of water discharged to the ponds was so high that there were periods when there was less than 4.5 ft of vertical space available to hold water (so-called freeboard). Without adequate space to discharge the water during a ZLD upset or maintenance, the facility risked a forced shutdown (figure).

Also, the original water cycle was arranged to provide demineralized makeup for the heat-recovery steam generators using a rental reverse osmosis (RO) system when the ZLD system was offline. This service cost the plant $100,000 monthly.

Solution. The Gila River team approached the water conservation challenge by implementing process changes to achieve the following:

- Enhance pond evaporation. The facility’s Title V air permit was modified to allow installation of spray evaporators in the ponds.

- Treat evap-pond water in the ZLD system. The plant’s Aquifer Protection Permit was modified to allow installation of floating pumps to transfer pond water to the ZLD system for treatment.

- Process well water into distillate. A dual-pass RO was installed to produce distillate-quality water when the brine concentrators are offline.

- Minimize cooling-tower blowdown. A new water-chemistry program and performance monitoring were put in place to increase cooling-tower cycles of concentration. The result: A 33% reduction in tower blowdown.

- Improve brine-concentrator performance. Anti-foaming agents and anti-scalants were added to the wastewater system to extend service runs of the brine concentrators by 25%.

Results. The various projects greatly improved the facility’s ability to manage its water. The positive results are reflected by the dramatic increase in freeboard during 2013 as shown in the chart. Here’s what was achieved:

chart. Here’s what was achieved:

- Reduced water consumption. With the ability to reuse water from the ponds, each 1000 gal processed by the ZLD eliminates the need to remove 950 gal from the local aquifer. Increased cycles in the cooling towers directly reduces water consumption by 1 million gpd and eliminates the need to process this water.

- Risk reduction in makeup supply. By installing a permanent RO system to produce distillate-quality water, Gila River eliminated the cost of rental units and assured two independent sources of HRSG makeup.

- Improved performance of the brine concentrators. At $50,000 or more per cleaning, extending brine-concentrator operating cycles saves significant maintenance dollars.

Project participants:

Process Engineer Steve Reinhart managed the water conservation and reuse project.