Challenge. For decades the electric-utility industry was stable, change slow to happen. This is no longer the case. Today, the industry is rapidly reshaping itself in response to political, economic, and regulatory pressures. Workforce changes also are on the fast track, with many employees retiring or leaving the industry. These senior personnel are being replaced by younger workers with different values and technical backgrounds. To respond effectively to the new paradigm, the industry needs an adaptable, flexible, and multi-skilled workforce.

Solution. NV Energy Generation has embraced the Hoshin process to develop a plan for realigning its workforce for the future. This process has these three primary characteristics:

- It involves fundamental change in the systems of the organization.

- It requires involvement by the entire organization.

- It is intended to bring the organization to the next level of performance.

The project, named Hoshin Workforce 2020, began with the development of nine strategies to guide the process. Example: Development of a fleet-wide process to manage external labor. Each strategy was led by a team tasked to develop an implementation plan. Team members represented the generation department, as well as human resources, supply chain, corporate communications, labor relations, and energy delivery. Nearly one-quarter of the employees within generation have been involved in the process, which has fundamentally changed how NV Energy Generation does business. Key breakthrough innovations include the following:

- A clear definition for core work—specifically, all the duties required for employees to produce electric power that cannot be obtained externally without degrading reliability, reducing quality, or increasing total long-term cost.

- A model that can be used to optimize and diversify staffing for each generation location.

- Use of competency-based assessments for employee development and retention.

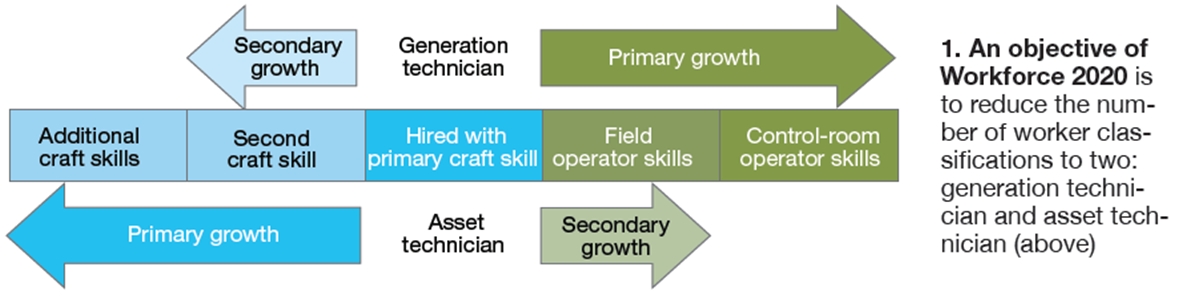

The mission of the Workforce 2020 project is to (1) build well-trained, skilled, motivated, and team-oriented employees, and (2) ensure employees will have the ability to successfully complete and lead tasks in many different capacities throughout the organization. By focusing on core work, the generation department has significantly reduced the number of job classifications, thereby improving the effectiveness of its training and recruiting programs.

NV Energy is negotiating with local bargaining unions to decrease the number of worker classifications to two positions: generation technician (focus on operations and support maintenance activities) and asset technician (focus on maintenance and support operation activities). Training programs are being developed for these two positions (Fig 1).Results. Work is ongoing and much remains to be done. Thus far, NV Energy Generation has developed three-year look-ahead (2015) workforce designs incorporating Hoshin core principles for each plant and for corporate services groups. Assuming the new workforce will be more efficient and non-core work will be outsourced, the number of employees is expected to shrink by about 7% over the next three years. Most plants already have begun defining what work is core and have prepared contracts for the non-core work.

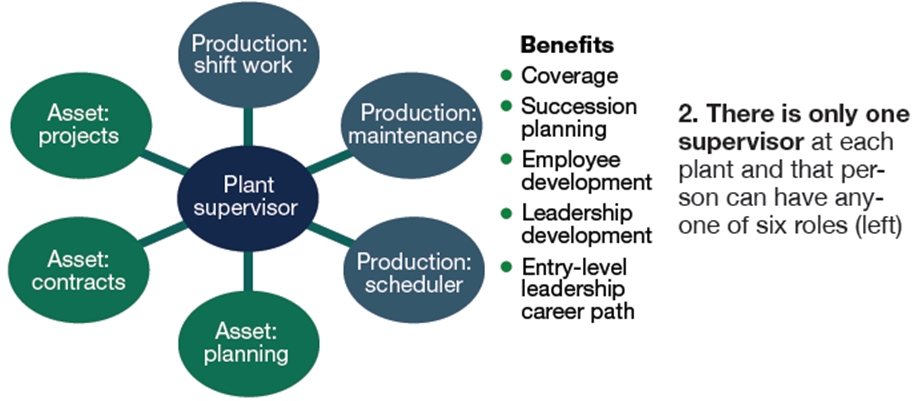

Traditional O&M managers are being replaced by production managers, with responsibility for day-to-day production and the management of bargaining-unit employees. Production managers focus only on core work. Plant-level asset managers are responsible for long-term performance of the physical facility, as well as core and non-core work, planning, and contractor oversight. There is only one supervisor at each plant and that person can take any of the following six roles: operations supervisor, maintenance supervisor, planning supervisor, scheduler, contracts supervisor, and project supervisor (Fig 2).

Traditional O&M managers are being replaced by production managers, with responsibility for day-to-day production and the management of bargaining-unit employees. Production managers focus only on core work. Plant-level asset managers are responsible for long-term performance of the physical facility, as well as core and non-core work, planning, and contractor oversight. There is only one supervisor at each plant and that person can take any of the following six roles: operations supervisor, maintenance supervisor, planning supervisor, scheduler, contracts supervisor, and project supervisor (Fig 2).

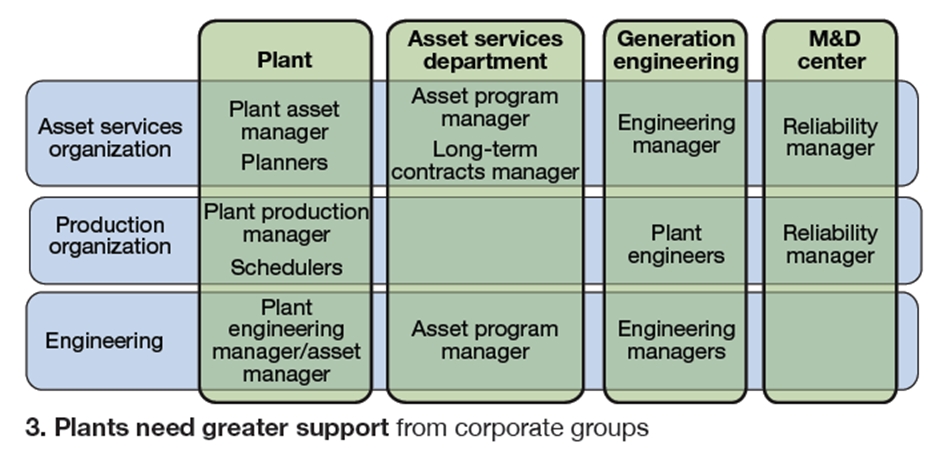

The plants will need greater support from corporate groups. The support required has been identified and the corporate groups are reorganizing to provide it (Fig 3). Two examples: a monitoring and diagnostic center and an asset management team. The M&D center will support plant operators with real-time diagnostics and provide reliability and performance engineering expertise. The asset management group will assist in monitoring plant performance and provide outage (overhaul) management services.

Project participants: All NV Energy Generation employees