A better approach to electrical-relay response training

Challenge. Millennium Power personnel believed a better approach to electrical-protection training was needed. Typical documentation consists of one-line drawings designed by engineers to implement plant protective equipment. One-lines are not designed for ease of troubleshooting: they lack description of the faults, and they do not contain corrective actions or guidance should a fault occur.

In most electrical events, the fault location is not readily apparent, and not every event results in obvious equipment damage. Plant staff must work backwards to be able to work from the relay information to locate and remediate faults. The information on the one-lines could be presented in a format more suited to troubleshooting.

Millennium one-lines consisted of approximately 10 different protection drawings prepared by several different engineering firms. All the drawings followed general IEEE convention but used nomenclature specific to the OEMs and EPCs. They were made by engineers to be read by engineers. In addition, they were developed in the context of how to protect the equipment rather than how to locate a fault.

Solution. Plant personnel developed a documentation package that flows from the relay observations to the fault. It contains guidance on faults, instructions for recommended testing, and remediation required to return equipment to service (sidebar).

The package includes training on equipment specific to the plant. The training and documentation package included a series of expected relay and damage observations for common electrical faults.

Not only do these provide a basis for comparison during an actual electrical fault, they make causality response training much more relevant. Each operator receives a bound set of reference materials containing electrical trip guidance and examples of causality responses.

Results. At most power stations, troubleshooting of complex electrical faults is a relatively infrequent experience, and misunderstanding the true nature of an event can have catastrophic consequences. Too often, the drive to meet commitments and generation schedules compels operators to make hasty, uninformed decisions.

This package gives the operator the tools, knowledge, and guidance to make well-informed decisions and set in place an appropriate course of action. Sometimes, the right answer is to stop and call for help; however, knowing when to do that is key. These guides lead the operator to the right decision and have proven to be short money well spent.

Project participants:

Tim Sheehan, plant systems superintendent

Bill Lovejoy, chief engineer, NAES Corp

How Millennium helps guide operators tasked with troubleshooting

The following example is for a 59G or 59N neutral overvoltage. Millennium has four neutral overvoltage relays—one each Beckwith M-3420 and M-3430 for both the steam and gas turbine/generators.

A 59GN trip indicates a grounded phase between the generator neutral and the low side of the GSU bushings. As one phase goes to ground, the voltage on the neutral increases to maintain the 3-phase relationship. This is a common trip. It can occur at field flashing when one phase fails to build voltage or it can occur immediately after closing the generator breaker when closing in on a grounded isophase. It frequently occurs with a 59 phase overvoltage.

Reset directions: Review oscillography, isolate the machine and isophase, and measure resistance to ground. On the first pass there is no need to break out the three phases at the generator neutral or GSU delta connection. However, if the readings are low it is necessary to break out the connections to determine and isolate the phase to troubleshoot.

It is possible to re-energize without measuring the resistance to ground. The neutral transformer limits the ground current flow below a level that would damage the generator core. However, the elevated voltages on the ungrounded phases (1.7 × normal) significantly increase the chance of a second fault developing to ground of those phases. IMPORTANT: If a second ground develops, significant ground current will flow and possibly destroy the unit.

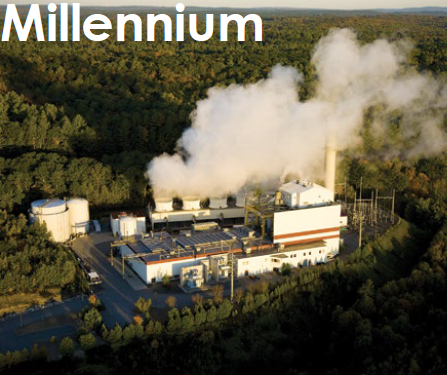

Millennium Power

Owned by Talen Energy

Operated by NAES Corp

360-MW, gas-fired, 1 × 1 combined cycle (501G) located in Charlton, Mass

Plant manager: Mark Winne