Blackhawk Station, Owned by Western Generation Partners LLC. Operated by CAMS

230-MW, gas-fired, 501D5A-powered 2 × 1 combined-cycle cogeneration plant located in Borger, Tex

Plant manager: Bryan Stout

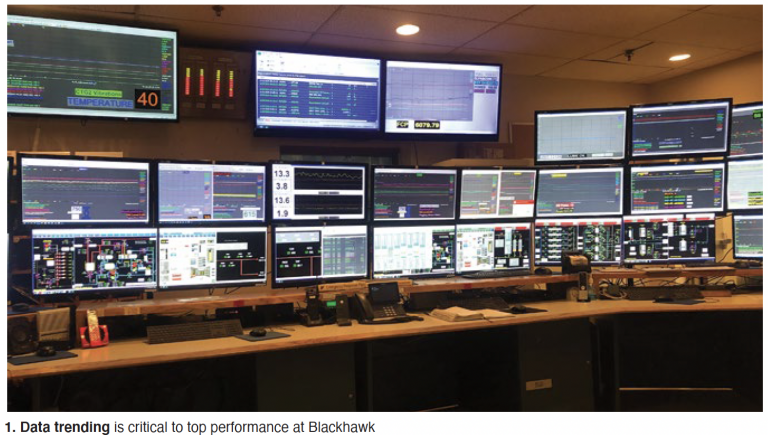

Trending data 24/7 helps improve plant availability, reliability

Challenge. Operate at high availability to assure reliable steam flow to the plant’s host refinery. Any forced outage has the potential to cause the steam host to lose millions of dollars in product.

Solution. To help assure reliable steam and electric production, Blackhawk personnel implemented a PI trending system to track plant performance around the clock (Fig 1). This upgrade has proved effective in detecting potential problems and enabling timely fixes.

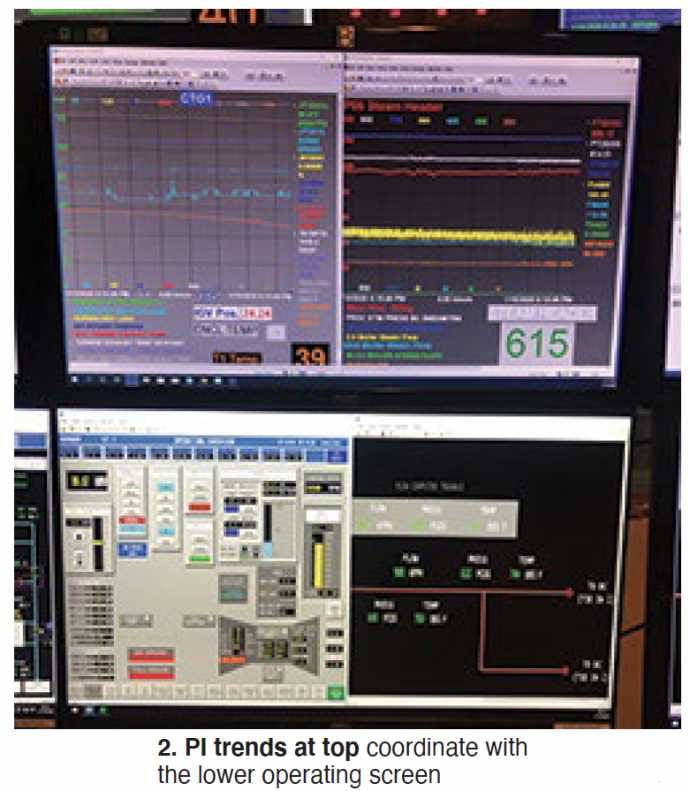

The PI system is used to collect data in Microsoft Excel and PI Processbook, thereby allowing operators to view trends on a computer screen above the DCS operating screen (Fig 2). Blackhawk currently runs a set of PI trends that coordinate with the operating screen. Example: If the DCS screen is on the drum and deaerator page, the PI trend above that screen will be trending drum and deaerator levels, valve positions, temperatures, and pressures.

Running PI system trends above the relevant DCS operating screen has proven vital to plant operation. The PI trends let the operators know exactly how their equipment is functioning. It has prevented equipment damage, unit trips, and environmental impacts, while keeping staff informed on how efficiently the equipment is performing. PI trends also assist as a great training tool, allowing new personnel to see how plant equipment and processes respond to operational changes.

Results. Here’s an example of how the PI trend above the operating screen prevented a unit from tripping: A CRO was dispatched to make load changes on his units to match grid demand. Power output was reduced on both units and monitored after reaching the desired megawatt setting. Everything was within normal limits; units were on set point with no abnormal DCS alarms.

The operator glanced up at the PI trends to double-check his moves and the system. He noticed that turbine vibrations were slowly increasing after the megawatt change. While they were not enough to trigger a DCS alarm at that time, the vibrations had changed from where they normally were at this load on the turbines. The operator watched the vibrations continue to climb.

The supervisor was informed of the situation. A solution was suggested and implemented, resulting in the vibrations backing down to a normal level. Had the PI trend not been available, the operator would not have known turbine vibrations were increasing until a DCS alarm was activated. At that point it would have been too late to call the supervisor to discuss the situation.

Here’s an example of how PI trends above and operating screen help boost efficiency: The deaerator (DA) at Blackhawk can use saturated or superheated steam for pegging. To increase efficiency, saturated steam is supplied to the DA from the boiler drum.

While returning a unit to service after a scheduled outage, with a new operator on the board, the startup went well and everything was looking fine. The outside operator came in from making rounds and looked over the PI trends to see how things were going. He noticed that the temperature of the pegging steam was trending higher than normal.

The CRO was informed; sure enough, the pegging steam was superheated, not saturated. The cause: A check valve did not close for some reason. The operator went back outside and made some valve adjustments that allowed the check valve to close and supply saturated steam for pegging. The operator was able to glance at a set of trends and catch the issue early.

PI trends also have proven vital during gas-turbine trips, to help understand why the trips occurred.

Blackhawk has experienced increased reliability, efficiency, and other benefits from running PI trends above the corresponding DCS screen.

Project participants:

Steven Frick, CRO

Michael Martinez, CRO