Safety-barricade tape warnings

Challenge. Hazardous operations—such as crane lifts, heavy equipment, welding, etc—typically require the use of “danger” or “caution” tape to prevent non-essential personnel from entering high-risk areas. In some cases, these hazardous operations may extend beyond a single shift or day. During an extended outage it is not uncommon to have multiple areas taped off, and in some cases, these taped off areas intersect with each other causing even more confusion.

Additionally, it is often difficult to find a suitable tie-off point for the tape without unnecessarily extending the barricaded area. Lack of knowledge about hazardous work zones as well as the difficulty transiting the work zones can cause misperception and has caused persons to unknowingly enter into danger areas.

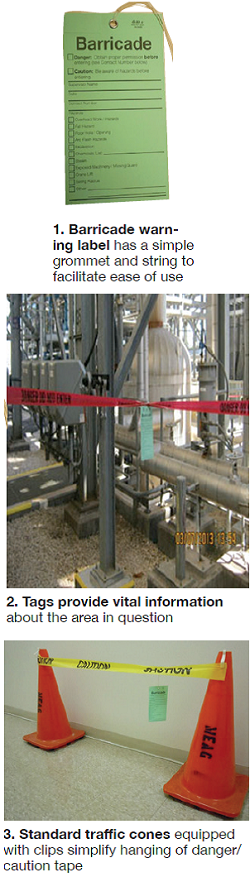

Solution. Site staff designed and professionally printed several “barricade” warning labels that have a simple grommet and attached string to facilitate ease of use (Fig 1). These tags provide vital information about the area in question, are easy to complete and hang, and provide a point of contact should additional information be required (Fig 2).

To address the tie-off issue, the site also purchased standard traffic cones and clips, which provide a simple and inexpensive method to rig the danger/caution tape exactly where it needs to be (Fig 3).

Results. Employees were trained on the new safety system, and it was added to our contractor orientation briefing with supplies of the tags made available at the contractor processing center. During our most recent outage, we received many positive comments from contractors and employees alike on the benefits of providing vital safety information.

Project participants:

Danny Fowler, EHS manager

Keith Feemster, plant manager (former)

MEAG Wansley Unit 9

Owned by Municipal Electric Authority of Georgia

Operated by NAES Corp

503-MW, gas-fired, 2 × 1 combined cycle located in Franklin, Ga

Plant manager: Keith Feemster (former)