How to configure controls for economic steam dispatch

Challenge. Steam for BASF Geismar is provided by one unfired HRSG, one duct-fired HRSG, and four conventional boilers—all producing superheated steam at 615 psig. Typical steam demand varies from about 630,000 to 860,000 lb/hr in serving nearly two dozen independent chemical manufacturing complexes onsite.

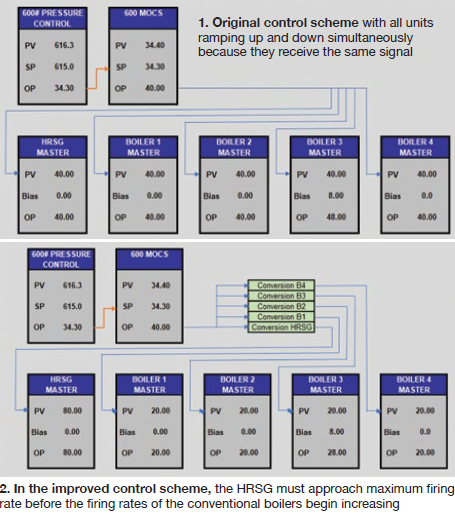

A multiple-output controls system (MOCS) monitors header pressure and controls the firing rates of the HRSG duct burners and boilers to maintain the proper pressure. As steam demand increases and header pressure begins to drop, the MOCS increases the firing rates on all five steam-producing units simultaneously. Conversely, as steam demand drops, the resulting rise in header pressure signals the MOCS to reduce the firing rates of all five units (Fig 1).

On an incremental basis, producing additional steam via the HRSG duct burners is more efficient than from the boilers. Reason: Sufficient preheated air already is available for combustion in the HRSG and only additional fuel (no additional air) is required to produce more steam. The HRSG’s efficiency advantage makes it more desirable to maximize steam production using the duct burners than by raising the firing rates of the conventional units.

Solution. Firing the more efficient unit(s) first, and the least efficient unit(s) last, when more steam is required, and reducing rates on the least efficient unit(s) first, and the more efficient unit(s) last, when less steam is required, is known as economic steam dispatch. To accomplish this, the MOCS control scheme was modified such that all steam producing units were not receiving the same signal; instead, a split-range control scheme was employed to favor steam production on the most efficient steam producing unit (Fig 2).

For the BASF Geismar site, the output splits were adjusted as shown below:

Before—MOCS output of 0% to 100%:

- HRSG firing rate of 0% to 100%.

- Boiler firing rate of 20% to 100%.

Note: A minimum firing rate of 20% is maintained on the conventional boilers to prevent overheating of superheater tubes because of inadequate steam flow.

After—MOCS output of 0% to 50%:

- HRSG firing rate of 0% to 100%.

- Boiler firing rate of 20% (no load change).

After—MOCS output of 50% to 100%:

- HRSG firing rate of 100% (no load change, maximum firing rate).

- Boiler firing rate of 20% to 100%.

This split range scheme allows the HRSG, the most efficient steam producer, to be loaded first and unloaded last thus providing steam to the site in the most cost-efficient manner.

Challenges overcome. Because the firing ramp rate for boilers using the new control scheme is more aggressive than previously, consideration had to be given to the boiler controls to ensure they could handle the increased ramp rate.

Boiler profiling, tuning, and testing took place to ensure the air control, fuel control, and drum level control could reliably handle the more aggressive ramp rates. Ramp rate limiters were employed on critical process parameters, such as boiler drum level, to ensure the faster ramp rate would not bring critical process variables outside of their predetermined “safe, reliable ranges.”

Results. The efficiency advantage of the HRSG over the four conventional boilers is about 8%, which at this site amounts to about 124.4 Btu/lb of steam produced. Moving 60,000 lb/hr of steam production from the boilers to the HRSG results in an annual fuel saving of about $195,000, assuming fuel at $3/million Btu.

Only DCS programming was required to make this improvement (no new capital was required). While not a huge savings relative to the size of the site, this savings will occur year after year and will increase as fuel prices inevitably rise again—all for just a few hours of programming and test time.

Project participants:

J C Rawls, utilities technology engineer

Troy Braud, I&C system technician

BASF Geismar

BASF Chemical Co

160-MW, gas-fired, 2 × 1 combined-cycle cogeneration facility located in Geismar, La.

Plant manager: Tom Yura