Athens Generating Plant

Owned by Kelson Energy

Operated by NAES Corp

1080 MW, gas-fired facility equipped with three 501G-powered 1 × 1 combined cycles, located in Athens, NYPlant manager: Steve Cole

Challenge. Athens Generating Plant has been plagued with seal-oil issues since first fire more than 20 years ago. Throughout the years, the seal-oil systems have received small tweaks and alterations with the goal of improving temperature regulation of the air-side seal oil at the gas turbine (TE) and collector ends (CE) of the hydrogen-cooled generator. Goals: Maintain the 120F ±5 deg F setpoint, and maintain the delta between the air-side and hydrogen-side seals at 3 deg F.

Most recently, Unit 3 tripped offline in early April 2022 because of generator vibrations. After the trip, the OEM’s diagnostic center was contacted to look into what could have caused the excessive vibrations. Its analysis concluded that there may have been a foreign object that passed through the rings, some sort of internal rub, or the fluctuation of seal-oil temperature and pressure, which they had noted in their report as having occurred just before the trip.

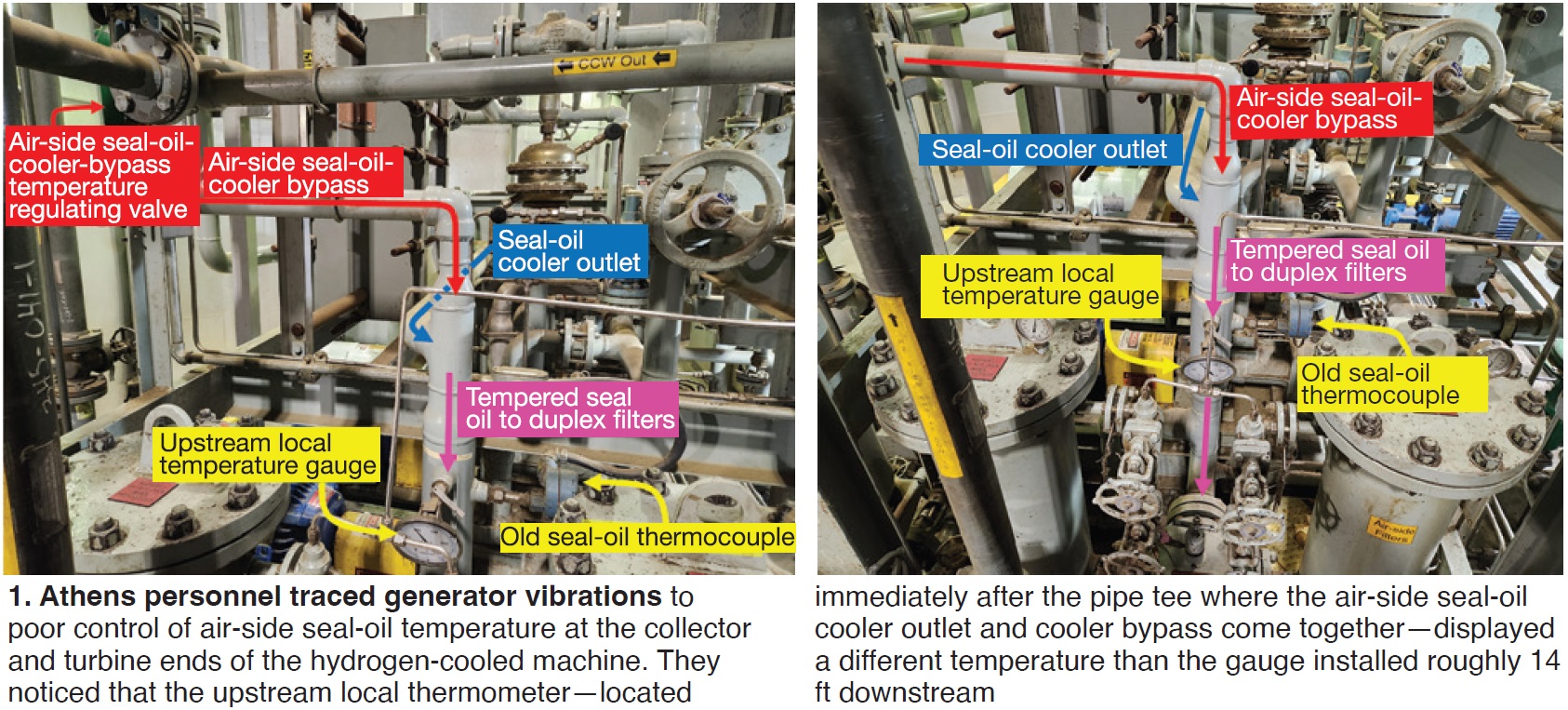

The recommendation was that a restart could be attempted while paying close attention to the vibration levels and seal-oil parameters. Athens restarted the unit and observed the vibrations and seal-oil parameters both locally and remotely. Personnel noticed that the upstream local thermometer (Fig 1)—located immediately after the pipe tee where the air-side seal-oil cooler outlet and cooler bypass come together—displayed a different temperature than the gauge installed roughly 14 ft downstream. The difference was about 10 deg F.

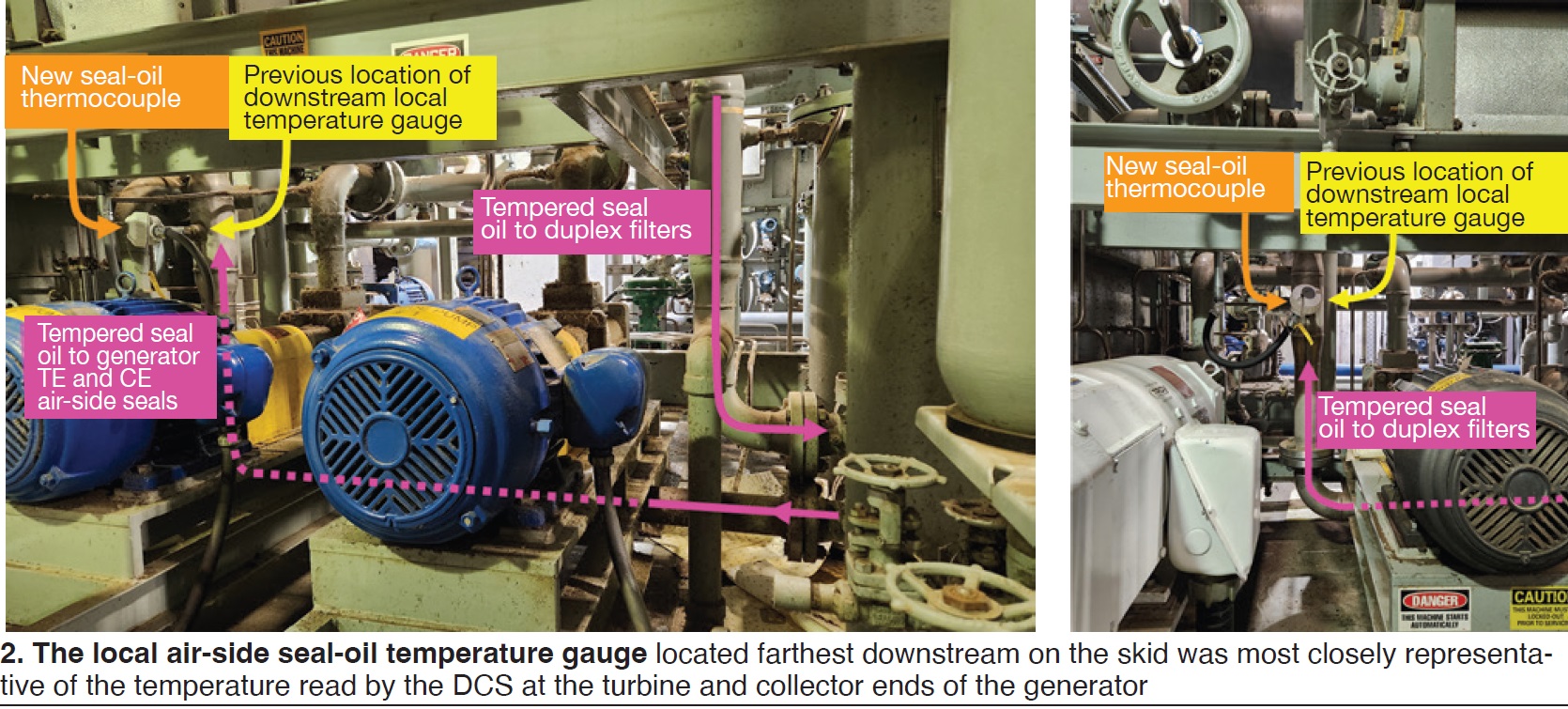

The local air-side seal-oil temperature gauge located furthest downstream on the skid (Fig 2) was most closely representative of the temperature read by the DCS at the turbine and collector ends of the generator.

Investigation of historical data on the seal-oil temperatures revealed that the air-side seal oil at the turbine and collector ends of the generator would fluctuate anywhere from 20 deg F cooler to over 10 deg F warmer than the seal-oil temperature setpoint. The regulating valve was maintaining the 122F setpoint, which receives feedback from that thermocouple, with very little error, while the temperatures at the generator TE and CE would fluctuate from as low as 102F to 132F.

Solution. The Athens team presented to the OEM’s engineering team its idea to install a thermocouple in the downstream drywell, where the local gauge is, and change the logic controlling the air-side seal-oil temperature regulating valve to use the value from the new thermocouple. The OEM approved the idea, and a management of change was created.

Athens I&C technicians installed a new thermocouple in place of the local indicator, wired the thermocouple to available terminals in the nearest I/O cabinet, and reworked the logic so the air-side seal-oil temperature was regulated using the values from the new thermocouple.

In addition, a single point of failure was mitigated by adding logic to revert to the old thermocouple, with a limited regulation rate, in the event of the new thermocouple provided inaccurate information. The intent is to keep the unit online while personnel troubleshoot and correct the bad-quality signal.

Results. After the new thermocouple was installed and logic confirmed, Athens put the thermocouple in service as main feedback to control the air-side seal-oil temperature regulating valve. It has had more than 3000 hours of service since the change was implemented and the results have been excellent.

The air-side seal-oil temperatures at the turbine and collector ends of the generator have been maintained within a 3-deg-F error since the new thermocouple was installed. That is much better than the periodic 20-deg-F error Athens was seeing prior to the change.

Since the change, there have been no vibrations or trips associated with the fluctuations in seal-oil temperatures. All three units at Athens have been changed, or are in the process of being changed, to the new seal-oil temperature regulating setup.

Project participants:

Chris Mitchell

Kyle Kubler

Todd Wolford

Eric VanZant

Kevin MacNeill

Jesse Ferenczy